15 years one-stop China custom CNC machining parts factory

Home / Product / Aluminum Parts /

As your aluminum CNC machining manufacturer, we have 40+ aluminum alloy materials, 100 CNC machining equipment, and 12 quality inspection processes. can provide you with a solution tailored to your specific needs.

Product Specification:

Custom CNC Machining Aluminum Stainless Steel Portable Coffee Hand Grinder Housing

13 years |

1 day |

0 pc |

90% |

|

Experience |

Lead time |

MOQ |

Countries customers |

| VMT mainly focus on producing custom made CNC portable coffee hand grinder housing. Customize CNC portable coffee hand grinder housing with competitive styles and prices according to customers' drawings and designs. Most of the customized CNC portable coffee hand grinder housing produced by VMT are manufactured according to customers’ designs, signed non-disclosure agreement with customers to protect customers’ designs from being violated. Therefore, here, we can only show the regular styles and semi-finished products of custom CNC portable coffee hand grinder housing. |

|

In the VMT CNC machining factory, we can provide comprehensive services for customized CNC portable coffee hand grinder housing. Whether you need CNC prototyping for testing or mass CNC machining production we have the capacity to meet your requirements. Contact us today to discuss your requirements and let us provide you with a custom CNC portable coffee hand grinder housing that will enhance your product performance and visual appeal. |

|

|

|

|

||||

|

|

||||||

CNC Coffee Hand Grinder Housing Prototype Machining |

CNC Coffee Hand Grinder Housing Surface Treatment |

CNC Coffee Hand Grinder Housing Material |

||||

| We specialize in providing high quality CNC machining services for CNC portable coffee hand grinder housing prototype production. Samples can be proofed within one day at the earliest, and customized CNC machining can be done according to drawings, but there is no stock. |

Surface treatments play a vital role in enhancing the aesthetics, durability and overall quality of an enclosure. 15 surface treatment options to meet your specific requirements. Any logo can be customized on the surface. |

We offer more than 30 high-quality materials to meet your specific requirements for CNC portable coffee hand grinder housing projects. Each material is rigorously tested to ensure its reliability, strength and suitability for CNC machining without increasing costs. |

|

Custom Logo

In our CNC Portable Coffee Hand Grinder Housing services, we understand the importance of branding and personalization. We offer custom logo and graphic surface design options to help you create a unique and distinctive look for your case.

Surface custom pattern

If you wish to add visual interest and texture to your CNC portable coffee hand grinder housing or improve the grip and ergonomics of your CNC portable coffee hand grinder housing, patterns provide a tactile surface by creating textured or raised areas that enhance the The user's grip and control of the device. This is especially important with handheld devices such as portable hand grinders, as it ensures a secure and comfortable grip while grinding coffee beans. |

|

|

|

|

|

||||

|

|

| By incorporating patterns into the surface of your CNC portable coffee hand grinder housing, you can enhance the functionality, branding, and overall appeal of the product. It provides grip, personalization, and differentiation, making your coffee grinder a standout choice for customers. |

|

|

|

||

|

|

|||

|

|

|

||

|

|

|

When it comes to the CNC portable coffee hand grinder housing, surface treatment plays a crucial role in enhancing the aesthetics, durability, and overall quality of the housing. We understand the importance of surface finishing and offer various options to meet your specific requirements. Let's explore the surface treatment options available for your CNC machined coffee grinder housing: |

|

1. Anodizing

|

|

|

2. Powder Coating

|

|

|

|

3. Polishing

|

|

|

|

4. Brushed Finish

|

|

|

| At our CNC portable coffee hand grinder housing service, we offer a range of high-quality materials to meet your specific requirements for your housing project. We understand the importance of selecting the right material to ensure durability, functionality, and aesthetic appeal. Let's explore the material services available for your CNC machined coffee grinder housing: |

|

|

Aluminum CNC Portable Coffee Hand Grinder Housing

Aluminum: Aluminum is a popular choice for CNC portable coffee hand grinder housing due to its lightweight nature and excellent corrosion resistance. It is a versatile material that can be easily machined, allowing for intricate designs and precise detailing. Aluminum housings offer a modern and sleek appearance while maintaining durability.

More Details>> |

|

|

|

Stainless Steel CNC Portable Coffee Hand Grinder Housing

Stainless Steel: Stainless steel is known for its exceptional strength, durability, and resistance to corrosion. It is a reliable choice for CNC portable coffee hand grinder housing that require robustness and longevity. Stainless steel housings provide a polished and professional look, making them suitable for both residential and commercial settings.

More Details>> |

|

|

|

Titanium CNC Portable Coffee Hand Grinder Housing

Titanium: Titanium is a premium material choice for those seeking the utmost strength and durability in their CNC portable coffee hand grinder housing. It offers excellent corrosion resistance and has a high strength-to-weight ratio. Titanium housings can withstand harsh environments and provide a luxurious and modern aesthetic.

More Details>> |

|

|

|

Custom Material Selection If you have specific material requirements for your CNC portable coffee hand grinder housing, we are open to discussing custom material options. Our team can work with you to identify and source materials that meet your unique needs, ensuring that your housing is tailor-made to your specifications. More Details>> |

|

| The manufacturing process of the CNC portable coffee hand grinder housing involves multiple steps to ensure precision, quality and functionality. Let's take a look at a typical processing workflow for creating a house: |

|

1. Design and Engineering

The first step in the process is the design and engineering phase. This involves creating a detailed 3D model of the CNC portable coffee hand grinder housing using computer-aided design (CAD) software. The design takes into account the desired dimensions, specifications, and any custom features such as logo engravings or patterns. |

|

2. Material Selection

Once the design is finalized, the next step is selecting the appropriate material for the CNC portable coffee hand grinder housing. Common materials include aluminum, stainless steel, or titanium, as mentioned earlier. The material is chosen based on factors such as durability, weight, and aesthetic requirements. High-quality materials ensure the longevity and performance of the housing. |

|

3. CNC Machining

CNC (Computer Numerical Control) machining is a precise and efficient method used to shape the raw material into the desired form. The 3D CAD model is converted into machine instructions that guide the CNC equipment in cutting, drilling, and shaping the material. CNC machines use various cutting tools, such as drills and end mills, to remove material and create the intricate features of the housing. |

|

4. Surface Treatment

After the CNC machining process, the CNC portable coffee hand grinder housing undergoes surface treatment to enhance its appearance and durability. Surface treatment options include anodizing, powder coating, polishing, and brushed finishes, as discussed earlier. The chosen surface treatment is applied to the housing to provide protection against corrosion, improve aesthetics, and achieve the desired texture or finish.

|

|

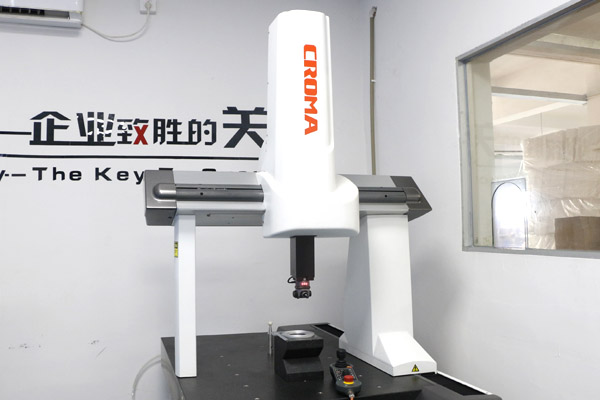

5. Quality Control

Throughout the entire process, rigorous quality control measures are implemented to ensure the housing meets the required standards. Inspection is carried out at each stage, including dimensional checks, surface finish assessment, and functionality testing. Any deviations or defects are addressed and corrected to maintain the highest level of quality. |

|

6. Final Inspection and Packaging

Before the CNC portable coffee hand grinder housing is packaged and shipped, a final inspection is conducted to verify that it meets all specifications and requirements. The housing is carefully examined for any flaws, ensuring it is free from defects and functions properly. Once approved, the housing is packaged appropriately to protect it during transit and delivered to the customer. |

| By following this processing workflow, CNC portable coffee hand grinder housing is created with precision, durability, and attention to detail. Each step contributes to the overall quality and functionality of the housing, resulting in a reliable and visually appealing product. |

|

Quality inspection reports are an important tool to ensure the quality and precision of your CNC turning work. We can provide a comprehensive overview of the finished product with a detailed test report on material and product performance, either from an in-house auditor or a third-party laboratory. Ensure finished product meets all customer requirements. |

|

Qualify Evaluation Report

For each order we receive, we can provide a list of quality inspection reports according to your processing requirements.

Inspection report

Certificate

ISO 9001:2015 IATF 16949:2015 ROHS Directive 12 patent certifications

|

|

|

|

Related suggestion

Related suggestionGive us a call or send an inquiry to our emailbox, we will answer your doubts according to your customers' requirements, and quote you immediately.