15 years one-stop China custom CNC machining parts factory

Home / Product / Stainless Steel Parts /

Choose us as your stainless steel CNC machining manufacturer, you can rest assured. We use different processes combined with CNC machining to meet your needs. Available in a variety of stainless steel materials, strict quality control processes are carefully monitored at each step to ensure stainless steel CNC parts meet the highest industry standards for performance and durability.

Product Specification:

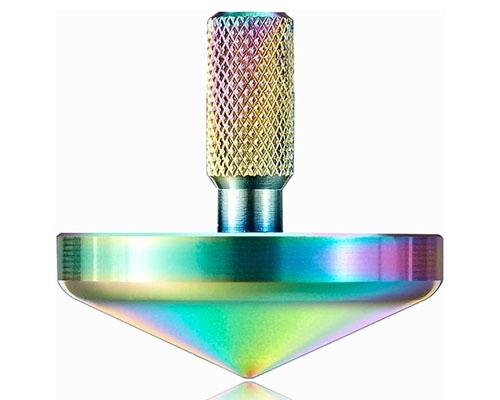

Custom CNC Metal Aluminum Stainless Steel Copper Spinning Top Machining Manufacturer Factory

13 years |

1 day |

0 pc |

90% |

|

Experience |

Lead time |

MOQ |

Countries customers |

|

Creating custom CNC machined metal spinning tops involves a meticulous process to ensure precision, balance, and visual appeal. Here's an overview of the services involved in crafting these captivating spinning toys: |

Custom CNC Metal Spinning Top Prototyping Machining

100 CNC machining equipment provide you with prototype manufacturing, evaluation, design and testing. We can complete and deliver CNC Metal Spinning Top prototype parts according to your specific requirements within 1 day. |

|

|

|

|

||

Custom CNC Metal Spinning Top Surface Treatment |

Custom CNC Metal Spinning Top Material |

||

|

We can provide a variety of surface treatment services according to your Custom CNC Metal Spinning processing project: polishing, anodizing, powder coating, laser engraving, custom graphics, etc. 12 quality inspection processes ensure that your CNC machined parts have a yield rate of 98%. |

Our own material library can provide you with special materials such as stainless steel, brass, copper, aluminum, titanium and tungsten, with material testing reports attached. There are professional CNC Metal Spinning Top processing project engineers to choose the right material for you. |

|

|

|

||

|

|

|||

|

|

|

||

|

|

|

||

|

When choosing surface treatments for custom CNC machined metal spinning tops, customers consider a combination of factors, including the treatment's advantages and pricing. Here's an overview of the advantages and a general price comparison for common surface treatments: |

|

1. Polishing CNC Machining Spinning Top

Advantages: Polishing involves smoothing the surface of the top to achieve a smooth, mirror-like finish.

|

|

|

2. Anodizing CNC Machining Spinning Top

Advantages: Provides corrosion resistance and increases the life of the top. Available in multiple color options for personalization.

|

|

|

|

3. Bead Blasting CNC Machining Spinning Top

Advantages:Creates a matte finish, adding a modern and textured appearance.Enhances grip and tactile feel during spinning.

|

|

|

|

4. Laser engraving CNC Machining Spinning Top

Advantages: Laser engraving uses a high-powered laser to etch designs, patterns, or text onto the surface of the top. Complex and personalized designs are possible.

|

|

|

|

5. Powder Coating CNC Machining Spinning Top

Advantages:Provides a uniform and durable coating.Offers a wide range of colors and finishes for customization.

|

|

|

|

|

|

6. Brushed CNC Machining Spinning Top

Advantages: Brushing involves using an abrasive material to create a pattern of fine parallel lines on the surface. Helps cover minor scratches and wear over time.

|

|

|

|

7. Heat coloring CNC Machining Spinning Top

Advantages: Creates a variety of colors on the surface depending on the temperature and duration of heating. Provides an artistic and personalized look.

|

|

|

|

Each surface treatment option offers a distinctive appearance and set of benefits. The choice of treatment depends on your aesthetic preferences, desired durability, and intended use of the spinning top. |

| The choice of material for custom CNC machined metal spinning tops is crucial, as it impacts the top's weight, durability, and aesthetics. Different materials offer distinct characteristics, allowing you to tailor the spinning top to your preferences. Here are some common materials used in crafting these captivating toys: |

|

Custom CNC Machining Stainless Steel Spinning Top

Characteristics: Stainless steel is a popular choice for spinning tops due to its exceptional durability and weight. It provides a satisfying heft, making it suitable for long spins.

More Details>> |

|

Custom CNC Machining Brass Spinning Top

Characteristics: Brass spinning tops are favored for their unique aesthetics. They have a warm, golden hue that develops a natural patina over time, adding character.

More Details>> |

|

Custom CNC Machining Copper Spinning Top

Characteristics: Copper spinning tops have a similar warm color to brass but tend to develop a patina more quickly. They are known for their distinct appearance.

More Details>> |

|

Custom CNC Machining Aluminum Spinning Top

Characteristics: Aluminum spinning tops are lightweight and come in various colors due to anodizing options. They are known for their precision and smooth spins.

More Details>> |

|

Custom CNC Machining Titanium Spinning Top

Characteristics: Titanium is known for its lightweight yet durable nature. It provides a unique blend of strength and a feather-light feel.

More Details>> |

|

Custom CNC Machining Tungsten Spinning Top

Characteristics: Tungsten is one of the densest materials available, making it incredibly heavy for its size. Tungsten tops offer unparalleled weight.

More Details>> |

| The choice of material for your custom CNC machined metal spinning top depends on your preferences for weight, appearance, and patina development. Stainless steel offers durability and substantial weight, while brass and copper provide unique aesthetics with evolving patinas. Aluminum allows for vibrant color options, and titanium offers a lightweight, modern feel. Tungsten is reserved for those who seek the heaviest and most intense spinning experience. |

| The manufacturing process for custom CNC machined metal spinning tops involves several meticulous steps to ensure precision, balance, and the highest quality. Here's an overview of the key stages in creating these captivating spinning toys: |

| Due to the signed confidentiality agreement, the following picture is not the production process of this part, it is for reference only: |

|

1. Material Selection

Material Selection: Choosing the right material is crucial, as the material affects its weight, durability and aesthetics. Common materials include stainless steel, brass, copper, aluminum, titanium, and even tungsten as an option. Material selection is based on customer preference and the intended use of the top. |

|

2. Design and Prototyping

Design and Prototyping: Designing a top using CAD software begins by defining the shape, size, and function of the top. Recreate the gyroscope prototype for testing to evaluate design, balance, and performance. Achieve the final product to meet the required specifications. |

|

3. CNC Machining

CNC Machining: CNC machining machines are used to precisely cut and shape selected materials according to CAD designs. CNC machining ensures tight tolerances and a high-quality finish. The top's body, stem, and any custom features are precisely machined in this step. |

|

4. Surface Treatment

Surface Treatment: Surface treatments are applied to enhance both functionality and aesthetics. These treatments can include polishing for a sleek finish, anodizing for color and corrosion resistance, or laser engraving for customization.The choice of surface treatment depends on the desired appearance and performance characteristics. |

|

5. Quality Control

Quality Control: Rigorous quality control checks are conducted throughout the manufacturing process. Dimensional accuracy, balance, and overall quality are carefully assessed to meet industry standards and customer specifications.Any imperfections or deviations are corrected to ensure that each spinning top meets high-quality standards. |

| Quality Testing Equipment |

|

|

|

|

||

|

|

|

|

||

|

|

|

|

6. Customization

Customization options allow customers to choose the size, weight, color and surface finish of the top, and graphics, logos or patterns can be added for personalization or promotional purposes. |

|

7. Packaging and Delivery

We have a variety of packaging methods. Select appropriate or customized metal gyroscope packaging methods according to customer needs and transportation methods to ensure safe transportation. |

|

The custom CNC machined metal spinning top manufacturing process combines precision engineering, material selection, weight distribution, and surface treatments to create a visually appealing and high-performance toy. |

|

Quality inspection reports are an important tool to ensure the quality and precision of your CNC turning work. We can provide a comprehensive overview of the finished product with a detailed test report on material and product performance, either from an in-house auditor or a third-party laboratory. Ensure finished product meets all customer requirements. |

|

Qualify Evaluation Report

For each order we receive, we can provide a list of quality inspection reports according to your machining requirements.

Inspection report

Certificate

ISO 9001:2015 IATF 16949:2015 ROHS Directive 12 patent certifications

|

|

|

|

Custom CNC Metal Spinning Top Machining FAQs

| Here are answers to some frequently asked questions about custom CNC machined metal spinning tops |

|

1. What materials are commonly used for custom CNC machined metal spinning tops?

Common materials include stainless steel, brass, copper, aluminum, titanium, and tungsten. Each material offers unique weight, aesthetics, and characteristics for spinning tops.

2. How does the choice of material impact the spinning top's performance?

The choice of material affects the top's weight, balance, and aesthetics. Materials like tungsten provide extreme weight for long spins, while aluminum offers a lightweight option. The material also influences the top's appearance and durability.

3. What surface treatments are available for custom spinning tops?

Surface treatments include polishing, anodizing, bead blasting, laser engraving, powder coating, brushed finishes, and heat coloring. Each treatment offers different visual effects, durability, and grip.

4. Can I customize the design of my spinning top?

Yes, you can customize the design, size, weight, color, and surface finish of your spinning top to match your preferences or branding needs. Custom graphics, logos, or patterns can also be added.

5. How are custom spinning tops balanced for smooth spins?

Custom spinning tops are carefully balanced during the manufacturing process to ensure smooth and prolonged spins. Weight distribution and fine-tuning are crucial elements of achieving balance.

6. What is the typical size range for custom spinning tops?

Custom spinning tops come in various sizes, from compact pocket-sized tops to larger desk or collector's tops. The size can be tailored to your specific requirements.

7. Are custom spinning tops suitable for collectors or promotional purposes?

Yes, custom spinning tops are popular among collectors and can be customized for promotional purposes. They make unique and memorable gifts or promotional items.

8. How do I maintain my custom CNC machined metal spinning top?

Maintenance is minimal. Keep your top clean and free from debris. Depending on the material, you may need to address patina development or surface wear over time.

9. Are custom spinning tops safe for children?

While spinning tops are generally safe, they may contain small parts that could pose a choking hazard for young children. Supervision is advised, and age-appropriate tops should be selected. |

| We hope these CNC Metal Spinning Top Machining FAQs answer your questions. If you have more questions or require further assistance, please feel free to contact our dedicated customer support team. We're here to help you create the perfect custom CNC Metal Spinning Top Machining for your vehicle. |

Related suggestion

Related suggestionGive us a call or send an inquiry to our emailbox, we will answer your doubts according to your customers' requirements, and quote you immediately.