15 years one-stop China custom CNC machining parts factory

Home / Product / Plastic Parts /

Product Specification:

13 years |

1 day |

0 pc |

90% |

|

Experience |

Lead time |

MOQ |

Countries customers |

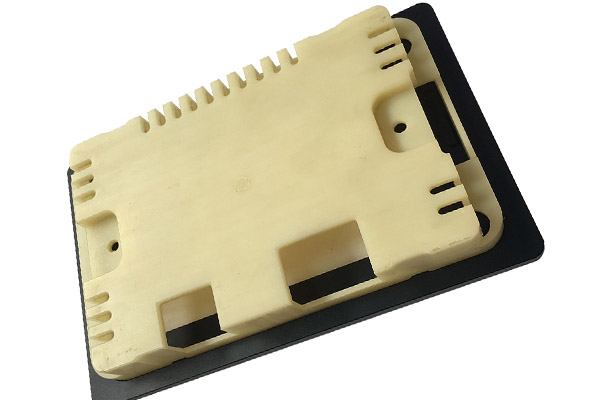

| Custom Precision Nylon Plastic CNC Machining Parts - OEM ODM CNC Milling Services Manufacturer - China VMT |

Custom Nylon Plastic CNC Machining Parts Services

Custom Nylon Plastic CNC Machining Parts Prototyping Machining

100 CNC machining equipment provide you with prototype manufacturing, evaluation, design and testing. We can complete CNC machining and delivery of nylon plastic CNC machining parts prototype parts according to your specific requirements within 1 day. |

|

|

|

|

||

Custom Nylon Plastic CNC Machining Parts Surface Treatment |

Custom Nylon Plastic CNC Machining Parts Material |

||

|

Our own material library can provide you with special materials such as stainless steel, brass, copper, aluminum, etc., with material testing reports attached. There are professional nylon plastic CNC machining parts machining project engineers to choose the right materials for you. |

We can provide a variety of surface treatment services based on your Custom nylon plastic CNC machining parts machining project: polishing, anodizing, powder coating, laser engraving, custom graphics, etc. 12 quality inspection processes ensure that your CNC machined parts have a yield rate of 98%. |

| Still selecting materials for your custom CNC machined metal nylon plastic CNC machining parts? Different materials have different properties, and you can customize the nylon plastic CNC machining parts to your liking. Here are some common materials used in manufacturing metal nylon plastic CNC machining parts: |

|

|

|

||

|

|

|

12 Quality Inspection Processes

| Refined production standards, providing you with precision parts with a pass rate of up to 98% |

|

|

|

|

||

| DFM Analysis | Dimensional Tolerance | Material Testing | ||

|

|

|

|

||

| CNC Machining | FQC detection | SPC / CKP | ||

|

|

|

|

||

| Problem Found | Problem Solving | OQC Detection | ||

|

|

|

|

||

| Surface Treatment | Full Inspection | Package |

| The following is the manufacturing process of customized CNC machined metal nylon plastic CNC machining parts. Due to the need to protect the rights and interests of customers, the following picture is not the manufacturing process of this part and is for reference only: |

|

|

|

||

| DFM Analysis | Material | CNC Machining | ||

|

|

|

|

||

| Surface Treatment | Quality Inspection | Package |

|

Quality Testing Equipment |

|

|

|

|

||

|

|

|

|

||

|

|

|

|

Custom Nylon Plastic CNC Machining Parts Quality Assurance

|

Quality inspection reports are an important tool to ensure the quality and precision of your CNC machining work. We can provide a comprehensive overview of the finished product with a detailed test report on material and product performance, either from an in-house auditor or a third-party laboratory. Ensure finished product meets all customer requirements. |

|

Qualify Evaluation Report

For each order we receive, we can provide a list of quality inspection reports according to your processing requirements.

Inspection report

Certificate

ISO 9001:2015 IATF 16949:2015 ROHS Directive 12 patent certifications

|

|

|

|

Custom Nylon Plastic CNC Machining Parts FAQs

|

Why is nylon used for CNC machining parts?

Nylon is a popular material for CNC machining because of its excellent strength, durability, and versatility. It offers high impact resistance, low friction, and good wear resistance, making it suitable for various mechanical applications. Nylon is also lightweight, chemically resistant, and has a good ability to absorb vibrations, which is essential for parts subjected to wear and tear.

What are the advantages of using CNC machining for nylon plastic parts?

CNC machining allows for high precision and repeatability when manufacturing nylon plastic parts. It can produce complex shapes, tight tolerances, and smooth finishes with minimal tooling requirements. Additionally, CNC machines can handle both large and small production runs, making it suitable for both prototyping and full-scale production of nylon components.

What are the different grades of nylon used in CNC machining?

The most common grades of nylon used in CNC machining are:

Nylon 6: Offers excellent strength, toughness, and resistance to wear and tear. Nylon 66: Known for its higher strength, heat resistance, and chemical stability. Nylon 6/12: Offers lower moisture absorption and better dimensional stability. Filled Nylon: Typically filled with glass or other materials to improve mechanical properties like stiffness and wear resistance.

How does moisture affect nylon plastic CNC machined parts?

Nylon is hygroscopic, meaning it absorbs moisture from the air, which can affect its dimensions and mechanical properties. Excess moisture absorption can lead to dimensional instability, reduced strength, and potential warping during machining. It’s essential to properly dry nylon before machining and, if possible, to store it in a controlled environment to minimize moisture-related issues.

What are the key benefits of using nylon plastic for mechanical components?

Nylon offers low friction, which makes it an excellent choice for applications requiring reduced wear, such as gears, bearings, and bushings. It’s also highly resistant to abrasion, chemicals, and solvents. Moreover, nylon is lightweight, reducing the overall weight of the part without sacrificing performance. It also offers good electrical insulating properties and can operate in a wide temperature range.

What machining processes are used for nylon plastic parts?

CNC machining processes used for nylon parts include:

CNC Milling: For creating complex geometries and precise cuts. CNC Turning: For cylindrical components like shafts or rods. CNC Routing: For cutting larger flat parts or sheets of nylon. CNC Drilling: To make accurate holes or slots. CNC Tapping: For creating threads in nylon parts.

Can nylon plastic parts be custom-colored?

Yes, nylon plastic can be colored using dyes or pigments during the manufacturing process, such as through injection molding or direct color mixing. However, for CNC machining, it’s more common to machine parts from pre-colored nylon or to apply a surface coating, like painting or anodizing, to achieve the desired color.

What is the maximum size of a part that can be CNC machined from nylon?

The size of the part that can be CNC machined from nylon depends on the size of the CNC machine and the material stock being used. For standard CNC machines, parts up to several feet in length and width can be machined. For large-scale parts, specialized equipment like a CNC router may be required to accommodate larger sheets or blocks of nylon.

What surface finishes are available for CNC machined nylon parts?

Common surface finishes for CNC machined nylon parts include:

Smooth Finish: Achieved by fine machining techniques or post-machining processes like sanding and polishing. Textured Finish: Applied through specific machining techniques or by adding a texture pattern during the CNC process. Painted/Coated: To improve appearance or add extra protection against wear and environmental factors. Laser Etching: For adding logos, patterns, or text directly onto the part.

How durable are CNC machined nylon parts compared to other plastics?

CNC machined nylon parts are known for their high strength, toughness, and wear resistance compared to other plastics like PVC, ABS, and polystyrene. Nylon has a higher tensile strength and better resistance to friction, making it suitable for applications where parts undergo heavy wear and require high durability. However, its moisture sensitivity and susceptibility to UV degradation should be considered when selecting nylon for outdoor applications.

What are the most common applications for CNC machined nylon parts?

CNC machined nylon parts are commonly used in various industries, including:

Automotive: For parts like bushings, bearings, gears, and brackets. Aerospace: For lightweight and durable components like spacers, seals, and mounts. Electronics: For connectors, housings, and insulation parts. Medical Devices: For surgical instruments, casings, and other specialized components. Consumer Goods: For components like handles, knobs, and appliance parts.

What factors influence the cost of CNC machining nylon parts?

The cost of CNC machining nylon parts can vary depending on:

Material Type: Different grades of nylon have varying costs. Part Complexity: More intricate designs with tight tolerances and detailed features require longer machining times. Production Volume: Larger production runs tend to reduce the cost per part due to economies of scale. Post-Processing: Additional processes such as finishing, coating, or assembly can add to the overall cost.

Can CNC-machined nylon parts be used in high-temperature applications?

Nylon can withstand temperatures up to around 180°F (82°C), depending on the grade. However, for applications involving higher temperatures, reinforced nylons or alternative materials, such as PEEK or polyimide, may be necessary. For moderate temperature applications, nylon parts perform well without significant degradation.

Is it necessary to dry nylon before CNC machining?

Yes, drying is often necessary because nylon absorbs moisture from the air, which can affect its machining characteristics. Moisture in the nylon can lead to dimensional changes and a rougher finish during machining. It is recommended to dry the nylon material in an oven or vacuum dryer to achieve optimal machining results.

What are the environmental impacts of CNC machining nylon plastic parts?

CNC machining of nylon plastic parts is relatively environmentally friendly compared to some other manufacturing processes. However, like any plastic, nylon can contribute to plastic waste if not properly disposed of or recycled. Many CNC shops use sustainable practices like recycling plastic scrap and using eco-friendly lubricants and coolants during machining. |

| We hope these CNC metal nylon plastic CNC machining parts faqs answer your questions. If you have more questions or require further assistance, please feel free to contact our dedicated customer support team. We're here to help you build the perfect custom nylon plastic CNC machining parts just for you. |

Contact Us

| Custom Precision Nylon Plastic CNC Machining Parts - OEM ODM CNC Milling Services Manufacturer - China VMT |

Related suggestion

Related suggestionGive us a call or send an inquiry to our emailbox, we will answer your doubts according to your customers' requirements, and quote you immediately.