15 years one-stop China custom CNC machining parts factory

112 |

Published by VMT at May 28 2025 | Reading Time:About 12 minutes

112 |

Published by VMT at May 28 2025 | Reading Time:About 12 minutes

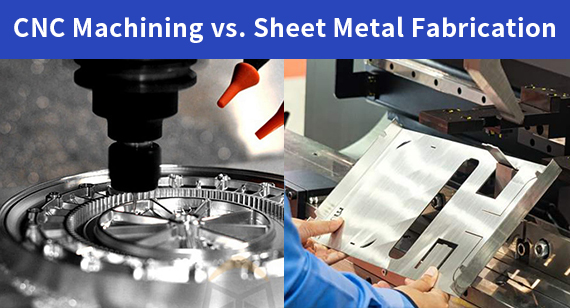

When you're faced with the task of manufacturing custom metal parts, the number of options available can quickly become overwhelming. Should you choose CNC machining for its precision, or sheet metal fabrication for its speed and efficiency? Selecting the wrong method can lead to increased costs, delays, and subpar product quality. Fortunately, understanding the key differences between these two popular manufacturing processes can simplify your decision. In this guide, we'll break down everything you need to know to help you make the right choice for your specific application.

CNC machining is ideal for high-precision, complex-shaped components with tight tolerances, while sheet metal fabrication is better suited for producing lighter, simpler, and cost-effective metal parts in larger volumes. Your project’s design, material, and function determine the best method.

Choosing between CNC machining and sheet metal fabrication isn’t just about the tools—it's about how each process aligns with your part design, timeline, and budget. Whether you're producing a prototype or scaling up for mass production, this article will guide you through the critical factors, from material options to geometric capabilities. If you're also exploring advanced finishing or assembly techniques, be sure to check our CNC machining services and sheet metal processing expertise for a complete production solution.

Understanding the key differences between CNC machining and sheet metal fabrication is essential for choosing the right manufacturing process. Each method offers unique advantages based on material type, geometry complexity, production speed, and cost. CNC machining is a subtractive process that excels in high-precision, complex components, while sheet metal fabrication is ideal for producing enclosures, brackets, and lightweight structures through cutting and bending. Selecting the correct process ensures better quality, performance, and cost-effectiveness. Let’s explore the fundamental distinctions that will guide you toward the right decision for your CNC machining parts or sheet metal components.

Equipment and Machinery

CNC machining utilizes high-precision, computer-controlled machinery such as CNC mills, lathes, routers, and multi-axis machining centers. These machines remove material from solid blocks through controlled cutting actions to shape detailed features. CNC machining factories typically invest in advanced equipment capable of producing parts with micron-level accuracy. Conversely, sheet metal fabrication relies on press brakes, turret punches, laser cutters, shears, and stamping machines. These tools work with thin metal sheets to cut and form them into the desired shapes. While CNC machining equipment is better for intricate parts, sheet metal processing machinery is optimized for fast, scalable production of flat and formed components.

Process Types

CNC machining includes milling, turning, drilling, grinding, and 5-axis machining. These processes are subtractive, meaning they remove material from a solid workpiece to create precise features. On the other hand, sheet metal fabrication includes cutting (laser, plasma, waterjet), forming (bending, stamping, rolling), and joining (welding, riveting, adhesive bonding). Sheet metal fabrication often involves multiple steps to reach the final shape. CNC machining is best for parts that require tight tolerances and complex 3D geometries, while sheet metal fabrication is ideal for larger, simpler designs with flat or bent profiles.

Material Shapes

CNC machining typically starts with solid bars, rods, or billets—cylindrical or rectangular in shape. These materials are machined down to the final part geometry, allowing for both external and internal details. In contrast, sheet metal fabrication begins with flat metal sheets, usually ranging from 0.5mm to 6mm thick. These sheets are cut, bent, and formed into structures. This difference in starting material shapes influences design flexibility: CNC machining offers more freedom for complex components, while sheet metal fabrication is more efficient for creating hollow or planar structures.

Common Materials

CNC machining supports a broad range of metals and plastics. Common materials include aluminum, stainless steel, carbon steel, titanium, brass, copper, Delrin, nylon, and PEEK. These materials are chosen based on strength, machinability, thermal resistance, and end-use requirements. In contrast, sheet metal fabrication is typically limited to malleable metals that can be bent without cracking. These include aluminum, stainless steel, galvanized steel, brass, and copper. Material selection in both methods depends on the intended application, but CNC machining is generally more versatile for harder materials and engineering plastics.

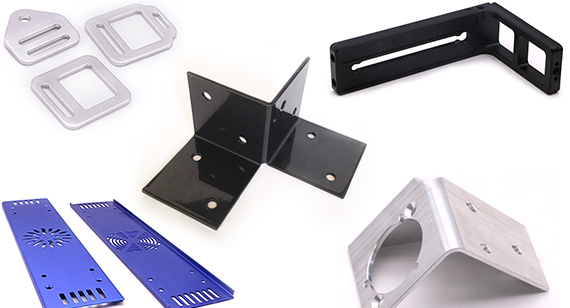

Finished Product

The end products from CNC machining are typically rigid, complex-shaped components with tight tolerances and high precision. These parts often require minimal post-processing and can include internal cavities, threaded holes, and fine surface details. In contrast, sheet metal fabrication produces parts like enclosures, brackets, panels, and ducts that are flat or folded in nature. These parts may need welding or fastening to become functional assemblies. If your project demands form-fitting, structurally rigid, or highly accurate components, CNC machining services are the superior choice. For larger, lightweight, or hollow shapes, sheet metal fabrication is more cost-effective.

Process Complexity

CNC machining excels at handling high complexity. Multi-axis machines can simultaneously cut multiple sides of a part, allowing for the creation of intricate geometries and internal features. Toolpaths can be programmed for extremely precise movements, giving designers full control over every contour. Sheet metal fabrication, however, is limited by bending radii and sheet thickness. Although it can achieve complexity through multi-step operations and assemblies, it's generally less capable of producing high-detail or 3D features. For projects requiring high process control and geometric intricacy, CNC machining parts provide a clear advantage.

Geometry

CNC machining is suitable for manufacturing parts with detailed internal and external geometries, such as cavities, pockets, undercuts, threads, and contours. It can produce both symmetrical and asymmetrical shapes with extreme precision. In contrast, sheet metal fabrication is limited to 2.5D geometry—mainly flat parts with bends, holes, or stamped features. While forming techniques can achieve certain 3D shapes, they’re not ideal for highly irregular or deeply contoured parts. If your design includes complex geometry, opt for CNC machining. For simpler shapes with bends or flanges, sheet metal processing is sufficient.

Dimensional Accuracy

When it comes to dimensional accuracy, CNC machining stands out. It routinely achieves tolerances as tight as ±0.005 mm, making it ideal for critical components in aerospace, medical, and electronics applications. Machinists can fine-tune settings to ensure every part meets exact specifications. In comparison, sheet metal fabrication typically allows for tolerances of ±0.2 mm, depending on the process and material. It’s sufficient for structural or non-critical parts but less suitable for assemblies where exact fits are necessary. If your project depends on precise alignment or fitment, CNC machining services offer the accuracy you need.

Material Waste

CNC machining is a subtractive process, meaning it removes material to create the desired part. This results in more material waste, especially for complex parts with low buy-to-fly ratios. However, the waste can sometimes be recycled depending on the material. Sheet metal fabrication is generally more material-efficient, as it uses flat sheets cut and bent to form parts. Nesting software maximizes sheet usage, reducing waste significantly. For sustainability-conscious projects or when working with expensive materials, sheet metal processing offers better material utilization and cost efficiency.

Machining Time

CNC machining can take longer per part, especially for complex shapes or multi-axis operations. Setup times, tool changes, and slower cutting speeds can extend production cycles, particularly for low-volume or prototype work. Sheet metal fabrication, on the other hand, can achieve faster turnaround times, especially for simple shapes produced in high volumes. With automated laser cutting and high-speed bending, sheet metal parts can be completed in minutes. For time-sensitive projects with basic designs, sheet metal processing offers superior speed. For high-detail work, CNC machining is worth the extra time investment.

Cost Considerations

CNC machining is often more expensive per unit, especially for low-quantity production. Costs include machine time, tooling, and setup, which add up quickly for complex parts. However, for intricate designs requiring high precision, it’s often the only viable option. Sheet metal fabrication is generally more affordable, particularly for high-volume production of simple parts. The initial tooling and setup costs are lower, and cycle times are faster. Choosing between the two depends on the complexity, quantity, and performance demands of your part. For cost-sensitive applications, sheet metal fabrication offers a clear advantage, unless precision is critical.

CNC machined parts can achieve exceptionally smooth surface finishes directly off the machine, depending on the material and tooling used. Additional post-processing such as polishing, anodizing, or bead blasting can further enhance the appearance and corrosion resistance. Sheet metal parts typically have rougher finishes, especially after cutting or bending, and may require more finishing work such as grinding, painting, or powder coating. If your product demands a refined look or smooth functional surface, CNC machining services can deliver superior results. Sheet metal fabrication is more suitable when the finish is not a top priority.

Automation

CNC machining has seen significant advances in automation, including robotic arms, automatic tool changers, and computer-aided manufacturing (CAM) software. These features allow for consistent quality and reduced labor costs, especially in CNC machining factories. Sheet metal fabrication also benefits from automation in laser cutting, bending, and stamping, but the manual nature of certain processes like welding or assembly limits full automation. If your goal is to scale with minimal human intervention, CNC machining offers more streamlined, repeatable operations. However, sheet metal fabrication remains highly competitive in high-throughput environments.

Throughput

Throughput—the number of parts produced in a given time—depends on design complexity and production setup. CNC machining can be slower, especially for one-off or complex parts, but it offers unmatched flexibility. Sheet metal fabrication shines in high-volume runs of simpler components. Automated cutting, bending, and stamping processes can produce thousands of parts in a short time. For mass production with consistent part geometry, sheet metal processing is the faster choice. CNC machining is more appropriate when custom designs, high precision, or variable production batches are involved.

Applications

CNC machining is widely used in industries that demand high precision and complex geometries, including aerospace, medical devices, automotive, defense, and electronics. It is ideal for parts like housings, connectors, gears, and intricate mechanical assemblies. Sheet metal fabrication is common in construction, HVAC, telecommunications, consumer electronics, and transportation. It’s the go-to for making chassis, brackets, cabinets, enclosures, and frames. Both methods can be used for prototyping and production, but the right choice depends on the functional requirements and design complexity of your part. For custom parts and advanced shapes, CNC machining services are unmatched. For lightweight, large-volume components, sheet metal fabrication offers speed and economy.

Here is a clear and professional comparison table for CNC Machining vs. Sheet Metal Fabrication, suitable for customer-facing content:

CNC Machining vs. Sheet Metal Fabrication: Key Differences

| Category |

CNC Machining |

Sheet Metal Fabrication |

| Equipment and Machinery |

CNC mills, lathes, routers, and multi-axis machining centers | Laser cutters, press brakes, shears, stamping presses |

| Process Types |

Subtractive (material is removed to form the part) | Deformative (material is cut, bent, or shaped) |

| Material Shapes |

Solid blocks (bars, billets, plates) | Flat sheet metal |

| Common Materials |

Aluminum, steel, brass, titanium, plastics | Aluminum, stainless steel, galvanized steel, copper |

| Finished Product |

Precision parts with complex 3D geometries | Folded, cut, or bent sheet-based parts |

| Process Complexity |

High — suitable for intricate internal/external features | Moderate — ideal for 2D profiles and bent forms |

| Geometry |

Highly complex 3D shapes with tight tolerances | Mostly 2D profiles with bends and welds |

| Dimensional Accuracy |

Very high (±0.001–0.005 inches typically) | Moderate to high (±0.005–0.030 inches depending on process) |

| Material Waste |

More waste due to cutting/removal | Less waste; efficient nesting and forming |

| Machining Time |

Longer for complex geometries or fine tolerances | Shorter for simple bent parts |

| Cost Considerations |

Higher for low volumes; optimized for precision | Cost-effective for medium to high volumes |

| Surface Finish |

Excellent with fine detail; can be polished, anodized, etc. | Good, but may need secondary treatments like powder coating |

| Automation |

High with CNC programs and robotics | Moderate to high with CNC laser cutting and automated bending lines |

| Throughput |

Slower; better suited for precision parts | Fast; ideal for high-volume production |

| Applications |

Aerospace, medical, automotive, robotics, electronics | Enclosures, brackets, panels, cabinets, HVAC systems |

Prototyping is a critical step in product development, but choosing the wrong manufacturing process can lead to delays, poor-quality parts, and increased costs. Many engineers and product designers struggle to decide between CNC machining and sheet metal fabrication for rapid prototyping. The pressure to produce accurate, functional prototypes quickly and cost-effectively can be overwhelming—especially with tight deadlines and limited budgets.

Fortunately, both CNC machining and sheet metal fabrication offer unique advantages for prototyping. By understanding the strengths and limitations of each process, you can confidently choose the method that fits your design goals, timeline, and functional requirements.

Yes, both CNC machining and sheet metal fabrication can be used for prototyping. CNC machining is ideal for high-precision, complex 3D parts, while sheet metal fabrication excels at creating structural prototypes with bent or formed geometries. Your choice depends on the prototype’s design, material, accuracy needs, and turnaround time.

Prototyping is not a one-size-fits-all process. The ideal method varies depending on the specific requirements of your part—such as geometry, volume, material type, and functional testing needs. In this section, we’ll explore how CNC machining and sheet metal fabrication compare in prototyping scenarios and help you determine which process—or a combination of both—is best suited for your project.

Using CNC Machining for Prototyping

CNC machining is a go-to method for prototyping when your design requires tight tolerances, complex geometries, and superior surface finishes. Whether it’s a metal or plastic component, CNC machining services can produce fully functional prototypes that closely mimic the final production parts. This is particularly valuable for industries such as aerospace, medical devices, and automotive, where exact specifications are essential.

CNC machining allows designers to iterate quickly, especially for components with intricate internal features or threads. Prototypes made from real engineering materials (like aluminum, stainless steel, or PEEK) provide reliable insights into how the part will perform under real-world conditions. Moreover, CNC machining factories can typically deliver parts within days, which accelerates product validation and time-to-market.

If your prototype demands precision, tight tolerances (as low as ±0.001 inch), and consistent repeatability, CNC machining is likely the most effective option.

Using Sheet Metal Fabrication for Prototyping

Sheet metal fabrication is an excellent choice for prototyping enclosures, brackets, panels, and components that will eventually be formed from flat sheets in production. It’s especially efficient for producing prototypes of parts with simple bends and cutouts that don’t require complex 3D machining. Sheet metal processing offers fast lead times and lower costs, especially when you need to evaluate a design’s fit and function without investing in expensive tooling.

This process is ideal for projects that require lightweight components, quick design adjustments, and scalable manufacturing methods. Sheet metal fabrication is also preferred when the prototype’s purpose is to assess structural integrity, mountability, or assembly compatibility. Common materials include aluminum, stainless steel, and galvanized steel—making it easy to match final production conditions.

If you’re working on structural or enclosure-style prototypes and want a fast, cost-effective solution, sheet metal fabrication might be the perfect fit.

Combining Both Processes for Hybrid Prototyping

In some cases, using both CNC machining and sheet metal fabrication in tandem can deliver the best results. For example, a prototype may include a precision-machined housing paired with fabricated sheet metal panels. This hybrid approach allows engineers to balance performance and cost while testing the overall functionality of a product system.

CNC machining parts can be integrated into a fabricated sheet metal assembly to simulate the final product more accurately. This not only validates mechanical function and fit but also provides a clear picture of how production processes will align.

For complex prototypes involving multiple components or mixed material needs, working with a CNC machining factory that also provides sheet metal fabrication services—such as VMT CNC—can streamline production and ensure cohesive results.

Cost is often the determining factor when selecting a manufacturing method, especially during the prototyping and early production phases. Engineers and procurement teams are under constant pressure to optimize budgets without sacrificing quality or speed. Yet, understanding why one process costs more than the other isn’t always clear-cut.

The truth is, CNC machining and sheet metal fabrication have distinct cost structures influenced by design, volume, materials, and required tolerances. By comparing these factors side by side, you can make more informed decisions that balance performance with production efficiency.

CNC machining generally incurs higher costs due to longer machining times, complex setup, and precision tooling, while sheet metal fabrication is often more cost-effective for simple, high-volume parts. However, the overall cost difference depends on factors like part geometry, material use, tolerances, and production scale.

To make an informed choice, it’s essential to examine the specific cost advantages each process offers. Below, we break down the primary cost drivers and benefits of CNC machining and sheet metal fabrication, so you can better align your design and production goals with your budget.

CNC Machining Cost Benefits

CNC machining is best known for producing high-precision parts, but this capability comes at a cost. The price is driven by machine run-time, complexity, material type, and finishing requirements. However, for certain projects, the investment is well worth the outcome.

Design Complexity

CNC machining can handle intricate geometries, undercuts, and internal features that are impossible in sheet metal fabrication. While this adds to the programming and machining time—thus increasing cost—it eliminates the need for separate components or assemblies, which can ultimately reduce total project expense in complex builds.

Precision Requirements

If your part requires tight tolerances (±0.001 in or better), CNC machining is often the only viable option. This level of precision requires high-end equipment and tooling, which increases cost but ensures consistent quality and dimensional accuracy—critical for aerospace, medical, or high-performance components.

Functional Requirements

CNC machining allows prototypes and end-use parts to be made from actual production-grade materials, such as aluminum, stainless steel, or engineering plastics. These materials can simulate real-world functionality in prototypes and eliminate the need for additional testing or secondary processing, reducing long-term costs.

Throughput

For low- to mid-volume production, CNC machining is efficient and scalable. Although per-unit cost is higher than sheet metal fabrication at scale, the lack of expensive tooling makes CNC machining more cost-effective for runs of 1 to 1,000 units, particularly in the prototyping stage.

Sheet Metal Fabrication Cost Benefits

Sheet metal fabrication is a leaner, faster, and often more affordable method for producing simple to moderately complex parts. Its pricing model is driven by material efficiency, speed of setup, and limited finishing requirements.

Part Sizes

Larger, flatter parts such as brackets, panels, and enclosures are typically more economical when fabricated from sheet metal. Since these components are cut and bent from standard sheet stock, material usage is optimized, which significantly lowers waste and material costs.

Design Complexity

For designs that can be manufactured with basic bends, cuts, or holes, sheet metal fabrication is substantially cheaper. The lack of multi-axis operations or complex fixture setups keeps labor and machine time to a minimum.

Throughput

Sheet metal fabrication excels at high-volume production. Once a design is finalized and tooling is created (if needed), parts can be rapidly produced in large quantities at low per-unit cost. This makes it ideal for mass production and repetitive part orders.

Material Specifications

Sheet metal parts are typically made from standard gauges of aluminum, stainless steel, or galvanized steel. These are readily available and easy to process, making them less expensive and easier to source. The cost savings here can be significant compared to exotic or custom billet materials used in CNC machining.

Here is a clear and professional comparison table summarizing the key cost differences between CNC Machining and Sheet Metal Fabrication:

Table: CNC Machining vs. Sheet Metal Fabrication – Key Cost Differences

| Cost Factor |

CNC Machining |

Sheet Metal Fabrication |

| Design Complexity |

High complexity increases cost due to longer programming and tool paths. | Cost-effective for simple designs; complex geometries may not be feasible. |

| Precision Requirements |

Delivers tight tolerances (±0.001 in), ideal for high-performance applications. | Limited to moderate tolerances, not suitable for ultra-precise components. |

| Material Waste |

More waste due to subtractive process, increasing material cost. | Minimal waste; parts are nested in flat sheets for optimal usage. |

| Functional Prototypes |

Ideal for parts using production-grade metals and plastics. | Functional prototypes possible, but mostly for simple structural parts. |

| Part Size |

Suitable for small to medium parts with fine detail. | More cost-efficient for larger, flat parts like panels or brackets. |

| Tooling Costs |

No need for custom tooling; lower upfront costs for short runs. | May require custom dies or fixtures, increasing setup cost for prototypes. |

| Throughput |

Cost-effective for low-to-mid volume production. | Highly efficient for mass production; lower cost per unit at high volumes. |

| Setup Time |

Longer setup due to CAD/CAM programming and fixturing. | Faster setup for standard parts; bending and cutting are streamlined. |

| Surface Finish |

Superior finishes achievable, often eliminating the need for post-processing. | Basic finishes standard; additional finishing steps add to cost. |

| Material Cost |

Typically higher due to billet material use and waste. | Lower cost using standard sheet metal sizes and thicknesses. |

| Automation Potential |

Highly automated but increases equipment and programming cost. | Semi-automated processes available at lower cost. |

Table: Precision Comparison – CNC Machining vs. Sheet Metal Fabrication

| Precision Factor |

CNC Machining |

Sheet Metal Fabrication |

| Tolerances |

Extremely tight tolerances (±0.001 in or better), ideal for critical components. | Moderate tolerances (±0.005 to ±0.030 in), suitable for structural applications. |

| Complex Geometries |

Excellent for producing intricate, detailed shapes with 3D complexity. | Limited to simpler geometries due to bending, cutting, and forming constraints. |

| Internal Features |

Capable of machining precise internal threads, cavities, and holes. | Challenging to produce complex internal features; additional processes needed. |

| Dimensional Stability |

High consistency and repeatability across parts in tight specs. | Good for flat and formed shapes but may suffer distortion under certain loads. |

| Surface Finishing |

Offers smooth finishes as low as Ra 0.8 µm; post-processing further improves it. | Basic finish from cutting/forming; post-finishing like coating or polishing needed. |

This table helps readers understand where CNC machining excels in precision manufacturing, especially for parts with tight tolerance and complex features, and where sheet metal fabrication is better suited for structural or larger-scale components.

CNC machining, short for Computer Numerical Control machining, is a subtractive manufacturing process that uses pre-programmed software to control machinery. These machines include lathes, mills, routers, grinders, and other tools that cut and shape material into precise components. Unlike manual operations, CNC machining offers unmatched consistency, repeatability, and precision—even for complex geometries and high-tolerance parts.

The process starts with a digital 3D CAD model, which is converted into a set of machine instructions (G-code). These instructions tell the CNC machine exactly how to move, how fast to cut, and what path to follow. This level of automation not only reduces human error but also increases production efficiency.

CNC machining is widely used to produce metal and plastic parts across industries like aerospace, automotive, medical, robotics, and consumer electronics. It supports both prototyping and high-volume production, making it a highly versatile and scalable manufacturing solution. Common materials used in CNC machining include aluminum, stainless steel, brass, titanium, and a wide range of engineering plastics.

With the ability to deliver tight tolerances, exceptional surface finishes, and complex part geometries, CNC machining is often the go-to choice when precision and performance are non-negotiable. If you're interested in seeing how CNC machining compares to other manufacturing methods, check out our CNC Machining vs. Sheet Metal Fabrication guide.

CNC machining encompasses a wide variety of operations, each tailored to specific part features, geometries, and performance requirements. By using different machining methods—milling, turning, drilling, grinding, and more—CNC machining services can deliver everything from simple holes to complex multi-axis contours with superior accuracy and surface quality.

Understanding the strengths of each CNC operation is key to choosing the right manufacturing strategy, minimizing cost, and achieving optimal part functionality. Below is a breakdown of the most common types of CNC machining operations used by professional CNC machining factories and manufacturers worldwide.

CNC Milling

CNC milling is one of the most versatile and widely used machining operations. It involves rotating multi-point cutting tools that remove material from a workpiece as it is clamped onto a fixed bed or table. The cutter moves along multiple axes (commonly 3-axis or 4-axis), enabling precise removal of material to form slots, pockets, contours, and flat surfaces.

Applications:

CNC milling excels in producing highly detailed features and tight tolerances, especially when combined with CAD/CAM software. VMT’s CNC machining services offer both vertical and horizontal milling to accommodate a wide range of project needs.

CNC turning (or lathe machining) is used to produce round or cylindrical parts. In this process, the workpiece rotates at high speed while a stationary cutting tool removes material to form symmetrical shapes such as shafts, bushings, and threaded parts.

Applications:

Turning is faster and often more cost-effective than milling for round components. Many CNC machining factories use it for high-volume runs due to its speed and efficiency.

Drilling is used to create round holes in a part using a rotating drill bit. In CNC machining, drilling operations are often integrated with milling or turning for a complete part solution.

Applications:

Threading, tapping, reaming, and countersinking can be integrated into the drilling cycle, streamlining production for parts that require multiple hole types or diameters.

Grinding

CNC grinding is a finishing process used to achieve extremely tight tolerances and smooth surface finishes. A rotating abrasive wheel is used to remove very fine layers of material from a part’s surface.

Applications:

While slower than other methods, CNC grinding is ideal for applications where dimensional accuracy and surface quality are critical.

5-axis machining allows the cutting tool to move along five different axes simultaneously. This enables extremely complex and precise parts to be machined in a single setup, reducing handling and improving consistency.

Applications:

At VMT, 5-axis CNC machining services are used for advanced projects that require flawless surface transition and tight tolerance across multiple features.

Swiss CNC machining, also known as Swiss-type turning, is ideal for producing small, high-precision cylindrical parts. In this method, the bar stock moves while the tools remain stationary—unlike traditional lathes.

Applications:

Swiss machining offers exceptional part quality for industries that demand microscopic precision, such as medical, electronics, and aerospace.

Mill-Turning

Mill-turn machines combine milling and turning capabilities in one system. This hybrid setup allows a single machine to perform complex operations on a single part without transferring between machines.

Applications:

Mill-turn centers are particularly valuable for complex parts that require a mix of round and angular features, such as turbine shafts or pump bodies.

CNC machining has become the cornerstone of modern precision manufacturing. From high-performance aerospace components to functional prototypes for consumer electronics, CNC machining delivers unmatched versatility, consistency, and speed. However, like any manufacturing process, it has its limitations. By understanding both the advantages and disadvantages, you can make an informed decision on whether CNC machining is the best solution for your specific project.

This section provides a clear comparison of the benefits and trade-offs of CNC machining, helping engineers, buyers, and designers evaluate its fit for their part requirements.

Advantages of CNC Machining

CNC machining offers numerous benefits that make it a preferred choice in various industries. Its key advantages include:

1. High Precision and Tight Tolerances

CNC machines are capable of producing parts with tolerances as tight as ±0.001 inches or better. This makes them ideal for industries like aerospace, medical, and defense where accuracy is non-negotiable.

2. Excellent Repeatability

Because the process is fully automated, once a part is programmed, it can be produced repeatedly with minimal variation. This ensures consistency across large production runs.

3. Compatibility with a Wide Range of Materials

CNC machining supports an extensive list of materials, including aluminum, stainless steel, titanium, brass, copper, and various engineering plastics. This versatility makes it easy to match the material to functional requirements.

4. Fast Turnaround for Prototyping and Low-Volume Production

Without the need for tooling, CNC machining can deliver high-quality prototypes and small-batch production parts in days rather than weeks.

5. Complex Geometry Capabilities

With multi-axis CNC machining (including 5-axis), complex features, undercuts, and intricate contours can be produced in a single setup.

6. Superior Surface Finishes

CNC-machined parts often come off the machine with excellent surface quality, minimizing or eliminating the need for secondary finishing processes.

7. Reduced Human Error

The automation of CNC machining reduces the risk of operator errors, improving part reliability and minimizing waste.

Disadvantages of CNC Machining

While CNC machining offers substantial benefits, it’s important to understand its limitations, especially when considering alternative processes like sheet metal fabrication.

1. Higher Costs for High Volumes

Compared to stamping or casting, CNC machining can be less cost-effective for very high-volume production due to longer machining times and tool wear.

2. Material Waste

CNC machining is a subtractive process, which means excess material is cut away. This can result in higher raw material costs, particularly with expensive metals.

3. Limited by Machine Size

While large-format CNC machines exist, the majority are limited to parts under a specific size envelope. For oversized components, additional processes or equipment may be needed.

4. Complex Programming Requirements

Complex parts require detailed CAD modeling and CAM programming, which can increase lead time and engineering costs during the design phase.

5. Initial Setup Time

Although tooling is not required, fixturing and machine setup still take time. For a one-off part, this may not be as efficient as other rapid prototyping methods.

6. Surface Limitations for Deep Cavities

In very deep or narrow cavities, CNC tools may have difficulty reaching without special tooling, potentially compromising accuracy or surface finish.

CNC machining remains one of the most powerful and flexible manufacturing methods available today. However, if your design involves flat parts, thin sheet profiles, or requires mass production at a lower cost, you may want to explore alternatives like Sheet Metal Fabrication.

Here’s a clear, professional comparison table summarizing the Advantages and Disadvantages of CNC Machining. This is ideal for quickly guiding customers through the decision-making process:

CNC Machining: Advantages vs. Disadvantages

| CNC Machining Advantages |

Description |

| High Precision & Tight Tolerances |

Up to ±0.001 inch for complex parts. |

| Excellent Repeatability |

Consistent quality across multiple production runs. |

| Supports a Wide Range of Materials |

Metals and engineering plastics. |

| Fast for Prototypes & Low-Volume Production |

No molds or tooling required. |

| Produces Complex Geometries |

Multi-axis machining enables intricate shapes. |

| Superior Surface Finishes |

Often eliminates the need for secondary processing. |

| CNC Machining Disadvantages | Description |

| Higher Cost for Large Volumes |

Less economical compared to casting/stamping. |

| Material Waste |

Subtractive process increases scrap, especially for expensive metals. |

| Limited Part Size |

Machine envelopes restrict size of workpieces. |

| Complex Programming |

Intricate parts require expert CAD/CAM skills. |

| Initial Setup Time |

Fixtures and tool paths require setup before production. |

| Tool Access Limitations |

Deep or narrow features may be harder to reach. |

| Automation Reduces Human Error |

Minimizes defects and ensures consistency. |

CNC machining is a core manufacturing process across multiple industries that demand precision, performance, and reliability. From mission-critical aerospace components to small, intricate optical housings, CNC machining delivers high-quality parts with exceptional accuracy and repeatability. Thanks to its compatibility with a wide range of materials and ability to handle complex geometries, CNC machining services are an ideal solution for both prototyping and mass production. Below is a detailed look at how CNC machining is used in various industries—and the specific types of CNC machining parts commonly produced in each.

Aerospace

The aerospace industry requires parts with the tightest tolerances, excellent strength-to-weight ratios, and resistance to extreme environmental conditions. CNC machining is extensively used to manufacture structural components, engine parts, brackets, turbine blades, and housings.

Common CNC Machined Parts in Aerospace:

Precision and safety are paramount in aerospace, making CNC machining factories the go-to choice for mission-critical parts.

In medical manufacturing, the demand for biocompatibility, sterilization resistance, and micro-precision is exceptionally high. CNC machining provides the level of accuracy required for surgical instruments, implantable devices, and diagnostic equipment.

Common CNC Machined Parts in Medical:

Thanks to its repeatability and traceability, CNC machining plays a crucial role in meeting stringent medical regulations.

CNC machining is widely used in the automotive sector for both performance and consumer vehicles. It supports fast prototyping, short-run production, and end-use part manufacturing with high accuracy and reliability.

Common CNC Machined Parts in Automotive:

With fast lead times and flexible production, CNC machining services help automotive manufacturers accelerate innovation and time to market.

Defense and Military

The defense industry demands robust, durable, and precise components that can operate in harsh environments. CNC machining meets these demands through its ability to work with advanced materials and deliver consistent results at scale.

Common CNC Machined Parts in Defense:

CNC machining factories serving the defense sector are often certified to meet military standards and specifications.

Robotics relies on lightweight, strong, and geometrically complex parts that allow for movement and modular integration. CNC machining enables precision-fit components required for automation and robotic systems.

Common CNC Machined Parts in Robotics:

Because robotic systems demand high dimensional accuracy, CNC machining is critical in ensuring proper function and integration.

In electronics, CNC machining is used to create high-tolerance enclosures, connectors, and thermal management parts such as heatsinks. The process supports both metal and plastic parts with tight internal features and surface finish requirements.

Common CNC Machined Parts in Electronics:

Precision and clean surface finishes are vital for electronic component protection and functionality.

General industrial applications require rugged, functional components built for longevity and performance. CNC machining helps produce parts used in heavy machinery, automation systems, and processing equipment.

Common CNC Machined Parts in Industrial Applications:

These parts often require strong materials like stainless steel or brass, which CNC machining handles with ease.

Precision optical components must be manufactured to tight tolerances to ensure perfect alignment and light transmission. CNC machining enables the fabrication of optical instrument housings and lens mounts with high dimensional accuracy.

Common CNC Machined Parts in Optical Industry:

High surface finish quality and material stability are key, and CNC machining delivers both for optical-grade components.

Below is a professional and easy-to-read table summarizing CNC Machining Applications and Typical Parts by Industry:

CNC Machining Applications & Parts by Industry

| Industry |

Common Applications |

Typical CNC Machined Parts |

| Aerospace |

High-performance, lightweight, and safety-critical components | Turbine blades, engine mounts, actuator housings, landing gear parts, control panels |

| Medical Devices |

Biocompatible, precise, and sterilization-resistant components | Surgical instruments, orthopedic implants, dental devices, MRI-compatible parts |

| Automotive |

Prototypes, performance components, and structural parts | Pistons, cylinder heads, gearbox housings, brake calipers, dashboard supports |

| Defense & Military |

Durable, high-tolerance components for extreme environments | Weapon components, drone parts, missile housings, night vision mounts, vehicle armor brackets |

| Robotics |

Precision-fit parts for motion, integration, and lightweight assembly | Robotic arms, joint housings, end effectors, chassis frames, brackets |

| Electronics |

Precision enclosures and parts with tight tolerances and superior surface finishes | Device housings, heat sinks, PCB enclosures, connector blocks, thermal management parts |

| Industrial |

Rugged, functional parts for machinery, automation, and production systems | Shafts, gears, bushings, valve bodies, hydraulic and pneumatic fittings |

| Optical |

Alignment-sensitive and finely finished components for vision and imaging systems | Lens mounts, optical housings, filter holders, microscope components, camera brackets |

Sheet metal fabrication is a manufacturing process that involves cutting, forming, and assembling flat sheet metal into finished parts or structures. These processes are typically performed using CNC-controlled equipment, including laser cutters, press brakes, stamping presses, turret punches, and welding stations.

This method is particularly well-suited for producing lightweight, durable, and cost-effective parts, especially those with uniform wall thicknesses. Sheet metal fabrication excels in creating components such as metal enclosures, panels, brackets, and frames, which are widely used across various industries due to their strength, aesthetic finish, and easy integration into assemblies.

One of the key benefits of sheet metal fabrication is its scalability. From a single prototype to high-volume production, it offers rapid turnaround and cost efficiency. The process is also compatible with a wide range of metals, including aluminum, stainless steel, carbon steel, copper, and brass, allowing for tailored solutions depending on strength, corrosion resistance, conductivity, and weight requirements.

Moreover, sheet metal fabrication provides design flexibility. Engineers can create custom parts with complex cutouts, precision bends, and tight tolerances using CNC-controlled machinery. With the right finishing processes—such as powder coating, painting, or anodizing—parts not only meet functional requirements but also achieve a professional, polished appearance.

Sheet metal processing is especially advantageous in industries that prioritize speed, cost, and reliability. For example:

Ultimately, whether you're launching a new product, improving an existing one, or optimizing your supply chain, sheet metal fabrication offers a fast, repeatable, and economically viable solution for high-quality metal components.

Sheet metal fabrication involves a combination of processes that convert flat sheet metal into functional parts and structures. These processes are divided into three core categories: cutting, forming, and joining—each playing a critical role in transforming raw material into a finished product. The process begins with cutting, which defines the basic shape of the part and determines the efficiency and precision of subsequent operations.

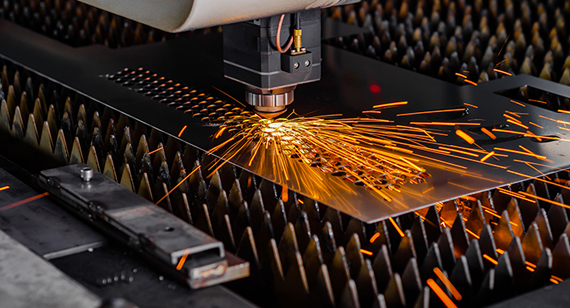

Cutting is often the first and most crucial step in sheet metal processing. The method you choose impacts not only dimensional accuracy and edge quality, but also cost and production time. With advancements in CNC technology, modern cutting techniques deliver exceptional precision, speed, and repeatability across both prototype and production volumes.

Let’s explore the different cutting processes used in sheet metal fabrication.

Cutting

Cutting is the process of separating material along a specified geometry to create a defined shape or outline. In sheet metal fabrication, cutting methods vary based on material type, thickness, tolerance requirements, and production volume. Cutting can be performed with thermal, mechanical, or water-based tools, each offering distinct advantages.

In modern CNC sheet metal fabrication, high-performance cutting machines are programmed to execute complex patterns with incredible precision. Whether you're producing small brackets or large structural panels, selecting the right cutting method ensures clean edges, minimal waste, and efficient throughput.

Types of Cutting

The cutting processes in sheet metal fabrication can be broadly categorized into:

Each method has its own strengths depending on the material, part complexity, and production needs.

Waterjet Cutting

Waterjet cutting uses a high-pressure stream of water, often mixed with abrasive particles, to cut through sheet metal. It's a cold-cutting process, meaning no heat is involved—making it ideal for materials that could warp or lose structural integrity from heat.

Key Advantages:

Best Use Cases: Stainless steel, titanium, copper, and heat-sensitive materials in aerospace, medical, and electronics industries.

Laser cutting uses a focused laser beam to melt, burn, or vaporize material, creating clean and precise cuts. It's one of the most widely used methods in CNC sheet metal fabrication due to its speed and precision.

Key Advantages:

Best Use Cases: Enclosures, decorative panels, intricate brackets, and components requiring tight tolerances.

Plasma Cutting

Plasma cutting works by creating an ionized gas (plasma) arc to melt and cut conductive metals. It’s faster than oxy-fuel torches and more affordable than laser cutting for thick metals.

Key Advantages:

Best Use Cases: Industrial parts, automotive frames, structural steel components, and heavy-duty fabrication projects.

Torches (Oxy-Fuel Cutting)

Oxy-fuel cutting uses a mixture of oxygen and fuel gas to ignite and cut through metals. While it's an older method, it's still used for cutting very thick carbon steels.

Key Advantages:

Best Use Cases: Structural steel cutting, field repairs, and low-precision, high-strength applications.

Mechanical Cutters

Mechanical cutting involves tools like shears, saws, turret punches, and notching machines to physically separate metal. It’s a highly efficient method for high-volume, standardized parts.

Key Advantages:

Best Use Cases: Flat panel cutting, brackets, and components with punched holes or slots.

Forming in Sheet Metal Fabrication

Once the sheet metal has been cut into the desired shape, the next step is forming—a mechanical process that reshapes the flat sheet without removing material. Forming operations are essential in CNC sheet metal fabrication, allowing manufacturers to bend, curve, or stretch the metal into a three-dimensional part that meets the required functionality and aesthetics.

Forming transforms flat patterns into functional products like enclosures, chassis, brackets, housings, and structural components. This process is typically done using CNC-controlled press brakes, rolling machines, dies, and other precision forming equipment to ensure consistency, repeatability, and dimensional accuracy.

The key to successful sheet metal forming lies in balancing material characteristics (such as ductility and thickness) with the desired shape and function of the final part. Now, let's explore the most common types of forming operations used in metal fabrication.

Types of Forming Operations

Bending

Bending is one of the most common and versatile forming processes. It involves deforming the sheet metal along a straight axis, typically using a press brake. By applying pressure with a punch and die, metal sheets are bent into angles—such as U-shapes, V-shapes, or custom profiles.

Advantages:

Applications: Electrical boxes, brackets, control panels, metal cabinets

Stretching

Stretching reshapes the metal by pulling it outward to thin and extend the surface. This process allows for smooth, curved surfaces that cannot be achieved through simple bending.

Advantages:

Applications: Aerospace panels, automotive body parts, architectural elements

Stamping uses a die and press to form sheet metal into specific shapes. It’s often a high-speed, high-volume process and includes sub-processes like embossing, coining, and flanging.

Advantages:

Applications: Automotive panels, heat shields, electronic component covers

Punching

Punching involves striking the sheet metal with a punch through a die to create holes, slots, or cutouts. CNC turret punches automate this process for precision and speed.

Advantages:

Applications: Vents, mounting holes, perforated panels, control interfaces

Spinning

Spinning (or metal spinning) involves rotating a metal disc on a lathe while applying pressure to form symmetrical shapes. This technique is often used for cylindrical or conical components.

Advantages:

Applications: Light fixtures, cookware, satellite dishes, aerospace cones

Rolling

Rolling gradually bends flat sheet metal into curved forms or cylinders using rolling machines. It’s ideal for long, smooth curves and large-scale parts.

Advantages:

Applications: Pipes, tanks, ducts, architectural panels

Each forming technique offers unique advantages, and the right method depends on the part’s design, application, and material. Combining multiple forming processes is common in complex sheet metal processing projects to achieve precise, functional, and attractive results.

Welding in Sheet Metal Fabrication

Once sheet metal parts have been cut and formed, the next critical step in the fabrication process is joining—combining two or more components into a single, cohesive assembly. Joining methods in sheet metal fabrication vary widely depending on the part design, strength requirements, material type, cost, and intended application.

From lightweight enclosures to heavy-duty structural frames, selecting the right joining technique ensures mechanical integrity, electrical performance, visual appeal, and long-term durability. Modern CNC machining factories utilize a combination of thermal, mechanical, and chemical joining methods, many of which are automated for speed and consistency.

Understanding the different types of joining operations empowers engineers and product developers to choose the optimal process for prototyping, short runs, or full-scale production.

Welding Sheet Metal

Welding is a permanent joining method where metals are fused together using heat (and sometimes filler material). It’s the most common joining method in sheet metal processing, especially for structural or load-bearing parts.

Common Welding Techniques:

Advantages:

Applications: Automotive frames, industrial enclosures, structural brackets, metal cabinetry

Brazing

Brazing involves heating a filler metal above its melting point (but below the base metal's) and flowing it into the joint by capillary action. It’s suitable for joining dissimilar metals and thin materials.

Advantages:

Applications: HVAC components, electrical enclosures, decorative assemblies, copper/brass fittings

Fasteners

Fasteners such as screws, bolts, rivets, and clinching systems are mechanical joining methods used to connect sheet metal parts, often allowing for disassembly and maintenance.

Advantages:

Applications: Consumer electronics housings, panels, sheet metal boxes, modular frames

Adhesive Bonding

Adhesive bonding uses industrial-grade glues or sealants to join metal parts. This method is especially useful when combining dissimilar materials or when aesthetics are important (no visible fasteners or weld marks).

Advantages:

Applications: Automotive trim, aerospace panels, electronics casings, appliance housings

Choosing the right joining method depends on factors like load-bearing needs, environmental exposure, production volume, cost, and appearance. In many CNC machining and sheet metal fabrication projects, a combination of joining techniques is used to balance performance, design, and manufacturability.

After cutting, forming, and joining, the final—but no less critical—stage in sheet metal fabrication is surface treatment or finishing. This step enhances the appearance, improves durability, protects against corrosion, and increases the functionality of the finished part. Whether the goal is to achieve a specific aesthetic effect, improve wear resistance, or meet stringent industry standards (like in aerospace or medical devices), finishing processes are an essential component of high-quality sheet metal processing.

Depending on the base material and end-use application, different surface treatments can be selected. CNC machining factories and metal fabrication services typically offer a wide range of surface finishing options to meet customer-specific requirements and ensure the CNC machining parts or sheet metal products are production-ready.

Below, we’ll explore the most commonly used finishing methods in sheet metal fabrication.

Painting

Painting is one of the most versatile and cost-effective finishing techniques for sheet metal components. It involves applying liquid paint to the surface via spraying, brushing, or dipping, followed by drying or curing.

Advantages:

Applications: Consumer electronics, appliances, signage, industrial equipment

Powder Coating

Powder coating is an advanced dry finishing process where electrostatically charged powder is sprayed onto the metal surface and cured under heat to form a hard, durable skin. It provides a superior finish compared to traditional paint and is widely used in both functional and decorative applications.

Advantages:

Applications: Automotive parts, furniture, control panels, outdoor enclosures

Anodizing

Anodizing is an electrochemical process used primarily on aluminum parts to thicken the natural oxide layer. It enhances corrosion resistance, allows for color dyeing, and improves surface hardness.

Advantages:

Applications: Aerospace components, medical devices, precision electronics housings, architectural metalwork

Other Surface Finishes

Depending on the project's requirements, additional or specialized surface treatments may be applied to further protect or enhance metal parts:

Electroplating

Adds a layer of metal (such as zinc, chrome, or nickel) for appearance, conductivity, or corrosion protection.

Sandblasting or Bead Blasting

Cleans and textures the metal surface, often used before painting or powder coating.

Passivation

A chemical treatment that improves corrosion resistance in stainless steel by removing free iron from the surface.

Brushing or Polishing

Enhances appearance with linear finishes or mirror-like smoothness, often used for decorative applications.

Chemical Conversion Coatings (e.g., Chromate)

Used for corrosion protection and paint adhesion, especially for aluminum and zinc-coated parts.

In CNC machining and sheet metal fabrication, the right surface treatment not only enhances product performance but also ensures your parts meet industry standards, branding requirements, and user expectations. Selecting the correct finish early in the design phase can significantly impact cost, lead time, and final part quality.

Sheet metal fabrication is a core manufacturing process used to transform flat metal sheets into functional parts and structures through cutting, bending, forming, and joining. Whether it's for low-volume prototypes or mass production, sheet metal fabrication offers a balance of flexibility, strength, and cost-effectiveness. For industries such as automotive, electronics, medical, aerospace, and industrial equipment, it remains a go-to solution for producing enclosures, brackets, panels, and housings.

However, like any fabrication method, sheet metal processing comes with its own set of pros and cons. Understanding these helps engineers, product developers, and buyers make informed decisions when choosing between sheet metal fabrication vs. CNC machining or other metal fabrication methods.

Advantages of Sheet Metal Fabrication

1. Cost-Effective for Medium to High Volumes

Sheet metal fabrication is highly efficient, especially when using automated laser cutting, CNC turret punching, and press brake forming. This makes it ideal for producing hundreds or thousands of parts at a relatively low cost per unit. Tooling and setup costs are spread across the volume, making it more economical at scale.

2. Lightweight Yet Strong Structures

Sheet metal parts are often lighter than machined components while still providing sufficient strength and durability. This makes them suitable for applications where weight reduction is crucial, such as in aerospace, automotive, and consumer electronics.

3. High Flexibility in Design

Fabrication processes support a wide range of geometries, hole patterns, bends, and cutouts. Designers have the freedom to modify or scale part designs easily without expensive retooling, which supports faster iteration during prototyping and production.

4. Fast Turnaround Time

With the help of CNC sheet metal equipment and streamlined digital workflows, parts can move from design to finished product quickly. Sheet metal factories equipped with modern automation can offer rapid production, making it a preferred choice for time-sensitive projects.

5. Wide Material Compatibility

Sheet metal fabrication works with a variety of metals including aluminum, stainless steel, carbon steel, copper, and brass. This gives engineers the flexibility to select the material that best meets the functional, aesthetic, and environmental needs of the product.

Disadvantages of Sheet Metal Fabrication

1. Limited to Relatively Simple 3D Forms

While sheet metal can be bent and shaped, it's inherently flat in its raw form. Creating complex or deep 3D geometries is challenging and may require additional joining or secondary machining, which increases cost and time.

2. Less Suitable for Tight Tolerances

Compared to CNC machining, sheet metal fabrication typically offers lower precision and tighter tolerances, especially for small or high-precision components. For parts requiring ±0.01 mm accuracy, CNC machining is the better choice.

3. Material Thickness Constraints

Sheet metal fabrication is optimized for thin to moderately thick materials (typically 0.5mm to 6mm). Thicker parts can be formed but may require heavy-duty machinery or multiple steps, which can be less efficient and more expensive.

4. Surface Finish Limitations

Depending on the process and material, sheet metal parts may show tool marks, scratches, or burrs. Additional surface finishing processes like powder coating, painting, or polishing are often necessary to meet appearance or corrosion resistance requirements.

5. Setup and Tooling Costs for Custom Jobs

For complex or custom designs, specialized tooling or die sets may be required—especially in stamping or forming operations. This adds to the initial setup cost, making it less ideal for low-volume or one-off projects without a long production run.

In summary, sheet metal fabrication offers excellent scalability, speed, and material versatility, making it ideal for many industrial and commercial applications. However, when high complexity, ultra-tight tolerances, or intricate geometries are needed, CNC machining services may provide a better alternative. By weighing the advantages and disadvantages, product developers can select the right process to optimize cost, quality, and lead time.

Here's a clear and professional comparison table summarizing the advantages and disadvantages of sheet metal fabrication:

Sheet Metal Fabrication: Advantages vs. Disadvantages

| Advantages | Description |

| Cost-effective for medium to high volumes |

Economical for large production runs due to low per-unit cost |

| Lightweight yet structurally strong |

Ideal for aerospace, automotive, and electronics applications |

| Flexible in design and modification |

Easy to change designs or scale production with minimal retooling |

| Fast turnaround with automated equipment |

Quick lead times with CNC sheet metal machinery |

| Wide material compatibility (aluminum, steel, copper, etc.) |

Offers options to match functional, aesthetic, and corrosion resistance needs |

| Disadvantages |

Description |

| Limited to simpler 3D geometries |

Cannot easily produce deep or highly complex 3D parts without additional steps |

| Less suitable for tight tolerances |

Typically not as precise as CNC machining for fine-feature components |

| Material thickness limitations |

Optimal for thin to medium sheets (0.5mm–6mm); thicker parts can be inefficient |

| May require secondary surface finishing |

May need painting, powder coating, or polishing to improve appearance/protection |

| Setup/tooling costs for custom or complex designs |

Stamping and forming operations may require custom tooling |

Sheet metal fabrication plays a critical role in a wide range of industries due to its versatility, strength-to-weight ratio, and cost-efficiency. This manufacturing process transforms flat metal sheets into customized components through precise cutting, bending, and assembling. Whether you need structural supports, electronic enclosures, or lightweight brackets, sheet metal fabrication offers scalable and reliable solutions.

Industries choose sheet metal processing because it supports both rapid prototyping and mass production, using a wide range of metals such as aluminum, stainless steel, copper, and carbon steel. With CNC machining services and sheet metal fabrication often working together, manufacturers can produce highly functional, aesthetically pleasing, and durable parts for everything from consumer electronics to aerospace applications.

Let’s explore the industries and parts that most frequently rely on sheet metal fabrication.

Applications of Sheet Metal Fabrication

| Industry |

How Sheet Metal Is Used |

| Automotive |

Body panels, battery enclosures, brackets, engine mounts, interior components |

| Aerospace |

Lightweight structural frames, aircraft panels, control boxes, and ducts |

| Consumer Electronics |

Device housings, heat sinks, mounting plates, metal frames for phones and laptops |

| Industrial Equipment |

Control cabinets, machine housings, safety guards, tool trays |

| Medical Devices |

Equipment casings, bracketry, surgical tool trays, electronic panels |

| Telecommunications |

Signal enclosures, server racks, shielding components |

| Defense & Military |

Tactical enclosures, armored panels, communication device casings |

| Construction |

HVAC systems, ductwork, roofing panels, custom brackets |

| Renewable Energy |

Solar panel mounts, wind turbine housings, power storage enclosures |

| Retail & Display |

Store fixtures, signage frames, point-of-sale systems, kiosk housings |

Common Sheet Metal Fabricated Parts

| Part Type |

Function/Use Case |

| Enclosures & Boxes |

Protect electronic or electrical components; often found in telecom and medical fields |

| Brackets & Mounts |

Support other components structurally or functionally in machines and assemblies |

| Chassis & Frames |

Base structural elements for various types of equipment |

| Panels & Covers |

Aesthetic and functional protection for electronics, HVAC units, and machinery |

| Ductwork & Vents |

Manage airflow in HVAC, industrial, or commercial building systems |

| Shelves & Racks |

Used for data centers, retail stores, or heavy-duty industrial environments |

| Custom Sheet Components |

Tailored parts for unique devices or systems, often produced in low to mid volumes |

Why Choose Sheet Metal Fabrication?

For applications requiring complex shapes or tighter tolerances, many companies integrate CNC machining services alongside sheet metal fabrication to deliver complete, high-precision assemblies.

Material selection is a critical factor that determines the success of any manufacturing process—whether you are using CNC machining or sheet metal fabrication. Each method supports a wide variety of materials with unique mechanical, thermal, and aesthetic properties. Understanding the material options available for CNC machining and sheet metal processing helps engineers, designers, and procurement teams choose the right material based on performance, cost, and application requirements.

Let’s explore what materials are most commonly used in each process, and how their properties impact part functionality and fabrication efficiency.

CNC Machining Materials

CNC machining is highly versatile and capable of working with a broad range of materials—including metals, plastics, and composites. Thanks to its subtractive nature and precision control, CNC machining is ideal for producing tight-tolerance components, even from hard or brittle materials.

What Metals Can Be Machined?

| Metal |

Key Characteristics |

Common Applications |

| Aluminum |

Lightweight, corrosion-resistant, excellent machinability | Aerospace parts, housings, fixtures |

| Stainless Steel |

Strong, corrosion-resistant, aesthetic surface finish options | Medical, food-grade equipment, mechanical parts |

| Carbon Steel |

High strength and durability, cost-effective | Automotive, structural, and general industrial components |

| Brass |

Easy to machine, corrosion-resistant, attractive finish | Valves, connectors, decorative parts |

| Copper |

Excellent thermal/electrical conductivity | Heat exchangers, electrical contacts |

| Titanium |

Extremely strong, corrosion-resistant, biocompatible | Aerospace, medical implants, high-performance parts |

| Magnesium Alloys |

Lightweight, good strength-to-weight ratio | Automotive, aerospace components |

What Plastics Can Be Machined?

| Plastic |

Key Characteristics |

Common Applications |

| ABS |

Tough, impact-resistant, easy to machine | Prototypes, housings, consumer goods |

| Delrin (POM) |

High strength, low friction, wear-resistant | Gears, bushings, automotive parts |

| Nylon |

Tough, flexible, abrasion-resistant | Bearings, fasteners, industrial machinery parts |

| PEEK |

High-performance plastic, heat-resistant, chemical-resistant | Medical, aerospace, and electronic components |

| PTFE (Teflon) |

Low friction, non-stick, high chemical resistance | Seals, gaskets, electrical insulators |

| Polycarbonate |

High impact strength, good transparency | Optical parts, safety enclosures |

| HDPE |

Lightweight, chemical-resistant, low cost | Fluid systems, containers, industrial tanks |

CNC machining services are ideal for working with engineering plastics where complex geometries, internal channels, or high thermal/chemical resistance are required.

Sheet Metal Fabrication Materials

Sheet metal fabrication generally works with metal materials that are available in flat sheets, rolled coils, or pre-cut blanks. The selection of materials depends on the required strength, ductility, corrosion resistance, and aesthetic appeal. The process typically supports metals that are easy to bend, cut, and form without cracking or significant springback.

Here are the most commonly used materials in sheet metal processing:

Stainless Steel

Carbon Steel

Copper

Brass

Choosing the Right Material for Your Application

When selecting between CNC machining and sheet metal fabrication, material compatibility is just one of the factors to consider. While CNC machining allows for high-precision machining of harder materials and complex shapes, sheet metal fabrication excels in scalability and efficiency for 2D to moderately 3D parts.

If your part needs tight tolerances, internal features, or complex designs, CNC machining parts may be ideal. For enclosures, panels, or structural parts with high throughput needs, sheet metal fabrication could be the smarter choice.

Selecting the optimal manufacturing process is a crucial decision that directly impacts product quality, cost, and delivery time. Both CNC machining and sheet metal fabrication offer distinct advantages tailored to different types of parts and production needs. Understanding when to use each process ensures efficient resource utilization and maximizes the performance of the final product. This guide will help you determine which process aligns best with your project requirements, based on factors like complexity, material, precision, cost, and production volume.

When to Use CNC Machining?

CNC machining is ideal when your project demands complex geometries, high precision, and superior surface finishes. This subtractive process offers unparalleled flexibility in working with a wide range of metals and plastics, making it perfect for custom and low-volume production.

Complex Shapes

CNC machining excels at producing intricate, 3D parts with complex curves, deep cavities, and fine internal features that are difficult or impossible to achieve through sheet metal forming.

Material Types

It supports a broad spectrum of materials—from hard metals like titanium and stainless steel to engineering plastics—allowing manufacturers to tailor material selection to precise functional and environmental requirements.

Precision and Accuracy

When tight tolerances and consistent dimensional accuracy are critical, CNC machining delivers unmatched repeatability and control, ensuring parts meet exact specifications.

Surface Finish

CNC machining typically produces superior surface finishes, reducing or eliminating the need for additional finishing operations.

Low Production Volumes

Due to relatively low setup costs and high flexibility, CNC machining is cost-effective for prototyping, custom parts, and small batch production runs.

When to Use Sheet Metal Fabrication?

Sheet metal fabrication is preferred for applications requiring efficient, cost-effective manufacturing of simpler parts, especially when volume and production speed are key considerations.

Cost

Sheet metal fabrication usually offers lower per-part costs for medium to large production runs, thanks to faster processing and lower material waste for thin sheet components.

Production Speed

Processes like laser cutting, bending, and stamping enable rapid production of parts, making sheet metal fabrication well-suited for quick turnaround projects.

Material Types

This process works best with metals available in sheet form, such as aluminum, stainless steel, carbon steel, copper, and brass, which are easy to cut and form.

Part Size

Sheet metal fabrication is ideal for flat or moderately complex parts such as panels, enclosures, brackets, and structural components that do not require deep 3D machining.

Quantity

Due to economies of scale, sheet metal fabrication becomes more economical as order quantities increase, especially for parts with repetitive shapes and standardized designs.

Summary

| Factors |

CNC Machining |

Sheet Metal Fabrication |

| Complexity |

High (complex 3D parts, fine details) | Moderate (mostly 2D to shallow 3D forms) |

| Material Range |

Wide (metals, plastics, composites) | Limited (sheet metals mainly) |

| Precision & Tolerances |

High precision, tight tolerances | Moderate precision, larger tolerances |

| Surface Finish |

Superior finishes, smooth surfaces | Requires additional finishing for smoothness |

| Production Volume |

Low to medium volumes | Medium to high volumes |

| Cost Efficiency |

Higher setup and per-part cost for large volumes | Cost-effective for medium to high volumes |

| Lead Time |

Longer setup and machining times | Faster production cycles |

Choosing between CNC machining and sheet metal fabrication depends on your specific project needs. For detailed, precision parts or low-volume custom manufacturing, CNC machining is typically the best fit. For larger volumes, cost-sensitive applications, and simpler geometries, sheet metal fabrication often offers the most efficient solution.

In today’s competitive manufacturing landscape, choosing a reliable partner for CNC machining and sheet metal fabrication is essential to ensure high-quality parts, fast delivery, and cost-effective solutions. At VMT, we specialize in offering comprehensive machining services tailored to meet the diverse needs of industries such as aerospace, automotive, medical, electronics, and more. With advanced equipment, expert craftsmanship, and a customer-centric approach, VMT is your trusted CNC machining factory and sheet metal processing partner.

Comprehensive CNC Machining Services

VMT provides precision CNC machining services that cover a wide range of processes including milling, turning, drilling, grinding, and 5-axis machining. Our expertise allows us to work with various metals and plastics, ensuring that your CNC machining parts meet stringent quality and tolerance requirements. Whether you need complex prototypes or small to medium batch production, our flexible capabilities guarantee efficiency and accuracy.

Expert Sheet Metal Fabrication Solutions

Our sheet metal fabrication services combine cutting-edge technology with skilled craftsmanship to deliver parts that meet your exact specifications. We handle everything from cutting and forming to joining and finishing, ensuring consistent quality and rapid turnaround.

Why Choose VMT?

Conclusion

Whether your project demands the precision and versatility of CNC machining or the efficiency and scalability of sheet metal fabrication, VMT stands ready to be your manufacturing partner. Our full suite of machining services ensures you receive superior quality, timely delivery, and competitive pricing—helping you bring your designs to life with confidence.

Explore more about our capabilities and discover how VMT can support your next project with expert CNC machining parts and sheet metal processing solutions.

Choosing between CNC machining and sheet metal fabrication is a decision that profoundly influences the success, cost-efficiency, and quality of your manufacturing project. Both processes offer unique strengths: CNC machining excels in producing complex, precision parts with tight tolerances and superior surface finishes, while sheet metal fabrication shines in delivering cost-effective, high-volume, and structurally reliable components.

By carefully considering factors such as part complexity, material selection, production volume, precision requirements, and budget constraints, you can select the process that best aligns with your specific application. Whether you need intricate prototypes or large-scale manufacturing of enclosures and structural parts, understanding the key differences and advantages of each method will empower you to make informed choices that optimize your production outcomes.

At VMT, we combine advanced technology, skilled craftsmanship, and a customer-centered approach to provide comprehensive CNC machining services and sheet metal processing solutions. Our expertise ensures your parts meet the highest standards of quality, precision, and delivery timelines—helping you stay competitive in today’s fast-paced market.

Explore our full range of services to leverage the best of both worlds and take your manufacturing projects to the next level with confidence and efficiency.

1. Which process is more environmentally friendly?

Sheet metal fabrication generally produces less material waste compared to CNC machining, making it somewhat more environmentally friendly for high-volume production. However, CNC machining can optimize material use with careful planning and recycling. Both processes can incorporate sustainable practices depending on the facility and material choices.