In the design of many CNC turning stainless steel parts, many of the designer's design ideas are derived from how to achieve the needs of the project application scenarios? Due to the high material and processing costs of CNC turning stainless steel parts, we have met the designer's requirements in the CNC turning manufacturing process. Under this premise, there are a variety of processes to choose from. In the case of ensuring the same quality, the production cost is completely different. At the beginning of a CNC turning stainless steel parts project, we usually arrange for our process engineers to analyze, evaluate and release DMF to designers for reference and optimization at this stage, so that the project can start smoothly and create value for the customer's brand.

Below we take CNC turning stainless steel parts advertising nails as an example, hoping to provide designers with a reference when designing similar parts so that CNC lathe parts processing can create value for customers and the market.

Introduction

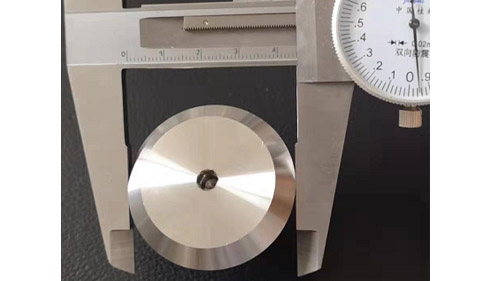

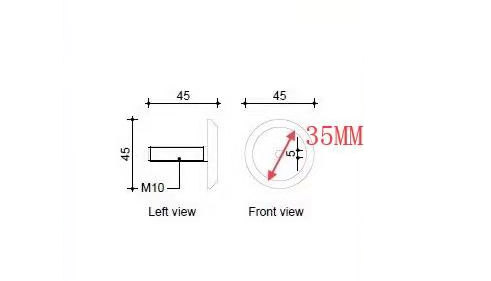

This is a curtain wall project for a high-end commercial building in Europe. The customer sent us the DFM evaluation process and found that the glass must be tightened with this 45MM CNC turning 316 stainless steel parts. For such parts with similar shapes, we generally consider directly buying bars with the same outer diameter for CNC turning. If the material cost is very high according to this process, we will incur a material cost of 3 USD.

When such a large-size bar is processed with M10 threads, the processing time will be very long, and the processing cost will exceed 2 US dollars. Due to the use of SUS303 stainless steel in the sample stage, the customer also experienced severe corrosion. In order to solve the above problems, we will carry out the following 5 steps.

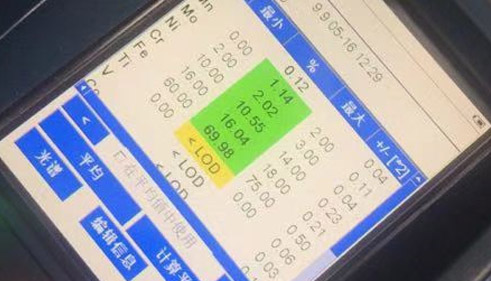

1. When selecting materials, we recommend that customers use SUS316 stainless steel. We tested the material at the beginning to verify that the material composition complies with ASTM standards.

|

Element name and chemical composition (%)

|

|

Material

|

C |

Mn |

Si |

P |

S |

Ni |

Mo |

Cr |

|

SUS316

|

≦0.08 |

≦2.0 |

≦1.0 |

≦0.045 |

≦0.03 |

10.0-14.0 |

2.0-3.0 |

16.0-18.0 |

2. Before starting to produce CNC turning stainless steel parts, we initially chose cold forging. The SUS316S stainless steel material is processed into a blank similar to the part, and then the blank is processed by CNC turning. During the evaluation process, we found that the customer's CNC turning stainless steel parts require an outer diameter of 45MM. The cost of using molds to produce molds is very high, the processing time is long, and there is no cost advantage at all. Our engineers immediately denied this processing method. The advantage of this process is for copper materials, stainless steel materials and large structures. Because after forging can a lot of raw materials can be saved, reduce the number of materials, and greatly reduce the processing time in the process, many CNC turned stainless steel parts are suitable for this process. With CNC numerical control lathes and CNC machining, it can greatly reduce the cost of parts and improve processing efficiency.

3. According to the structure of this CNC turning stainless steel part advertising nail and the designer's requirements, we released another process plan, using stainless steel plate material to punch out the strong part of the cap, and then using M10 internal hexagonal standard screws to embed in the stainless steel In the plate, and riveted with M10 screws, the CNC turning stainless steel parts have a good overall torque. In this process, we must pay attention to whether the hexagon socket meets the standard specifications, to prevent customers from installing incorrectly and poorly, and to ensure the verticality of the plane of the M10 screw and the advertising nail head.

4. In order to make CNC turning stainless steel parts with high torque and make the structure more reliable, we adopted the welding method. The riveted CNC turned stainless steel parts are directly welded to the head and screws. We designed grooves at the solder joints to make the solder just right. Fill the grooves and prepare for follow-up work. Please note that the solder must have the same composition as SUS316.

5. Use a CNC lathe to process the outer surface of CNC turning stainless steel parts, turning to remove the size reserved in the design, and CNC turning stainless steel parts that meet the customer's drawing size and surface texture are perfectly processed. After the production is completed, the salt spray test, the torque size and the appearance are 100% tested. The good news is that our yield rate can reach more than 98%, which once again proves the feasibility of this process and directly saves customers 50% of the cost. Customers are very satisfied with this and thank us for our efforts. This is the best return for us.

In summary

Based on the above process and actual verification, this process is a mature CNC lathe parts processing process, which greatly improves the production and processing efficiency of CNC turning stainless steel parts, and also creates value for the customer's cost. Among them is an example of CNC turning stainless steel parts. In many application fields, there are many CNC turning stainless steel parts close to this structure. Its design only needs to be copper, stainless steel, and titanium materials, because the characteristics of this material are the high cost of raw materials. And the slow processing time and other conditions, we can evaluate and consider the application of the above several processes to cooperate with the processing applications of CNC lathe parts and CNC machining parts. At the same time, aluminum alloy can also be used for specific structures. There is no way to list all of them, welcome Every designer proposes to you more inquiries.

Make CNC lathe processing more efficient! SHENZHEN VMT METAL PRODUCT CO., LIMITED is a professional CNC machining turning services company, we can provide free evaluation and design solutions! You are welcome to ask all questions, and we will help you!