15 years one-stop China custom CNC machining parts factory

949 |

Published by VMT at Feb 02 2025 | Reading Time:About 8 minutes

949 |

Published by VMT at Feb 02 2025 | Reading Time:About 8 minutes

Sheet metal bending is a vital process in manufacturing that involves reshaping metal sheets by applying force. The process is used to create a wide variety of shapes and structures needed in industries ranging from automotive to aerospace. But like any advanced manufacturing technique, sheet metal bending requires precision, knowledge of materials, and the right machinery. If you're in the business of CNC machining or manufacturing, understanding sheet metal bending and its best practices can improve the quality, efficiency, and cost-effectiveness of your projects.

In this guide, we will explore everything you need to know about sheet metal bending, from the types of materials used to the best practices in the bending process, so you can apply this technique effectively to your CNC machining services or any related applications.

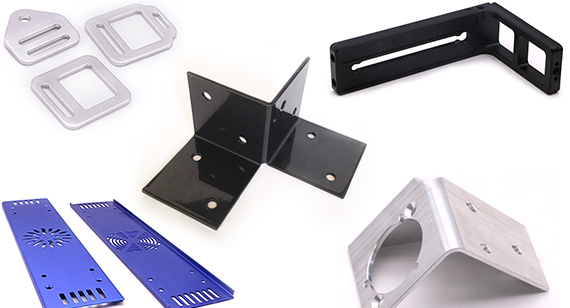

Sheet metal bending is the process of deforming a metal sheet to an angle, typically using a press brake or a similar machine. The process is designed to form the metal into specific shapes, such as brackets, enclosures, or chassis parts, without altering the material's integrity. The metal is bent around a straight axis, creating a bend that can range from a small angle to a full 90 degrees or more.

The bending process is widely used across industries because of its ability to produce parts that are both durable and precise. Sheet metal bending is common in CNC prototype machining and custom CNC machining, where precise control over bend angles and material thickness is essential.

In practice, sheet metal bending provides a fast and cost-efficient way to produce components with complex geometries. For manufacturers, it offers the ability to scale production quickly, reduce the need for additional welding or assembly, and achieve better design flexibility.

When bending sheet metal, there are several steps that must be followed to ensure precision and quality. The process generally involves preliminary design, preparation of the bending files, the actual bending operation, and post-bending finishing. Here's a closer look at each step:

Step 1: Preliminary Design

Before bending sheet metal, a design is essential. This includes determining the shape, dimensions, material type, and bend angles. Proper planning helps avoid errors, reduce material wastage, and achieve optimal results. Most CNC machining factories rely on CAD software to create detailed designs and 3D models.

Step 2: Prepare Files

Once the design is ready, files are prepared and converted into machine-readable formats, typically G-code. This allows CNC machines to follow the exact path required for bending. This step ensures that precision is maintained throughout the entire manufacturing process.

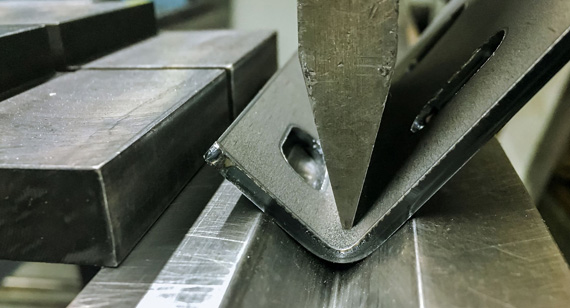

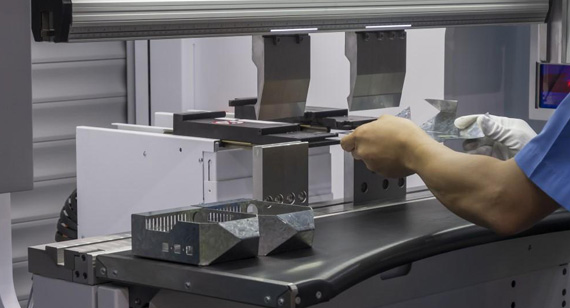

Step 3: Bending Process

The metal sheet is placed into a press brake or bending machine. The machine applies force to the metal at predetermined locations, bending it into the desired shape. The type of machine and bending method selected will depend on the material's properties and the complexity of the design.

Step 4: Finishing Process

After the bending operation, the part may require finishing processes such as deburring, grinding, or coating to enhance its appearance and function. These steps ensure that the part meets all quality standards and is ready for final assembly or use.

Sheet metal bending is a widely used manufacturing process that plays a crucial role in the production of a variety of products across numerous industries. The ability to bend metal sheets into different shapes makes this technique ideal for manufacturing parts and components that require precise angles, complex geometries, or lightweight yet strong materials. Let’s explore some of the most common applications for bending sheet metal:

The automotive industry makes extensive use of sheet metal bending for producing body panels, brackets, and structural components. Components like fenders, doors, and chassis are all made using sheet metal bending methods. Due to the need for strength and precision, automotive manufacturers rely on advanced CNC machining services to ensure that the parts are produced with exact measurements, optimal thickness, and minimal waste.

Aerospace

The aerospace industry demands precision and strength, which makes sheet metal bending a critical process in manufacturing aircraft fuselages, wings, and interior components. The lightweight and durable nature of the materials used in sheet metal bending, such as aluminum and titanium alloys, makes them ideal for applications where weight and performance are critical.

Sheet metal bending is used to produce various enclosures for electronics and frames for home appliances. These parts require accuracy and the ability to house delicate components securely while maintaining structural integrity. Examples include computer enclosures, refrigerator parts, and microwave frames.

Construction

Sheet metal is extensively used in HVAC systems, roofing, and decorative trim for buildings. Bending allows for the formation of ducts, panels, and architectural elements that need to be precise and durable. Stainless steel and galvanized steel are often the materials of choice in these applications due to their resistance to corrosion and long lifespan.

Heavy Machinery

Industrial machines often feature structural elements such as frames, covers, and brackets, all of which are commonly produced through sheet metal bending. These parts need to withstand significant stresses and strains, and bending is an efficient way to produce them from high-strength steel or aluminum.

Furniture and Fixtures

In the furniture industry, sheet metal is often bent to create components like furniture frames, cabinets, and wall panels. Metal is used in office furniture, shelving units, and storage systems, thanks to its strength and durability.

Consumer Products

Many consumer goods, such as heating units, kitchen appliances, and decorative metal parts, also utilize sheet metal bending to create components that are both functional and aesthetically pleasing.

Each of these industries benefits from the versatility of sheet metal bending, making it one of the most important manufacturing processes for creating functional and high-quality parts.

There are several bending methods that manufacturers use, depending on the application, material, and complexity of the required shape. The two most common types of sheet metal bending are press bending and rolling. Let’s explore each in more detail:

Bending is typically done using either a press brake or a rolling machine. These machines use mechanical or hydraulic force to apply a bending load on sheet metal. The bending method chosen will depend on factors such as the material’s thickness, the radius of the bend, and the desired shape. The type of bending process also affects the precision, cost, and manufacturing speed.

Press Bending Machine

A press brake is one of the most versatile machines used for bending sheet metal. It uses a set of dies to shape the metal into the desired form. The bending operation is carried out by applying force to the metal sheet, with the press brake's upper die (the punch) pressing down into the lower die (the die block). Press brakes can handle a wide range of sheet metal materials, including steel, aluminum, and stainless steel.

The bending processes carried out by press brakes can be divided into two main types: air bending and bottom bending.

Air Bending

Bottom Bending

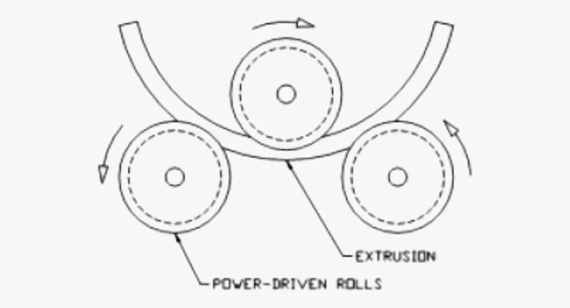

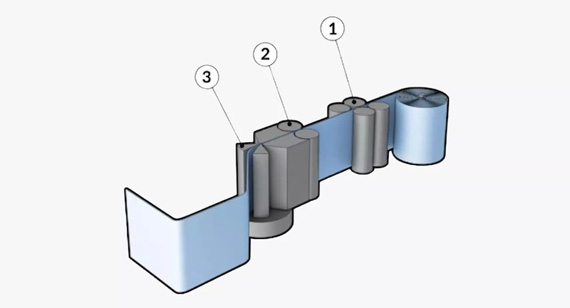

Rolling

Rolling is another essential method of bending sheet metal, primarily used for creating cylindrical shapes and large-radius bends. Roll bending utilizes a set of three rollers that progressively bend the sheet metal as it moves through the machine. This process is especially useful for applications where the metal must be bent in a continuous curve, such as in the production of pipes, ducts, and tanks.

Rolling is primarily used for larger parts or parts with curved geometries that cannot be effectively produced by press brakes. It’s ideal for forming large sheets or coils of metal into curves, arcs, or cylinders. Rolling typically requires a different set of rollers depending on the material’s thickness and the desired radius.

Roll bending can accommodate both thin and thick materials, though it’s more commonly used with thinner sheets. The amount of curvature depends on the settings of the rollers and the thickness of the metal being processed.

Conclusion

Both press bending machines and rolling serve essential roles in sheet metal bending, with each method having its advantages depending on the application. Press bending is ideal for creating specific, precise bends with relatively simple shapes, while rolling is better suited for creating curves and continuous cylindrical forms. Understanding these types of sheet metal bending will help you choose the right technique for your manufacturing needs, ensuring quality, efficiency, and precision in the final product. Whether you are working with CNC machining services or looking to implement custom CNC machining processes in your production, these methods are essential tools for creating high-quality sheet metal components.

Sheet metal bending is a versatile and essential process in manufacturing, enabling the creation of parts with various shapes and angles. Understanding the different bending methods is crucial for achieving precise and high-quality results. Below are 10 of the most common sheet metal bending methods, each with its own unique advantages and ideal applications.

Each sheet metal bending method has its own specific characteristics, suited for different materials, thicknesses, and design requirements. Some methods are ideal for simple bends, while others are used for creating complex geometries or continuous curves. Let’s explore 10 popular bending techniques in more detail:

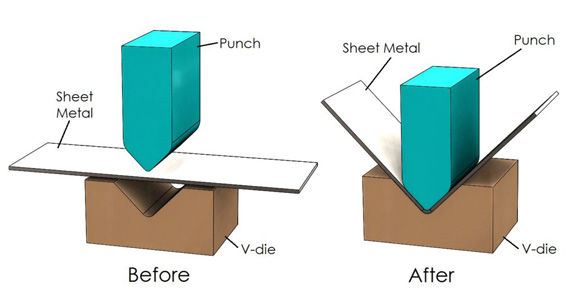

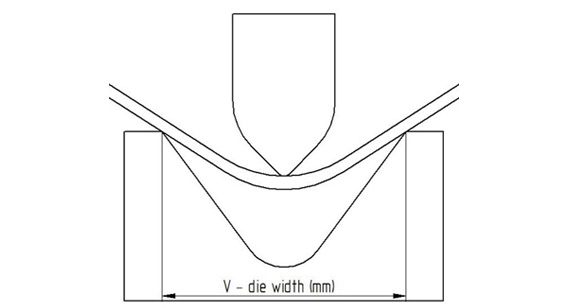

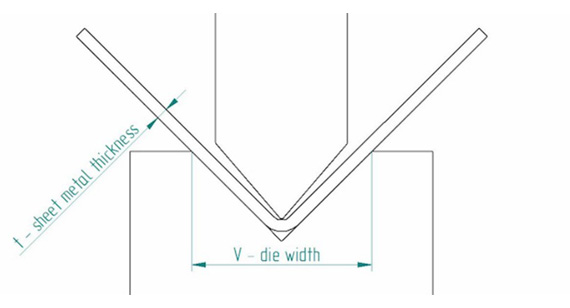

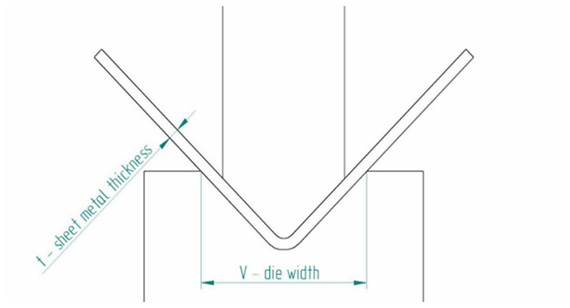

Method #1: V-Bend

Description:

The V-bend is one of the most common bending methods, primarily used for creating simple bends with precise angles. In this method, the sheet metal is pressed between a punch and a die that is in the shape of the letter "V." The force applied causes the sheet to conform to the V-shaped die, creating a clean, consistent bend.

Applications:

V-bending is used in a wide range of industries, including automotive and aerospace, for parts that require a clean, sharp bend.

Method #2: U-Bend

Description:

In the U-bend method, the sheet metal is bent into a U-shaped form. This process involves the use of a punch and die that forms a curve, creating a 180-degree bend. The U-bend is commonly used when parts need to be bent into a curved shape, providing a deeper and more pronounced angle than V-bending.

Applications:

U-bending is often used in the production of pipes, tubes, and ducts for HVAC systems or automotive parts requiring round or curved features.

Method #3: Air Bend

Description:

Air bending is a flexible method in which the sheet metal is pressed against the punch and die, but there is a gap between the die and the sheet. This gap allows for a variety of bend angles without requiring an exact fit. The process is highly versatile and can create a wide range of angles.

Applications:

Air bending is ideal for parts where the bend angle is not critical and can accommodate variations. It's widely used for production of light to medium gauge sheet metal components.

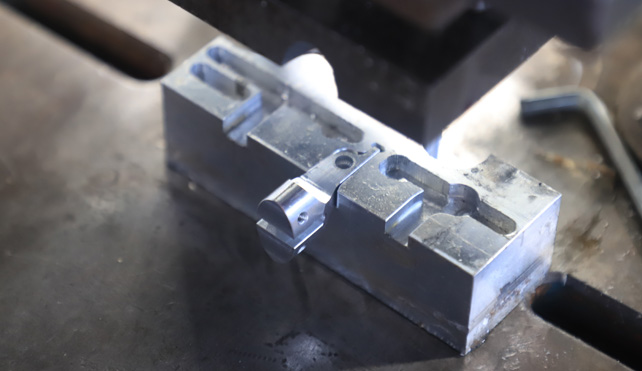

Method #4: Bottom Bend

Description:

Bottom bending involves full contact between the punch, die, and sheet metal, allowing for more precise and accurate bends compared to air bending. This method is often used for more demanding applications where tight tolerances are required. The process uses a die cavity, ensuring that the sheet follows the die's geometry exactly.

Applications:

Used in industries requiring precision, such as automotive manufacturing, electronics, and appliance fabrication.

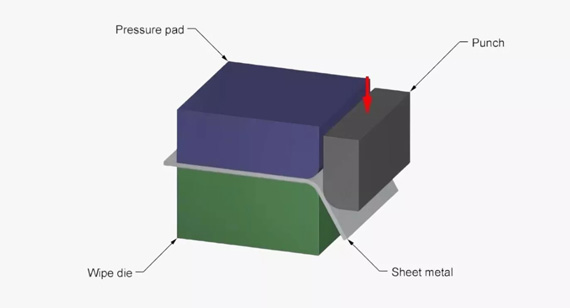

Method #5: Wipe Bend

Description:

The wipe bend method uses a specialized die to push the sheet metal around a curved punch. The die does not make contact with the sheet along its entire surface, only at specific points, which minimizes strain. This process creates clean bends with little to no deformation in the material.

Applications:

Wipe bending is frequently used for parts that require smooth, shallow curves, such as electronic enclosures and industrial containers.

Method #6: Roll Bend

Description:

Roll bending uses a set of three rollers to gradually bend the sheet metal into a curve. The sheet metal is fed through the rollers in a continuous process, which makes it ideal for producing long, smooth curves. This method is commonly used for producing cylindrical shapes or large-radius bends.

Applications:

Commonly used in the production of pipes, tubes, ducts, and large structural components for industries like aerospace, automotive, and construction.

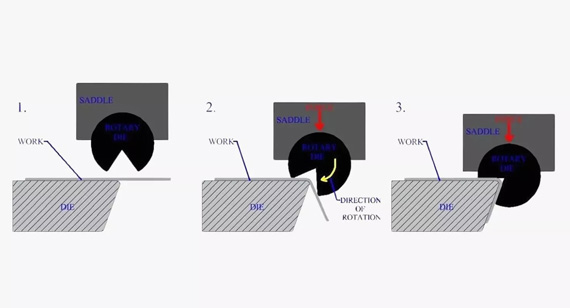

Method #7: Rotary Bend

Description:

The rotary bend method involves the use of a rotating die to bend the metal sheet. This technique allows for the bending of sheets into complex curves and angles without requiring multiple passes. The rotary motion of the die reduces friction and helps in maintaining consistent bend quality.

Applications:

Rotary bending is commonly used for parts that require complex curves, such as furniture frames, brackets, and industrial components.

Method #8: Coining

Description:

Stamping is a sheet metal forming process in which a die is used to cut, shape, or bend the metal. The metal sheet is placed into a die and a punch is used to stamp the shape. While stamping can also involve cutting and punching operations, it is effective for creating sharp, clean bends as well.

Applications:

Stamping is heavily used in industries like automotive (for body panels, hoods), electronics, and consumer goods (for appliance parts and housings).

Method #9: Step Bend

Description:

In the step bend method, the metal is bent incrementally to create a series of "steps" along the sheet. Each step involves a small bend, and the final shape is created by multiple bends stacked on top of each other. This method is ideal for parts with multiple angles.

Applications:

Step bending is used for parts that require complex geometries or sequential bends, such as brackets, structural frames, and component housing in electronics.

Method #10: Plate Roll Bending

Description:

Plate roll bending uses a set of three rollers to gradually bend a metal sheet into a cylindrical or conical shape. The process is especially effective for creating large-radius bends on thicker sheets of metal. The three-roll system allows the sheet to move through the rollers until the desired curvature is achieved.

Applications:

This method is primarily used for creating tanks, vessels, pipes, and barrels for industries that require large, rounded parts, such as petrochemical and construction industries.

Conclusion

Each of the ten sheet metal bending methods offers unique advantages that make them suitable for different manufacturing needs. Whether you require precise bends, complex shapes, or continuous curves, selecting the right bending technique is essential for achieving high-quality results in your products. As you explore these methods, it’s important to consider factors like the material type, thickness, bend radius, and desired outcome to ensure the most efficient and cost-effective production process.

By utilizing CNC machining and custom CNC machining services, you can achieve even greater precision and efficiency in your bending processes, ensuring that your products meet exact specifications and quality standards. Whether you are involved in automotive manufacturing, aerospace, or consumer goods production, understanding these methods will help you choose the best technique for your project.

Sheet metal bending is a critical process in manufacturing, used to form and shape various materials to meet the specific requirements of industries such as automotive, aerospace, electronics, and construction. The material selected for bending plays a crucial role in determining the quality and efficiency of the bend, as different materials have unique properties such as tensile strength, hardness, and flexibility. Below, we explore some of the most common sheet metal materials suitable for bending and their key characteristics.

When selecting materials for sheet metal bending, several factors must be considered, including the material's surface finish, production (MPA), tensile strength (MPA), and hardness. These factors affect how the material behaves during the bending process, including its ability to withstand stress and deformation without cracking or breaking. Additionally, each material adheres to national standards that define their properties, ensuring consistency and quality across different industries.

Steel

Description:

Steel is one of the most commonly used materials in sheet metal bending due to its excellent strength, versatility, and relatively low cost. Steel's ability to form a variety of shapes makes it suitable for a wide range of applications, including automotive parts, structural components, and machinery.

Aluminum – Aluminum Alloy

Description:

Aluminum and its alloys are widely used in sheet metal bending due to their lightweight nature, corrosion resistance, and ease of formability. They are often used in industries where weight reduction is critical, such as in the aerospace, automotive, and transportation sectors.

Stainless Steel

Description:

Stainless steel is a corrosion-resistant material often used for applications that require both strength and resistance to harsh environmental conditions. It is highly valued in industries such as food processing, medical equipment, and construction.

Copper

Description:

Copper is known for its excellent electrical conductivity, thermal properties, and corrosion resistance. It is widely used in applications like electrical wiring, heat exchangers, and roofing materials. Copper also bends easily due to its high ductility.

Brass

Description:

Brass, an alloy of copper and zinc, is highly valued for its combination of good strength, corrosion resistance, and aesthetic appearance. It is commonly used in electrical and plumbing applications, as well as for decorative items.

Conclusion

Choosing the right material for sheet metal bending is essential to ensure a successful and cost-effective manufacturing process. Each material—whether it’s steel, aluminum, stainless steel, copper, or brass—offers distinct advantages based on its physical properties, such as tensile strength, hardness, and surface finish. By understanding these properties, manufacturers can select the appropriate material for their specific application, ensuring the durability, precision, and performance of the final product. Whether you're working on CNC machining projects or custom CNC machining services, knowing your material’s characteristics will help in achieving the highest quality sheet metal parts.

Sheet metal bending is a widely used manufacturing process in industries ranging from automotive to aerospace, construction, and consumer goods. It involves the shaping of flat metal sheets into predetermined angles by applying force using press brakes, rollers, or other bending equipment. The decision to use sheet metal bending depends on various factors, such as the complexity of the part, material requirements, and production goals. In this section, we will explore the key advantages and disadvantages of sheet metal bending and when it is the most suitable option for your manufacturing needs.

Advantages of Sheet Metal Bending

Sheet metal bending offers numerous benefits that make it a popular choice in modern manufacturing. Below, we explore the key advantages of utilizing sheet metal bending in production.

Speed of Manufacturing

One of the primary reasons manufacturers choose sheet metal bending is its speed. The process is relatively quick, especially when automated machinery like CNC bending machines are used. Once the initial setup and toolings are prepared, bending large quantities of parts can be done rapidly, reducing the overall lead time for production. This is particularly useful in industries where fast turnaround times are critical.

Precision

Sheet metal bending, particularly when done with CNC machines, offers high levels of precision and repeatability. The accuracy of the angles and dimensions of each bend can be consistently controlled, ensuring that parts fit together perfectly without the need for extensive post-processing or rework. This level of precision is essential for industries such as electronics, automotive, and aerospace, where part fitment is critical.

Reduce Post-Processing

Due to its precision, sheet metal bending can reduce or even eliminate the need for additional finishing steps, such as welding, grinding, or other forms of post-processing. For example, parts bent to the right dimensions might not require any welding at all, which leads to savings in both time and labor costs. This also contributes to a smoother, more streamlined production process.

Lighter Weight

Sheet metal bending often results in parts with thinner material and reduced weight compared to traditional machining methods. For industries like automotive manufacturing, where weight reduction is essential for fuel efficiency and performance, sheet metal bending provides an ideal solution. The ability to achieve lightweight structures without sacrificing strength is a key advantage.

Low Cost, Almost No Tooling

Compared to other manufacturing processes like die casting or injection molding, sheet metal bending generally requires lower tooling costs. The tools, such as press brakes and bending dies, are relatively inexpensive and reusable for various parts, making it a cost-effective option. The simplicity of the tooling reduces the overall production costs, especially for low to medium-volume production runs.

Reduce Part Complexity

In many cases, sheet metal bending allows for the creation of complex geometries without the need for multiple steps or separate parts. Instead of relying on welding or assembling multiple components, a single sheet metal part can be bent into a highly intricate design, simplifying the entire manufacturing process. This leads to fewer steps, reduced chances of error, and a more efficient production workflow.

Disadvantages of Sheet Metal Bending

While sheet metal bending offers numerous advantages, it also comes with certain limitations and challenges that manufacturers need to consider. Below, we discuss the main disadvantages of sheet metal bending and how they might impact production.

Thickness Limitations

Sheet metal bending is best suited for thin to moderately thick materials. Extremely thick sheets may not bend easily and could require more force than available in standard bending machines. For materials with thicknesses beyond a certain limit (typically over 6mm), alternative processes such as laser cutting, water jet cutting, or machining may be more effective. The material’s ability to bend without cracking or breaking decreases as thickness increases, so manufacturers must consider material limits when designing parts.

Need for Consistent Thickness

For optimal results, the material used in sheet metal bending must have consistent thickness throughout. Variations in thickness can lead to uneven bending, inaccurate angles, or weak points that might cause failure during use. Therefore, manufacturers need to ensure that the sheet metal material meets specific quality standards for thickness, or they may encounter challenges during the bending process.

Manufacturing Costs

While the tooling for sheet metal bending is generally low-cost, the initial setup and machine programming can involve higher upfront costs. For smaller production runs, these setup costs can be significant, making it less cost-effective compared to other manufacturing processes. Additionally, the type of material and the complexity of the part can drive up costs. For high-volume production, however, sheet metal bending becomes far more cost-effective over time.

Production Issues

Despite being a relatively straightforward process, sheet metal bending can experience issues during production. Problems such as material springback, inaccurate bend angles, or tool wear can impact the quality of the final product. Manufacturers must monitor the bending process carefully, ensuring that tooling is in good condition and that the bending machine is calibrated correctly. Inaccurate bends can lead to costly rework or scrapping of parts, especially if tight tolerances are required.

Conclusion

Sheet metal bending is a versatile and cost-effective manufacturing process, particularly when speed, precision, and lightweight components are critical. The ability to bend thin sheets of metal into complex shapes with high accuracy makes it suitable for various industries, including automotive, aerospace, and electronics. However, manufacturers need to be aware of its limitations, such as thickness restrictions, the need for consistent material properties, and potential production issues. By understanding the advantages and disadvantages of sheet metal bending, businesses can make informed decisions about when and how to incorporate this process into their production workflows.

Sheet Metal Bend Design Considerations

Sheet metal bending is a precise and critical process that requires careful design considerations to ensure quality and accuracy in the final product. Whether you're designing parts for automotive, aerospace, or other industries, understanding the fundamental principles of sheet metal bending can significantly affect the efficiency and success of your manufacturing process. In this section, we’ll explore key design considerations that will guide you in creating functional and manufacturable bent sheet metal components.

Before diving into the specific design considerations, it’s essential to first understand some of the key terms commonly used in sheet metal bending. These terms play a significant role in ensuring the accuracy of the bent part, and a solid understanding will help you make more informed decisions throughout the design process.

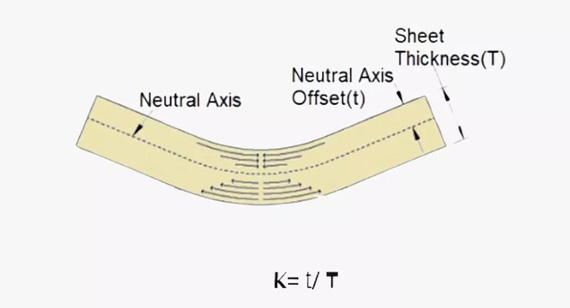

Neutral Axis

The neutral axis is the imaginary line running through the sheet metal part during the bending process where no elongation or compression occurs. This is crucial because materials on either side of the neutral axis experience either tension or compression when bent. Understanding the neutral axis is essential for calculating bend allowances and ensuring the part does not experience undue stress or deformation.

Tension Zone

The tension zone refers to the side of the metal sheet that stretches during the bending process. This occurs on the outside of the bend, and it is important to account for this during design to prevent cracking or distortion. Material properties such as ductility influence how well the metal will stretch without failure.

Compression Zone

The compression zone is the side of the sheet metal that is compressed during the bending process. The compression zone can cause the metal to buckle or wrinkle if excessive force is applied. To minimize the risk of these issues, it's essential to consider the metal's thickness and bend radius.

Bend Line

The bend line represents the location where the bend occurs. It is crucial to calculate this accurately to ensure that the finished part fits within the desired dimensions. The bend line is typically located at the midpoint of the material thickness.

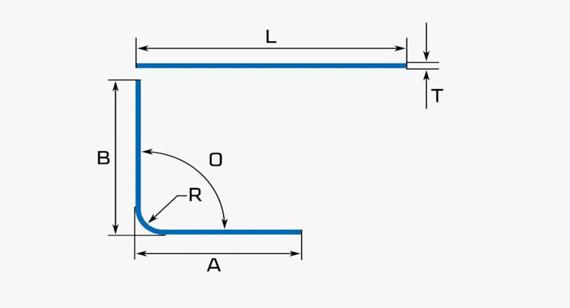

Flange Length

Flange length refers to the distance from the bend line to the edge of the metal sheet, where the part extends or forms a flange. Proper flange length is necessary for ensuring a strong bend and for fitting the component into its intended design.

Key Considerations for Sheet Metal Bending Design

After understanding the basic terminology, it’s time to explore the essential factors to keep in mind when designing sheet metal parts for bending.

Bend Radius

The bend radius is the smallest radius that a sheet metal can bend without cracking or deforming. A larger bend radius reduces the risk of metal failure and is generally preferred, but it may require more space in the design. On the other hand, a smaller bend radius requires careful consideration to avoid excessive stress in the metal, especially with brittle materials.

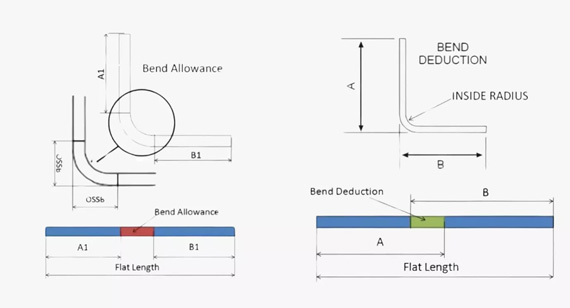

Bend Deduction (Bend Length)

Bend deduction refers to the amount of material that will be "deducted" or reduced in length due to the bending process. This is important for ensuring the part fits together as designed. Accurate bend deductions are critical for complex geometries and parts that need to interlock with others in a larger assembly.

Bend Allowance

Bend allowance is the amount of additional material that is required to make room for the bend. It accounts for the stretching of the material during bending and must be included in the design to ensure that the part ends up with the correct dimensions after bending. Proper bend allowance calculations are essential to achieve the desired fit and function.

Distance of Hole from Edge

The location of holes in relation to the bend line is crucial. If a hole is placed too close to a bend, it may distort or tear during the bending process. The recommended distance from the bend line to the hole is typically at least one and a half times the material thickness, depending on the material and bend radius.

K Factor

The K factor is a constant used in the bending process to calculate the bend allowance, based on the material's thickness and its relationship to the neutral axis. It varies depending on the material being bent and the type of machine used for the process. The K factor helps ensure that the bend allowance is accurate, which is essential for precise part manufacturing.

Bend Relief

Bend relief refers to the removal of material at the end of a bend to prevent cracking or deformation. Adding relief cuts at the bend’s ends can help reduce stress concentration and improve the overall integrity of the part. These cuts also prevent the material from being pinched or compressed during the bending process, allowing for cleaner bends.

Springback

Springback is a phenomenon that occurs when a material tends to return to its original shape after being bent. This happens because metals have an inherent elastic property, causing them to "spring back" after the external force is removed. Understanding springback is crucial for precise design and planning, as the final angle of the bend will be different from the angle set during the bending process.

Factors Affecting Springback

Several factors influence how much springback occurs during bending, including:

Bend Sequence

The order in which bends are made can affect the final result. Incorrect bending sequences can cause warping or distortion. It’s important to plan the bending sequence to avoid creating internal stresses that could lead to deformation or misalignment. The correct sequence ensures the part maintains its overall shape and dimensional accuracy.

Grain Direction

The grain direction of the metal affects how it bends. Bending along the grain direction usually results in smoother, more predictable bends, while bending against the grain can lead to cracking or other issues. Properly aligning the grain direction with the bend line can improve the quality and strength of the bent part.

Machining Tolerances

Achieving precise tolerances is vital when designing sheet metal parts for bending. There are a few rules of thumb to help guide the design process:

Rule of Thumb:

Tonnage

Tonnage refers to the amount of force required to bend the sheet metal. The required tonnage increases with the thickness of the material and the size of the bend. Accurately calculating tonnage ensures that the press brake or bending machine can apply the correct amount of force to achieve the desired bend without overloading the machine or causing defects.

Heat-Affected Zone (HAZ)

The heat-affected zone refers to the portion of the material near the bend where the heat from the bending process may cause changes in the material’s properties, such as hardness or tensile strength. While this is more of a concern in welding or heat treatment processes, it’s something to keep in mind when designing parts that require extreme precision and material integrity in the bend area.

Conclusion

Understanding these key design considerations for sheet metal bending is essential for ensuring successful manufacturing. From neutral axis placement to springback control, each factor plays a critical role in achieving accurate, durable, and functional bent parts. By carefully considering these elements and incorporating them into the design process, manufacturers can optimize their sheet metal bending operations, resulting in high-quality components that meet precise specifications.

Sheet Metal Bending Compared to Other Processes

Sheet metal fabrication encompasses a variety of processes, each with its own strengths and applications. While sheet metal bending is often the go-to method for shaping parts, it is essential to understand how it compares with other fabrication methods like laser cutting, CNC punching, stamping, and shearing. Each of these processes has its own advantages depending on the specific requirements of a project, such as accuracy, material thickness, and production scale. In this section, we will compare sheet metal bending to these other common techniques and outline when each is best suited for use.

Sheet metal fabrication is a critical component of manufacturing in industries such as automotive, aerospace, and construction. However, the selection of a manufacturing process largely depends on the part's design requirements, production volume, and material type. To make an informed decision, it’s essential to compare the advantages, limitations, and suitability of each process.

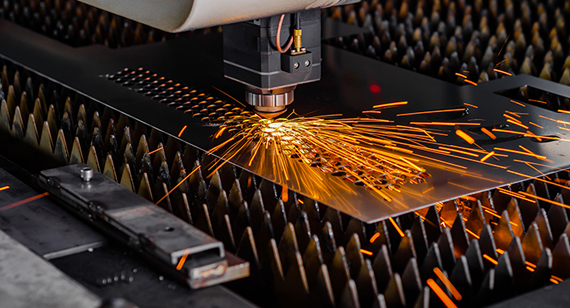

Best Suited For

Laser cutting is an excellent choice for precise, intricate designs in thin to medium sheet metal. This process is particularly well-suited for cutting complex shapes and fine details in materials such as steel, aluminum, and stainless steel.

Process Accuracy Level

Laser cutting is known for its high level of precision, capable of achieving tolerances as tight as ±0.1 mm, making it ideal for parts requiring exact shapes and smooth, clean cuts.

Thickness (mm)

Laser cutting is most effective for thin to medium thicknesses, typically up to 25mm, depending on the material. For thicker materials, alternative cutting methods such as plasma cutting may be more appropriate.

Custom Tooling Required

No custom tooling is typically required for laser cutting. The process relies on a CNC-controlled laser, which means that design changes can be easily accommodated without the need to create new dies or tools.

Minimum Order Quantity

Laser cutting is particularly well-suited for low to medium production runs, making it ideal for prototyping or small batches. As no custom tooling is required, it offers flexibility in part production with minimal setup costs.

Lead Time from CAD to First Production

Laser cutting has a relatively short lead time. Once the CAD design is finalized, the machine setup is quick, and parts can be produced within a few hours or days, depending on the complexity and volume.

Best Suited For

CNC sheet metal bending is most effective when forming parts that require a precise bend with tight tolerances. It is ideal for creating angular shapes, flanges, and complex three-dimensional geometries in materials like steel, aluminum, and stainless steel.

Process Accuracy Level

CNC bending offers high accuracy, generally achieving tolerances of ±0.5 mm or better, depending on the machine and part complexity. The precision of CNC bending allows for the creation of highly functional parts with minimal defects.

Thickness (mm)

CNC bending is suitable for a wide range of material thicknesses, typically from 0.5 mm to 12 mm, depending on the bending machine and material type. Heavier gauge materials may require specialized equipment to achieve accurate bends.

Custom Tooling Required

CNC sheet metal bending requires custom tooling, such as press brake dies. However, the tooling requirements are generally less complex than other processes, and tooling can be easily adjusted for different part geometries.

Minimum Order Quantity

CNC bending is suitable for both low and high-volume production. It is particularly effective for low to medium production runs, where quick setup and flexibility in design changes are important.

Lead Time from CAD to First Production

CNC bending generally has a moderate lead time. While the setup and programming of the CNC machine require time, it is relatively quick compared to stamping or die-casting processes. The lead time for the first production piece is typically within 1-2 days.

CNC Punching

Best Suited For

CNC punching is ideal for producing holes, notches, and cutouts in sheet metal. This process is highly effective for making parts that require repetitive hole patterns, such as brackets, panels, and frames.

Process Accuracy Level

CNC punching provides high accuracy, typically achieving tolerances of ±0.2 mm. However, compared to laser cutting, the process may leave burrs or rough edges that require secondary finishing processes.

Thickness (mm)

CNC punching is most effective for thin to medium material thicknesses, typically up to 6 mm. While it can be used for thicker materials, other processes like laser cutting or waterjet cutting may be better suited for more substantial materials.

Custom Tooling Required

Custom tooling is required for CNC punching. The process uses punch and die sets that must be designed specifically for each part. However, these tools can be reused for multiple parts with similar designs, making it cost-effective for medium to high-volume production.

Minimum Order Quantity

CNC punching is suitable for medium to high-volume production runs, making it ideal for mass production of parts that require multiple holes or cutouts. However, for low-volume runs, it may not be as cost-effective as laser cutting.

Lead Time from CAD to First Production

CNC punching typically has a short lead time once the tooling is set up. However, if new tooling is required, the lead time may increase. Generally, punching can begin production quickly after setup, often within 1-3 days.

Stamping

Best Suited For

Stamping is best suited for high-volume production of simple to moderately complex parts. It is particularly effective for making parts with uniform shapes, such as brackets, panels, and enclosures, in industries like automotive and consumer goods.

Process Accuracy Level

Stamping is highly accurate, capable of achieving tolerances as tight as ±0.1 mm in some cases. However, this can vary based on material thickness and part complexity.

Thickness (mm)

Stamping is generally suitable for materials ranging from 0.5 mm to 10 mm thick. For thicker materials, other processes like deep drawing or die casting might be more appropriate.

Custom Tooling Required

Stamping requires custom dies, which are created for each specific part. The tooling can be expensive to produce, but once set up, stamping can provide highly consistent, high-speed production.

Minimum Order Quantity

Stamping is highly suitable for high-volume production runs, as the initial cost of tooling can be offset by the large number of parts produced. It is less ideal for low-volume production due to the high upfront tooling costs.

Lead Time from CAD to First Production

Stamping has a longer lead time for first production due to the time required for tooling creation. Once the tooling is ready, production speeds up significantly, and parts can be produced rapidly.

Shearing

Best Suited For

Shearing is ideal for cutting straight lines or simple shapes in sheet metal. It is often used for preparing raw materials for further processing, such as cutting large sheets into smaller pieces before bending or welding.

Process Accuracy Level

Shearing provides relatively high accuracy for straight cuts, typically within ±0.5 mm, but it is less accurate for intricate shapes compared to laser cutting or CNC punching.

Thickness (mm)

Shearing is suitable for a wide range of material thicknesses, typically from 0.5 mm to 12 mm. It is most effective for medium to thick materials and is commonly used in heavy manufacturing industries.

Custom Tooling Required

Shearing requires custom blades or dies, depending on the material type and thickness. While the tooling costs are lower than for stamping or punching, shearing does require specific setups for each part or sheet size.

Minimum Order Quantity

Shearing is best suited for both low and high production volumes. It is ideal for cutting large batches of material into smaller pieces, which are then used for other processes such as bending or welding.

Lead Time from CAD to First Production

Shearing typically has a fast lead time once the machine is set up, often within a few hours. Since it is a straightforward cutting process, there are fewer delays compared to processes that require custom tooling, such as stamping or CNC punching.

Conclusion

When choosing between sheet metal bending and other fabrication methods, it’s important to understand each process's strengths and limitations. While sheet metal bending excels at creating precise angles and complex geometries, other methods like laser cutting, CNC punching, and stamping may be more appropriate for different production needs. The selection of the most suitable process will depend on factors such as material thickness, required accuracy, custom tooling, production volume, and lead time. By understanding the characteristics of each process, manufacturers can optimize their operations for better efficiency, cost-effectiveness, and product quality.

Designing sheet metal for bending is a crucial step in ensuring that the final part not only meets design specifications but also adheres to the practical constraints of manufacturing processes. Proper planning and consideration of several factors can significantly enhance the efficiency and quality of the bending operation. Below are some practical tips for designing bent sheet metal to achieve optimal results while minimizing errors, rework, or scrap.

Sheet metal bending is a widely used process in manufacturing that can shape a variety of materials into the desired forms. However, achieving precise bends and maintaining structural integrity during the bending process requires careful design considerations. From managing material thickness to selecting the right bend radius and incorporating design features like relief slots and hole placement, understanding how these elements affect the bending process is essential for both part functionality and manufacturability.

Maintain Uniform Thickness

One of the primary considerations in sheet metal bending is ensuring that the material thickness is consistent throughout the part. Variations in thickness can lead to uneven bends, poor material flow, or even material failure during the bending process. When selecting materials for a bent part, it’s crucial to work with sheets that have uniform thickness to avoid the need for compensatory adjustments during manufacturing.

Bend Radius and Direction

The bend radius is one of the most critical factors in sheet metal bending design. It refers to the inner radius of the bend and plays a significant role in determining the material's ability to form without cracking. A radius that is too small for the material’s thickness will cause the metal to tear, while too large a radius may result in less precise bends or underperforming parts.

Avoid Continuous Bends

While bends are an essential aspect of sheet metal design, continuously bending a part without breaks can introduce complications. A series of consecutive bends, particularly those located too closely together, can lead to material deformation, difficulties in controlling part geometry, and, ultimately, production inefficiencies.

Use Bend Relief Slots

Bend relief slots are essential for preventing the material from cracking or tearing at the edge of the bend. These slots, which are cut along the bend line, relieve the stress that accumulates at the point where the material bends.

Proper Hole and Slot Location

Holes and slots located too close to the bend can cause deformation or splitting during the bending process. It’s important to plan hole and slot placement carefully to ensure the part remains structurally sound after bending.

Countersunk Hole Design

Countersinking a hole is a common design feature when designing sheet metal parts that require screws or bolts to fit flush with the surface. This is especially important when the sheet metal part will be attached to another component.

Proper Curl Size

When designing a curled edge (such as for a lip or flange), the size of the curl is essential for both aesthetic and functional purposes. A curl that is too large or too small can affect the material's integrity and the part’s strength.

Design Hem

Hemming is a process where the edges of the sheet metal are folded over to create a smooth, rounded edge. Hemming serves to reinforce edges, improve safety (by removing sharp edges), and increase the part’s aesthetic appeal.

Flange and Chamfer Design

Flanges and chamfers are commonly incorporated into sheet metal parts to provide additional strength or for ease of assembly. These features are especially important when designing parts that will be welded or bolted together.

Tags and Grooves

Tags are small areas left uncut or partially cut to hold the sheet metal in place during the manufacturing process. These are typically removed later during the finishing stage. Grooves, on the other hand, are shallow cuts made in the metal for decorative or functional purposes, such as allowing a part to snap into place.

Crimp

Crimping is used to connect two pieces of sheet metal or to shape a piece into a specific form, often to ensure a tight fit. When designing for crimping, make sure that the crimp area is well-defined and the material thickness is appropriate for the crimping tool.

Conclusion

Designing bent sheet metal involves a delicate balance of material selection, geometric planning, and process understanding. Following these practical design tips—such as maintaining uniform thickness, using appropriate bend relief, and properly placing holes and slots—can significantly improve the manufacturability of your parts. Whether you're designing simple brackets or complex enclosures, considering these factors early in the design process will help ensure efficient production, fewer defects, and superior final products.

By mastering these principles, manufacturers can optimize their sheet metal designs for bending operations, ultimately leading to a more streamlined workflow, reduced costs, and high-quality results.

Bending sheet metal can be a tricky process for beginners, but with the right knowledge and preparation, anyone can master it. Whether you're designing a simple part or a more complex assembly, understanding the key considerations for successful metal bending is essential. Here are seven tips that can help beginners avoid common pitfalls and improve the quality of their bent sheet metal parts.

Bending sheet metal involves more than just applying force to the material—it's about understanding how the material behaves under pressure, knowing when to apply heat, and making sure the right tools are used for the job. In this guide, we’ll cover some essential tips that every beginner should know to make their bending projects easier and more successful.

1. Watch Out for Springback

Springback is a phenomenon that occurs when the sheet metal "springs back" to its original shape after being bent. This happens due to the material's inherent elasticity. For beginners, this can be frustrating, as the final bend may not match the intended angle or shape.

2. Always Use a Press Brake

For accurate and consistent bends, a press brake is essential. A press brake uses a die and punch to apply force evenly across the material, ensuring that bends are clean and precise. Beginners often try to bend sheet metal using less specialized tools, which can lead to uneven or poor-quality results.

3. Make Sure the Metal is Ductile Enough

Ductility refers to a material’s ability to stretch and deform without breaking. For sheet metal bending, the metal must be ductile enough to bend without cracking or breaking at the bend line.

4. Don’t Forget the Process Location Holes

When designing sheet metal parts for bending, it's easy to forget about the placement of holes and slots. These features are critical to the part’s final functionality, but if placed incorrectly, they can interfere with the bending process, leading to deformation or weak spots.

5. Use Bend Allowances

Bend allowances account for the material that gets stretched or compressed when it's bent. Without this consideration, your final part may end up with the wrong dimensions, which could cause issues during assembly or fitting.

6. Apply Heat to Thick Bends

Thicker metals require more force to bend, and without the proper preparation, they may crack or deform. Heat can be used to soften the material, making it easier to bend, especially in more complex or tight-radius bends.

7. Mask the Surface to Protect It

When bending sheet metal, especially materials like stainless steel or aluminum, the surface can get scratched or marked, which affects the aesthetics and functionality of the part. To avoid this, you can mask the surface with a protective film or tape before bending.

Always Plan Your Bends

One of the most important tips for beginners is to always plan your bends ahead of time. Understanding the sequence of bends, the direction of grain, and the part's final dimensions can prevent a lot of errors and wasted material.

Sheet metal bending can seem challenging at first, but by following these seven tips, beginners can set themselves up for success. From understanding how to compensate for springback to ensuring proper bend allowances, each step plays an important role in producing high-quality parts. By using the right tools, materials, and techniques, you'll not only improve the quality of your bent parts but also speed up the overall production process. Whether you're a beginner or an experienced fabricator, these tips will help you create better, more precise sheet metal bends every time.

1. What are the best sheet metal bending methods?

The best sheet metal bending methods depend on the material, thickness, and the part's specific requirements. Common methods include:

Each method has its strengths and is selected based on factors like part geometry, material type, and production volume.

2. Is sheet metal easy to bend?

Sheet metal can be easy or challenging to bend depending on the material's thickness, ductility, and hardness. Thin, soft metals like aluminum are easier to bend, while thicker, more rigid metals like stainless steel can be more challenging and may require more force or heat.

3. What are the advantages of sheet metal bending?

4. What are the disadvantages of sheet metal bending?

5. What is the easiest way to bend sheet metal?

The easiest way to bend sheet metal, especially for beginners, is to use a manual brake or press brake for controlled and accurate bending. For DIY or small-scale projects, a bench top brake is a good option, especially for thinner materials.

6. What are the rules for bending sheet metal?

Some important rules to follow when bending sheet metal include:

7. Which tools are best for bending sheet metal cleanly?

The best tools for bending sheet metal cleanly are:

For beginners, using a press brake or a manual bending brake is highly recommended to achieve cleaner bends.

8. Is it better to heat the metal before bending it?

Yes, heating the metal before bending it can make the process easier, especially for harder metals like steel or stainless steel. Heating softens the material, reducing the risk of cracking or breaking. However, it requires control to avoid overheating and compromising the material's properties.

9. How can beginners use heat to bend metal?

Beginners can use heat to bend metal by applying localized heat to the area of the bend using a propane torch or an oven for larger parts. The goal is to soften the material enough to make it more pliable, but not so much that it melts or weakens.

10. Does heating and then cooling metal make it stronger?

Heating and then cooling metal does not necessarily make it stronger. In fact, rapid cooling (quenching) can harden certain metals like steel, but it can also lead to brittleness. In many cases, controlled heating and slow cooling (annealing) are used to relieve stress and make the metal more ductile.

11. Can you heat metal to make it ductile?

Yes, heating metal can make it more ductile by increasing its ability to deform without cracking. This process is especially useful for hard-to-bend metals like stainless steel, which may become brittle at room temperature.

12. What does putting hot metal in water do?

Putting hot metal in water (a process called quenching) rapidly cools the metal, which can increase its hardness. However, this also makes the metal more brittle, which may not be ideal for parts that require flexibility.

13. Does heating metal make it more pliable?

Yes, heating metal increases its pliability or ductility, making it easier to bend. The process is called annealing, and it helps reduce the internal stresses in the material, making it more flexible.

Tip: When bending metals that are prone to cracking, such as cold-rolled steel, annealing can make them much easier to form.

14. Does heat make metal easier to cut?

Yes, heat can make metal easier to cut, as it softens the material. Heat treatments like torch cutting or plasma cutting work by melting the metal at the cutting point, allowing for cleaner cuts with less force required.

These FAQs provide a basic understanding of sheet metal bending, its methods, tools, and material properties. Whether you're a beginner or a seasoned professional, these answers can guide you through the bending process and help you achieve better results in your projects.