15 years one-stop China custom CNC machining parts factory

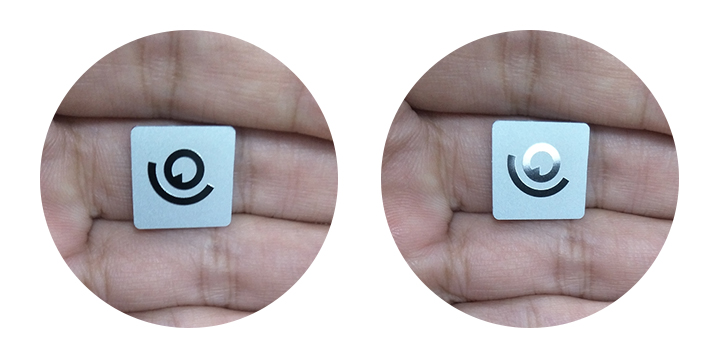

For this aluminum alloy logo nameplate, the size specification is 15 (length) * 15 (width) * 1 (height), and the material is AL6061. When this aluminum CNC machined part is first sampled, the customer has no surface renderings and no physical reference. It's just a rough verbal description. What kind of appearance is required to make the best look? Which kind of process is used? After the nameplate is inlaid on the main body, it will have a finishing touch, and the cost needs to be controlled within the scope of its requirements.

In response to customer needs, after receiving the customer’s sample order, the R&D personnel passed the process verification of a variety of solutions, so that the customer finally accepted the process effect of CNC machining + plane polishing + exposure and development + anodizing, and the customer received I was very satisfied after the samples, and the aluminum logo nameplate CNC machining parts were also smoothly mass-produced according to this process.

VMT has been focusing on aluminum CNC machining parts services for 11 years. It is good at processing all kinds of aluminum precision CNC machining parts shells. Surface treatment is a one-stop service CNC machining factory. It strictly follows the customer's CNC machining requirements for production and processing, combining hot and cold forging, die casting, and extrusion. CNC turning and milling various difficult surface treatment processes, etc., to provide you with the best quality solutions and reduce customer CNC machining costs.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!