15 years one-stop China custom CNC machining parts factory

Home / Product / Aluminum Parts /

As your aluminum CNC machining manufacturer, we have 40+ aluminum alloy materials, 100 CNC machining equipment, and 12 quality inspection processes. can provide you with a solution tailored to your specific needs.

Product Specification:

Custom CNC Machining Aluminum Stainless Steel Titanium Waterproof Pill Case Box Manufacturer

13 years |

1 day |

0 pc |

90% |

|

Experience |

Lead time |

MOQ |

Countries customers |

Our Custom CNC Waterproof EDC Pill Bottle Manufacturer

| We are a professional custom CNC waterproof EDC pill bottle service manufacturer, can precisely design the pill bottle according to your requirements. Whether it's a specific size, shape or function, these services ensure that the final product meets the unique needs of an individual or business. This level of customization provides a solution that is perfectly fit for its intended purpose, enhancing user experience and satisfaction. |

| CNC waterproof edc pill bottles are specially designed containers that provide the waterproof and moisture protection of tall water bottles. Manufactured with CNC machining process to ensure precision and durability. These pill bottles are made of high-quality materials such as aluminum or stainless steel, and have an advanced sealing mechanism to effectively prevent water from entering. |

|

Custom CNC Waterproof EDC Pill Bottle services provide individuals and businesses with the opportunity to create personalized and high-quality pill bottles tailored to their specific needs. This article explores the different aspects of these services, including CNC prototyping, material options, and surface treatments, highlighting the benefits they offer. |

CNC Waterproof Edc Pill Bottle Prototype Machining

CNC prototyping is an integral part of custom CNC waterproof EDC vial services. It involves using CNC machining to create an exact prototype of the desired pill bottle design. This process allows designs to be tested and refined before going into full production, saving costs and ensuring that the final product meets customer requirements. |

|

|

|

|

||

CNC Waterproof Edc Pill Bottle Surface Treatment |

CNC Waterproof Edc Pill Bottle Material |

||

|

One of the advantages of custom CNC waterproof edc pill bottle services is the availability of various material options. Clients can choose from a range of materials, such as high-quality plastics, metals, or even specialized materials that offer specific properties like UV resistance or antimicrobial properties. This flexibility allows for customization based on the desired durability, weight, and aesthetic preferences. |

To further enhance the appearance and performance of the custom CNC waterproof edc pill bottle, 15 different surface treatments can be applied. These treatments include options such as polishing, sandblasting, anodizing, or custom coatings. Surface treatments not only provide a visually appealing finish but also offer additional protection against scratches, corrosion, or fading due to prolonged exposure to external elements. |

| Custom CNC waterproof edc pill bottle services provide a range of benefits, including tailored designs, enhanced durability, and personalized branding opportunities. By utilizing CNC prototyping, selecting from multiple material options, and applying surface treatments, clients can create pill bottles that meet their specific needs. Whether for personal use or as promotional merchandise, custom CNC waterproof edc pill bottle offer a reliable and customized solution. |

|

Custom Logo

Personalized Design and Branding Opportunities

Custom CNC Waterproof EDC Pill Bottle services offer opportunities for personalized design and branding. Clients can incorporate their logos, custom labels, or branding elements onto the pill bottle, providing a unique and professional appearance. This branding opportunity allows businesses to reinforce their brand identity and create a memorable impression among customers. |

|

| Some products have signed a confidentiality agreement and are not allowed to be exported. The following are the customized logo effects on the surface of other products for reference: |

|

|

|

|

Surface custom pattern

To add visual interest and texture to the CNC waterproof EDC vial, we can create textured or raised areas on the surface of the CNC waterproof EDC vial by improving the grip and ergonomics of the CNC waterproof EDC vial, the pattern provides a tactile surface , enhancing the user's grip and control over the product. |

|

| We incorporate patterns into the surface of CNC waterproof EDC medicine bottle shells through CNC machining or surface treatment process to enhance the function, brand and overall appeal of the product. Give your CNC Waterproof EDC Pill Bottles grip, personalization and differentiation to make your CNC Waterproof EDC Pill Bottle unique. |

|

|

|

||

|

|

|||

|

|

|

||

|

|

|

Surface treatments play a vital role in enhancing the appearance, durability, and performance of custom CNC waterproof EDC pill bottles. Here are some common surface treatments that can be applied to these pill bottles: |

|

1. Anodizing

Anodizing: Anodizing is primarily used for metal pill bottles. It involves an electrochemical process that creates an oxide layer on the surface of the metal, increasing its corrosion resistance and providing a decorative, colored finish. |

|

|

2. Powder Coating

Custom Coatings: Custom coatings can be applied to the pill bottle surface to provide additional protection and aesthetic appeal. These coatings can include powder coating, liquid coating, or specialized coatings like scratch-resistant or antimicrobial coatings. |

|

|

|

3. Polishing

Polishing: Polishing the surface of the pill bottle creates a smooth and glossy finish. It improves the overall aesthetic appeal and provides a sleek look to the bottle. |

|

|

|

4. Sandblasting

Sandblasting: Sandblasting involves spraying fine particles onto the surface of the pill bottle at high pressure. This process creates a textured finish, adding a unique visual effect and enhancing grip. |

|

|

| These surface treatments not only enhance the visual appeal of the custom CNC waterproof EDC pill bottles but also offer additional protection against wear and tear, ensuring that the bottle maintains its functionality and aesthetics over time. The choice of surface treatment depends on the desired appearance, functionality, and the material used in the pill bottle's construction. |

| When it comes to manufacturing a custom CNC waterproof EDC pill bottle, selecting the right materials is essential. The choice of materials directly impacts the durability, functionality, and aesthetics of the final product. We will explore some of the materials commonly used in the production of custom CNC waterproof EDC pill bottles. |

|

|

Aluminum CNC Waterproof EDC Pill Bottle

Aluminum: Aluminum is a popular material choice for custom CNC waterproof EDC pill bottles due to its excellent combination of strength, lightweight nature, and corrosion resistance. It offers superb durability and can withstand various environmental conditions, making it suitable for outdoor and travel applications. Additionally, aluminum can be anodized to enhance its resistance to scratches and provide a sleek finish.

More Details>> |

|

|

|

Stainless Steel CNC Waterproof EDC Pill Bottle

Stainless Steel: Stainless steel is another material widely used in the manufacturing of custom CNC waterproof EDC pill bottles. It offers excellent strength, corrosion resistance, and longevity. Stainless steel can withstand harsh conditions, making it ideal for rugged environments. Moreover, it provides a premium look and feel, adding a touch of sophistication to the pill bottle.

More Details>> |

|

|

|

Titanium CNC Waterproof EDC Pill Bottle

Titanium: Titanium is a premium material choice for those seeking the utmost strength and lightweight properties in their custom CNC waterproof EDC pill bottles. It is known for its exceptional corrosion resistance, high tensile strength, and biocompatibility. Although titanium is more expensive than other materials, it offers unparalleled durability and a distinct aesthetic appeal.

More Details>> |

|

|

|

Custom Material Selection

If you have specific material requirements for your CNC waterproof EDC vials, we can discuss custom material options. Identify and meet your unique material needs, tailored to your CNC machined parts.

More Details>> |

|

|

|

Medical-Grade Plastics

Certain medical-grade plastics, such as high-density polyethylene (HDPE) or polypropylene (PP), are suitable options for custom CNC waterproof EDC pill bottles. These materials provide good chemical resistance, are lightweight, and can be easily customized through CNC machining processes. They are also cost-effective, making them a practical choice for certain applications.

More Details>> |

|

| The manufacturing process for custom CNC waterproof EDC pill bottles involves several precise steps to ensure the creation of high-quality and functional products. In this section, we will walk you through the typical manufacturing process for custom CNC waterproof EDC pill bottles.The specific process can be viewed, quality control process. |

|

1. Design and Specifications

The first step in the manufacturing process is the design and specification phase. This involves working closely with our design team to determine the desired dimensions, features, and aesthetics of the pill bottle. We take into consideration factors such as size, shape, capacity, sealing mechanisms, and any additional requirements you may have. |

| Due to the signed confidentiality agreement, the following picture is not the production process of this part, it is for reference only: |

|

2. Material Selection

Once the design and specifications are finalized, the appropriate materials are selected based on the desired characteristics and performance of the pill bottle. Common materials for custom CNC waterproof EDC pill bottles include aluminum, stainless steel, titanium, medical-grade plastics, and carbon fiber. The material selection depends on factors such as strength, weight, corrosion resistance, and visual appeal. |

|

3. CNC Machining

CNC (Computer Numerical Control) machining is a precise and automated manufacturing process used to shape the pill bottle components from the chosen materials. It involves programming CNC machines to accurately cut, mill, drill, and shape the raw material into the desired form based on the approved design. CNC machining ensures high accuracy, repeatability, and consistency in the manufacturing process. |

|

4. Surface Treatment

After the CNC machining process, the pill bottle components undergo surface treatments to enhance their functionality, aesthetics, and durability. Surface treatment options may include anodizing, passivation, powder coating, polishing, laser etching, and customized branding. These treatments provide protection against corrosion, wear, and environmental factors while adding visual appeal.

|

|

5. Assembly

Once the individual components are machined and surface treated, they are ready for assembly. The assembly process involves joining the components together, ensuring proper alignment and functionality. This may include attaching lids, seals, and any additional features required for the waterproofing of the pill bottle. Assembly is performed with precision to guarantee a tight and secure seal. |

|

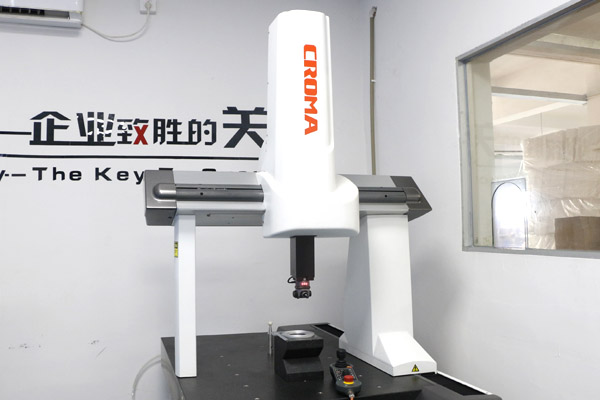

6. Quality Control

Throughout the entire process, rigorous quality control measures are implemented to ensure the housing meets the required standards. Inspection is carried out at each stage, including dimensional checks, surface finish assessment, and functionality testing. Any deviations or defects are addressed and corrected to maintain the highest level of quality. |

|

7. Packaging and Delivery

The final step is the packaging and delivery of the custom CNC waterproof EDC pill bottles. The products are carefully packaged to protect them during transportation. We prioritize secure and efficient delivery methods to ensure that the pill bottles reach you in optimal condition and within the specified timeframe. |

|

Conclusion

|

Custom CNC Waterproof EDC Pill Bottle Application

|

Outdoor activities

For outdoor enthusiasts and adventurers, having a reliable and waterproof pill bottle is crucial. Whether you're camping, hiking, or engaging in water sports, this pill bottle will keep your medication safe and dry, ensuring optimal effectiveness when you need it the most.

Traveling

When traveling, it's essential to have a secure and convenient way to carry your medication. The CNC Waterproof EDC Pill Bottle is designed for portability, allowing you to keep your pills easily accessible during your journey. Its compact size and waterproof feature provide peace of mind, whether you're traveling by air, land, or sea.

Medical use

CNC Waterproof EDC Pill Bottle is not only suitable for outdoor enthusiasts but also beneficial for individuals with medical conditions. Whether you require daily medication or have emergency pills, this bottle ensures that your medication remains intact and protected. Its durability and water resistance make it a reliable option for those who value the safety and effectiveness of their medication. |

|

Quality inspection reports are an important tool to ensure the quality and precision of your CNC turning work. We can provide a comprehensive overview of the finished product with a detailed test report on material and product performance, either from an in-house auditor or a third-party laboratory. Ensure finished product meets all customer requirements. |

|

Qualify Evaluation Report

For each order we receive, we can provide a list of quality inspection reports according to your processing requirements.

Inspection report

Certificate

ISO 9001:2015 IATF 16949:2015 ROHS Directive 12 patent certifications

|

|

|

|

Custom CNC Waterproof EDC Pill Bottle FAQ

|

FAQ 1: How long does the CNC prototyping process take?

The duration of the CNC prototyping process depends on factors such as the complexity of the design and the availability of materials. Generally, it can range from a few days to a couple of weeks.

FAQ 2: Can I choose specific materials for my custom bottle?

Yes, custom CNC Waterproof EDC Pill Bottle services offer a range of material options. You can select materials based on your desired properties, such as durability, weight, or special features.

FAQ 3: What types of surface treatments are available?

There are various surface treatments available for custom CNC Waterproof EDC Pill Bottles, including polishing, sandblasting, anodizing, or custom coatings. These treatments enhance the appearance and provide additional protection for the bottle.

FAQ 4: Can I request a custom logo or branding on the bottle?

Absolutely! Custom CNC Waterproof EDC Pill Bottle services allow for personalized branding. You can request the inclusion of your logo, custom labels, or branding elements to create a unique and professional look.

FAQ 5: Is the custom CNC waterproof EDC pill bottle more expensive?

The cost of a custom CNC waterproof EDC pill bottle will depend on factors such as the design complexity, material selection, and desired quantity. While customization may add to the cost, it offers unique benefits and value that justify the investment. |

Related suggestion

Related suggestionGive us a call or send an inquiry to our emailbox, we will answer your doubts according to your customers' requirements, and quote you immediately.