15 years one-stop China custom CNC machining parts factory

93 |

Published by VMT at Aug 01 2025 | Reading Time:About 9 minutes

93 |

Published by VMT at Aug 01 2025 | Reading Time:About 9 minutes

When selecting stainless steel for your product or project, the decision isn’t just about cost—it’s about performance, durability, and long-term value. Many engineers and purchasers unknowingly choose the wrong grade, leading to premature failure, higher maintenance costs, or customer dissatisfaction. If you're unsure whether 304 or 409 stainless steel is right for your CNC machined parts, you're not alone. Fortunately, by understanding the core differences between 304 stainless steel and 409 stainless steel, you can make a smarter, more informed choice that delivers better results. This guide will clarify the key distinctions between these two popular materials, especially in CNC machining services, helping you avoid costly mistakes and ensure long-term success.

304 stainless steel offers superior corrosion resistance, aesthetics, and strength, making it ideal for high-end or demanding applications. 409 stainless steel is a more affordable, heat-resistant option commonly used in automotive exhaust systems. Your best choice depends on your project's environmental conditions, budget, and performance needs in stainless steel CNC machined parts.

Before diving into detailed comparisons, it’s important to understand how 304 and 409 stainless steel differ not just in composition, but also in performance, cost, and suitability for CNC machining. Whether you're sourcing from CNC machining factories or evaluating material for stainless steel CNC machined parts, a clear understanding will save you time and money—and help you deliver quality components with confidence.

Key Points Summary

304 stainless steel is an austenitic alloy known for its excellent corrosion resistance, formability, and versatility. Composed primarily of iron, chromium (18–20%), and nickel (8–10.5%), it is the most widely used stainless steel grade in the world. Its ability to resist oxidation and corrosion makes it suitable for everything from kitchen equipment and food processing machinery to architectural paneling and medical devices.

For CNC machining services, 304 stainless steel is valued for its clean finish and excellent machinability after annealing. It also welds well and maintains strength even at cryogenic temperatures. Because of its non-magnetic nature and aesthetic appeal, it’s widely used in environments that demand both hygiene and durability. However, it is more expensive than lower-grade steels like 409.

When CNC machining factories receive orders for premium, corrosion-resistant stainless steel CNC machined parts, 304 stainless is often the first recommendation. Its reliability, performance, and availability in numerous forms make it the go-to material for a wide range of industries.

409 stainless steel is a ferritic stainless steel primarily composed of iron and chromium (10.5–11.75%), with trace amounts of carbon and titanium. Unlike 304, it contains very little or no nickel, which significantly lowers its cost. Though it lacks the high corrosion resistance of 304, it offers excellent heat resistance and is particularly suitable for high-temperature applications.

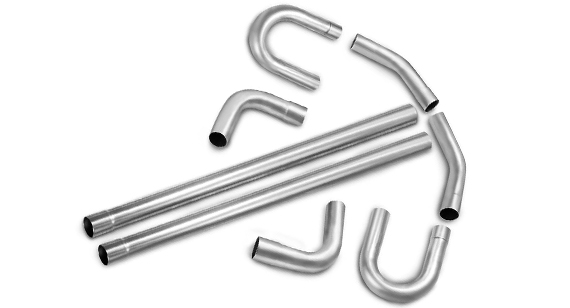

Because of its affordability and heat resistance, 409 stainless steel is a popular material in the automotive industry, especially for exhaust systems. It provides decent structural integrity at elevated temperatures and resists oxidation, making it a practical solution for parts exposed to extreme heat but low moisture.

409 stainless steel CNC machined parts are widely used when budgets are tight, and corrosion resistance is not the top priority. CNC machining factories that specialize in automotive or industrial heat applications often maintain large inventories of 409 stock shapes due to its demand. It's magnetic, easy to weld, and while it doesn't polish as beautifully as 304, it performs reliably in the right environment.

Deciding whether 304 stainless steel or 409 stainless steel is better depends entirely on the specific application, environmental exposure, performance expectations, and budget. Both grades have distinct advantages, and their value becomes apparent only when matched to the right use case—especially in the realm of stainless steel CNC machined parts.

304 stainless steel is the superior choice in terms of corrosion resistance, strength, surface finish, and overall durability. Its higher nickel and chromium content offers exceptional resistance to rust, oxidation, and chemical degradation, making it ideal for marine environments, food processing, chemical handling, and architectural applications. For CNC machining services that demand hygienic, long-lasting, and aesthetically pleasing components, 304 stainless steel CNC machined parts are often the first choice. It also offers better formability and weldability, which is critical in complex or precision-engineered products.

On the other hand, 409 stainless steel is better suited for high-heat applications where corrosion resistance is secondary. It's the preferred material in automotive exhaust systems due to its excellent heat tolerance and lower cost. While it does not offer the same level of corrosion protection as 304, it can still perform well in dry or mildly corrosive environments. CNC machining factories often recommend 409 stainless steel CNC machined parts when a customer needs a heat-resistant and economical solution without sacrificing basic structural integrity.

In summary, if corrosion resistance, cleanliness, and appearance are top priorities, 304 stainless steel is the better option. If budget constraints and heat resistance are more important, 409 stainless steel provides a practical and effective alternative. Consulting with CNC machining services can help determine which grade aligns best with your project’s technical and financial requirements.

Here's a clear, professional comparison table summarizing the key differences between 304 stainless steel and 409 stainless steel, optimized for customers evaluating materials for CNC machining services:

304 Stainless Steel vs. 409 Stainless Steel: Key Differences

| Property |

304 Stainless Steel |

409 Stainless Steel |

| Type |

Austenitic stainless steel | Ferritic stainless steel |

| Corrosion Resistance |

Excellent; ideal for marine, food, and medical use | Moderate; suitable for dry or mild environments |

| Heat Resistance |

Good, but not as high as 409 | Excellent; performs well in high-temperature zones |

| Strength |

Higher tensile strength | Lower tensile strength |

| Cost |

Higher due to nickel content | More affordable; low nickel content |

| Machinability |

Good; better after annealing | Fair; slightly harder but still machinable |

| Weldability |

Excellent; smooth, strong welds | Good; may require pre-heating in some cases |

| Magnetic Properties |

Non-magnetic (in annealed condition) | Magnetic |

| Aesthetic Appearance |

Bright, smooth, highly polishable | Duller finish; not ideal for decorative use |

| Typical Applications |

Food processing, marine parts, medical equipment | Automotive exhausts, industrial furnace components |

| CNC Machining Suitability |

Excellent for precision, polished parts | Good for structural and high-temp parts |

| Common Forms |

Sheets, bars, rods, coils, CNC machined components | Sheets, pipes, mufflers, CNC machined components |

| CNC Machined Parts |

Premium stainless steel CNC machined parts | Cost-effective 409 stainless steel CNC machined parts |

This table offers a quick and intuitive overview for engineers, buyers, and product managers evaluating materials for their next project. If you need help determining which is more suitable for your specific application, CNC machining factories like VMT can offer tailored guidance and material selection support.

When comparing 304 stainless steel and 409 stainless steel for industrial or commercial use, it’s essential to look beyond surface-level attributes. While both are widely used in CNC machining services, they differ significantly in performance, machinability, cost, and environmental suitability. Understanding their unique characteristics will help engineers and purchasing managers make the best material choice for stainless steel CNC machined parts. This section breaks down the critical technical differences, providing a side-by-side analysis of their composition, hardness, corrosion and wear resistance, welding behavior, heat tolerance, and cost implications in practical applications.

Composition

Composition is the most fundamental difference between 304 and 409 stainless steel.

For CNC machining factories, this variation in composition affects not only the corrosion performance of the part but also how the material responds during machining, welding, and post-processing.

Hardness

Hardness impacts a material’s resistance to indentation and wear under pressure.

This difference makes 304 more suitable for applications where wear and pressure resistance are important, such as structural frames and fasteners. In CNC machining services, higher hardness also supports better dimensional stability in machined components.

Corrosion Resistance

Corrosion resistance is a key differentiator between the two grades.

For customers seeking long-term durability in corrosive environments, 304 stainless steel CNC machined parts are the better investment. However, for automotive exhaust or dry industrial applications, 409 may suffice.

Wear Resistance

Wear resistance relates to how well a material withstands abrasion, friction, or surface damage.

CNC machining factories may recommend 304 when the finished part will experience repetitive movement or surface contact, ensuring better longevity and reduced maintenance.

Oxidation Resistance

Oxidation resistance is crucial in high-temperature environments where metal parts are exposed to air and heat.

If your project involves exposure to prolonged high temperatures, 409 stainless steel CNC machined parts may offer a performance and cost advantage.

Welding

Weldability plays a significant role in fabrication and post-machining assembly.

For projects requiring extensive welding after CNC machining, 304 is often preferred unless cost or temperature factors make 409 more suitable.

Heat Resistance

Heat resistance refers to how well a material maintains its properties at elevated temperatures.

When working with CNC machined parts for high-heat industrial applications, CNC machining factories often recommend 409 as the more thermally stable and economical option.

Machinability

Machinability affects production speed, tool wear, and finishing quality in CNC machining services.

In CNC machining factories, tool selection, cooling systems, and part design often determine whether 304 or 409 provides better throughput and finish quality.

Cost

Cost is a decisive factor for many customers choosing between stainless steel grades.

For budget-sensitive projects or high-volume production, 409 stainless steel CNC machined parts offer substantial cost savings—especially in industries like automotive manufacturing.

Applications

Applications often dictate material choice more than specifications alone.

CNC machining services should always consider the final use-case environment before selecting the appropriate material to ensure optimal performance and cost efficiency.

Here is a detailed comparison table summarizing the key differences between 304 stainless steel and 409 stainless steel, structured for clarity and optimized for clients considering materials for stainless steel CNC machined parts.

304 vs. 409 Stainless Steel: Key Differences Table

| Category |

304 Stainless Steel |

409 Stainless Steel |

| Type |

Austenitic stainless steel | Ferritic stainless steel |

| Chemical Composition |

18–20% Cr, 8–10.5% Ni, low C | 10.5–11.75% Cr, trace Ni, stabilized with Ti |

| Hardness (HRB) |

~70–90 (annealed); increases after cold work | ~60–80, depending on processing |

| Corrosion Resistance |

Excellent; ideal for marine, food, and chemical environments | Moderate; suitable for dry, non-aggressive environments |

| Wear Resistance |

High; withstands friction and surface contact | Moderate; sufficient for low-friction parts |

| Oxidation Resistance |

Good; resists scaling up to ~870°C | Excellent; stable at high temperatures up to ~675°C |

| Weldability |

Excellent; minimal cracking and distortion | Good; may require preheating and specific filler materials |

| Heat Resistance |

Good, but deteriorates faster under prolonged heat | Excellent; ideal for continuous high-temperature exposure |

| Machinability |

Moderate; tends to work-harden, requires slower machining speeds | Easier to machine; less nickel makes it more tool-friendly |

| Magnetic |

Non-magnetic (in annealed form) | Magnetic |

| Aesthetic Finish |

Bright, smooth, highly polishable | Duller surface; not suited for decorative applications |

| Cost |

Higher; due to nickel and alloying elements | Lower; economical choice for less corrosive environments |

| Common Applications |

Food equipment, marine parts, medical devices, chemical tanks, decorative structures | Automotive exhausts, agricultural equipment, furnace parts, industrial applications |

| CNC Machining Use |

Preferred for premium, corrosion-resistant machined parts | Preferred for heat-resistant, cost-effective machined parts |

| Best Use Case |

Corrosive, high-strength, and aesthetic environments | High-temperature, dry, or budget-limited environments |

This table allows customers and engineers to quickly evaluate which material better suits their project, especially when sourcing from CNC machining factories or requesting stainless steel CNC machined parts.

Understanding the specific properties of 304 and 409 stainless steel is essential for making informed material decisions—especially when it comes to stainless steel CNC machined parts. While both materials are commonly used in CNC machining services, they differ significantly in their mechanical, thermal, and chemical characteristics. This section explores the foundational differences in their chemical composition, which directly impacts corrosion resistance, heat tolerance, and machinability. Whether you're a product designer, engineer, or procurement specialist, knowing these details will help you select the right material for your next machining project.

304 Stainless Steel and 409 Stainless Steel: Chemical Composition

Chemical composition is the building block of material performance. The presence—or absence—of elements like chromium, nickel, carbon, and molybdenum dramatically influences a material’s corrosion resistance, machinability, and suitability for high-temperature applications. Below is a direct comparison of the typical elemental breakdown of 304 stainless steel and 409 stainless steel, based on industry standards and mill specifications. This information is particularly critical for CNC machining factories and engineers working on precision CNC machined parts.

Chemical Composition Table: 304 vs. 409 Stainless Steel

| Element |

304 Stainless Steel (%) |

409 Stainless Steel (%) |

| Chromium (Cr) |

18.0 – 20.0 | 10.5 – 11.75 |

| Nickel (Ni) |

8.0 – 10.5 | ≤ 0.5 (typically none) |

| Carbon (C) |

≤ 0.08 | ≤ 0.08 |

| Manganese (Mn) |

≤ 2.00 | ≤ 1.00 |

| Silicon (Si) |

≤ 0.75 | ≤ 1.00 |

| Phosphorus (P) |

≤ 0.045 | ≤ 0.045 |

| Sulfur (S) |

≤ 0.03 | ≤ 0.02 |

| Nitrogen (N) |

≤ 0.10 | Not specified |

| Iron (Fe) |

Balance | Balance |

| Molybdenum (Mo) |

Not typically present | Not typically present |

| Titanium (Ti) |

Not present | Stabilized with Ti (≤ 0.75) |

Key Takeaways

The physical properties of stainless steel significantly impact its performance in manufacturing and final applications. For those sourcing stainless steel CNC machined parts, understanding differences in density, thermal behavior, corrosion resistance, and machinability is critical. These characteristics affect not only part performance but also machining efficiency, material costs, and long-term durability. This section provides a side-by-side breakdown of the most relevant physical properties of 304 stainless steel and 409 stainless steel, guiding engineers and procurement teams in selecting the best material for their specific CNC machining projects.

Physical Properties Comparison Table

| Property |

304 Stainless Steel |

409 Stainless Steel |

| Density (g/cm³) |

7.93 | 7.75 |

| Melting Point (°C) |

1,400 – 1,450 | 1,430 – 1,530 |

| Thermal Conductivity (W/m·K at 100°C) |

~16.2 | ~24.5 |

| Electrical Resistivity (Ω·m) |

~0.73 × 10⁻⁶ | ~0.60 × 10⁻⁶ |

| Thermal Expansion (10⁻⁶/K) |

16.0 – 17.2 | 11.0 – 13.0 |

| Corrosion Resistance |

Excellent; resists acids, chlorides, moisture | Moderate; surface rust possible in humid air |

| Magnetic Properties |

Non-magnetic (in annealed condition) | Magnetic |

| Formability |

Excellent; ideal for complex shapes | Good; slightly less ductile |

| Machinability (Annealed) |

Fair; work-hardens quickly, requires slow speeds | Easier to machine; lower alloy content |

| Environmental Adaptability |

Performs well in corrosive, marine, and sanitary environments | Performs well in dry, high-heat conditions |

Detailed Insights

For CNC machining services, understanding these physical properties allows for better design, reduced wear on tools, and higher-quality outcomes. Whether you need corrosion-resistant 304 stainless steel CNC machined parts or heat-resistant 409 stainless steel CNC machined parts, choosing the right grade ensures cost efficiency and long-term reliability.

Mechanical properties determine how a material behaves under physical forces such as tension, compression, bending, and fatigue. For CNC machining factories, understanding these properties is essential to ensure that the stainless steel CNC machined parts perform reliably under real-world conditions. Whether you're designing components that require structural strength, flexibility, or fatigue resistance, this comparison between 304 stainless steel and 409 stainless steel will help you match material capabilities to performance requirements.

Mechanical Properties Table: 304 vs. 409 Stainless Steel

| Property | 304 Stainless Steel | 409 Stainless Steel |

| Hardness (HRC) | ~20 (annealed) | ~15–20 (annealed) |

| Hardness (HV) | ~150–200 | ~130–180 |

| Hardness (HRB) | ~70–90 | ~65–80 |

| Tensile Strength (MPa) | 505 – 735 | 380 – 450 |

| Yield Strength (0.2% offset, MPa) | ~215 | ~170 |

| Elongation (at break, %) | ≥ 40% | ≥ 20% |

| Ductility (%) | High; maintains flexibility under stress | Moderate; more rigid and brittle |

| Ultimate Tensile Strength (MPa) | Up to 735 | Up to 450 |

| Reduction of Area (Z/%) | ~60% | ~40% |

| Heating Temperature (°C) | Up to 870°C (intermittent), 925°C (continuous) | Up to 675°C (intermittent), 815°C (continuous) |

| Elastic Modulus (GPa) | ~193 – 200 | ~200 |

| Fatigue Strength (MPa) | ~240 – 310 | ~150 – 200 |

| Shear Strength (MPa) | ~283 | ~220 – 240 |

| Shear Modulus (GPa) | ~77 | ~77 |

| Poisson’s Ratio | ~0.29 | ~0.27 – 0.30 |

Detailed Analysis

Summary

For most CNC machining projects that prioritize mechanical strength, formability, and fatigue resistance, 304 stainless steel CNC machined parts are the optimal solution. However, when cost constraints and high-heat applications are key factors, 409 stainless steel CNC machined parts offer a practical, dependable alternative.

Choosing the right stainless steel grade depends not only on physical and mechanical properties but also on the real-world trade-offs each material presents. Understanding the pros and cons of 304 stainless steel and 409 stainless steel helps customers make informed decisions based on performance needs, cost limitations, environmental exposure, and desired lifespan of the CNC machined components.

Below is a clear breakdown of each grade’s advantages and disadvantages to support project-specific material selection.

304 Stainless Steel: Advantages and Disadvantages

304 stainless steel is one of the most commonly used austenitic stainless steels. Known for its excellent corrosion resistance, good strength, and versatility in machining, it is a preferred choice in industries like medical, food processing, and marine.

304 Stainless Steel Advantages

| Advantage |

Benefit |

| High corrosion resistance | Withstands moisture, acids, and chemicals—ideal for food and marine uses |

| Good formability and ductility | Easily bent, formed, or drawn—saves on machining and shaping time |

| Excellent weldability | Strong, clean welds with minimal post-treatment |

| Non-magnetic (annealed condition) | Suitable for sensitive equipment and instruments |

| High surface finish quality | Ideal for polished CNC machined parts or decorative applications |

| Broad availability | Widely stocked by CNC machining factories—shorter lead times |

| Consistent mechanical properties | Maintains reliability across a range of temperatures and environments |

304 Stainless Steel Disadvantages

| Disadvantage |

Limitation |

| Higher material cost | Contains more nickel—more expensive than ferritic grades like 409 |

| Less heat resistance than 409 | Continuous use above 870°C may degrade properties |

| Susceptible to chloride stress corrosion cracking | Not ideal for highly salty or chlorinated environments |

| May work-harden during machining | Requires optimized CNC machining parameters or post-machining annealing |

409 Stainless Steel: Advantages and Disadvantages

409 stainless steel is a ferritic grade known for its cost-efficiency and heat resistance. Though it offers lower corrosion resistance, it is widely used in automotive exhaust systems, industrial furnaces, and low-cost CNC machined components that must handle high heat but don’t require a decorative finish.

409 Stainless Steel Advantages

| Advantage |

Benefit |

| Affordable pricing | Lower alloy content—ideal for budget-sensitive projects |

| Excellent oxidation and heat resistance | Suitable for temperatures up to 815°C—perfect for exhaust or furnace parts |

| Readily weldable | Compatible with most welding processes |

| Magnetic properties | Useful in structural and sensor-related applications |

| Good mechanical strength for general-purpose use | Meets most basic structural and support part requirements |

409 Stainless Steel Disadvantages

| Disadvantage |

Limitation |

| Moderate corrosion resistance | Not ideal for humid, marine, or chemical-rich environments |

| Lower ductility and elongation | Less suitable for complex forming or high-impact loads |

| Duller surface finish | Not recommended for decorative CNC machined parts |

| More prone to rust compared to austenitic grades | Requires protective coatings in corrosive conditions |

Conclusion

If you need durability, appearance, and corrosion resistance, 304 stainless steel is the premium choice for your CNC machining project. For cost-sensitive, high-temperature applications, 409 stainless steel offers excellent value. Leading CNC machining factories can help you strike the right balance between performance and budget by evaluating both materials in relation to your part’s specific operating environment.

Heat treatment is a crucial factor in determining the mechanical properties, corrosion resistance, and workability of stainless steels during CNC machining processes. Both 304 stainless steel and 409 stainless steel respond differently to heat due to their distinct chemical structures—austenitic for 304 and ferritic for 409. Understanding their heat treatment behavior helps engineers and buyers choose the right material for high-performance or cost-sensitive steel CNC machining parts.

304 Stainless Steel: Heat Treatment Characteristics

304 stainless steel is non-hardenable by heat treatment due to its austenitic structure. However, it can be strengthened through cold working and softened through annealing.

| Heat Treatment Process |

Details and Effects |

| Annealing |

Heated to 1010–1120°C, then rapidly cooled to restore ductility after work-hardening |

| Stress Relief |

Heated to 450–600°C to reduce internal stresses without affecting corrosion resistance |

| Quenching |

Not typically used—does not increase hardness like in martensitic steels |

| Sensitization Risk |

Prolonged exposure between 450–850°C may cause chromium carbide precipitation (intergranular corrosion risk) |

Note: For CNC machining factories working with 304, post-machining annealing may be applied to relieve stress and enhance dimensional stability.

409 Stainless Steel: Heat Treatment Characteristics

409 stainless steel, being a ferritic stainless steel, can be heat treated to modify its mechanical properties, but it does not harden in the same way as carbon steels or martensitic stainless steels.

| Heat Treatment Process |

Details and Effects |

| Annealing | Heated to 790–900°C and air-cooled to improve formability and restore ductility |

| Stabilization Annealing | Performed at around 800°C to enhance weld performance and resist intergranular corrosion |

| Stress Relieving | Heated to 600–700°C—helps reduce residual stress from forming or welding processes |

| Grain Growth Control | Overheating above 950°C may lead to coarse grains and reduced ductility |

409 is preferred in high-temperature environments, like automotive exhaust systems, where oxidation resistance is more important than mechanical strength or corrosion resistance.

Conclusion

Whether your application requires precision CNC machining services, welding preparation, or thermal resistance, understanding each alloy’s heat treatment behavior ensures better material performance and longer part life.

When selecting the right stainless steel for industrial or commercial use, understanding its real-world applications is essential. Both 304 stainless steel and 409 stainless steel serve specific roles across various industries, depending on their corrosion resistance, mechanical strength, heat tolerance, and cost efficiency. This section explores how each grade is utilized in real-world scenarios—critical knowledge for those sourcing stainless steel CNC machined parts or evaluating materials through CNC machining services.

304 Stainless Steel: Applications and Uses

Known for its excellent corrosion resistance and non-magnetic properties, 304 stainless steel is the most widely used austenitic alloy in the world. It offers high strength, good formability, and a clean surface finish—making it ideal for hygiene-critical and appearance-focused industries.

Food and Beverage Industry

Chemical Processing

Architectural Applications

409 Stainless Steel: Applications and Uses

A ferritic stainless steel containing less chromium and virtually no nickel, 409 stainless steel is a cost-effective solution where oxidation resistance and high-temperature stability matter more than surface finish or extreme corrosion resistance. It's a material of choice in many heat-intensive and structural applications.

Automotive Industry

Agricultural Equipment

Heat Exchangers

Furnace Components

Conclusion

For businesses sourcing from CNC machining factories, selecting the right stainless steel grade ensures durability, performance, and cost control tailored to your industry needs.

Here's a clear, professional comparison table summarizing the applications and uses of 304 stainless steel and 409 stainless steel, optimized for customers considering steel CNC machining parts or industrial applications.

304 Stainless Steel vs. 409 Stainless Steel: Applications and Uses

| Industry |

304 Stainless Steel |

409 Stainless Steel |

| Automotive Industry |

Mufflers, exhaust pipes (low-corrosion areas), frames, trims, window components | Exhaust systems, mufflers, catalytic converter housings |

| Food & Beverage |

Kitchen sinks, countertops, food processing tanks, dispensers | Not commonly used due to lower corrosion resistance |

| Medical Devices |

Surgical instruments, implants, hospital furniture | Rarely used due to lower hygiene standards and corrosion resistance |

| Chemical Processing |

Storage tanks, piping systems, heat exchangers | Limited use; suitable only for low-corrosive environments |

| Architectural |

Railings, decorative panels, doors, elevator trims | Rare; finish and corrosion resistance typically not sufficient for aesthetics |

| Agricultural Equipment |

Rarely used due to high cost | Tractor exhausts, protective covers, structural parts exposed to heat/weather |

| Heat Exchangers |

In corrosive fluid systems requiring long-term durability | HVAC shells and tubes where high heat resistance is essential |

| Furnace Components |

Heat-resistant applications with aesthetic or hygienic needs | Furnace linings, radiant tubes, burners |

| CNC Machined Parts |

Premium stainless steel CNC machined parts for corrosion-sensitive applications | Cost-effective CNC parts used in heat-resistant or structural environments |

Note:

When choosing between 304 stainless steel and 409 stainless steel, cost is often one of the most decisive factors—especially for businesses seeking efficient CNC machining services or bulk materials for production. While both steels offer unique advantages, they come with different price points, long-term value, and processing costs. This section breaks down the financial aspects of each to help buyers make informed decisions when selecting material for steel CNC machining parts or industrial fabrication.

Initial Cost Comparison

304 Stainless Steel:

Higher upfront cost due to its higher nickel and chromium content, which contributes to better corrosion resistance and a more refined finish.

409 Stainless Steel:

More affordable thanks to its low nickel and moderate chromium content. It is considered a cost-effective alternative for less corrosive environments.

Long-Term Cost Benefits

304 Stainless Steel:

409 Stainless Steel:

Processing Costs

304 Stainless Steel:

409 Stainless Steel:

Market Prices

| Steel Type |

Average Price (per kg) |

Influencing Factors |

| 304 Stainless Steel | $2.50 – $4.00 USD/kg | High nickel content, global demand, corrosion resistance |

| 409 Stainless Steel | $1.20 – $2.00 USD/kg | Lower alloying elements, used in mass-market automotive applications |

Note: Prices vary by region, quantity, and market fluctuations. Contact your CNC machining factory for up-to-date quotes and bulk pricing.

Conclusion

Here's a professional, clear, and customer-oriented cost and price comparison table for 304 stainless steel vs. 409 stainless steel, tailored to decision-makers considering CNC machining services:

304 Stainless Steel vs. 409 Stainless Steel: Cost and Price Comparison

| Category |

304 Stainless Steel |

409 Stainless Steel |

| Initial Material Cost |

$2.50 – $4.00 USD/kg (higher due to nickel content and corrosion resistance) | $1.20 – $2.00 USD/kg (lower due to fewer alloying elements) |

| Long-Term Value |

High: Excellent durability, reduced maintenance, longer replacement cycles | Moderate: May corrode faster, potentially higher lifetime maintenance costs |

| Machining Cost |

Higher: Tougher to cut and drill, causes more tool wear | Lower: Softer, easier to process with basic tools |

| Welding Cost |

Lower: Excellent weldability | Higher: Requires specific techniques for clean welds |

| Finishing Cost |

Higher: Frequently polished for aesthetic or hygienic purposes | Lower: Typically used in hidden or non-cosmetic applications |

| Typical Use Cases |

Food-grade equipment, medical parts, architectural trims, corrosion-critical components | Automotive exhausts, heat shields, agricultural equipment, furnace components |

| Cost-Efficiency |

Best for high-performance or hygiene-sensitive applications | Best for high-volume, cost-sensitive, and heat-exposed applications |

Conclusion:

The following table compares the national standards and corresponding grades of 304 and 409 stainless steel in major countries and regions. It is useful for international procurement, import and export trade, and CNC machining clients in selecting materials:

304 Stainless Steel vs. 409 Stainless Steel: National Standards and Equivalent Grades

|

Standard System / Country |

304 Stainless Steel Equivalent Grades |

409 Stainless Steel Equivalent Grades |

| China (GB Standard) |

0Cr18Ni9 / 06Cr19Ni10 | 0Cr11Ti / 06Cr11Ti |

| USA (ASTM / SAE) |

ASTM A240 / A276 Type 304 UNS S30400 |

ASTM A240 / A268 Type 409 UNS S40900 |

| Japan (JIS Standard) |

SUS304 | SUS409 / SUS409L |

| Germany (DIN / EN) |

X5CrNi18-10 (1.4301) | X6CrTi12 (1.4512) |

| UK (BS Standard) |

304S15 / 304S31 | 409S17 |

| France (NF / AFNOR) |

Z7CN18-09 | Z6CT12 |

| European Union (EN 10088) |

X5CrNi18-10 | X6CrTi12 |

| UNS Number (Worldwide) |

S30400 | S40900 |

| Stainless Steel Type |

Austenitic Stainless Steel | Ferritic Stainless Steel |

| Typical Magnetic Behavior |

Non-magnetic (annealed condition) | Magnetic |

Material Selection Tips for Customers:

Here's a comprehensive table comparing the stock shapes typically available for 304 stainless steel and 409 stainless steel, which is especially useful for clients in the CNC machining, fabrication, or metal parts sourcing sectors.

304 Stainless Steel vs. 409 Stainless Steel: Stock Shapes

| Stock Shape |

304 Stainless Steel Availability |

409 Stainless Steel Availability |

Notes / Applications |

| Pipes |

Widely available | Commonly available | Used in plumbing, structural supports, exhaust systems |

| Sheets |

Extensive availability | Widely available | Ideal for paneling, appliance covers, structural cladding |

| Coils |

Standard form | Standard form | Used in continuous production lines, automotive and industrial fabrication |

| Rods |

Readily available | Available | Common in precision machining, axles, pins |

| T-Bars |

Less common but available | Rare | Mostly used in architectural or structural frameworks |

| Flat Bars |

Widely available | Available | Used in brackets, supports, and mounting systems |

| Round Bars |

Extensive availability | Available | Essential for turning, milling, and shaft components |

| Hexagonal Bars |

Standard for fasteners | Uncommon | Popular in nuts, bolts, and decorative machining |

| Square Bars |

Commonly stocked | Less commonly stocked | Useful in structural framing and CNC blocks |

| Triangular Bars |

Rarely available | Rare | Usually custom-fabricated for specific design needs |

| Hollow Bars |

Available | Available | Used in bushings, spacers, and lightweight structural parts |

| Threaded Bars |

Standard availability | Available | Frequently used in bolted connections, industrial assemblies |

| Pump Shafts |

Specifically manufactured | Available on request | Requires precision machining for fluid handling systems |

| Ship Axles |

Marine grade variants available | Rare | 304L marine-grade is preferred; 409 generally not used in critical marine applications |

Customer Tips for CNC Machining Projects:

Choosing between 304 stainless steel and 409 stainless steel depends on your application’s performance requirements, environmental exposure, and budget constraints. Both are popular choices in the metal fabrication and CNC machining industries, but they serve distinct roles. Below is a breakdown to help manufacturers, engineers, and procurement teams make the right material decision.

When Should You Use 304 Stainless Steel?

304 stainless steel is the workhorse of the stainless steel family, best known for its superior corrosion resistance, excellent formability, and clean finish. Choose 304 stainless steel if:

| Condition |

Why 304 is Ideal |

| High Corrosion Risk |

Ideal for marine, food, and chemical environments due to its 8–10.5% nickel and 18–20% chromium composition. |

| Aesthetic Finish Required |

Its smooth surface polish is suitable for visible components (e.g., kitchen equipment, architectural trims). |

| Hygiene is Critical |

Preferred in food and medical industries due to its non-reactive and easy-to-clean nature. |

| Higher Temperature Exposure |

Can handle temperatures up to 870°C (1600°F) without scaling or significant structural damage. |

| Frequent Welding Needed |

Excellent weldability without post-weld treatment, unlike some ferritic grades. |

| Industries that benefit most: Food and beverage, medical, chemical, marine, architectural. | |

When Should You Use 409 Stainless Steel?

409 stainless steel is a ferritic stainless steel offering good oxidation resistance at a lower cost, making it the economical choice for non-decorative, heat-exposed applications. Choose 409 stainless steel if:

| Condition |

Why 409 is Suitable |

| Cost Sensitivity |

Contains less nickel, making it significantly more affordable than 304. |

| Moderate Corrosion Resistance is Acceptable |

Suitable for indoor or mild outdoor exposure where full corrosion resistance is not needed. |

| High-Heat Conditions |

Performs well in high-heat environments like automotive exhaust systems. |

| Welded Components in Exhaust Systems |

Commonly used in mufflers, manifolds, and tubes where price-to-performance is optimized. |

| Mass Production Projects |

Excellent choice when machining large batches for general structural or industrial use. |

| Industries that benefit most: Automotive, agricultural equipment, HVAC, and heat exchanger manufacturing. | |

Conclusion

Need help choosing the right material for your CNC machining services or steel part fabrication? We can help analyze your design needs and recommend the ideal material for quality, efficiency, and cost control.

Choosing the correct stainless steel grade is crucial for ensuring your project meets performance, durability, and budget expectations. Both 304 and 409 stainless steel offer distinct advantages, and understanding their strengths will help you make an informed decision.

Consider Your Project Environment

Budget and Volume

Fabrication and Machining Needs

Application Examples

| 304 Stainless Steel |

409 Stainless Steel |

| Food & beverage processing equipment | Automotive mufflers and exhaust components |

| Medical instruments and implants | Agricultural machinery |

| Architectural trim and railings | Heat exchangers and furnace parts |

| Chemical storage tanks and piping | HVAC systems |

Final Recommendation

Selecting the right stainless steel grade is critical for project success. For expert advice tailored to your product design and manufacturing needs, contact our CNC machining factories team specializing in stainless steel CNC machined parts.

Choosing the right material for exhaust pipes is crucial to ensure durability, performance, and cost-effectiveness. Among the many stainless steel grades available, 304 stainless steel stands out as the preferred choice for exhaust systems across industries. Its balanced properties provide a winning combination that meets the demanding conditions of exhaust environments, including high temperatures, corrosive gases, and mechanical stress. Below, we explore why 304 stainless steel excels in exhaust pipe applications, particularly for manufacturers requiring precision CNC machining services.

Excellent Corrosion Resistance

304 stainless steel contains approximately 18% chromium and 8–10.5% nickel, providing outstanding resistance to oxidation and corrosion. Exhaust pipes are continually exposed to moisture, road salts, and corrosive combustion by-products, which can rapidly degrade lower-grade metals. The corrosion resistance of 304 stainless steel significantly reduces rust formation, ensuring structural integrity and safety over time.

Increased Strength and Durability

The combination of chromium and nickel also enhances the mechanical strength of 304 stainless steel. This alloy maintains excellent tensile strength and impact resistance, allowing exhaust pipes to withstand vibrations, thermal expansion, and mechanical shocks without cracking or deforming. Its toughness makes 304 ideal for harsh operating conditions in vehicles and industrial engines.

Better Heat Resistance

Exhaust pipes operate under high-temperature conditions, often exceeding 600°C during normal engine operation. 304 stainless steel retains its mechanical properties and oxidation resistance at elevated temperatures up to 870°C, preventing premature failure caused by thermal fatigue or scaling. This heat tolerance also improves the safety and reliability of exhaust components.

Longer Service Life

Due to its superior corrosion and heat resistance, exhaust pipes made from 304 stainless steel typically last much longer than those made from alternative grades such as 409 stainless steel or carbon steel. Longer service life means reduced maintenance costs and fewer replacements, delivering excellent value over time, especially for fleets or high-mileage vehicles.

Aesthetic Appeal

Besides functional benefits, 304 stainless steel offers a smooth, bright finish that resists discoloration and tarnishing. For visible exhaust systems, especially in passenger vehicles or motorcycles, this aesthetic quality enhances overall product appeal and customer satisfaction. The ability to polish or finish 304 stainless steel parts further adds to its desirability in premium applications.

Conclusion

For exhaust pipe manufacturers and CNC machining factories specializing in stainless steel CNC machined parts, 304 stainless steel represents the best choice. Its excellent corrosion resistance, mechanical strength, heat tolerance, durability, and aesthetic qualities ensure top performance and longevity. Choosing 304 stainless steel helps reduce warranty claims and boosts customer confidence in your products.

When selecting materials for exhaust pipes, balancing cost, durability, and performance is essential. 409 stainless steel is often considered a cost-effective alternative to higher-grade alloys like 304 stainless steel. This section explores the suitability of 409 stainless steel for exhaust pipe applications, highlighting its advantages and limitations to help manufacturers and purchasers make informed decisions.

Advantages of 409 Stainless Steel for Exhaust Pipes

409 stainless steel contains less nickel and chromium compared to 304, making it significantly more affordable. For high-volume automotive exhaust production, this cost saving can be substantial without severely compromising performance.

Designed specifically for high-temperature applications, 409 stainless steel performs well under continuous heat exposure typical in exhaust systems. It offers good oxidation resistance up to approximately 650°C, which covers most vehicle operating conditions.

While it does not match 304 stainless steel’s corrosion resistance, 409 still offers protection against rust and corrosion in relatively mild environments, especially when protected by coatings or paints.

Limitations to Consider

409 stainless steel’s reduced chromium and lack of significant nickel content make it less resistant to aggressive corrosion, especially in environments with high moisture, road salt, or acidic compounds.

Unlike 304, 409 is ferritic and magnetic, which might affect certain applications requiring non-magnetic materials.

409 stainless steel can be more challenging to weld cleanly compared to 304, requiring specific welding processes and post-treatment to avoid brittleness or cracking.

Due to its lower corrosion resistance, exhaust pipes made from 409 stainless steel may have a shorter lifespan, especially in harsh environments, leading to more frequent replacements.

Typical Applications

409 stainless steel is widely used in automotive exhaust systems, including mufflers, catalytic converter housings, and exhaust pipes for passenger vehicles, trucks, and agricultural machinery. Its combination of heat resistance, affordability, and adequate durability makes it a preferred choice in many mass-production scenarios.

Conclusion

409 stainless steel is suitable for exhaust pipes when balancing cost and performance is critical, especially in applications with moderate corrosion exposure and high-temperature demands. However, if superior corrosion resistance, longer lifespan, and aesthetic finish are priorities, 304 stainless steel is the better choice.

For precision CNC machining of exhaust components, discussing your project requirements with experienced CNC machining factories can help determine the optimal stainless steel grade to meet your performance and budget goals.

At VMT, we understand that precision, quality, and timely delivery are crucial when sourcing stainless steel CNC machined parts. Whether you need components made from 304 stainless steel, 409 stainless steel, or other alloys, VMT is your trusted partner for reliable CNC machining services tailored to meet diverse industrial needs.

Comprehensive Material Expertise

VMT specializes in machining a wide range of stainless steels, including 304 and 409 grades, ensuring that each part meets your exact specifications. Our deep material knowledge helps optimize machining parameters, reduce waste, and enhance product durability — essential for applications in automotive, medical, food processing, and architectural sectors.

Advanced CNC Machining Capabilities

Equipped with state-of-the-art CNC milling, turning, drilling, and Swiss machining centers, VMT delivers complex and high-precision parts with tight tolerances. Our skilled engineers leverage the latest CAD/CAM technologies to transform your designs into high-quality stainless steel parts efficiently.

Quality Control and Certification

Quality is at the heart of our operation. VMT enforces rigorous inspection protocols at every stage—from raw material sourcing to final packaging. We provide full material traceability, certifications, and third-party testing on request, ensuring that every stainless steel CNC machined part meets international standards and your project requirements.

Customized Solutions and Prototyping

No matter the batch size—prototype, small volume, or mass production—VMT offers flexible solutions. We work closely with clients to refine designs, recommend materials (304 vs. 409 stainless steel), and optimize manufacturing processes for cost-effectiveness and performance.

Timely Delivery and Competitive Pricing

With an efficient supply chain and lean manufacturing practices, VMT ensures fast turnaround times without compromising quality. Our competitive pricing structure, especially for 304 and 409 stainless steel CNC machined parts, provides excellent value for your investment.

Customer Support and After-Sales Service

From initial consultation to post-delivery support, VMT’s customer service team is dedicated to your satisfaction. We provide technical guidance, order tracking, and responsive communication, making your experience seamless and worry-free.

Get Started with VMT Today

Looking for trusted CNC machining factories to supply premium stainless steel parts? Contact VMT now for a consultation or quote. Let us help bring your project to life with precision-crafted stainless steel CNC machined parts tailored to your exact needs.

Selecting the right stainless steel grade is a critical decision that impacts the performance, durability, and cost-efficiency of your CNC machined parts. 304 stainless steel stands out for its exceptional corrosion resistance, superior strength, excellent heat tolerance, and polished appearance, making it the ideal choice for applications demanding high reliability and aesthetic appeal—such as food processing, medical devices, architectural components, and premium exhaust systems.

On the other hand, 409 stainless steel offers a practical and economical alternative, especially suited for heat-resistant applications like automotive exhaust systems, agricultural equipment, and furnace parts. While it may not match 304 in corrosion resistance or finish, its cost-effectiveness and adequate mechanical properties make it a preferred option for large-scale, budget-conscious projects.

Understanding the differences in chemical composition, physical and mechanical properties, national standards, and stock availability helps manufacturers and procurement teams make informed choices tailored to their specific needs. Whether you prioritize longevity and appearance or cost savings and heat resistance, choosing the right stainless steel grade ensures optimal performance and value.

At VMT, we specialize in providing high-quality 304 stainless steel CNC machined parts and 409 stainless steel CNC machined parts, backed by advanced machining technology, rigorous quality control, and dedicated customer service. Contact us today to discuss your project requirements and receive expert guidance on selecting the best material and machining solution for your needs.

1. Is 304 stainless steel the best?

304 stainless steel is one of the most widely used and versatile stainless steels, offering excellent corrosion resistance, strength, and weldability. While it is “best” for many applications, other grades like 316 may be better suited for highly corrosive environments.

2. What are the weaknesses of 304 stainless steel?

Its main weaknesses are susceptibility to pitting and crevice corrosion in chloride-rich environments and lower resistance to stress corrosion cracking compared to more specialized grades like 316.

3. Does 304 stainless steel rust?

Under normal conditions, 304 stainless steel resists rust. However, in harsh environments with high chloride exposure or poor maintenance, it can develop surface rust.

4. Does 409 stainless steel rust?

409 stainless steel has moderate corrosion resistance but is more prone to rust than 304, especially in wet or salty environments.

5. Is 409 stainless steel magnetic?

Yes, 409 stainless steel is ferritic and magnetic, unlike the non-magnetic 304 stainless steel.

6. What is the difference between 304 and 400 stainless steel?

304 is an austenitic stainless steel with higher nickel content, offering better corrosion resistance and formability. The 400 series (including 409) is ferritic or martensitic, generally less corrosion-resistant but more heat-resistant and magnetic.

7. Can you weld 304 to 409?

Yes, but welding 304 to 409 requires careful technique to avoid issues like brittleness or cracking. Proper filler materials and post-weld treatments are recommended.

8. What is the cheapest grade of stainless steel?

Generally, ferritic grades like 409 or 430 stainless steel are cheaper than austenitic grades like 304 and 316.

9. Which is better, 304 or 430 stainless steel?

304 is better in corrosion resistance and weldability. 430 is magnetic and less corrosion-resistant but more cost-effective for certain applications.

10. What is the difference between 409 and 316?

316 stainless steel offers superior corrosion resistance due to added molybdenum, making it ideal for marine and chemical environments, while 409 is cost-effective for automotive and heat-resistant uses.

11. Is 304 stainless steel better than 440 stainless steel?

304 is better for corrosion resistance and formability. 440 is a high-carbon stainless steel used mainly for cutlery and wear-resistant applications.

12. Which is stronger, 304 or 316 stainless steel?

Both have similar strength, but 316 provides better corrosion resistance, especially in chloride-rich environments.

13. How can I tell if it’s 304 or 316 stainless steel?

Chemical analysis or specific corrosion tests are the most accurate. 316 contains molybdenum, which improves corrosion resistance, especially against chlorides.

14. Why is 316 more expensive than 304?

Because 316 contains molybdenum and higher nickel content, increasing raw material and processing costs.

15. Will 304 stainless steel rust in salt water?

304 may rust in prolonged saltwater exposure due to chloride ions but performs well in less aggressive environments. For marine use, 316 is preferred.

16. Is 409 stainless steel food grade?

409 is not typically considered food grade due to its lower corrosion resistance.

17. How can I prevent 304 stainless steel from rusting?

Regular cleaning, avoiding chloride exposure, and applying protective coatings can prevent rust.

18. Is 304 stainless steel suitable for marine use?

304 can be used in mild marine environments but is generally less suitable than 316 stainless steel for prolonged saltwater exposure.

19. How long does it take for 304 stainless steel to rust?

Under normal conditions, 304 rarely rusts. However, in harsh environments with salt or chemicals, rust can appear within weeks to months without proper maintenance.