15 years one-stop China custom CNC machining parts factory

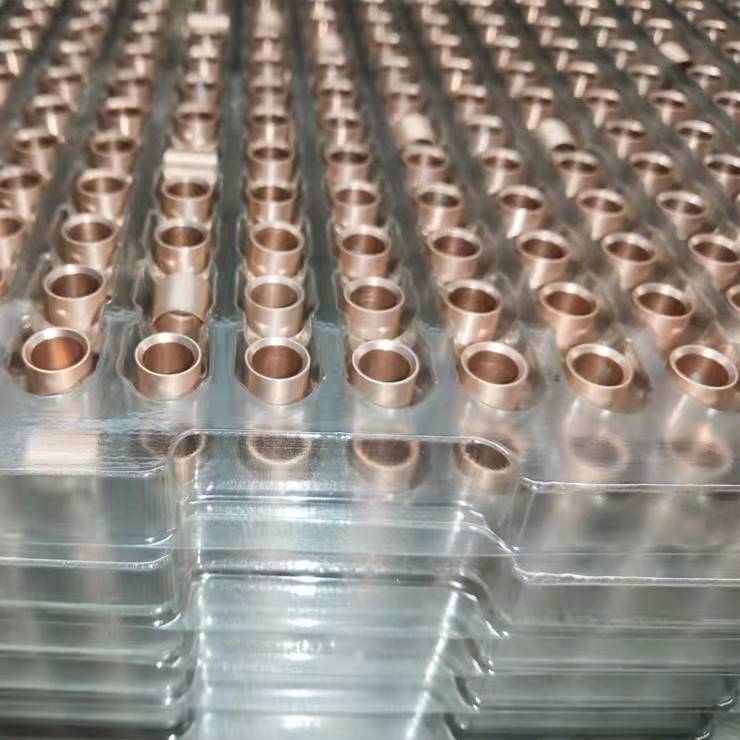

Automatic Lathe machining of Aluminum Earphone Shell

Client Company Name: Malaysia Plantronics

Customer requirements: CNC machining has uniform lines and no burr

Quantity: 3000000 pieces

Material: AL6063-T6

CNC machining method: Automatic lathe machining

Surface treatment: Golden anodized

Delivery time:200 days

Google's website recently received an inquiry from Plantronics, Malaysia. It is necessary to make an aluminum alloy earphone shell, the surface needs to be gold anodized, and the CNC machining pattern is uniform. Because of the large number of orders, a company with stable delivery time and strong strength is needed. cooperate.

VMT has nearly 160 sets of CNC machining centers, CNC lathes, turning and milling composite walking machines, automatic lathes and other equipment. The CNC machining quality is strictly implemented in accordance with IS09001 and IS016949 standards.

CNC machining machines are produced 24 hours a day. After detailed communication with customers, they have obtained the customer's recognition of our numerical control machining strength and delivery ability and finally placed a purchase order of 3 million pieces.

Because the surface of this aluminum alloy earphone shell requires uniform texture, many CNC machining factories will use CNC turning to process it, but in order to reduce costs, we have successfully changed the design of customized tools and fixtures on automatic lathes. From the original CNC turning machining to automatic lathe machining, the efficiency in the production process has been increased by 200%, thereby reducing the cost by 50%. Customers have purchased in large quantities in 19 years, and our monthly shipments have reached 300,000. Customers create value!

VMT has been focusing on a one-stop CNC machining service factory for aluminum alloy housings, precision CNC machining parts and high-quality surface treatment of electronic products for the past 1 year. If you have a project about to start, and you are looking for a cooperative CNC machining factory. You can contact us, VMT will provide you with efficient and high-quality solutions.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!