15 years one-stop China custom CNC machining parts factory

Home / Product / Aluminum Parts /

As your aluminum CNC machining manufacturer, we have 40+ aluminum alloy materials, 100 CNC machining equipment, and 12 quality inspection processes. can provide you with a solution tailored to your specific needs.

Product Specification:

13 years |

1 day |

0 pc |

90% |

|

Experience |

Lead time |

MOQ |

Countries customers |

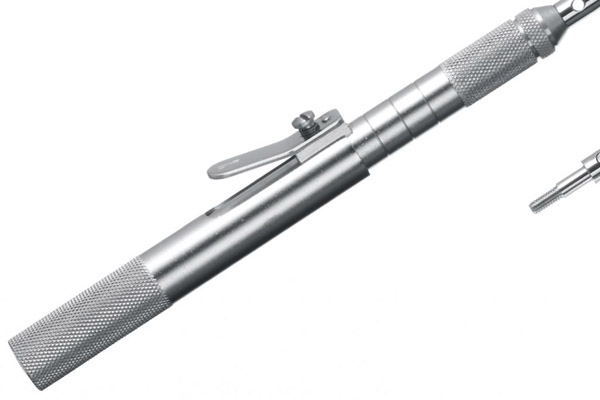

| Custom Aluminum CNC Dental Automatic Crown Remover Handle Parts Precision Machining - OEM ODM CNC Milling Services Manufacturer - China VMT |

Custom CNC Aluminum CNC Dental Automatic Crown Remover Handle Machining Services

Custom CNC Aluminum CNC Dental Automatic Crown Remover Handle Prototyping Machining

100 CNC machining equipment provide you with prototype manufacturing, evaluation, design and testing. We can complete CNC machining and delivery of aluminum CNC dental automatic crown remover handle prototype parts according to your specific requirements within 1 day. |

|

|

|

|

||

Custom CNC Aluminum CNC Dental Automatic Crown Remover Handle Surface Treatment |

Custom CNC Aluminum CNC Dental Automatic Crown Remover Handle Material |

||

|

Our own material library can provide you with special materials such as stainless steel, brass, copper, aluminum, etc., with material testing reports attached. There are professional CNC aluminum CNC dental automatic crown remover handle machining project engineers to choose the right materials for you. |

We can provide a variety of surface treatment services based on your Custom CNC aluminum CNC dental automatic crown remover handle machining project: polishing, anodizing, powder coating, laser engraving, custom graphics, etc. 12 quality inspection processes ensure that your CNC machined parts have a yield rate of 98%. |

| Still selecting materials for your custom CNC machined metal aluminum CNC dental automatic crown remover handle? Different materials have different properties, and you can customize the CNC aluminum CNC dental automatic crown remover handle to your liking. Here are some common materials used in manufacturing metal aluminum CNC dental automatic crown remover handle: |

|

|

|

||

|

|

|

12 Quality Inspection Processes

| Refined production standards, providing you with precision parts with a pass rate of up to 98% |

|

|

|

|

||

| DFM Analysis | Dimensional Tolerance | Material Testing | ||

|

|

|

|

||

| CNC Machining | FQC detection | SPC / CKP | ||

|

|

|

|

||

| Problem Found | Problem Solving | OQC Detection | ||

|

|

|

|

||

| Surface Treatment | Full Inspection | Package |

| The following is the manufacturing process of customized CNC machined metal aluminum CNC dental automatic crown remover handle. Due to the need to protect the rights and interests of customers, the following picture is not the manufacturing process of this part and is for reference only: |

|

|

|

||

| DFM Analysis | Material | CNC Machining | ||

|

|

|

|

||

| Surface Treatment | Quality Inspection | Package |

|

Quality Testing Equipment |

|

|

|

|

||

|

|

|

|

||

|

|

|

|

Custom CNC Aluminum CNC Dental Automatic Crown Remover Handle Machining Quality Assurance

|

Quality inspection reports are an important tool to ensure the quality and precision of your CNC machining work. We can provide a comprehensive overview of the finished product with a detailed test report on material and product performance, either from an in-house auditor or a third-party laboratory. Ensure finished product meets all customer requirements. |

|

Qualify Evaluation Report

For each order we receive, we can provide a list of quality inspection reports according to your processing requirements.

Inspection report

Certificate

ISO 9001:2015 IATF 16949:2015 ROHS Directive 12 patent certifications

|

|

|

|

Custom CNC Aluminum CNC Dental Automatic Crown Remover Handle Machining FAQs

|

1. What is a CNC aluminum dental automatic crown remover handle?

A CNC aluminum dental automatic crown remover handle is a specialized tool designed to assist dental professionals in the efficient removal of dental crowns. It is machined from aluminum using CNC (Computer Numerical Control) technology, ensuring precise dimensions and a lightweight yet durable construction that facilitates ease of use during dental procedures.

2. Why is aluminum used for the crown remover handle?

Aluminum is preferred for several reasons: Lightweight: Reduces hand fatigue for dental practitioners during prolonged use. Durability: Offers excellent strength and resistance to wear, essential for dental tools that undergo frequent sterilization and handling. Corrosion resistance: Naturally resists rust and corrosion, making it suitable for use in a clinical environment where exposure to moisture and sterilization agents is common. Biocompatibility: Aluminum is generally safe for use in dental applications, reducing the risk of adverse reactions.

3. What advantages does CNC machining provide for manufacturing these handles?

CNC machining offers significant benefits, including: Precision: Ensures that each handle is manufactured to exact specifications, allowing for a perfect fit and function. Customization: Can produce various handle designs, grip patterns, and ergonomic features tailored to specific dental practices or preferences. Consistency: Automated processes provide uniform quality across multiple units, essential for bulk orders. Complex geometries: Capable of creating intricate designs that enhance functionality, such as non-slip grips or integrated features.

4. What surface finishes are available for CNC-machined aluminum crown remover handles?

Several finishing options can enhance the appearance and functionality of the handles: Anodizing: Increases corrosion resistance and can add color for aesthetic appeal or to differentiate between tools. Brushing or polishing: Produces a smooth or textured finish for improved grip and a professional look. Powder coating: Offers a durable, colored finish that can withstand wear and tear in a clinical environment. Laser engraving: Allows for custom branding or identification markings on the handle.

5. How durable are CNC-machined aluminum crown remover handles?

CNC-machined aluminum handles are designed to be highly durable, capable of withstanding: Frequent sterilization: Designed to endure repeated autoclaving and cleaning without degrading. Wear and tear: Resistant to impacts, scratches, and other forms of damage commonly encountered in dental settings. Corrosion: The properties of aluminum help prevent rust and degradation over time, ensuring longevity.

6. Can CNC machining accommodate custom features for crown remover handles?

Yes, CNC machining can include various custom features, such as: Ergonomic designs: Tailored handle shapes and grips to improve comfort and control during use. Non-slip surfaces: Textured grips that enhance handling, especially when gloves are worn. Integrated mechanisms: Features such as ratcheting or locking mechanisms to facilitate the crown removal process. Color coding or branding: Custom colors or engravings for easy identification in multi-tool setups.

7. What types of dental procedures can benefit from using these crown remover handles?

CNC aluminum crown remover handles are primarily used in: Crown removals: Assisting in the removal of temporary or permanent crowns during dental procedures. Retreatment cases: Useful in cases where a crown needs to be replaced or repaired. General restorative dentistry: Any procedure requiring access to underlying tooth structures after crown placement.

8. What is the typical lead time for producing custom CNC aluminum crown remover handles?

Lead times can vary based on factors such as: Design complexity: More intricate designs may require additional machining time. Order quantity: Larger production runs may take longer to complete. Finishing processes: Additional treatments like anodizing or powder coating can extend the timeline. Generally, lead times can range from 3 to 6 weeks, depending on the specifics of the order.

9. How can I request a quote for custom CNC aluminum dental crown remover handles?

To obtain a quote, you should provide: Design files: CAD drawings or detailed specifications, including dimensions and tolerances. Material preferences: Specify the type of aluminum alloy (e.g., 6061, 7075). Surface finish options: Indicate desired finishes or coatings. Quantity needed: Specify how many units are required. Customization details: Include any specific design features or branding needs. Intended use: Provide context on how the handle will be used in dental procedures.

10. Are there specific care instructions for aluminum crown remover handles?

To maintain the appearance and functionality of aluminum crown remover handles, consider the following care tips: Cleaning: Use a soft cloth with mild soap and water; avoid abrasive cleaners that may scratch the surface. Regular inspection: Check for any signs of wear, damage, or loosening of any integrated mechanisms. Proper sterilization: Follow recommended sterilization procedures to ensure the handle remains hygienic and safe for use. Storage: Store in a clean, dry area to prevent contamination or damage. |

| We hope these CNC metal aluminum CNC dental automatic crown remover handle faqs answer your questions. If you have more questions or require further assistance, please feel free to contact our dedicated customer support team. We're here to help you build the perfect custom CNC aluminum CNC dental automatic crown remover handle just for you. |

Contact Us

Related suggestion

Related suggestionGive us a call or send an inquiry to our emailbox, we will answer your doubts according to your customers' requirements, and quote you immediately.