15 years one-stop China custom CNC machining parts factory

232 |

Published by VMT at Dec 30 2024 | Reading Time:About 6 minutes

232 |

Published by VMT at Dec 30 2024 | Reading Time:About 6 minutes

Are you struggling to meet the ever-increasing demands for high-precision, durable, and innovative parts in the automotive industry, only to face skyrocketing costs and lengthy production delays? Many automotive manufacturers find themselves in a constant battle between keeping up with cutting-edge design requirements and managing practical constraints such as tooling, material selection, and production consistency. This often results in slower time-to-market, higher scrap rates, and dissatisfied customers. Fortunately, CNC Machining for the Automotive Industry offers a transformative solution by providing unmatched precision, versatility, and efficiency. By leveraging CNC machining design, custom CNC machining services, and the expertise of a reliable CNC machining factory, you can accelerate your prototyping, streamline mass production, and maintain the rigorous standards demanded by modern automotive applications. This comprehensive guide will explore the advantages of CNC machining in automotive manufacturing, highlight its diverse applications, and delve into the best materials to meet both performance and cost goals.

CNC machining for the automotive industry leverages computer-controlled machines to produce automotive CNC machining parts with exceptional precision and repeatability. Key advantages include higher production speed, automation, repeatability, accuracy, design flexibility, multi-material support, customization, and consistent quality. These benefits significantly enhance manufacturing efficiency and the overall performance of CNC machining parts in automotive applications.

To fully grasp why CNC machining is so crucial for automotive manufacturing, it's essential to first understand its role and the numerous advantages it brings. From expediting prototyping to producing engine components with remarkable accuracy, CNC machining stands at the forefront of technological innovation in the automotive realm. By exploring its applications, commonly used materials, and quality control measures, you’ll gain insights into how to optimize CNC Prototype Machining and CNC Machining Services for your automotive projects.

Preface

In the automotive industry, the focus on performance, safety, and innovation continues to intensify as manufacturers strive to meet evolving consumer demands and stringent regulatory standards. CNC Machining for the Automotive Industry is playing a pivotal role in addressing these challenges by enabling precise, consistent, and cost-effective production of automotive CNC machining parts. Whether it's for prototyping new vehicle components or executing high-volume manufacturing, CNC machining ensures rapid turnaround times, unmatched accuracy, and broad material compatibility.

This complete guide delves into why CNC machining is so integral to modern automotive applications. It outlines the benefits that CNC machining provides, describes where and how it’s applied, presents an overview of preferred materials, and concludes with insights on quality control and future trends. By understanding these facets, automotive professionals, designers, and manufacturers can maximize the potential of CNC machining and maintain a competitive edge in a market that demands both innovation and reliability.

CNC machining plays a critical role in the automotive industry by bridging the gap between cutting-edge design requirements and practical manufacturing constraints. Given the sector’s need for high-volume production, tight tolerances, and varied material options, CNC machining stands out for its precision and versatility. Here’s how:

Precision and Tolerance Control: Automotive components like engine pistons, transmission parts, and brake system components demand exceptionally tight tolerances to ensure optimal performance and safety. CNC machining delivers high accuracy and repeatability, ensuring these parts meet exact specifications.

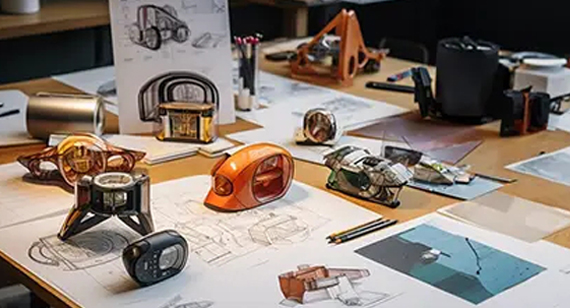

Prototyping and Customization: In an industry where rapid innovation is key, CNC machining aids in CNC prototype machining by swiftly turning complex CAD designs into physical models. This rapid prototyping capability is invaluable for testing new automotive concepts, refining designs, and delivering customized parts for specialized vehicles.

Complex Geometry Handling: Modern vehicles boast intricate designs and weight-reducing features. CNC machines can handle complex geometries, multiple axes, and specialized cutting tools, allowing for the creation of lightweight yet structurally sound components.

Material Efficiency: CNC machining, when executed with CNC machining design best practices, ensures minimal waste, reduces manufacturing costs, and supports sustainability goals. The precise removal of material means components are produced with the highest efficiency, particularly beneficial for expensive metals like titanium or composites.

Scalability: Whether the requirement is for limited production runs or large-scale manufacturing, CNC machining can be scaled accordingly. Programming changes allow for quick adaptation to new designs, making it convenient for diverse automotive needs.

Overall, CNC machining’s role in the automotive industry is multifaceted, supporting everything from concept validation to production of key mechanical and aesthetic components. This synergy between design freedom, material flexibility, and cost-effectiveness explains why automotive manufacturers worldwide increasingly rely on CNC machining parts for their vehicles.

CNC machining has revolutionized automotive manufacturing by providing advanced capabilities that optimize both production and product quality. From engine components and transmission parts to interior trims and custom prototypes, automotive OEMs (Original Equipment Manufacturers) and suppliers leverage CNC machining to stay ahead in a fiercely competitive market. Below are the key advantages that underline CNC machining’s importance in the automotive world.

Production Speed

One of the standout benefits of CNC machining is its high production speed. Once a CNC machining design is finalized in CAD software, the computer-controlled process executes machining operations rapidly and accurately. This automation drastically cuts down the time for each machining cycle, enabling automotive factories to meet tight production deadlines. Compared to manual processes, CNC machining eliminates many human errors and delays, ensuring consistent throughput and quicker lead times.

Automation

Automation is a cornerstone of CNC machining. With minimal operator intervention needed, a CNC machine follows programmed instructions to perform complex operations like milling, turning, and drilling. Automation not only reduces labor costs but also ensures that each part is produced identically, enhancing uniformity across production batches. This consistency is paramount for automotive components, which must fit seamlessly during assembly to uphold vehicle reliability and safety.

Repeatability

Automotive parts often require production in large volumes, where each unit must match precise design specifications. CNC machining provides exceptional repeatability, making it possible to produce thousands of identical parts without any variance. This is particularly valuable in automotive systems like fuel injection, power steering, or braking, where even minor dimensional variations can impact performance and safety.

Accuracy and Precision

Achieving micrometer-level precision is a hallmark of CNC machining for the automotive industry. Crucial components, such as cylinder heads or valve bodies, demand extremely tight tolerances to maintain engine efficiency and adherence to emissions standards. CNC machines excel at reaching these tight tolerances, eliminating cumulative errors often seen in manual fabrication processes. This level of accuracy ensures that automotive parts function optimally over their operational life.

Flexibility

Automotive designs frequently evolve to incorporate new features or address emerging market demands. CNC machining stands out for its flexibility—programming changes can be swiftly executed, allowing manufacturers to adapt product lines without significant retooling. Whether it’s modifying an existing model or developing a new prototype, CNC machining accommodates changes efficiently, minimizing production downtime.

Support for Multiple Materials

The automotive industry utilizes a wide spectrum of materials, from lightweight plastics to high-strength steel alloys. CNC Machining Services cater to these diverse material requirements, enabling manufacturers to choose the most suitable material for each component. This material versatility is crucial for balancing weight reduction, mechanical performance, and cost considerations in vehicle design.

Customization

Modern vehicles, especially premium or specialized models, often offer customization options such as personalized interior trim pieces or specialized performance parts. CNC machining supports customization seamlessly, allowing custom CNC machining factories to produce one-off or low-volume custom orders without incurring prohibitive costs. This is key for aftermarket automotive parts, performance upgrades, and motorsport components that must maintain high quality standards while catering to specific needs.

Consistency

Maintaining consistent part quality across an entire production run is critical for automotive safety and brand reputation. CNC machining enables this consistency by ensuring each part is manufactured to the same precise specifications. This high degree of consistency translates into smoother assembly processes, fewer rejections, and reduced warranty claims—all essential for managing costs and maintaining customer trust in the automotive market.

Rapid innovation is a hallmark of the automotive industry, where designs evolve swiftly to address consumer demands, regulatory changes, and technological advancements. CNC machining plays a pivotal role in automotive prototyping, enabling quick iteration and reducing time-to-market. Prototypes created through CNC Prototype Machining allow engineers to test functionality, fit, and form before committing to large-scale production. This ensures that design changes can be validated swiftly, cutting costs associated with rework or tooling modifications.

Concept Development

During the concept development stage, design teams generate multiple ideas for a new vehicle model or component. CNC machining is employed to create tangible prototypes, enabling stakeholders to visualize and interact with the design physically. Feedback from engineers, designers, and potential customers can then guide further refinements, ensuring that the final concept aligns with technical feasibility and market requirements.

“Fail fast, learn faster” is a guiding mantra in modern product development. Rapid prototyping with CNC machining embodies this ethos by turning digital CAD designs into physical parts in a matter of days—or even hours. This speed is invaluable for evaluating design iterations, comparing different material options, or testing new structural features. By quickly producing prototypes, automotive manufacturers can compress development cycles and bring innovative features to market faster.

Design Verification

Critical automotive components, such as engine or drivetrain parts, must undergo rigorous testing before full-scale production. CNC machining produces prototypes that mirror the final part’s dimensions, tolerances, and material properties. Engineers can perform tests such as stress analysis, thermal assessment, and vibration studies on these prototypes to confirm that the design meets performance criteria. Early detection of design flaws reduces late-stage modifications and associated costs.

Functional Testing

Functional testing ensures that new automotive components perform reliably under real-world conditions. CNC-machined prototypes can be installed in test vehicles or simulation rigs to evaluate factors like durability, noise, vibration, and harshness (NVH). In safety-critical systems, such as braking or steering, verifying functionality is paramount. CNC machining’s precision facilitates accurate testing, leading to data-driven refinements that enhance final product reliability.

Integration with Other Technologies

CNC-machined prototypes integrate seamlessly with other manufacturing technologies, including 3D printing and injection molding. For instance, a design team may use CNC machining to create a robust, functional prototype of an engine block while utilizing 3D printing for less critical aesthetic components. This hybrid approach maximizes efficiency and leverages each technology’s strengths, further streamlining automotive prototyping and development.

While CNC machining is invaluable for prototyping, it is equally critical in large-scale production of automotive components. Its precision, versatility, and repeatability make it indispensable for high-volume manufacturing. CNC machining addresses a range of automotive parts, from engine components to interior trims, ensuring each piece meets exacting standards and stringent safety regulations.

Interior Panels

Automotive interior panels such as dashboards, door panels, and center consoles demand high quality finishes and complex geometries. CNC machining ensures these parts have the precise cutouts for controls, displays, and other features, while maintaining a consistent appearance. Materials can range from plastics to lightweight composites, and CNC machines can handle them all while preserving fine details.

Starter Motors

Starter motors require precisely machined housings and intricate internal components. Tolerances must be tight to ensure the motor performs reliably under repeated use. CNC machining design considerations include maintaining uniformity in hole diameters for shafts, consistent wall thickness, and the use of suitable metals like steel or aluminum. High repeatability of CNC machining ensures that each starter motor component meets these standards.

Cylinder Heads

Cylinder heads are a prime example of Automotive CNC Machining Parts that demand impeccable precision. They contain vital features such as intake and exhaust ports, combustion chambers, and coolant passages. Even slight deviations can lead to poor engine performance or failures. CNC machining allows for fine control over complex surfaces and ensures uniform flow characteristics, maximizing engine efficiency and reliability.

Drive Axles

Drive axles transmit power from the engine to the wheels, requiring components that can withstand significant torque and rotational stress. CNC machining services produce robust axles from high-strength steels or alloys, ensuring tight tolerances for bearings and seals. The automated nature of CNC ensures that each drive axle is identical, reducing vehicle vibrations and supporting overall driveline performance.

Gearboxes

Gearboxes contain multiple precision gears, shafts, and housings that must mesh perfectly for smooth power transmission. CNC machining’s ability to achieve micrometer-level accuracies and maintain consistent part geometry makes it the go-to technology for gearbox components. High-quality gearboxes help reduce noise, optimize fuel efficiency, and improve overall vehicle performance.

AN fitting are widely used in fuel, oil, and coolant systems due to their reliability and ease of maintenance. These connectors require precise threading and dimensional accuracy to prevent leaks under pressure. CNC machining factory operations produce these connectors with high-quality finishes, ensuring proper sealing and compatibility with automotive fluid systems.

Light Housings

Modern vehicles often feature sophisticated lighting systems, including LED assemblies and intricate lens designs. CNC machining allows manufacturers to create complex light housings that precisely accommodate LEDs, reflectors, and wiring channels. Durable plastics or metals can be used, providing both structural integrity and aesthetic appeal.

Customized Parts

Customization is a growing trend in the automotive sector, driven by consumers seeking unique and personalized vehicles. Custom CNC machining enables the production of tailored parts, from bespoke trim pieces to performance upgrades. By providing low-volume or one-off capabilities, CNC machining allows automotive enthusiasts and specialty manufacturers to differentiate their products while upholding high-quality standards.

In the automotive industry, material selection is critical for ensuring that CNC machining parts meet the demands of performance, durability, and cost-effectiveness. From lightweight metals like aluminum to advanced composites, each material offers distinct properties suited to specific automotive applications. CNC machining supports a broad range of materials, making it an ideal manufacturing process for diverse automotive components. The following sections explore the common metals, plastics, and composites used in automotive CNC machining.

Metals form the backbone of automotive structural and mechanical components, providing the necessary strength, heat resistance, and longevity. CNC machining effectively handles metals of varying hardness and composition, enabling high-precision and high-volume production.

Aluminum’s low density, excellent machinability, and corrosion resistance make it a mainstay for CNC machining part design in the automotive industry. Commonly used in engine blocks, cylinder heads, transmission housings, and structural components, aluminum alloys strike a balance between weight reduction and mechanical performance.

Common Grades:

Cast Iron

Cast iron is known for its excellent damping properties, compressive strength, and wear resistance, making it a staple in engine components such as cylinder blocks and brake discs. Its ability to absorb vibrational energy reduces noise and wear, crucial for enhancing vehicle comfort and stability.

Grades Used Include:

Steel Alloys

Steel alloys remain indispensable in automotive manufacturing due to their high strength, toughness, and fatigue resistance. They are commonly used in structural components, drive shafts, gears, and safety-critical parts.

Common Steel Alloys Include:

Titanium Alloys

Titanium alloys combine excellent strength-to-weight ratios with corrosion resistance, making them valuable for high-performance or high-temperature automotive components such as exhaust systems and engine valves. Though more expensive than steel or aluminum, titanium’s unique properties can significantly enhance vehicle efficiency and performance in premium or motorsport contexts.

Copper Alloys

Copper alloys, like brass and bronze, offer excellent conductivity, wear resistance, and machinability. They are often used in electrical components, cooling systems, and bushings where reliable conductivity or lubrication is required.

Noteworthy Grades Include:

Plastics

Plastics have gained prominence in automotive design for reducing weight, improving fuel efficiency, and enhancing design flexibility. CNC machining can handle various plastics, allowing manufacturers to create durable, lightweight components, especially for interior and electronic applications.

Here Are Some Commonly Used Plastics:

Composites

Composite materials offer a unique blend of high strength, low weight, and excellent structural performance. CNC machining of composites demands specialized tooling and careful handling, but the resulting components can significantly enhance vehicle efficiency and performance.

Common Composite Materials Include:

Quality control is paramount in automotive CNC machining, given the sector’s emphasis on reliability, safety, and regulatory compliance. From CNC machining part design through final inspection, rigorous quality control practices ensure that each component meets performance requirements and industry standards. Below are the key measures and certifications that uphold part accuracy and precision throughout automotive manufacturing processes.

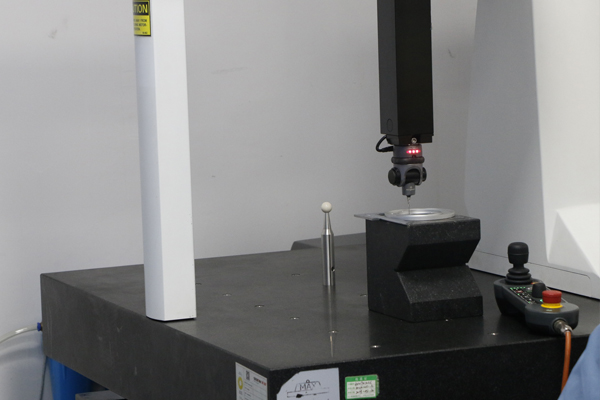

Dimensional Inspection

Dimensional inspection verifies that each CNC-machined part adheres to the specified tolerances and dimensions. Tools such as coordinate measuring machines (CMMs) and optical comparators provide precise measurements, identifying any deviations that could affect part functionality or assembly.

Material Testing

Materials used in automotive CNC machining parts must exhibit the required mechanical properties and composition. Techniques like tensile testing, hardness testing, and chemical analysis confirm that materials meet specifications, ensuring components can withstand operational stresses.

Process Monitoring

Continuous process monitoring tracks parameters like spindle speeds, feed rates, and cutting tool conditions. Automated alerts and real-time data collection enable quick intervention if any parameter drifts from established norms, reducing scrap rates and ensuring consistency.

Surface Finish Evaluation

Surface finish is critical in automotive applications, affecting attributes like friction, wear, and aesthetics. Profilometers and surface roughness testers evaluate the finish quality, ensuring that components align with design requirements for smooth interfaces and performance.

Statistical Process Control (SPC)

SPC applies statistical methods to monitor manufacturing processes and detect variations early. By charting measurement data and analyzing process stability, manufacturers can maintain consistent quality levels and reduce production costs through preemptive actions.

First Article Inspection (FAI)

FAI involves inspecting and verifying the first part produced from a new or modified process against the design specifications. This practice confirms that all production parameters and equipment settings are correct before full-scale manufacturing begins, preventing large-scale defects and material waste.

Meeting global standards and certifications demonstrates a CNC machining factory’s commitment to quality, safety, and environmental responsibility. Below are key standards that underpin CNC machining services in the automotive sector:

Compliance with these standards not only ensures high-quality automotive CNC machining parts but also cultivates customer trust and opens doors to broader market opportunities.

A variety of CNC machine tools cater to the diverse manufacturing needs of the automotive industry. Each machine type offers unique capabilities in terms of part geometry, material handling, and production volume. Understanding these CNC machine types enables automotive manufacturers to optimize their tooling investments, enhance production efficiency, and achieve superior custom CNC machining results.

Major CNC Machine Types

CNC Milling Machines

CNC milling machines employ rotating cutting tools to remove material from a workpiece. They offer exceptional versatility in creating complex 3D shapes, pockets, and cavities, making them indispensable for engine components, transmission housings, and other automotive parts that demand precise multi-axis milling.

CNC lathes rotate the workpiece while stationary cutting tools shape its exterior and interior surfaces. Ideal for cylindrical parts, CNC lathes are extensively used in producing shafts, rods, and drive axles. Multi-axis lathes can also handle more intricate geometries, extending their application range in the automotive sector.

CNC Grinders

Surface and cylindrical grinders equipped with CNC controls provide high-precision finishing, critical for components that require tight dimensional tolerances and superior surface finishes. Automotive parts like bearings, gears, and valve seats often benefit from CNC grinding operations to enhance performance and longevity.

CNC Plasma Cutters

CNC plasma cutters utilize ionized gas at high temperatures to slice through metals like steel and aluminum. While not as precise as milling or lathing, they excel at quickly cutting large sheet metal parts used in vehicle frames and body panels. CNC plasma cutting is also cost-effective for mid-to-high-volume automotive applications requiring two-dimensional cuts.

CNC Electric Discharge Machines (EDM)

EDM removes material through electrical discharges between an electrode and the workpiece. This non-contact method is invaluable for producing complex internal geometries, fine details, or parts where conventional cutting tools are impractical. Automotive mold-making for injection components or die-casting uses EDM extensively.

CNC Routers

Although more commonly associated with wood, CNC routers can also handle some plastics, composites, and light metals. They are occasionally used in automotive manufacturing for non-critical interior components, display housings, and trimming plastic panels.

While CNC machining delivers clear benefits in terms of precision and flexibility, it’s natural for automotive manufacturers to weigh its cost against other production methods like injection molding, die casting, or forging. The decision hinges on factors such as part complexity, production volume, lead times, and required material properties. Although the initial outlay for CNC machining services can be higher per unit in small volumes, the long-term benefits and cost-effectiveness often become evident as production scales or design complexity increases.

Long-Term Benefits and Cost-Effectiveness

Reduced Waste

CNC machining allows for precise control over material removal, significantly minimizing waste compared to traditional subtractive methods. This reduction in material waste not only lowers raw material costs but also supports sustainability goals—a growing concern in modern automotive manufacturing.

Reduced Labor Costs

With high levels of automation and fewer manual steps, CNC machining reduces labor costs. Once the CAD/CAM files are set, the process requires minimal supervision, enabling operators to oversee multiple machines or focus on other tasks. This efficiency translates into lower per-part labor costs over time.

Production Flexibility

Unlike specialized tooling required for injection molding or die casting, CNC machining relies on reprogrammable equipment. Design changes or product variations can be accommodated swiftly by updating the G-code, eliminating the need for extensive retooling or new mold creation. This flexibility allows automotive manufacturers to adapt to market shifts or design revisions rapidly and cost-effectively.

Increased Precision and Quality

The accuracy of CNC machining reduces defects, rework, and warranty claims. Parts that fit seamlessly and function reliably lower the overall cost of quality. Reduced scrap and fewer post-processing steps also improve the bottom line, making CNC machining a prudent choice for critical or high-performance automotive components.

Scalability

CNC machining can handle both low-volume runs and high-volume production, making it suitable for a variety of automotive manufacturing scenarios. As part designs mature and demand grows, scaling up production simply involves adding more machine capacity or optimizing process parameters, rather than investing in entirely new production lines or molds.

Both CNC machining and 3D printing have emerged as pivotal technologies in automotive manufacturing, offering unique advantages for part design, prototyping, and production. While 3D printing excels in creating complex geometries and reducing tooling costs, CNC machining remains indispensable for producing high-tolerance, robust components. Understanding the comparative benefits and limitations of these processes aids automotive manufacturers in selecting the most suitable approach for specific project requirements.

Production Methods

Materials

Precision and Tolerances

Speed and Output

Cost Impact

Applications in the Automotive Industry

Injection molding and CNC machining are both widely used in automotive manufacturing, but each process offers distinct advantages and limitations depending on the application. The choice between them hinges on part complexity, production volumes, materials, and cost considerations. This section outlines the key differences to help automotive manufacturers determine which process best aligns with their production goals.

What Is the Difference Between Injection Molding and CNC Machining?

Injection molding is an additive process where molten material (usually plastic) is injected into a custom mold, then cooled to form the desired shape. CNC machining, on the other hand, is a subtractive process that removes material from a solid block. These fundamental differences in approach lead to varying production capabilities and cost structures.

Here Are 4 Key Differences Between Injection Molding and CNC Machining in Applications:

Materials

Production Volume

Precision and Customization

Cost Impact

The automotive industry continues to evolve at a rapid pace, shaped by growing consumer demands for efficient, safe, and eco-friendly vehicles, as well as regulatory pressures and global competition. CNC Machining remains central to this transformation, with emerging trends poised to reshape how automotive components are designed, manufactured, and integrated. Below are some key future trends that underscore the evolving landscape of automotive CNC machining parts.

Advanced Materials for Better Performance

Lightweight, high-strength materials like advanced aluminum alloys, composites, and specialized steels are increasingly favored for automotive applications. These materials reduce vehicle weight, enhance fuel efficiency, and improve safety. CNC machining will play a vital role in processing these advanced materials, requiring specialized tooling and optimized machining strategies to accommodate unique material properties.

Artificial Intelligence in CNC Cars

Artificial Intelligence (AI) is revolutionizing manufacturing, from predictive maintenance to adaptive machining. In CNC machining for the automotive industry, AI-driven systems can analyze real-time data on tool wear, vibration, and temperature, automatically adjusting cutting parameters to maintain part quality. This level of intelligence minimizes downtime, reduces scrap, and ensures consistent production cycles.

Application of CNC in Self-Driving Cars

Self-driving cars depend on an array of sensors, control units, and safety-critical components. CNC machining ensures the precision needed for housings, brackets, and other parts that protect sensitive electronics and lidar systems. As autonomous vehicles advance, the demand for highly accurate, rugged, and lightweight CNC machined parts will grow, making CNC machining services indispensable.

Ordering automotive CNC machining parts involves careful planning and collaboration with CNC machining factory providers. From design intricacies to material selection, each decision influences cost, lead time, and final part quality. Below are essential considerations and tips to streamline the ordering process and ensure successful outcomes.

Processing Capabilities:

Quality Control Systems:

Costs:

Minimum Order Quantity:

On-Time Delivery:

By considering these factors, you can optimize CNC machining part design decisions, fostering a seamless ordering experience and ensuring that your automotive CNC machined parts meet performance and scheduling requirements.

VMT specializes in delivering high-precision CNC machining services tailored to the automotive industry. Our comprehensive offerings encompass everything from CNC prototype machining to large-scale production runs, ensuring that each CNC machining part design is crafted with utmost accuracy and reliability. Leveraging state-of-the-art equipment and a dedicated team of experts, VMT guarantees top-tier quality standards, adherence to strict tolerances, and on-time deliveries. Whether you require engine components, drivetrain parts, interior trims, or customized solutions, VMT stands as your trusted partner for next-generation automotive manufacturing. Experience the transformative power of CNC machining with VMT, where innovation, quality, and customer satisfaction drive every project.

CNC machining has become a linchpin in the automotive industry, offering solutions that meet the sector’s stringent demands for precision, speed, material versatility, and consistency. From the early stages of prototyping to full-scale production of engine components, gearboxes, interior panels, and more, CNC machining ensures parts are manufactured with exacting accuracy and minimal waste. The technology’s adaptability in handling metals, plastics, and composites further broadens its applications, allowing manufacturers to tailor solutions to evolving market needs and customer preferences.

By understanding and implementing best practices in CNC machining part design, automotive manufacturers can significantly reduce lead times, cut production costs, and maintain high-quality standards across every batch. Whether it’s for rapid prototyping of new vehicle concepts or mass production of critical powertrain components, CNC machining delivers the reliability and precision that modern vehicles demand. Coupled with robust quality control measures, adherence to industry standards, and strategic partnerships with CNC machining factory providers, the automotive sector can continue to innovate and thrive. In an industry that constantly pushes the boundaries of efficiency, performance, and sustainability, CNC machining remains an indispensable ally.

What Products Does the Automotive Industry Produce Using CNC Machining?

The automotive industry uses CNC machining to produce a wide range of components, including engine blocks, cylinder heads, gearboxes, chassis parts, interior panels, starter motors, brake system parts, and customized aesthetic trims. CNC machining is also pivotal for rapid prototyping of new vehicle designs and small-volume runs of specialized or high-performance components.

What CNC Machines Does the Automotive Industry Use?

Automotive manufacturing often employs CNC milling machines, CNC lathes, CNC grinders, CNC plasma cutters, and CNC EDM for various applications. Each machine type offers unique advantages in terms of precision, surface finish, material compatibility, and throughput. Combining multiple machines allows for comprehensive in-house production.

What Materials Are Used in Automotive CNC Machining?

Automotive CNC machining commonly uses metals like aluminum alloys, cast iron, steel alloys, and titanium for high-strength parts, as well as plastics like ABS, Polycarbonate, and Nylon for lightweight or interior components. Advanced composites, such as CFRP and GFRP, are also used where strength-to-weight ratios and performance are paramount.

How Is CNC Used in the Automotive Industry?

In the automotive industry, CNC machining is utilized throughout the product lifecycle—from rapid prototyping and design validation to full-scale production of engine, transmission, chassis, and interior parts. CNC machining services enable precise manufacturing of complex geometries, delivering tight tolerances, superior surface finishes, and repeatable quality essential for modern vehicles.