15 years one-stop China custom CNC machining parts factory

355 |

Published by VMT at Jul 21 2025 | Reading Time:About 8 minutes

355 |

Published by VMT at Jul 21 2025 | Reading Time:About 8 minutes

In industries where performance under extreme conditions is non-negotiable—like aerospace, marine, or chemical processing—material failure can lead to catastrophic outcomes. Engineers often rely on Inconel alloys for their superior resistance to heat, corrosion, and pressure. But while Inconel is excellent for performance, it’s notoriously difficult to machine. This presents a challenge: how can manufacturers maintain the integrity of such a tough material without sacrificing efficiency or precision?

This article explores Inconel Alloy machining from every angle—its unique composition, exceptional properties, and the common difficulties faced during CNC machining. For professionals seeking reliable CNC machining services or looking to understand Inconel Alloy CNC machining parts better, this guide will help you navigate this complex material confidently.

Inconel Alloy machining is the process of cutting or shaping nickel-based superalloys that resist heat, corrosion, and pressure. Due to its high work hardening rate and toughness, Inconel requires specialized CNC machining tools, optimized speeds, and coolants. Machining Inconel successfully demands experience, precision, and the right equipment from a qualified CNC machining factory.

Inconel’s combination of nickel, chromium, and other strengthening elements offers unmatched performance in extreme environments, but these same properties make it a challenge to cut, drill, or shape using conventional machining techniques. Understanding Inconel’s composition and characteristics is key to mastering its CNC processing. Let’s begin by exploring what Inconel alloy is made of and why it behaves the way it does during machining.

Key Points Summary: Inconel Alloy Machining

What is Inconel?

Inconel is a group of high-performance nickel-based alloys known for their exceptional heat resistance, oxidation resistance, and corrosion resistance—especially in extreme environments such as aerospace, marine, and chemical plants.

What’s in Inconel?

Key elements include nickel, chromium, molybdenum, niobium, and iron, which give it high strength and resistance to thermal expansion, oxidation, and chemical attack.

Why is Inconel difficult to machine?

Inconel work-hardens rapidly, generates high cutting forces and heat, wears tools quickly, and can deform under stress. It demands special tools, coolants, and techniques.

What tools and parameters are needed?

Effective machining requires carbide or ceramic tools, high-pressure emulsion coolants, and precisely controlled cutting speed, feed rate, and depth of cut. A rigid setup and toolpath strategy are essential.

Are there specialized Inconel grades?

Yes. Grades like Inconel 600, 625, and 718 are used for different applications, each with unique machinability challenges and strengths.

What are common applications?

Inconel is used in turbine blades, exhaust systems, nuclear reactors, marine fasteners, oil & gas components, and medical devices, due to its resilience in heat, pressure, and corrosive environments.

What does machining Inconel cost?

Higher than most materials due to tool wear, longer machining times, heat management, and the need for specialized CNC machining services and factories with experience in superalloy processing.

How to choose a machining service provider?

Select a CNC machining factory with proven experience in Inconel Alloy CNC machining parts, excellent quality assurance, and technical capability for both prototype and mass production.

Inconel is a family of nickel-based superalloys known for their exceptional strength, heat resistance, and corrosion resistance, especially in extreme environments. Developed by Special Metals Corporation, Inconel alloys are widely used in industries where materials must withstand high temperatures, high pressure, aggressive chemicals, or oxidizing atmospheres—conditions where conventional stainless steel would fail.

These alloys are primarily composed of nickel (typically over 50%), and are often combined with chromium, iron, molybdenum, niobium, and titanium to enhance mechanical and chemical performance. The result is a material that not only resists rust, scale, and acid but also maintains its structural integrity at temperatures exceeding 1000°C (1832°F).

Inconel’s oxidation resistance makes it ideal for aerospace jet engines, power plants, chemical processing, marine applications, and nuclear reactors. It retains tensile strength at high temperatures, resists thermal fatigue, and is virtually immune to chloride stress-corrosion cracking.

However, these very properties make Inconel Alloy machining difficult. Its toughness, work hardening, and low thermal conductivity present serious challenges during CNC processing. That's why industries often seek experienced CNC machining factories that specialize in Inconel Alloy CNC machining parts to ensure precision, reliability, and cost-efficiency.

In summary, Inconel is not just a metal—it's a solution for some of the world’s most demanding engineering problems.

Inconel Alloy is a high-performance nickel-based superalloy specifically engineered to withstand extreme temperatures, corrosion, and mechanical stress. Its outstanding strength and stability come from a carefully designed blend of elements, each contributing to a specific property that enhances its performance in CNC machining, aerospace, marine, chemical processing, and power generation applications.

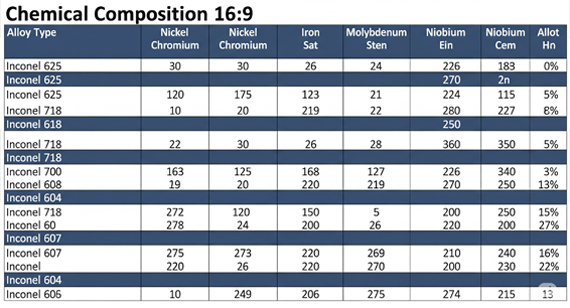

Below is a breakdown of the primary elements found in most Inconel grades (such as Inconel 600, 625, 718), and their roles:

Nickel (Ni) – 50% to 72%

Nickel is the base element and provides core strength, corrosion resistance, and oxidation resistance at high temperatures. It also enables the alloy to maintain its structure and toughness under mechanical and thermal stress.

Chromium (Cr) – 14% to 23%

Chromium enhances the alloy’s oxidation resistance and forms a protective oxide layer on the surface. This is critical for use in aerospace engines, chemical reactors, and marine components exposed to harsh environments.

Iron (Fe) – 5% to 18%

Iron adds structural integrity and economical balance. It’s often included in variable amounts depending on the grade, helping balance cost with performance.

Aluminum (Al) – Up to 1.0%

Aluminum improves oxidation resistance and contributes to the formation of a thermally stable oxide film, which helps maintain performance at very high temperatures.

Carbon (C) – Less than 0.1%

Carbon enhances creep strength and wear resistance, but its content must be carefully controlled to avoid compromising ductility and weldability.

Titanium (Ti) – 0.6% to 1.2%

Titanium stabilizes the microstructure and increases strength at elevated temperatures. In Inconel 718, it plays a key role in precipitation hardening, giving the alloy excellent fatigue and tensile strength.

Molybdenum (Mo) – 8% to 10%

Molybdenum significantly boosts resistance to pitting, crevice corrosion, and stress-corrosion cracking—especially in chloride-rich environments like seawater.

Niobium (Nb) – 3% to 5%

Niobium enhances creep resistance, weldability, and strength through precipitation hardening. Inconel 625 and 718 rely heavily on this element to achieve their superior mechanical properties.

Each of these elements plays a unique role in making Inconel Alloy CNC machining parts perform where other metals fail. The tailored composition also means Inconel machining requires specialized knowledge, tools, and CNC machining services that can handle its complexity.

Here is a clear and professional table summarizing the composition of Inconel alloy and the role of each element:

| Element |

Typical Content (%) |

Function / Contribution |

| Nickel (Ni) |

50% – 72% | Base element; provides high temperature strength, corrosion and oxidation resistance |

| Chromium (Cr) |

14% – 23% | Enhances oxidation and corrosion resistance; forms protective oxide layers |

| Iron (Fe) |

5% – 18% | Adds structural strength and cost-effectiveness |

| Aluminum (Al) |

Up to 1.0% | Improves oxidation resistance; contributes to thermal stability |

| Carbon (C) |

< 0.1% | Increases hardness and creep strength; must be controlled for weldability |

| Titanium (Ti) |

0.6% – 1.2% | Boosts strength at high temperatures; aids precipitation hardening |

| Molybdenum (Mo) |

8% – 10% | Increases resistance to pitting, crevice corrosion, and stress-corrosion cracking |

| Niobium (Nb) |

3% – 5% | Enhances creep strength, weldability, and overall mechanical properties via hardening |

This composition table helps CNC machining factories and engineers quickly understand why Inconel Alloy machining requires expert handling and the right tooling and parameters.

Here is a comprehensive and easy-to-understand table summarizing the mechanical and physical properties of Inconel alloy that are most relevant to CNC machining:

| Property Type |

Property |

Typical Value (for Inconel 718) |

Relevance to CNC Machining |

| Mechanical |

Hardness |

~330 HB (Brinell) | Makes machining more difficult; requires harder cutting tools and slower speeds |

| Fatigue Resistance |

Excellent (endurance limit >400 MPa) | Ensures durability in high-stress environments like aerospace and marine | |

| High Strength |

UTS: ~1240 MPa; Yield: ~1030 MPa | Enables use in load-bearing, high-temperature applications, but adds machining complexity | |

| Physical |

Thermal Conductivity |

11.4 W/m·K (at 20°C) | Low conductivity causes heat to concentrate at the cutting edge, increasing tool wear |

| Thermal Expansion |

13 µm/m·K (at 20–100°C) | Can lead to thermal distortion during machining if not managed properly | |

| Density |

~8.19 g/cm³ | Heavier material affects handling and increases machine load |

These properties explain why Inconel Alloy CNC machining parts require specialized CNC machining services and the right expertise from a professional CNC machining factory. Managing heat, tool wear, and thermal distortion are key challenges when working with Inconel.

Inconel alloy is widely recognized as one of the most reliable materials for extreme environments, from jet engines and power turbines to chemical plants and deep-sea applications. Its unique blend of strength, oxidation resistance, and corrosion resistance sets it apart from conventional metals like stainless steel or titanium. However, these same characteristics come with certain trade-offs, particularly when it comes to machinability and cost. Understanding both the advantages and disadvantages of Inconel Alloy is essential for making an informed decision about its use in CNC machining parts and industrial components.

Advantages of Inconel Alloy

Exceptional High-Temperature Strength:

Inconel maintains its mechanical properties even at temperatures exceeding 1000°C (1832°F), making it ideal for turbine blades, aerospace components, and exhaust systems.

Outstanding Corrosion and Oxidation Resistance:

The high nickel and chromium content provides excellent protection against oxidation, acids, and chloride-induced corrosion, making it suitable for marine and chemical processing environments.

High Fatigue and Creep Resistance:

Inconel exhibits superior fatigue strength and resistance to deformation under prolonged exposure to stress and heat, which is crucial for aerospace and power generation components.

Long Service Life in Harsh Conditions:

Its ability to resist scaling, pitting, and cracking extends its lifespan, reducing the frequency of replacements and lowering maintenance costs over time.

Versatility Across Industries:

Inconel is used in oil and gas, power plants, automotive, marine, nuclear, and medical devices, demonstrating its adaptability in various applications.

Disadvantages of Inconel Alloy

Difficult Machinability:

Inconel’s work-hardening tendency, high toughness, and poor thermal conductivity make CNC machining challenging. It requires specialized cutting tools, slow speeds, and careful parameter optimization.

High Cost of Material and Processing:

Both the raw material and its machining cost are significantly higher than stainless steel or titanium due to tool wear, long processing times, and specialized equipment requirements.

Tool Wear and Heat Generation:

Machining Inconel generates intense heat and accelerates tool wear, which increases the cost of production and the need for frequent tool changes.

Limited Availability in Some Forms:

Certain grades or shapes of Inconel (like custom bars or forgings) can be difficult to source, leading to longer lead times.

Heavier Weight Compared to Alternatives:

With a density of 8.19 g/cm³, Inconel is heavier than materials like titanium, which can be a drawback in weight-sensitive applications.

Here is a clear comparison table summarizing the advantages and disadvantages of Inconel Alloy in the context of CNC machining:

| Aspect |

Advantages of Inconel Alloy |

Disadvantages of Inconel Alloy |

| High-Temperature Strength |

Maintains excellent mechanical strength even above 1000 °C | Requires specialized tooling and machining strategies to cut effectively at high hardness |

| Corrosion Resistance |

Highly resistant to oxidation, acids, chlorides, and seawater | More expensive than stainless steel or titanium due to costly alloying elements |

| Fatigue & Thermal Resistance |

Resists thermal cycling, shock, and high-cycle fatigue in extreme environments | Work-hardens rapidly, increasing tool wear and cutting difficulty |

| Dimensional Stability |

Maintains shape and size under high loads and temperatures | Poor thermal conductivity leads to heat buildup, requiring high-pressure coolant |

| Versatility in Harsh Conditions |

Widely used in aerospace, marine, nuclear, and chemical industries | Slower machining speeds and reduced productivity |

| Long Service Life |

Durable under cyclic stress and corrosive attack, resulting in lower long-term maintenance costs | Complex chip control and rougher surface finish if not machined properly |

| Weldability |

Some grades (e.g., Inconel 625, 718) offer good weldability with proper techniques | Welding requires strict control to avoid hot cracking and metallurgical defects |

Yes — Inconel alloy is considered one of the most difficult materials to process, especially through conventional CNC machining methods. Its inherent strength, toughness, and high resistance to heat and deformation, which make it ideal for extreme environments, also present major challenges during cutting, milling, drilling, or turning.

Why Inconel Is Challenging to Machine

High Work Hardening Rate:

One of the main reasons Inconel alloy is difficult to machine is its tendency to work harden rapidly. As the cutting tool engages the material, the surface layer becomes significantly harder, increasing resistance to further machining and accelerating tool wear. This means if the tool dwell time is too long or cutting speeds are incorrect, subsequent passes can become much more difficult.

Extremely High Cutting Temperatures:

Inconel has poor thermal conductivity, which means the heat generated during cutting stays concentrated near the cutting zone. This not only reduces tool life, but also increases the risk of distortion, warping, or surface defects if not properly controlled.

Increased Tool Wear:

The combination of high strength and poor heat dissipation leads to rapid tool degradation. Even the best carbide or coated tools may wear down quickly unless machining parameters and coolant delivery are optimized.

Built-up Edges and Poor Surface Finish:

Inconel’s chemical composition can lead to built-up edge formation on cutting tools, making it difficult to maintain surface quality. Inconsistent finishes or dimensional inaccuracies are common without advanced strategies like high-pressure coolant or optimized tool paths.

Vibration and Deflection Risks:

Due to the alloy’s high stiffness, any lack of rigidity in the machine setup can lead to chatter and dimensional inaccuracy. Strong fixturing and the right machine selection are essential for precision CNC machining of Inconel alloy CNC parts.

Is It Impossible to Machine?

No, not at all. While Inconel alloy machining is difficult, CNC machining factories with the right expertise, tooling, and process control can handle it effectively. Techniques such as using ceramic tools, high-pressure coolant, optimized feed rates, and rigid setups significantly improve the success rate.

Companies like VMT, which specialize in Inconel alloy CNC machining services, are well-equipped to overcome these challenges and deliver high-quality Inconel alloy components with precision and efficiency.

Inconel alloy is notoriously difficult to machine, especially when compared to common engineering materials like stainless steel or aluminum. Its machinability rating is significantly lower, often between 10% to 30% of standard free-machining steels, depending on the specific Inconel grade (e.g., Inconel 718 or 625). While this may seem discouraging, successful Inconel alloy CNC machining is possible with the right strategies, tools, and experience.

Why Inconel Has Low Machinability

High Strength and Toughness

Inconel alloys retain exceptional mechanical strength at elevated temperatures, which makes them ideal for aerospace and high-heat industrial environments — but also harder to cut. The material resists deformation, causing tools to work harder and wear out faster.

Work Hardening Tendency

Inconel has an extreme tendency to work harden during cutting operations. This means that if the tool hesitates or re-engages previously cut material, it faces a much harder surface. Without aggressive and continuous cuts, machining becomes inefficient or damaging to tools.

Poor Heat Dissipation

The alloy’s low thermal conductivity traps heat in the cutting zone. This elevates temperatures during machining, which increases tool wear, promotes thermal cracking, and makes dimensional control more difficult.

Factors That Improve Machinability

Despite its reputation, Inconel’s machinability can be managed through:

Machinability by Grade

| Inconel Grade |

Relative Machinability |

Typical Use Case |

| Inconel 600 | Moderate (25–30%) | Heat exchangers, chemical processing |

| Inconel 625 | Difficult (20–25%) | Marine, aerospace, nuclear |

| Inconel 718 | Very difficult (10–20%) | Aerospace turbine parts, oil tools |

Conclusion

Inconel alloy is far from easy to machine, but it is not impossible — and its exceptional properties often outweigh the challenges. When done correctly, Inconel alloy CNC machining services produce parts that outperform traditional metals in durability, heat resistance, and strength. That’s why many CNC machining factories like VMT have invested in the tools, technology, and expertise needed to process Inconel efficiently and reliably.

Machining Inconel alloy presents unique difficulties due to its complex physical and mechanical properties. These challenges require careful consideration and specialized techniques to ensure precision, efficiency, and tool longevity. Understanding the key factors that contribute to the difficulty of Inconel machining helps manufacturers and engineers optimize processes and select appropriate equipment for CNC machining parts made from this demanding material.

High Work Hardening Rates

One of the primary challenges when machining Inconel is its high rate of work hardening. As the cutting tool engages the material, the surface layer becomes significantly harder due to plastic deformation. This rapid hardening increases resistance to cutting, causing the tool to wear faster and potentially fail if machining parameters are not carefully controlled. Work hardening also reduces the material’s machinability as the cutting progresses, requiring consistent cutting conditions to maintain efficiency.

High Cutting Forces and Tool Wear

Inconel’s exceptional strength and toughness mean that cutting tools experience high cutting forces during machining. These forces increase tool stress and contribute to accelerated wear. Conventional tooling materials often struggle to maintain sharpness and durability, so specialized carbide or coated tools with superior hardness and heat resistance are necessary. Without proper tooling and optimized feed rates, tool life can be drastically shortened, raising production costs.

High Amounts of Heat Generated During Machining

Due to its poor thermal conductivity, Inconel alloy does not dissipate heat efficiently. Instead, heat concentrates near the cutting edge, causing localized thermal stress. Excessive heat can degrade tool coatings, induce thermal cracking, and distort the workpiece. Managing this heat requires effective cooling strategies, such as high-pressure coolant delivery or cryogenic cooling, to protect both the tool and the material’s surface integrity.

Risk of Workpiece Deformation

Inconel’s high strength combined with poor heat dissipation can cause uneven thermal expansion during machining. This increases the risk of workpiece deformation or dimensional inaccuracies. Maintaining a rigid machine setup and using steady, optimized machining parameters help mitigate this risk. Precise fixturing and clamping are essential to reduce vibration and ensure consistent part quality.

Key Factors Contributing to These Challenges

These combined factors make machining Inconel alloy a demanding process that requires careful planning, appropriate tooling, and skilled operators to achieve precision and efficiency in CNC machining services.

Machining Inconel alloys demands specialized tools and techniques due to the material’s toughness, work hardening behavior, and poor heat dissipation. Choosing the right cutting tools, coolant systems, machining parameters, and ensuring a stable setup are critical for achieving high-quality, precise parts while maximizing tool life and productivity. This section explores these essential elements in detail.

Choosing the Right Cutting Tool

The choice of cutting tool plays a pivotal role in Inconel machining success. The ideal cutting tool must withstand high temperatures, resist abrasive wear, and maintain sharpness despite the alloy’s high strength and rapid work hardening.

Specifications for an Ideal Cutting Tool:

Carbide tools are the most commonly used for Inconel machining. Their hardness and thermal resistance allow them to endure the intense conditions created during cutting. Carbide inserts offer longevity and efficiency, especially when combined with specialized coatings.

Tools coated with materials like Titanium Nitride (TiN), Titanium Carbonitride (TiCN), or Aluminum Titanium Nitride (AlTiN) improve wear resistance, reduce friction, and provide thermal barriers that protect the cutting edge from heat damage. Coated carbide tools are highly recommended for prolonged tool life.

The tool geometry must favor efficient chip evacuation and reduce cutting forces. Tools with sharper cutting edges, positive rake angles, and optimized clearance angles help minimize work hardening and prevent built-up edge formation.

The Role of Coolant in Machining Inconel

Proper cooling is crucial to manage the heat generated during machining Inconel, protecting both the tool and the workpiece from thermal damage.

Recommended Coolant Types:

Water-based emulsion coolants offer excellent cooling and lubrication properties, helping to dissipate heat quickly and reduce tool wear.

High-pressure coolant systems improve penetration into the cutting zone, enhancing chip evacuation and cooling efficiency. This is especially important for deep-hole drilling and milling of complex parts.

Optimizing Machining Parameters

Adjusting cutting parameters is essential to balance productivity with tool life and part quality.

Inconel requires relatively low cutting speeds to prevent excessive heat buildup and tool wear.

Moderate to high feed rates help avoid work hardening by ensuring continuous cutting action without dwelling on the same surface.

Shallower depths of cut reduce cutting forces and heat generation but may increase machining time; an optimal balance must be found.

Ensure Tight Setup

A rigid and stable setup reduces vibration and deflection, which is crucial when machining tough materials like Inconel.

Use precision tool holders with minimal runout to maintain tool accuracy and surface finish.

Strong, secure clamping prevents movement and vibration that can cause dimensional errors and poor surface quality.

Machines with high rigidity, stable spindles, and sufficient power are necessary to handle the high forces during Inconel machining.

By combining the right cutting tools, coolant systems, optimized parameters, and a stable setup, CNC machining factories like VMT can effectively machine Inconel alloy parts with superior quality, accuracy, and efficiency.

Machining Inconel alloys requires not only the right tools and parameters but also advanced techniques to overcome its inherent challenges. These methods help improve productivity, extend tool life, maintain surface integrity, and ensure dimensional accuracy. This section highlights several advanced strategies that experienced CNC machining factories use when working with Inconel.

Check Tool Wear Regularly

Importance of Monitoring and Changing Tools:

Due to Inconel’s high strength and work hardening tendency, cutting tools wear out faster than with many other materials. Regular inspection and timely replacement of worn tools are critical to avoid poor surface finish, dimensional inaccuracies, and increased machining time. Monitoring tool wear helps prevent catastrophic tool failure and reduces scrap rates, ensuring consistent quality.

Start with Solution Metal

Benefits:

Machining Inconel in its solution annealed condition, which softens the alloy before final hardening, can significantly improve machinability. Starting with this softer metal reduces cutting forces and tool wear, allowing easier material removal. After machining, heat treatments like aging or precipitation hardening restore the alloy’s full mechanical properties.

Continuous Cutting with Ceramic Cutting Tools

Advantages:

Ceramic cutting tools can withstand extremely high temperatures and resist abrasive wear better than carbide tools. Using ceramics allows for continuous cutting at higher speeds with less frequent tool changes, enhancing productivity. Their hardness helps maintain sharp edges and improves surface finish, especially during roughing operations.

Strategies to Avoid Pecking

Techniques:

Pecking, or intermittent cutting, often causes excessive work hardening and tool wear in Inconel machining. To avoid this, manufacturers use:

These strategies reduce thermal cycling and mechanical shock to both tool and workpiece.

Post-Machining Operations on Inconel

Grinding and Honing:

Due to Inconel’s tough nature, final surface finishing often requires grinding or honing. These processes improve dimensional accuracy and surface smoothness beyond what is achievable by cutting alone. Grinding removes small amounts of material with precision, while honing enhances surface texture, reduces residual stresses, and prepares parts for critical applications like aerospace or medical devices.

By integrating these advanced techniques—regular tool monitoring, machining solution metal, ceramic tools, avoiding pecking, and precise finishing—CNC machining factories can achieve efficient, high-quality Inconel alloy parts tailored for demanding industries.

Inconel alloys come in several grades, each with unique compositions and properties that influence their machinability. Understanding these differences helps in selecting the right machining strategies and tools to optimize performance and cost-effectiveness. The most commonly machined grades include Inconel 600, 625, and 718, each suited for different applications and presenting distinct challenges during machining.

Inconel 600

Inconel 600 is a nickel-chromium alloy known for its excellent oxidation resistance and good mechanical properties at elevated temperatures. It is widely used in industries requiring high corrosion resistance and thermal stability.

Applications:

Typical applications include heat exchangers, furnace components, chemical processing equipment, and aerospace parts exposed to high temperatures.

Challenges:

Machining Inconel 600 can be difficult due to its tendency to work harden rapidly and generate significant heat. Maintaining tool sharpness and applying appropriate cooling are critical to managing these challenges and avoiding premature tool wear or part deformation.

Inconel 625

Inconel 625 is a nickel-chromium-molybdenum alloy that offers superior strength, excellent corrosion resistance, and good weldability. It is a popular choice for demanding environments, including marine and chemical processing.

Applications:

Commonly used in marine engineering, nuclear reactors, aerospace components, and chemical processing equipment where both strength and corrosion resistance are vital.

Challenges:

The alloy’s high strength and work hardening properties require careful control of machining parameters. Tool wear and heat generation remain significant concerns, necessitating the use of advanced tooling and cooling techniques to ensure efficient machining.

Inconel 718

Inconel 718 is a precipitation-hardened nickel-chromium alloy that combines high strength, corrosion resistance, and excellent toughness. It is widely used in aerospace, nuclear, and high-performance engineering sectors.

Applications:

Typical uses include jet engine components, gas turbines, aerospace structural parts, and nuclear reactors where strength and temperature resistance are critical.

Challenges:

Inconel 718’s combination of toughness and strength makes it particularly challenging to machine. It requires low cutting speeds, precise tool geometry, and rigorous cooling to prevent rapid tool wear and workpiece deformation. The alloy’s complex microstructure also increases the risk of work hardening.

By tailoring machining strategies to the specific characteristics of each Inconel grade, CNC machining services can deliver high-quality parts optimized for their intended industrial applications.

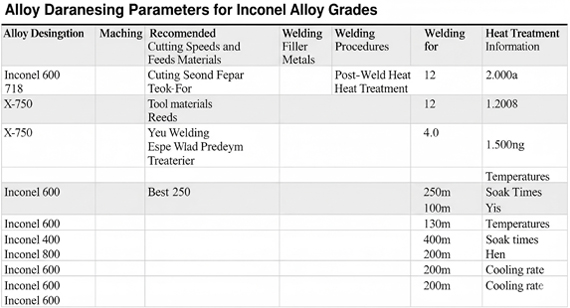

Here is a table summarizing the machining characteristics of Inconel 600, 625, and 718:

| Inconel Grade |

Introduction |

Applications |

Challenges |

| Inconel 600 |

Nickel-chromium alloy with excellent oxidation resistance and high-temperature stability. | Heat exchangers, furnace components, chemical processing, aerospace parts. | Rapid work hardening, high heat generation, requires sharp tools and effective cooling. |

| Inconel 625 |

Nickel-chromium-molybdenum alloy with superior strength and corrosion resistance. | Marine engineering, nuclear reactors, aerospace, chemical processing. | High strength and work hardening cause tool wear; needs advanced tooling and cooling. |

| Inconel 718 |

Precipitation-hardened nickel-chromium alloy with high strength and toughness. | Jet engine parts, gas turbines, aerospace structures, nuclear reactors. | Very tough and strong; requires low cutting speeds, precise tooling, and rigorous cooling. |

Despite the challenges posed by Inconel alloys, machining grades 625 and 718 provides several notable benefits. These alloys are engineered for high-performance applications, and their specific properties translate into advantages that justify the machining effort and investment. Understanding these benefits helps manufacturers optimize their processes and deliver superior end products.

Increased Durability

Both Inconel 625 and 718 exhibit exceptional mechanical strength and corrosion resistance, which contribute to the longevity and reliability of machined parts. This durability means that components can withstand harsh environments—such as high temperatures, chemical exposure, and mechanical stress—without degrading, reducing the need for frequent replacements or repairs.

Excellent Durability

In addition to their mechanical strength, these alloys resist fatigue and stress corrosion cracking better than many other metals. Machined parts maintain their integrity over long service periods, making Inconel 625 and 718 ideal for critical applications in aerospace, marine, and power generation industries. The machining process, while demanding, results in parts that deliver outstanding performance and safety margins.

In summary, machining Inconel 625 and 718 yields parts with superior durability and reliability, making them worth the investment for industries that require materials capable of performing under extreme conditions.

Inconel, a high-performance nickel-chromium superalloy, is renowned for its exceptional heat resistance, corrosion resistance, and mechanical strength under extreme conditions. Due to these unique properties, it is widely used in industries where traditional materials fail — especially under high temperature, high stress, or highly corrosive environments.

CNC machining of Inconel requires advanced tooling, process expertise, and thermal management, but the payoff is components that excel in longevity, reliability, and safety. Below is an overview of how machined Inconel parts serve critical functions across various sectors.

Aerospace Industry

In aerospace, Inconel is prized for its performance at high altitudes and extreme engine temperatures. CNC-machined Inconel parts are essential for flight safety and fuel efficiency.

Typical Parts:

Although less common than in aerospace, Inconel is used in high-performance and motorsport vehicles where heat and stress resistance are critical.

Typical Parts:

Oil and Gas Industry

Inconel thrives in the harsh conditions of downhole and offshore environments — including exposure to high-pressure, high-temperature, and corrosive substances.

Typical Parts:

Power Generation

Inconel is used extensively in both fossil fuel and nuclear power plants due to its ability to withstand high temperatures and oxidation.

Typical Parts:

Chemical Processing Industry

Chemical plants demand materials that resist corrosive agents, especially in processes involving acids, solvents, and elevated temperatures.

Typical Parts:

Marine Industry

Inconel offers excellent resistance to seawater corrosion and stress cracking, making it ideal for marine hardware and offshore installations.

Typical Parts:

Inconel’s biocompatibility and strength make it suitable for specialized medical instruments and implants used in extreme or repeated sterilization conditions.

Typical Parts:

Nuclear Industry

The alloy’s radiation resistance and high-temperature stability make it ideal for nuclear reactor applications.

Typical Parts:

Conclusion

Machining Inconel is a challenge — but one worth overcoming for industries that demand safety, performance, and durability under the harshest conditions. Whether you are building a jet engine or developing components for offshore drilling, machined Inconel parts deliver unmatched reliability and value over time.

Looking for a precision machining partner with Inconel expertise?

We offer ISO-certified, high-precision CNC machining services tailored for Inconel components — from prototyping to volume production.

Here's a clear and professional table summarizing the applications of machined Inconel across various industries, with specific part examples:

Table: Applications of Machined Inconel in Various Industries

| Industry |

Applications / Typical Parts |

| Aerospace |

- Turbine blades - Jet engine exhaust systems - Afterburner components - Rocket engine parts - Heat shields |

| Automotive |

- Turbocharger housings - Exhaust manifolds - EGR valves - Racing engine components |

| Oil & Gas |

- Valves and valve seats - Drill collars - Pump shafts - Sealing rings - Wellhead components |

| Power Generation |

- Gas turbine blades and vanes - Combustion chamber liners - Steam generator tubing (nuclear) - Heat exchanger components |

| Chemical Processing |

- Reactor vessels - Pumps and agitators - Heat exchangers - Valve stems and seats - Corrosion-resistant piping |

| Marine |

- Propeller shafts - Subsea connectors - Pump components - Anti-corrosion fasteners - Valve assemblies |

| Medical Devices |

- Orthopedic instruments - Surgical tools - Radiation therapy components - Implant accessories |

| Nuclear |

- Reactor core components - Fuel element cladding - Heat exchanger tubes - Containment vessel parts |

Machining Inconel, a high-performance nickel-chromium superalloy, is significantly more expensive than machining common metals like aluminum or mild steel. The elevated cost is due to its exceptional hardness, poor thermal conductivity, rapid work hardening, and the specialized tooling and expertise required to handle it. If you're planning to source CNC machined Inconel parts, understanding the underlying cost drivers can help you make informed decisions.

1. Material Hardness and Work Hardening

Inconel is extremely strong at high temperatures and quickly work-hardens during machining. This makes the cutting process more difficult, requiring slower feed rates and shallower cuts, which increases total machining time.

Impact on cost:

2. Tool Wear

Inconel is abrasive and thermally resistant, leading to rapid tool degradation. Even with coated carbide or ceramic tools, inserts need to be replaced frequently.

Impact on cost:

3. Processing Time

Because of the need for reduced spindle speeds and lighter passes, machining Inconel can take significantly longer compared to most other materials.

Impact on cost:

4. Specialized Equipment and Expertise

Not all CNC shops are equipped to handle Inconel. Those that do often use advanced multi-axis machines, high-pressure coolant systems, and thermal management strategies, along with experienced machinists.

Impact on cost:

5. Comparative Cost Analysis vs Other Materials

| Material | Relative Machining Cost | Machinability Rating | Remarks |

| Aluminum 6061 | 1× (Baseline) | Excellent (Machinability 100%) | Very low tool wear and fast machining speeds |

| Stainless Steel 304 | 2× | Moderate (45–50%) | Slower machining, moderate tool wear |

| Titanium Grade 5 | 3×–4× | Difficult (20–30%) | Heat buildup, hard on tools, similar to Inconel |

| Inconel 718 | 4×–8× | Very Difficult (10–15%) | High tool wear, thermal resistance, work hardening |

Conclusion

Machining Inconel is a high-investment, high-reward process. While the cost per part can be 4–8 times higher than common materials due to tool wear, longer cycle times, and specialized requirements, the benefits are undeniable for industries that demand unmatched heat resistance, strength, and corrosion performance.

Looking to machine Inconel components with tight tolerances and premium quality?

We offer ISO-certified precision CNC machining, optimized for Inconel alloys from prototype to volume production — with transparent quoting and expert technical support.

Inconel alloys, known for their exceptional heat resistance, corrosion resistance, and mechanical strength, are widely used in aerospace, energy, and chemical industries. However, these very properties also make Inconel extremely challenging to machine using conventional methods like milling or turning. Tool wear, heat buildup, and work hardening can lead to poor surface finish and high costs.

To overcome these issues, manufacturers increasingly turn to non-traditional machining techniques that remove material without direct mechanical contact. These advanced processes allow for higher precision, minimal thermal damage, and improved surface integrity — ideal for complex Inconel components.

Below are three widely used non-traditional methods for machining Inconel alloys:

1. Electro-Spark Machining (ESM)

Also known as Electrical Discharge Machining (EDM)

How It Works:

Electro-spark machining removes material via rapid electrical discharges (sparks) between an electrode and the Inconel workpiece submerged in dielectric fluid. The intense localized heat melts and vaporizes tiny amounts of material without applying cutting forces.

Advantages:

Typical Applications:

2. Electrochemical Machining (ECM)

How It Works:

ECM is a non-contact, non-thermal process where the Inconel workpiece (anode) is dissolved electrochemically by a conductive electrolyte while a shaped cathode (tool) defines the geometry.

Advantages:

Typical Applications:

3. Photo-Chemical Machining (PCM)

Also known as Chemical Etching

How It Works:

PCM uses a photoresist mask to define the area to be etched. The masked Inconel sheet is then exposed to a chemical etchant that selectively removes material without mechanical force.

Advantages:

Typical Applications:

Conclusion

Non-traditional machining methods offer precision, reliability, and efficiency for Inconel alloys where conventional cutting fails. Whether it's EDM for deep cavities, ECM for complex shapes, or PCM for high-accuracy sheet components, these technologies expand what's possible in manufacturing high-performance nickel alloys.

Need help selecting the right machining process for your Inconel parts?

Our team provides custom manufacturing solutions using both traditional and non-traditional methods — ensuring cost-effective production and top-tier quality from prototype to full-scale production.

Here's a professional and easy-to-read comparison table outlining the key non-traditional machining methods for Inconel alloys:

Table: Non-Traditional Machining Methods for Inconel Alloys

| Method |

Process Description |

Key Advantages |

Typical Applications |

| Electro-Spark Machining (EDM) |

Uses electrical discharges (sparks) to erode material in a dielectric fluid |

- No mechanical contact - High precision - Works on hard materials |

- Turbine blades - Aerospace tooling - Precision dies and molds |

| Electrochemical Machining (ECM) |

Uses controlled anodic dissolution in an electrolyte, shaped by a cathode tool |

- No tool wear - No heat-affected zone - Excellent for mass production |

- Jet engine nozzles - Turbomachinery parts - Power generation parts |

| Photo-Chemical Machining (PCM) |

Uses light-sensitive masks and chemical etching to pattern and remove thin material |

- Ideal for thin parts - No distortion or burrs - Low-cost prototyping |

- Microfilters - Medical components - Fuel cell plates |

Inconel alloys are renowned for their strength, corrosion resistance, and ability to perform in extreme environments. However, their difficult machinability presents unique challenges that only highly capable CNC service providers can handle. Choosing the right machining partner is critical to achieving precision, cost-efficiency, and long-term performance — especially when dealing with aerospace, energy, or medical-grade components.

Here are the key factors to consider when selecting a trusted Inconel machining service provider:

1. Technical Capabilities

Not all CNC machine shops are equipped to machine Inconel effectively. The right provider should offer:

Tip: Ask about their experience with Inconel grades such as 718, 625, or 939 — each has different machining requirements.

2. Industry Experience

Inconel components are often used in mission-critical applications, so your machining partner should have proven success in high-performance sectors.

Look for experience in:

Tip: Check for client references, past project examples, and whether they understand industry-specific tolerances and documentation.

When working with difficult alloys like Inconel, quality cannot be compromised. A reliable service provider should have robust quality control protocols, including:

Tip: Ask for a sample inspection report or quality checklist for similar Inconel parts.

4. Rapid Prototyping to Mass Production

Whether you're developing a prototype or scaling up for production, flexibility is essential. The right provider should offer:

Tip: A partner who understands how to go from concept to full production seamlessly can save you both time and money.

5. Delivery and Turnaround Time

In industries where speed is critical, delayed delivery can mean missed deadlines or revenue loss. A dependable Inconel machining partner should offer:

Tip: Ask about average lead time for Inconel parts and whether they offer guaranteed turnaround for prototypes.

Conclusion

Choosing the right Inconel machining service provider is not just about price — it’s about precision, reliability, and long-term value. Look for a partner with technical expertise, industry experience, quality certifications, production flexibility, and reliable delivery. This ensures your Inconel components meet the highest standards — whether in a jet engine, offshore rig, or medical device.

Need a trusted partner for high-performance Inconel machining?

We offer ISO-certified, full-service CNC machining tailored for nickel alloys — from prototype to production, with guaranteed quality and competitive lead times.

Here's a professional and easy-to-understand comparison table that summarizes the key criteria for choosing an Inconel machining service provider:

Table: Key Factors for Selecting an Inconel Machining Service Provider

| Criteria |

What to Look For |

Why It Matters |

| Technical Capabilities |

- 5-axis CNC machines - High-pressure coolant systems - Inconel-grade tooling - EDM/ECM/PCM methods |

Ensures precision, surface quality, and efficiency when machining tough Inconel alloys |

| Industry Experience |

- Projects in aerospace, oil & gas, medical, etc. - Familiarity with Inconel 625, 718, 939 |

Demonstrates understanding of industry-specific standards and performance expectations |

| Quality Assurance |

- ISO 9001, AS9100, IATF certifications - CMM inspections - Full traceability and documentation |

Guarantees reliability, consistency, and compliance with technical and regulatory requirements |

| Prototyping to Production |

- Low-volume machining - Scalable production - DFM support - Post-processing capabilities |

Offers flexibility for both new product development and high-volume orders |

| Delivery & Turnaround Time |

- Fast lead times - On-time delivery track record - Expedited service availability |

Minimizes project delays and helps meet critical production or market launch schedules |

Precision Machining for High-Performance Nickel Alloys

Why Choose VMT for Inconel Machining?

At VMT Metal Product Co., Ltd., we specialize in CNC machining of high-temperature, corrosion-resistant alloys like Inconel 625, 718, and more. Our advanced equipment and expert engineering team ensure your parts meet the highest standards for strength, durability, and dimensional accuracy — even in the most demanding industries.

Our Inconel Machining Capabilities

| Capability |

Details |

| CNC Machining |

3-, 4-, 5-axis milling and turning centers; tight tolerances up to ±0.005mm |

| Swiss CNC / CNC Turning |

Ideal for small, high-precision Inconel parts with complex geometries |

| Non-Traditional Machining |

EDM, ECM, and chemical etching for hard-to-machine or delicate components |

| Secondary Operations |

Surface finishing, threading, deburring, polishing, heat treatment, coatings |

| Prototyping to Mass Production |

Flexible for small batches and scalable to high-volume orders |

Industries We Serve

Typical Inconel Parts We Machine

Why VMT?

Get a Quote Today

Whether you need a prototype or a full production run, VMT is your trusted partner for precision Inconel CNC machining.

Contact us today to request a free quote or technical consultation.

Inconel alloy stands out as one of the most resilient and high-performance materials used in CNC machining, especially for applications requiring strength, corrosion resistance, and thermal stability. From aerospace turbine blades to chemical reactors, machined Inconel alloy parts provide unmatched reliability in some of the world’s harshest environments. However, this strength comes at a cost — Inconel machining is notoriously challenging due to its high hardness, work hardening tendencies, and intense heat generation during processing.

Despite these challenges, advances in cutting tools, coolant systems, and machining strategies have made it increasingly feasible to produce high-precision Inconel alloy CNC machining parts. Grades like Inconel 625 and Inconel 718 offer unique machining benefits, including excellent fatigue resistance and strength-to-weight ratios, making them indispensable in sectors like oil & gas, marine, and nuclear.

When selecting a CNC machining service provider for Inconel alloy machining, it’s essential to consider their technical capabilities, industry experience, and ability to deliver tight tolerances and high repeatability. A professional CNC machining factory like VMT offers end-to-end solutions.

Inconel machining is no ordinary task — it demands expertise, precision equipment, and an unwavering commitment to quality. At VMT, we combine all three to deliver high-performance, corrosion- and heat-resistant parts that meet the rigorous standards of industries like aerospace, energy, and medical.

From rapid prototyping to mass production, our ISO-certified facilities and skilled engineering team ensure that every Inconel component is machined to exact specifications, inspected thoroughly, and delivered on time. With advanced capabilities in multi-axis CNC, EDM, and secondary processing, we’re equipped to tackle even the most complex projects with speed, accuracy, and cost-efficiency.

In summary, while Inconel alloy machining is demanding, it’s far from impossible. With the right methods, tools, and machining partner, manufacturers can harness the full potential of this superalloy and bring highly durable, high-performance parts to life across a wide range of industries.

When performance matters and failure is not an option — VMT is the machining partner you can trust.

1. Can Inconel alloys be milled?

Yes, Inconel alloys can be milled using high-performance CNC machines equipped with the right tooling and thermal control strategies. However, due to its hardness and work-hardening nature, milling must be done with controlled parameters and sharp, coated tools.

2. Is Inconel harder to machine than titanium?

Yes. While both are challenging, Inconel is generally considered more difficult to machine than titanium due to its extreme heat resistance, rapid work hardening, and tendency to cause tool wear.

3. What makes Inconel a difficult material to machine?

4. What is the most effective machining technique for cutting Inconel alloys?

CNC milling and turning with coated carbide or ceramic tools is effective for most applications. For complex shapes, EDM (Electrical Discharge Machining) or ECM (Electrochemical Machining) may be better suited.

5. Can Inconel be machined using conventional CNC machines? Or are special tools required?

Conventional CNC machines can be used, but they must be paired with specialized tooling, such as carbide tools with TiAlN or AlTiN coatings, and equipped with high-pressure coolant systems to manage heat.

6. How do high cutting temperatures during Inconel machining affect tool life?

High cutting temperatures accelerate tool wear and degradation, often causing chipping, deformation, or coating failure. This shortens tool life significantly if not properly managed.

7. What role does coolant play in making Inconel machining more efficient?

Coolant is crucial for:

8. How can work hardening of Inconel be prevented during machining?

9. What types of cutting tools are best for machining Inconel?

10. How do you maintain surface integrity when machining Inconel?

11. What is the best way to cut Inconel?

The best method depends on the part:

12. What is the best coating for cutting Inconel?

These coatings resist heat and provide excellent wear protection.

13. Can you cut Inconel with a plasma cutter?

Technically yes, but not recommended. Plasma cutting can introduce thermal stress, warping, and surface oxidation, which compromises part quality.

14. What tools are used in machining Inconel?

15. What is the best tool for Inconel?

Coated carbide tools (AlTiN or TiAlN-coated) with a positive rake angle and optimized geometry for heat dissipation and chip evacuation.

16. Can you cut Inconel with high-speed steel (HSS)?

Not efficiently. HSS tools wear out quickly and are not suitable for sustained or high-precision Inconel machining.

17. What is the difference between machining Monel and Inconel?

18. Why is Inconel so difficult to weld?

Inconel has a high risk of cracking, oxidation, and porosity during welding. Specialized techniques, filler metals, and pre/post-heat treatments are required.

19. What is the cutting speed of Inconel?

Typical cutting speed is 10–30 m/min, depending on the tool, Inconel grade, and machine rigidity. Speeds must be carefully optimized to prevent tool failure.

20. Why does Inconel crack?

Cracking can occur due to:

21. How difficult is Inconel to machine?

Very difficult. Machinability ratings for Inconel range from 10–20% compared to free-machining steel (100%), meaning 10x slower material removal rates and higher tool wear.

22. Why is Inconel 718 difficult to machine?

23. Which is stronger, Titanium or Inconel?

Inconel is generally stronger at high temperatures and has better oxidation resistance, while titanium is lighter and more biocompatible. Selection depends on application needs.

24. How much does Inconel cost?

Inconel is an expensive material. Prices vary by grade and form but typically range from $30–$80 per kg, and significantly higher for processed parts due to machining complexity.