15 years one-stop China custom CNC machining parts factory

567 |

Published by VMT at Jul 18 2025 | Reading Time:About 8 minutes

567 |

Published by VMT at Jul 18 2025 | Reading Time:About 8 minutes

If you're selecting a material for high-performance, precision-engineered parts, it’s easy to feel overwhelmed by the many stainless steel grades available. Whether you're manufacturing cookware, medical devices, or industrial tools, the right material directly impacts your product's durability, performance, and cost. That’s where 18/10 stainless steel comes in—a highly popular, corrosion-resistant, and machinable alloy known for its superior finish and strength. In this article, you'll discover why this material is a top choice for CNC machining services, especially when aesthetics and longevity are priorities.

18/10 stainless steel is an alloy composed of 18% chromium and 10% nickel, offering excellent corrosion resistance, luster, and formability. It is a variant of 304 stainless steel and is ideal for manufacturing cookware, medical tools, and architectural components via CNC machining processes.

Understanding the full capabilities of 18/10 stainless steel can help engineers, procurement teams, and product designers make smarter choices. In this detailed guide, you'll learn about its definition, composition, physical and mechanical properties, typical applications, and how it compares to other stainless steel grades. If you're considering CNC machining factories to produce 18/10 stainless steel CNC machining parts, this article will equip you with all the insights you need.

Key Points

18/10 stainless steel refers to a type of austenitic stainless steel that contains approximately 18% chromium and 10% nickel by weight. This composition enhances its corrosion resistance, luster, and formability, making it highly desirable for both consumer and industrial applications. The high nickel content also provides greater ductility and a smoother finish, which is particularly valuable in CNC machined parts used in consumer-facing products like kitchenware and medical tools.

What Does 18/10 Stainless Steel Mean?

The term "18/10" represents the ratio of chromium (18%) to nickel (10%) in the alloy. Chromium improves oxidation resistance and forms a passive layer to protect the material, while nickel increases its ability to withstand corrosion and improves surface smoothness. This composition places it within the 304 stainless steel family, making it one of the most commonly used materials in stainless steel CNC machining parts due to its balance of strength, appearance, and machinability.

Are 304 Stainless Steel and 18/10 Stainless Steel the Same?

Yes, 18/10 stainless steel is a type of 304 stainless steel, which can contain between 8–10.5% nickel and 18–20% chromium. While all 18/10 stainless is 304-grade, not all 304 stainless is necessarily 18/10. The exact formulation may vary slightly by supplier or application, but 18/10 is considered one of the highest-quality versions due to its improved corrosion resistance and finish.

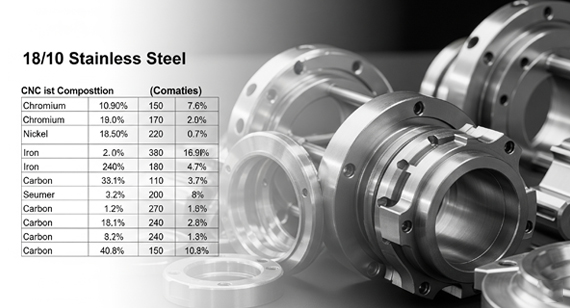

Understanding the chemical composition of 18/10 stainless steel is essential for evaluating its performance in various applications. Each element in the alloy plays a specific role in determining its mechanical strength, corrosion resistance, machinability, and appearance. For engineers, product designers, and buyers working with CNC machining services, knowing these components helps ensure that the selected material will meet functional and regulatory requirements. Below is a breakdown of the primary elements that define 18/10 stainless steel CNC machining parts.

Iron (Fe)

Iron serves as the base metal in 18/10 stainless steel. It provides the alloy with structural integrity and forms the foundation on which other alloying elements interact. Though iron by itself is prone to corrosion, the addition of chromium and nickel significantly enhances its durability and resistance properties.

Chromium (Cr) – ~18%

Chromium is the key alloying element that gives 18/10 stainless steel its excellent corrosion and oxidation resistance. At approximately 18%, chromium forms a thin, stable, and passive layer of chromium oxide on the surface, protecting the metal from moisture, chemicals, and rust. This is what makes stainless steel CNC machining parts suitable for kitchenware, medical equipment, and harsh environments.

Nickel (Ni) – ~10%

Nickel enhances the alloy’s corrosion resistance and improves its ductility and formability. At around 10%, nickel allows the steel to retain its austenitic structure, making it non-magnetic and easier to machine and polish. This contributes to the smooth, shiny finish often seen in 18/10 stainless steel CNC machining parts, especially for aesthetic or hygienic uses.

Manganese (Mn)

Manganese helps improve the hot-working properties and overall strength of the alloy. It also acts as a deoxidizer during the steelmaking process and balances the effect of sulfur, preventing brittleness. This makes it especially valuable in ensuring dimensional stability during CNC machining.

Silicon (Si)

Silicon is used as a deoxidizing agent during the manufacturing of stainless steel. It improves the alloy’s strength and enhances resistance to oxidation at high temperatures. Though present in small quantities, it contributes to better machinability and heat tolerance in demanding industrial applications.

Carbon (C)

Carbon is tightly controlled in 18/10 stainless steel, typically at very low levels. While small amounts of carbon can increase hardness and strength, excessive carbon content can reduce corrosion resistance by forming chromium carbides. For CNC machining factories, low-carbon stainless steel is preferred for its weldability and resistance to intergranular corrosion.

Nitrogen (N)

Nitrogen increases the tensile strength and pitting resistance of the alloy. Though present in small amounts, it plays a role in improving the steel’s mechanical performance without compromising corrosion resistance. This is especially important for parts exposed to aggressive cleaning agents or chemicals.

Phosphorus (P)

Phosphorus content is kept minimal in high-quality stainless steels. While it can improve machinability, excessive phosphorus reduces toughness and may lead to brittleness. In precision CNC machining services, controlling phosphorus ensures high-strength, crack-resistant parts.

Sulfur (S)

Sulfur is sometimes added in trace amounts to enhance machinability, especially in free-machining grades. However, too much sulfur can decrease corrosion resistance. In 18/10 stainless steel CNC machining parts, sulfur is carefully controlled to balance ease of machining with long-term performance.

Here's a clear, professional table summarizing the chemical composition of 18/10 stainless steel, ideal for inclusion in a CNC machining industry article:

Table: Chemical Composition of 18/10 Stainless Steel

| Element |

Symbol |

Typical Content (%) |

Function & Benefits |

| Iron |

Fe | Balance (Base Metal) | Provides structural strength and serves as the primary matrix of the alloy. |

| Chromium |

Cr | ~18% | Enhances corrosion and oxidation resistance by forming a passive chromium oxide layer. |

| Nickel |

Ni | ~10% | Improves corrosion resistance, ductility, and enables austenitic (non-magnetic) structure. |

| Manganese |

Mn | ≤ 2% | Improves hot workability and acts as a deoxidizer; balances sulfur's brittleness. |

| Silicon |

Si | ≤ 1% | Strengthens the alloy and increases oxidation resistance; acts as a deoxidizer. |

| Carbon |

C | ≤ 0.08% | Increases hardness and strength; low levels preserve corrosion resistance. |

| Nitrogen |

N | ≤ 0.10% | Enhances tensile strength and pitting resistance. |

| Phosphorus |

P | ≤ 0.045% | Improves machinability in small amounts; excessive content reduces toughness. |

| Sulfur |

S | ≤ 0.030% | Enhances machinability in controlled amounts; too much reduces corrosion resistance. |

This table is optimized for both engineers and procurement specialists looking to understand 18/10 stainless steel in the context of stainless steel CNC machining parts.

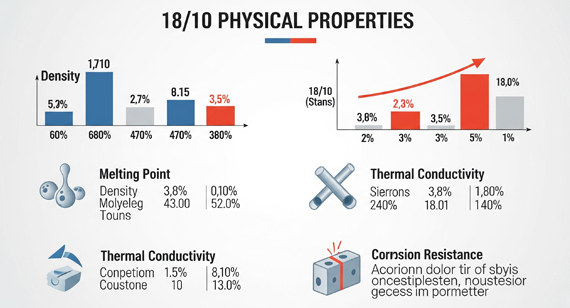

Understanding the physical properties of 18/10 stainless steel is crucial for manufacturers, engineers, and procurement specialists who are considering this material for precision CNC machining parts. The composition of 18% chromium and 10% nickel provides not only excellent corrosion resistance but also imparts distinctive physical characteristics that make this alloy ideal for applications in cookware, medical devices, and architectural components.

18/10 stainless steel is widely appreciated for its high durability, formability, and stability under heat and mechanical stress. These attributes ensure reliable performance in harsh and variable environments. For CNC machining factories and industries requiring accurate, reliable, and consistent production outcomes, knowing these physical properties helps in making informed decisions regarding machining tolerances, heat resistance, and dimensional control.

Below is a detailed breakdown of the most important physical properties that define 18/10 stainless steel, helping guide its usage in various industries and design applications.

Table: Physical Properties of 18/10 Stainless Steel

| Property |

Typical Value |

Description and Relevance |

| Density | ~7.9 g/cm³ | Indicates the weight per unit volume; essential in load-sensitive designs or structural applications. |

| Melting Point | 1400–1450 °C | High-temperature tolerance enables use in cookware, exhaust systems, and industrial parts. |

| Thermal Conductivity | ~16.2 W/m·K | Suitable for thermal regulation applications, such as kitchen appliances and heat exchangers. |

| Coefficient of Thermal Expansion | ~16.0 × 10⁻⁶ /K (20–100 °C) | Affects dimensional stability with temperature changes; crucial for high-precision machining. |

| Electrical Resistivity | ~0.73 × 10⁻⁶ Ω·m | Important for applications where moderate electrical insulation is needed. |

| Modulus of Elasticity | ~193 GPa | Reflects stiffness and resistance to deformation; vital in mechanical design and durability. |

Let me know if you’d like me to move on to the mechanical properties section next, or expand this with application-specific implications for CNC machining services.

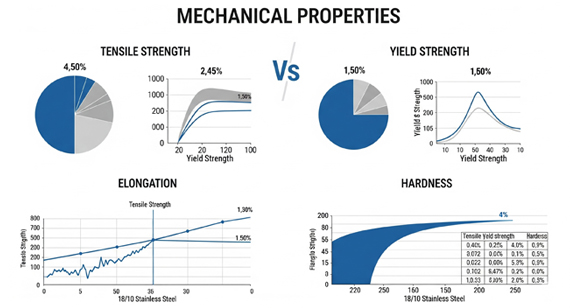

The mechanical properties of 18/10 stainless steel are what make it a top choice in industries ranging from medical equipment manufacturing to food-grade cookware production. For companies that rely on high-performance CNC machining services, understanding how this alloy behaves under stress, heat, and environmental factors is critical for part design and long-term product reliability.

18/10 stainless steel—closely associated with the austenitic 304 grade—exhibits excellent tensile strength, moderate hardness, high ductility, and outstanding resistance to corrosion. These mechanical attributes make it especially suitable for both decorative and functional parts that must withstand impact, vibration, and wear. When annealed, the material also demonstrates good machinability, helping CNC machining factories optimize tool life and reduce cycle times.

Engineers and product designers choosing between different stainless steel grades for their CNC machined parts often prioritize not only strength and hardness but also how easily the material forms, resists corrosion, and retains durability over time. The mechanical profile of 18/10 stainless steel meets these demands reliably.

Table: Mechanical Properties of 18/10 Stainless Steel

| Mechanical Property |

Typical Value / Range |

Description & Relevance |

| Poisson's Ratio |

~0.29 | Reflects material's ability to contract laterally when stretched; useful for stress analysis. |

| Tensile Strength |

500–750 MPa | Indicates how much force the steel can withstand when pulled before breaking. |

| Yield Strength |

~215 MPa | The stress level at which the material begins to deform permanently; key for load-bearing parts. |

| Vickers Hardness (HV) |

~155–200 | Measures surface hardness; relevant for wear resistance and machining behavior. |

| Rockwell Hardness (HRB) |

~70–90 HRB | Common hardness scale used to assess machinability and durability. |

| Brinell Hardness (HB) |

~150–200 | Widely used scale for bulk hardness; helps determine tool wear during machining. |

| Elongation at Break |

~40–55% | High ductility allows the material to bend without breaking; ideal for forming applications. |

| Modulus of Elasticity |

~193 GPa | Measures stiffness and resistance to deformation under load; important in structural parts. |

| Corrosion Resistance |

Excellent | Withstands rust, oxidation, and chemical exposure—perfect for kitchen, marine, and medical use. |

| Magnetic Properties |

Non-magnetic (in annealed state) | Aids in applications requiring non-interference with magnetic fields (medical, electronics). |

| Formability |

Excellent | Easily shaped and bent without cracking; great for complex CNC machined designs. |

| Machinability (Annealed) |

Moderate | Machines well when softened; requires appropriate speeds and feeds to reduce tool wear. |

| Durability |

High | Resists fatigue, stress cracking, and physical wear; ensures product longevity. |

| High Temperature Resistance |

Up to 870 °C (continuous use) | Suitable for heat-exposed parts like exhausts, cookware, and industrial systems. |

Beyond its impressive mechanical strength and corrosion resistance, 18/10 stainless steel possesses several other critical properties that make it a preferred material for high-end consumer products, food-grade equipment, architectural elements, and CNC machining parts. These characteristics—such as its non-reactive surface, appealing appearance, and easy-to-clean nature—are particularly important in industries where hygiene, aesthetics, and surface integrity matter just as much as structural performance.

For CNC machining factories like VMT, these properties play a crucial role in delivering stainless steel CNC machining parts that not only perform reliably but also meet strict visual and sanitary standards. Whether the final product is a polished kitchen appliance or a medical-grade component, understanding these properties helps manufacturers and designers select the right material for both function and form.

Let’s explore these standout traits that differentiate 18/10 stainless steel from other materials in real-world applications.

Highly Non-Reactive Surface

One of the defining traits of 18/10 stainless steel is its exceptional chemical stability. The high chromium (18%) and nickel (10%) content creates a passive oxide layer on the surface, making it non-reactive to acidic and alkaline substances. This is particularly beneficial for cookware, medical tools, and food processing equipment, where contamination or material degradation cannot be tolerated. Unlike reactive metals like aluminum or carbon steel, 18/10 stainless steel does not leach flavors or react with acidic ingredients like tomatoes or vinegar, making it safe and hygienic for sensitive environments.

Appearance

Aesthetically, 18/10 stainless steel is prized for its bright, mirror-like finish. The presence of nickel enhances luster and helps maintain a smooth, elegant appearance even after repeated use. This makes it a go-to choice for decorative CNC machining parts in appliances, jewelry, kitchenware, and architectural hardware. Its ability to resist discoloration, staining, and tarnishing ensures that finished products retain their premium look for years. Additionally, the material’s finish can be customized—from brushed matte to high-polish—offering greater design flexibility for industrial designers and manufacturers.

Cleanliness

18/10 stainless steel’s non-porous and smooth surface makes it remarkably easy to clean and sanitize. It resists buildup of bacteria, grime, and organic material, which is essential in foodservice, healthcare, and laboratory settings. The material does not absorb odors or harbor pathogens, and it stands up well to detergents, hot water, and harsh disinfectants. This property aligns well with regulatory hygiene standards and is a key reason why it’s widely used for CNC-machined kitchen tools, surgical instruments, and pharmaceutical-grade equipment. Cleanliness also extends the life of components and enhances product reliability in demanding environments.

Here is a clear and concise table summarizing the “Other Properties of 18/10 Stainless Steel” for quick reference:

| Property |

Description |

| Highly Non-Reactive Surface |

Chemically stable; does not react with acidic or alkaline substances. Ideal for cookware, food-grade, and medical CNC machining parts. |

| Appearance |

Bright, mirror-like finish with excellent luster; resists tarnishing and discoloration. Suitable for aesthetic and premium-grade components. |

| Cleanliness |

Smooth, non-porous surface is easy to sanitize. Resists bacterial buildup and meets hygiene standards in food and medical industries. |

This table complements the earlier detailed descriptions and is perfect for visual learners or quick product comparison.

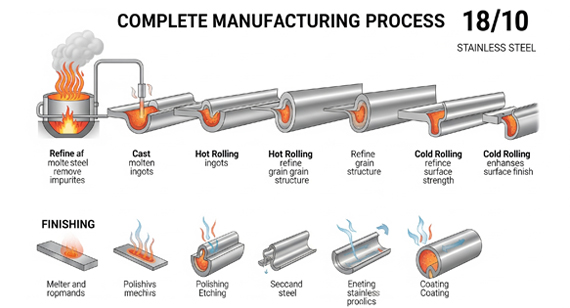

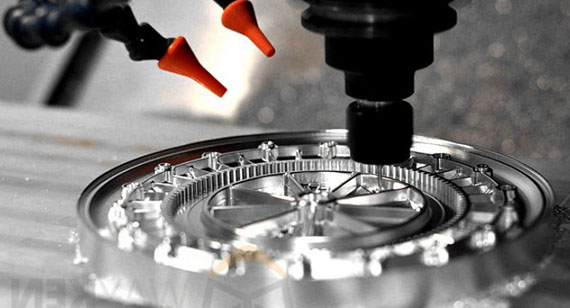

The manufacturing process of 18/10 stainless steel is a precise and controlled sequence of metallurgical steps that ensures the final material possesses superior strength, corrosion resistance, and aesthetic qualities. From melting raw materials to final cutting, each stage contributes to the consistency and performance of stainless steel CNC machining parts. Understanding this process helps customers evaluate the quality behind components sourced from reliable CNC machining factories like VMT.

1. Melting

The production begins with the melting of raw materials—mainly iron, chromium, and nickel—in an electric arc furnace (EAF). Temperatures exceed 1,600°C to create a homogeneous molten alloy. Scrap stainless steel is often added during this stage to promote sustainability and reduce costs.

2. Refining

Next, the molten alloy undergoes a refining process in an Argon Oxygen Decarburization (AOD) converter. This reduces excess carbon and sulfur content, helping to enhance corrosion resistance, ductility, and cleanliness of the alloy. It’s also during this step that precision adjustments to the 18/10 alloy composition are made.

3. Casting

The refined molten steel is then poured into molds or passed through continuous casting machines to form billets, blooms, or slabs. These semi-finished forms will undergo further shaping and treatment.

4. Hot Rolling

Hot rolling transforms cast shapes into thinner sheets or bars. This process occurs at high temperatures and reduces material thickness, improves grain structure, and enhances mechanical properties. It is essential for preparing the steel for machining into CNC parts.

5. Annealing

Annealing involves reheating the hot-rolled steel to soften it, relieve internal stresses, and improve ductility. This stage is crucial for ensuring the material's formability and machinability, particularly for complex 18/10 stainless steel CNC machining parts.

6. Pickling

After annealing, the material is pickled—immersed in acid solutions to remove scale and oxidation from the surface. This step ensures the steel is clean, bright, and corrosion-resistant, making it suitable for food-grade and medical applications.

7. Cold Rolling (Optional)

In applications requiring higher precision and smoother finishes, cold rolling is performed. This involves rolling the steel at room temperature, further enhancing strength, surface finish, and dimensional accuracy.

8. Cutting

Finally, the processed stainless steel is cut into final dimensions for further fabrication or direct use in CNC machining services. This includes sheets, bars, rods, or coils ready for high-precision machining into end-use components.

Table: Manufacturing Process of 18/10 Stainless Steel

| Stage |

Description |

| Melting |

Raw materials melted in an electric arc furnace; base alloy formed. |

| Refining |

Impurities removed; alloy composition adjusted using AOD. |

| Casting |

Molten alloy shaped into billets, blooms, or slabs. |

| Hot Rolling |

Reduces thickness; improves mechanical structure and surface uniformity. |

| Annealing |

Relieves stress; increases ductility and machinability. |

| Pickling |

Removes surface scale and oxides; enhances corrosion resistance. |

| Cold Rolling (Optional) |

Further refines surface and enhances strength; used for precision applications. |

| Cutting |

Material trimmed or shaped for use in CNC machining factories or final applications. |

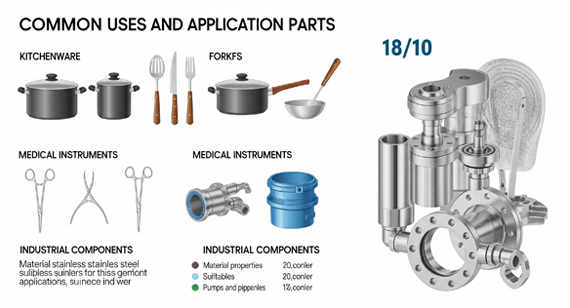

The remarkable combination of durability, corrosion resistance, and aesthetic appeal makes 18/10 stainless steel a versatile material widely used across many industries. Its composition of 18% chromium and 10% nickel not only protects against rust but also ensures a bright, polished surface that withstands daily wear. This makes it ideal for producing stainless steel CNC machining parts that require both functionality and visual appeal. VMT’s CNC machining services leverage these properties to deliver high-quality parts across various applications.

Cookware (Pots, Pans, Cooking Utensils)

Due to its excellent corrosion resistance and non-reactive nature, 18/10 stainless steel is a favorite choice for cookware. It withstands high cooking temperatures, resists staining, and maintains a clean, hygienic surface. Cookware made from 18/10 stainless steel provides durability and a polished finish, perfect for kitchen environments where safety and longevity are priorities.

Cutlery (Forks, Knives, Spoons)

Cutlery benefits from the material’s hardness and corrosion resistance. Knives, forks, and spoons made from 18/10 stainless steel remain sharp and rust-free even after frequent washing and exposure to moisture, making them a standard in households and restaurants worldwide.

Kitchen Appliances

From refrigerators to dishwashers and coffee makers, many kitchen appliances incorporate 18/10 stainless steel components. This material ensures appliances not only look modern and sleek but also maintain long-term resistance to corrosion and wear.

Architectural Elements (Window Frames, Decorative Parts)

The bright, polished surface and weather resistance of 18/10 stainless steel make it ideal for architectural features. It is used in window frames, decorative trims, and handrails, offering both strength and aesthetic appeal in commercial and residential buildings.

Automotive Parts (Grilles, Exhaust Pipes, Trim, Body Panels)

In the automotive sector, 18/10 stainless steel is prized for its strength and corrosion resistance under harsh environmental conditions. Parts such as grilles, exhaust pipes, ductwork, and trim elements benefit from the steel’s ability to resist rust and maintain structural integrity.

Medical and Dental Equipment

Because 18/10 stainless steel is hygienic, easy to sterilize, and biocompatible, it’s commonly used in medical instruments and dental tools. Its resistance to corrosion and staining ensures safety and longevity in critical healthcare environments.

Building Materials (Roofing, Cladding, Handrails)

For building infrastructure, 18/10 stainless steel offers excellent durability against weather and environmental factors. It is often used for roofing materials, exterior cladding, and handrails, where long-lasting corrosion resistance and aesthetic value are crucial.

Food and Chemical Industry (Tanks, Cans, Pipes)

Its chemical inertness and corrosion resistance make 18/10 stainless steel suitable for tanks, cans, and piping systems in food processing and chemical plants. It ensures product purity and prevents contamination.

Transportation

In transportation, the steel’s durability and corrosion resistance are used in manufacturing parts exposed to various environmental stresses, contributing to safer, longer-lasting vehicles and infrastructure.

Refrigeration

Refrigeration units utilize 18/10 stainless steel for their durability and hygienic properties, especially in commercial food storage where cleanliness and resistance to moisture are vital.

Industrial (Machine Parts, Tools, Equipment)

Industrial machinery and tooling often require materials that withstand heavy use and exposure to corrosive environments. 18/10 stainless steel meets these demands with its strength, corrosion resistance, and machinability.

Jewelry (Watches, Bracelets, Rings, Earrings)

Lastly, 18/10 stainless steel is popular in jewelry making due to its attractive shine, durability, and hypoallergenic properties, making it a cost-effective alternative to precious metals.

VMT’s expertise in producing high-precision 18/10 stainless steel CNC machining parts ensures customers receive components that meet strict quality standards across all these varied industries. Explore VMT’s full range of CNC machining services to find the right solution for your project needs.

Here is a table summarizing the uses and applications of 18/10 stainless steel:

| Application Area |

Description and Benefits |

Industry Application Parts Examples |

| Cookware |

Durable, corrosion-resistant, non-reactive, ideal for pots, pans, and cooking utensils. | Saucepan bodies, frying pan surfaces, steamer inserts |

| Cutlery |

Maintains sharpness, resists rust and staining, suitable for forks, knives, and spoons. | Knife blades, fork tines, spoon bowls |

| Kitchen Appliances |

Sleek appearance, corrosion-resistant parts for refrigerators, dishwashers, and coffee makers. | Refrigerator shelves, dishwasher racks, coffee machine casings |

| Architectural Elements |

Used in window frames, decorative trims, and handrails for strength and aesthetic appeal. | Window frames, handrails, decorative panels |

| Automotive Parts |

Strong, corrosion-resistant for grilles, exhaust pipes, trim, and body panels. | Exhaust systems, front grilles, trim moldings |

| Medical and Dental Equipment |

Hygienic, easy to sterilize, biocompatible; used in surgical tools and dental instruments. | Surgical scalpels, dental mirrors, implant components |

| Building Materials |

Weather-resistant for roofing, cladding, and handrails, ensuring durability and corrosion resistance. | Roofing sheets, cladding panels, stair handrails |

| Food & Chemical Industry |

Chemical inertness for tanks, cans, pipes, ensuring product purity and resistance to contamination. | Storage tanks, piping systems, chemical processing vessels |

| Transportation |

Durable components for vehicles and infrastructure exposed to harsh environments. | Rail components, bus interiors, bridge fittings |

| Refrigeration |

Used in commercial refrigeration for hygienic, corrosion-resistant surfaces. | Cooling coils, refrigeration panels, compressor parts |

| Industrial Machinery |

Withstands heavy use and corrosive environments; used in machine parts, tools, and equipment. | Machine housings, cutting tools, conveyor components |

| Jewelry |

Attractive shine, hypoallergenic, durable alternative to precious metals in watches, bracelets, rings, earrings. | Watch cases, bracelets, rings, earring settings |

This table now clearly links each application area with practical examples of 18/10 stainless steel CNC machining parts, helping customers better understand the material’s broad industrial uses.

Choosing the right material is crucial for CNC machining parts, especially when balancing performance, durability, and cost. 18/10 stainless steel, widely used in manufacturing, offers a compelling mix of strength and corrosion resistance, yet it has some limitations that buyers should consider. Understanding its advantages and disadvantages helps manufacturers and clients make informed decisions about when to specify 18/10 stainless steel CNC machining parts.

18/10 stainless steel provides excellent corrosion resistance, durability, and hygienic properties, making it ideal for demanding CNC machining applications. However, it comes with higher costs and susceptibility to specific corrosive environments, requiring careful material selection for each project.

To fully leverage 18/10 stainless steel in CNC machining, it’s essential to weigh its strengths against its weaknesses. Let’s explore these characteristics to understand where this material excels and where alternatives might be more suitable.

18/10 Stainless Steel: Advantages

Better Corrosion Resistance

18/10 stainless steel contains 18% chromium and 10% nickel, which creates a passive oxide layer, offering outstanding resistance to rust and oxidation. This makes it ideal for CNC machining parts exposed to moisture, acids, or food environments, ensuring long-lasting performance.

Durable and Can Withstand Heavy Loads and Mechanical Stress

Its excellent mechanical properties allow 18/10 stainless steel parts to resist deformation and wear. This durability supports applications where strength and longevity are critical, such as industrial components and structural parts.

Hygienic Stainless Steel, Easy to Clean and Sterilize

Thanks to its smooth, non-porous surface, 18/10 stainless steel is easy to sanitize, a key benefit for medical, food processing, and pharmaceutical industries requiring stringent hygiene standards.

Surface Appearance

The bright, polished finish of 18/10 stainless steel parts enhances aesthetics for visible applications like kitchenware and architectural elements, combining functionality with elegance.

Weldability

This grade supports strong, clean welds, allowing complex assemblies and custom parts in CNC machining services without compromising structural integrity.

Easy to Form

18/10 stainless steel can be formed and shaped into intricate designs, enabling precision in CNC machining factories for custom applications.

Recyclability

Environmentally conscious manufacturers appreciate that 18/10 stainless steel is 100% recyclable, reducing waste and supporting sustainable production.

18/10 Stainless Steel: Disadvantages

Expensive

Compared to other stainless steel grades and metals, 18/10 stainless steel typically carries a higher cost due to its nickel content and quality, impacting budget-sensitive projects.

Produces Slight Magnetic Pull

While generally considered non-magnetic, certain manufacturing processes can induce slight magnetism in 18/10 stainless steel, which might affect sensitive electronic applications.

Degrades Easily in Salt Water, Chlorides, and Highly Corrosive Environments

Despite its corrosion resistance, 18/10 stainless steel is vulnerable in environments with high chloride concentrations, such as seawater, which can cause pitting and stress corrosion cracking.

High Melting Point

Its relatively high melting point requires more energy during melting and manufacturing processes, potentially increasing production time and costs in CNC machining factories.

Non-Magnetic (with exceptions)

For some applications where magnetic properties are required, 18/10 stainless steel may not be suitable, necessitating the use of alternative materials.

Stress Corrosion Cracking

In specific conditions like exposure to tensile stress and corrosive media, 18/10 stainless steel can suffer from stress corrosion cracking, limiting its use in extreme environments.

By carefully evaluating these advantages and disadvantages, CNC machining service providers and clients can optimize material choices, ensuring high-quality, durable, and cost-effective 18/10 stainless steel CNC machining parts.

Here’s a clear and professional table summarizing the advantages and disadvantages of 18/10 stainless steel tailored for CNC machining contexts:

| Aspect |

Advantages |

Disadvantages |

| Corrosion Resistance |

Excellent resistance due to chromium-nickel passive layer, ideal for moisture and food contact. | Susceptible to pitting and stress corrosion cracking in saltwater and chloride environments. |

| Durability & Mechanical Strength |

High strength, withstands heavy loads and mechanical stress. | — |

| Hygiene & Cleanliness |

Smooth, non-porous surface easy to clean and sterilize, suitable for medical and food industries. | — |

| Surface Appearance |

Bright, polished finish enhances aesthetics for visible parts. | — |

| Weldability |

Supports strong, clean welds for complex assemblies. | — |

| Formability |

Easily formed into intricate, precise shapes during CNC machining. | — |

| Recyclability |

Fully recyclable, supporting sustainable manufacturing practices. | — |

| Cost |

— | Higher cost due to nickel content and manufacturing complexity. |

| Magnetic Properties |

Generally non-magnetic, suitable for many applications. | May develop slight magnetism after some manufacturing processes, limiting some uses. |

| Melting Point |

— | High melting point increases production energy and time. |

| Stress Corrosion Cracking |

— | Vulnerable under tensile stress and corrosive environments, limiting extreme use cases. |

This table offers a concise overview to guide decisions in choosing 18/10 stainless steel CNC machining parts versus alternative materials.

304 stainless steel is one of the most widely used grades of stainless steel globally, known for its excellent corrosion resistance, formability, and durability. To ensure consistent quality and performance across various applications, 304 stainless steel is manufactured and tested according to several internationally recognized industry standards. These standards define the chemical composition, mechanical properties, testing methods, and certification requirements.

Key Industry Standards for 304 Stainless Steel

ASTM Standards (American Society for Testing and Materials)

ISO Standards (International Organization for Standardization)

EN Standards (European Norm)

JIS Standards (Japanese Industrial Standards)

Why These Standards Matter

Adherence to these industry standards ensures that 304 stainless steel CNC machining parts meet critical quality benchmarks for strength, corrosion resistance, and durability. This guarantees reliability in demanding applications such as medical devices, food processing, automotive parts, and architectural components.

Manufacturers and CNC machining factories rely on these standards to produce stainless steel CNC machining parts that perform consistently and safely across industries, providing customers with confidence in their material selection.

If you want to explore more about stainless steel grades and CNC machining services, feel free to check other detailed guides or contact VMT’s expert CNC machining factories for tailored solutions.

Here is a table summarizing the industry standards for 304 stainless steel:

| Standard |

Organization |

Scope/Description |

Application |

| ASTM A240 / A240M | American Society for Testing and Materials (ASTM) | Specification for chromium and chromium-nickel stainless steel plate, sheet, and strip | Pressure vessels, general engineering |

| ASTM A276 | ASTM | Stainless steel bars and shapes specification | Machining parts, structural components |

| ASTM A312 | ASTM | Specification for seamless and welded stainless steel pipes | Piping systems |

| ASTM A479 | ASTM | Stainless steel bars and shapes for fasteners and industrial parts | Fasteners, bolts |

| ISO 9443 | International Organization for Standardization (ISO) | Stainless steel grades for corrosion-resistant steels | General corrosion-resistant applications |

| ISO 3506 | ISO | Mechanical properties and testing for stainless steel fasteners | Fasteners |

| EN 10088-1 | European Committee for Standardization (CEN) | Stainless steel grades and chemical composition including 304 (X5CrNi18-10) | European stainless steel applications |

| EN 10213 | CEN | Requirements for stainless steel bars for general engineering | Engineering components |

| JIS G4303 | Japanese Industrial Standards (JIS) | Stainless steel bars chemical and mechanical property standards | Japanese industrial use |

This table provides a clear and concise overview of the key international industry standards that govern the production and use of 304 stainless steel, especially relevant to CNC machining parts.

18/10 stainless steel, renowned for its excellent corrosion resistance and durability, is widely used across industries such as cookware, medical equipment, automotive, and architectural applications. However, depending on the country or region, different national standards specify the exact composition, mechanical properties, and manufacturing processes of this stainless steel grade.

Understanding these standards and their equivalents is crucial for manufacturers and clients in the CNC machining industry to ensure consistency, quality, and compatibility when sourcing or producing 18/10 stainless steel CNC machining parts. These standards define not only the chemical composition—primarily 18% chromium and 10% nickel—but also the material’s mechanical characteristics, heat treatment requirements, and testing methods.

For example, the American ASTM standard classifies 18/10 stainless steel as Type 304, one of the most common stainless steel grades globally. In Europe, EN 10088-1 governs the equivalent grade known as X5CrNi18-10. Japan follows the JIS G4303 standard with SUS304, which is chemically and mechanically comparable to Type 304. China’s national standard GB/T 20878 designates 1Cr18Ni9 as the equivalent grade, aligning with the global composition but tailored to local manufacturing practices.

Additionally, countries like Germany (DIN 17440), India (IS 6911), and Russia (GOST 5632-72) have their own versions of 18/10 stainless steel standards, each ensuring that the material meets performance expectations for diverse applications in their regional markets.

For companies providing stainless steel CNC machining services or manufacturing CNC machining parts, awareness of these standards and equivalents is vital. It enables precise material selection, adherence to international quality norms, and smooth collaboration between global supply chains and CNC machining factories.

Table: 18/10 Stainless Steel National Standards and Equivalent Grades

Here is a clear and detailed table outlining 18/10 stainless steel: national standards and equivalent grades for easy reference:

| Country / Region |

Standard |

Equivalent Grade |

Description |

| USA |

ASTM A240 / A276 | Type 304 | Common grade for stainless steel, includes 18% chromium and 10% nickel. |

| Europe |

EN 10088-1 | X5CrNi18-10 (304) | European standard equivalent to 18/10 stainless steel, widely used in industry. |

| Japan |

JIS G4303 | SUS304 | Japanese Industrial Standard equivalent to 304 stainless steel. |

| China |

GB/T 20878 | 1Cr18Ni9 (304) | Chinese national standard equivalent to 18/10 stainless steel. |

| Germany |

DIN 17440 | X5CrNi18-10 | German standard for 304 stainless steel grade. |

| India |

IS 6911 | SS304 | Indian standard for stainless steel with composition matching 18/10 steel. |

| Russia |

GOST 5632-72 | 08X18H10 | Russian equivalent to 304 stainless steel with 18% Cr and 10% Ni. |

This table helps manufacturers and users in CNC machining services and stainless steel CNC machining parts industries identify and match 18/10 stainless steel to regional standards for smooth procurement and quality assurance.

18/10 stainless steel is widely regarded for its excellent corrosion resistance, durability, and attractive finish. However, it is important to understand how it compares to other common stainless steel grades to make informed decisions in CNC machining services, especially when selecting stainless steel CNC machining parts for specific applications.

18/10 Stainless Steel vs. 304 Stainless Steel

18/10 stainless steel and 304 stainless steel are often considered the same grade because 18/10 refers to the percentage of chromium (18%) and nickel (10%) in the alloy, which matches the composition of Type 304 stainless steel. Both offer good corrosion resistance and durability, making them highly suitable for cookware, cutlery, and general industrial applications. However, "18/10" is typically used in consumer goods terminology, whereas "304" is the industrial classification.

18/10 Stainless Steel vs. 316 Stainless Steel

316 stainless steel contains molybdenum (about 2-3%), which provides enhanced corrosion resistance, especially against chlorides and marine environments. Compared to 18/10 stainless steel, 316 is superior in resisting pitting and crevice corrosion, making it ideal for chemical processing, marine applications, and medical devices. However, 316 is more expensive and less commonly used for general cookware or household applications.

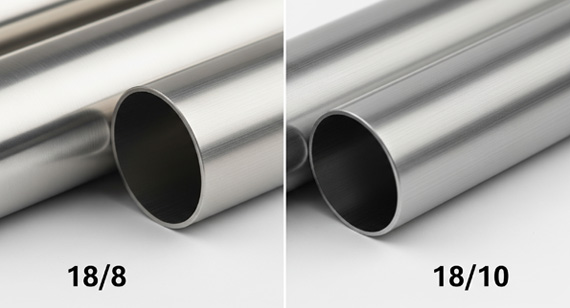

18/8 Stainless Steel vs. 18/10 Stainless Steel

18/8 stainless steel has a slightly lower nickel content (approximately 8%) compared to 18/10 stainless steel. This difference affects corrosion resistance and shine; 18/10 stainless steel generally offers better resistance and a shinier finish. Both grades are widely used in kitchenware, but 18/10 is often preferred for higher-end products due to its improved durability and aesthetic appeal.

18/10 Stainless Steel vs. 18/0 Stainless Steel

18/0 stainless steel contains 18% chromium but no nickel, making it magnetic and less corrosion-resistant compared to 18/10 stainless steel. It is often used in budget kitchenware where magnetism is needed (e.g., magnetic cutlery for dishwasher compatibility), but it lacks the durability and corrosion resistance of 18/10 stainless steel, making it less ideal for demanding environments.

18/10, 18/8, and 18/0 Stainless Steel

These grades differ mainly in nickel content, affecting corrosion resistance, magnetic properties, and price. 18/10 offers the best corrosion resistance and shine, followed by 18/8, while 18/0 is more affordable but less resistant to corrosion. Choosing the right grade depends on application requirements, budget, and desired product longevity.

Table: Comparison of 18/10 Stainless Steel and Other Common Stainless Steel Grades

| Steel Grade |

Chromium (%) |

Nickel (%) |

Corrosion Resistance |

Magnetic Properties |

Common Uses |

Cost |

| 18/10 Stainless Steel |

18 | 10 | Excellent | Non-magnetic | Cookware, cutlery, medical devices, CNC machining parts | Moderate to high |

| 304 Stainless Steel |

18 | 8-10 | Excellent | Non-magnetic | Industrial applications, food processing, CNC machining parts | Moderate |

| 316 Stainless Steel |

16-18 | 10-14 | Superior (especially marine) | Non-magnetic | Marine, chemical, medical, high-corrosion environments | High |

| 18/8 Stainless Steel |

18 | 8 | Good | Non-magnetic | Kitchenware, appliances | Moderate |

| 18/0 Stainless Steel |

18 | 0 | Moderate to low | Magnetic | Budget cutlery, magnetic applications | Low |

This detailed comparison helps CNC machining factories and customers select the appropriate stainless steel CNC machining parts based on performance, cost, and application requirements. For expert stainless steel CNC machining services, understanding these distinctions is crucial for optimizing part quality and durability.

Choosing the right material is a critical step in any manufacturing or machining project. When it comes to stainless steel, 18/10 stainless steel offers a compelling balance of strength, corrosion resistance, and aesthetic appeal. But is it the ideal choice for your specific needs? Understanding its properties and typical applications can help make this decision easier.

18/10 stainless steel is especially well-suited for projects that demand excellent corrosion resistance and durability. Its composition of 18% chromium and 10% nickel forms a protective layer against rust and staining, making it highly resistant to wear and environmental damage. This makes it perfect for kitchenware, medical instruments, architectural components, and food processing equipment. Additionally, its bright, polished surface retains an attractive finish over time, which is important for visible or decorative parts.

If your project involves parts exposed to high humidity, frequent cleaning, or corrosive substances—such as in chemical processing or marine environments—18/10 stainless steel is often the preferred choice. It also performs well under mechanical stress, making it reliable for structural components and machine parts manufactured through stainless steel CNC machining services.

However, 18/10 stainless steel may not always be the best option. For applications requiring extreme corrosion resistance in highly aggressive environments, grades like 316 stainless steel might be more appropriate despite higher costs. Similarly, for projects with tight budgets or magnetic requirements, lower nickel grades such as 18/8 or 18/0 stainless steel could suffice.

In summary, 18/10 stainless steel is an excellent all-around material for many CNC machining parts, offering durability, corrosion resistance, and a premium finish. Its suitability ultimately depends on your project’s environment, mechanical requirements, and budget. Consulting with experienced CNC machining factories can help ensure the right stainless steel CNC machining parts are selected to meet your performance and cost goals.

Deciding when to select 18/10 stainless steel for machining projects depends on the specific requirements of your application. This grade of stainless steel is widely recognized for its excellent combination of corrosion resistance, durability, and aesthetic appeal, making it a popular choice across various industries. Understanding the conditions that favor 18/10 stainless steel machining helps ensure optimal performance and cost-efficiency.

Firstly, 18/10 stainless steel machining is ideal when corrosion resistance is a top priority. The 18% chromium content forms a strong passive layer on the surface, preventing rust and corrosion even in humid or mildly corrosive environments. The 10% nickel enhances this resistance further, providing excellent protection in food processing, kitchenware, medical devices, and chemical equipment. For components like cookware, cutlery, surgical tools, or food storage tanks, 18/10 stainless steel is often the preferred material due to its hygienic properties and ease of cleaning.

Secondly, projects requiring good mechanical strength combined with a polished, attractive finish benefit from 18/10 stainless steel machining. This material withstands mechanical stress and maintains its surface quality over long-term use. Therefore, it suits architectural applications such as decorative panels and handrails, automotive parts that demand durability and corrosion resistance, and consumer products where appearance matters.

Moreover, 18/10 stainless steel is suitable when biocompatibility and safety are essential. It’s commonly used in medical and dental equipment because it does not react with bodily fluids and is easy to sterilize, which is critical for maintaining hygiene standards.

However, it is important to note that 18/10 stainless steel machining may not be the best choice for extremely harsh chemical environments or saltwater exposure where higher-grade steels like 316 are preferred. Also, for applications sensitive to cost, lower-grade stainless steels or alternative materials may offer better value.

In conclusion, choose 18/10 stainless steel machining when your project demands a balance of corrosion resistance, mechanical strength, aesthetic appeal, and hygienic properties. Consulting with CNC machining services and factories specializing in stainless steel CNC machining parts can help optimize material selection for your specific application, ensuring quality and efficiency.

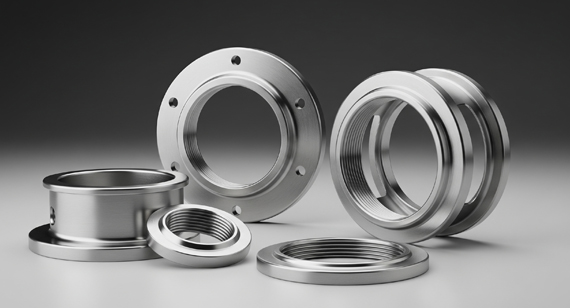

VMT stands as a trusted leader in providing high-quality stainless steel CNC machined parts, serving a broad range of industries with precision and reliability. With advanced CNC machining services, VMT specializes in manufacturing stainless steel CNC machining parts that meet rigorous industry standards and customer specifications. Leveraging state-of-the-art CNC machining factories equipped with modern technology, VMT ensures consistent quality, rapid turnaround times, and competitive pricing.

At VMT, the focus is on delivering parts made from premium stainless steel grades, including 18/10 stainless steel, to meet the demanding requirements of sectors such as medical, automotive, food processing, architecture, and industrial manufacturing. The company’s expertise covers complex geometries, tight tolerances, and surface finishes that align perfectly with client needs.

VMT’s CNC machining services encompass the entire production process, from material selection and precision cutting to finishing and quality inspection. This end-to-end capability ensures that each stainless steel CNC machined part not only performs reliably but also exhibits superior corrosion resistance, durability, and aesthetic appeal.

By choosing VMT as your stainless steel CNC machining parts services factory, clients gain a partner committed to innovation, quality, and customer satisfaction. Whether you require small batches or large-scale production, VMT’s professional team works closely with you to optimize design, material, and manufacturing processes.

For businesses looking to enhance their product quality with durable and precisely machined stainless steel components, VMT offers unparalleled CNC machining expertise and factory capabilities to bring your projects from concept to reality efficiently and economically.

In today’s competitive manufacturing landscape, selecting the right material and machining process is crucial for delivering high-quality, reliable parts. 18/10 stainless steel stands out as a versatile and durable choice, combining excellent corrosion resistance, mechanical strength, and aesthetic appeal. Its balanced composition of 18% chromium and 10% nickel offers superior performance in demanding environments, making it ideal for a wide range of applications from cookware and medical instruments to automotive and architectural components.

Through advanced CNC machining services, factories like VMT are able to transform 18/10 stainless steel into precision parts that meet exacting industry standards and customer requirements. The blend of stainless steel’s inherent properties and the precision of CNC machining ensures components that are not only functional but also long-lasting and visually appealing.

While 18/10 stainless steel may come with higher upfront costs compared to other materials, its durability, corrosion resistance, and ease of maintenance provide significant long-term value. Choosing 18/10 stainless steel CNC machining parts means investing in quality, safety, and sustainability.

Ultimately, understanding the chemical composition, physical and mechanical properties, manufacturing processes, and applications of 18/10 stainless steel empowers manufacturers and designers to make informed decisions. Whether you require parts for everyday consumer products or specialized industrial equipment, 18/10 stainless steel combined with professional CNC machining services is a smart, dependable choice.

For businesses seeking expert stainless steel CNC machining parts services, partnering with a reliable factory like VMT ensures access to cutting-edge technology, quality assurance, and tailored solutions that drive success in today’s demanding markets.

1. Will 18/10 cutlery rust?

18/10 stainless steel offers excellent corrosion resistance due to its high chromium and nickel content. While it is highly resistant to rust, improper care or exposure to harsh environments (such as saltwater) can cause surface rust. Proper cleaning and drying prevent rust formation.

2. Can 18/10 stainless steel be recycled?

Yes, 18/10 stainless steel is fully recyclable. It is an environmentally friendly material that can be melted down and reused without losing its properties, making it sustainable for manufacturing CNC machining parts.

3. What is the best grade of stainless steel?

The best grade depends on the application. For general purposes, 18/10 stainless steel (equivalent to 304 grade) is widely regarded as high-quality due to its balance of corrosion resistance, durability, and machinability.

4. Is 18-10 stainless steel good?

Yes, 18-10 stainless steel is considered premium grade, especially in cookware and cutlery, because it combines durability, corrosion resistance, and an attractive finish, making it suitable for CNC machined parts requiring precision and reliability.

5. What grade is 18-10 stainless steel?

18-10 stainless steel is generally equivalent to AISI 304 stainless steel, featuring 18% chromium and 10% nickel.

6. Is 18-10 stainless steel worth the money?

Definitely. Its superior durability and corrosion resistance justify the slightly higher price compared to lower-grade stainless steels, ensuring longer-lasting parts and less maintenance.

7. Is 18/10 the same as 316 stainless steel?

No, 316 stainless steel contains molybdenum, providing better corrosion resistance in chloride environments, making it ideal for marine applications. 18/10 (304) stainless steel is more common in everyday applications.

8. Is 18-10 stainless steel good for induction?

Yes, 18-10 stainless steel can be compatible with induction cooktops if it contains sufficient ferromagnetic material or has a magnetic base.

9. What is the safest stainless steel cookware?

18/10 stainless steel is considered one of the safest options due to its non-reactive surface, resistance to leaching chemicals, and ease of cleaning.

10. How do you know if stainless steel is genuine?

Authentic stainless steel is magnetic only in certain grades, has a smooth, shiny surface, and does not rust easily. Verification through material certificates or testing by CNC machining factories like VMT ensures authenticity.

11. Does stainless steel rust?

While stainless steel resists rust, it can develop surface rust if exposed to extreme conditions without maintenance.

12. How to identify quality stainless steel?

Quality stainless steel exhibits uniform composition, excellent corrosion resistance, and consistent mechanical properties. Certificates of conformity from CNC machining services can confirm quality.

13. Why does my 18-10 stainless steel rust?

Rust may appear if the steel is exposed to salt, harsh chemicals, or left wet for extended periods. Proper cleaning and drying help prevent rust.

14. Does 18-10 stainless steel scratch?

Yes, like most metals, 18-10 stainless steel can scratch under abrasive contact, but it maintains its strength and corrosion resistance despite minor scratches.

15. Is 18-10 stainless steel oven safe?

Yes, 18-10 stainless steel withstands high oven temperatures, making it suitable for cookware and industrial parts.

16. Is 180 stainless steel safer than 1810 stainless steel?

180 stainless steel contains no nickel and lower chromium, making it less corrosion-resistant compared to 18/10 (1810), which is safer and more durable.

17. Is 18-10 a quality stainless steel?

Yes, it is a top-quality stainless steel widely used in CNC machining parts for its balance of strength, corrosion resistance, and machinability.

18. Is 18-10 stainless steel safe to eat with?

Absolutely, it is food-safe, non-toxic, and widely used for cutlery and cookware.

19. Is 18-10 stainless steel good for frying pans?

Yes, its durability and heat resistance make it an excellent choice for frying pans and other cookware.

20. What grade of stainless steel is best for cooking?

304 stainless steel (18/10) is the most popular due to its corrosion resistance and ease of cleaning.

21. Is it safe to scratch a stainless steel pan?

Minor scratches do not affect safety or performance but maintaining the surface prolongs lifespan and appearance.

22. Why does stainless steel scratch so easily?

Its hardness makes it resistant to deformation, but contact with harder materials can cause surface scratches.

23. How to clean 18-10 stainless steel cookware?

Use mild detergents and non-abrasive sponges. Avoid harsh chemicals to maintain its finish and prevent corrosion.