15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

117 |

Published by VMT at May 27 2024

117 |

Published by VMT at May 27 2024

Introduction

Within the vast landscape of manufacturing, sheet metal fabrication occupies an indispensable position due to its unique process characteristics and wide application areas. From simple metal sheets to complex structural components, sheet metal fabrication technology continues to drive the development of the manufacturing industry. This article delves into the definition, processes, types of techniques, material selection, surface treatment options, design considerations, and Design for Manufacturing (DfM) techniques in sheet metal fabrication, while exploring the necessity of top-tier sheet metal manufacturing.

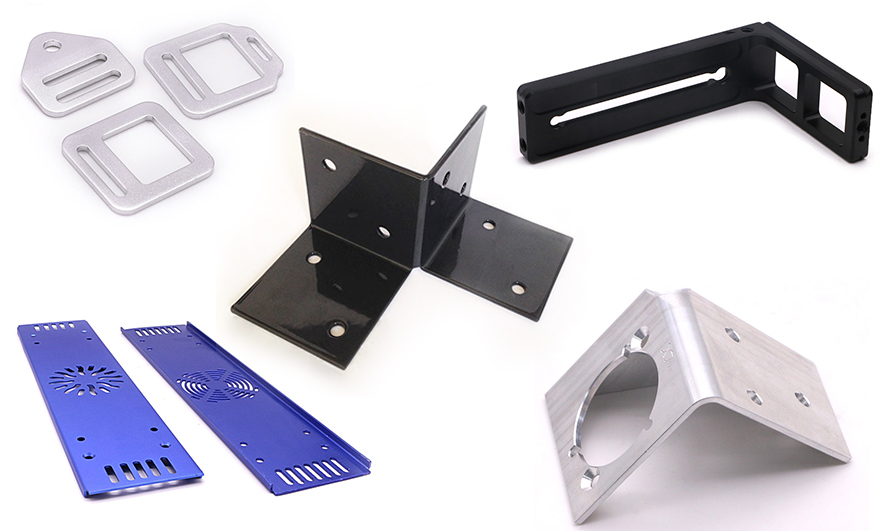

What is Sheet Metal Fabrication?

Sheet metal fabrication, in brief, is the process of machining metal sheets to form metal parts or structural components of desired shapes and sizes. These processing steps include but are not limited to cutting, bending, punching, welding, etc. Sheet metal fabrication technology is widely used in electronics, communication, automotive, aerospace, medical equipment, and other fields, making it an essential part of modern manufacturing.

The Process of Creating Sheet Metal Parts

Idea Generation: Designers or engineers need a clear idea of sheet metal part design, usually based on product functional requirements, aesthetic considerations, and cost factors.

Engineering Drawing Creation: Detailed engineering drawings are created using Computer-Aided Design (CAD) software based on the design concept. The engineering drawing should include information such as part dimensions, shapes, materials, surface treatments, etc.

Design for Manufacturability (DfM) Analysis: Before formal production, the engineering drawings need to undergo a DfM analysis to ensure that the designed parts can be manufactured under existing equipment and process conditions. This includes checking factors such as part tolerances, machining difficulties, material selection, etc.

Prototype Development: After the DfM analysis is approved, prototype development takes place. Prototypes are made using rapid prototyping techniques (such as 3D printing) or traditional manual methods to create physical models of the parts.

Prototype Testing: Prototypes undergo testing to verify if their functionality and performance meet design requirements. This includes dimension measurements, structural strength tests, corrosion resistance tests, etc.

Mass Production: After passing prototype testing, mass production commences. Metal sheets are processed using CNC machining equipment (such as CNC punching machines, CNC bending machines, etc.) to create the required sheet metal parts.

Common Types of Sheet Metal Fabrication Techniques

Cutting: Metal sheets are cut using equipment such as laser cutting machines, shearing machines, or water jet cutting machines to obtain the desired shapes and sizes.

Bending: Metal sheets are bent using a press brake to form curves or angles.

Punching: Punching machines and dies are used to punch holes or shapes on metal sheets.

Welding: Welding equipment is used to join multiple metal sheets or parts together to form more complex structures.

Assembly: Multiple processed sheet metal parts are assembled together to form the final product.

Material Selection for Sheet Metal Fabrication

The selection of materials for sheet metal fabrication depends on the functional requirements, aesthetic requirements, and cost considerations of the product. Common sheet metal materials include cold-rolled sheets (SPCC), hot-rolled sheets (SHCC), galvanized sheets, stainless steel, aluminum sheets, etc. These materials have their characteristics, such as low cost and easy formability for cold-rolled sheets; high strength but difficult formability for hot-rolled sheets; good corrosion resistance for galvanized sheets; high corrosion resistance but high cost for stainless steel; lightweight and easy processing for aluminum sheets. When selecting materials, various factors need to be considered to choose the most suitable material.

Surface Finishing Selection for Sheet Metal Fabrication

Surface treatment in sheet metal fabrication is aimed at improving the corrosion resistance, wear resistance, aesthetics, etc., of the parts. Common surface treatment methods in sheet metal fabrication include brushing, sandblasting, painting, powder coating, plating, anodizing, etc. These treatment methods have their characteristics, such as brushing to create a fine texture on the surface of the parts; sandblasting to remove dirt and rust from the surface of the parts; painting to give the parts a smooth and bright color; plating to improve the corrosion resistance and wear resistance of the parts; anodizing to form a dense oxide film on the surface of the parts to enhance their corrosion resistance. When selecting surface treatment methods, the specific requirements and usage environment of the product need to be considered.

Design Considerations for Sheet Metal Fabrication

When designing sheet metal parts, several points need to be considered:

Relationship between Sheet Metal Thickness and Design Dimensions: It needs to be clear whether the design dimensions of the parts include the sheet metal thickness to avoid dimensional deviations due to thickness issues.

Feasibility of Manufacturing Processes: Consider whether the shape, size, and material of the parts are suitable for existing manufacturing processes and equipment.

Manufacturing Cost and Efficiency: Try to reduce manufacturing costs and improve production efficiency while meeting design requirements.

Strength Design: The strength design of sheet metal parts is one of the key points of design, ensuring that the parts can withstand sufficient loads and impacts during use.

Convenience and Rationality of Assembly: Consider the assembly sequence and installation space of the parts to ensure the convenience and rationality of assembly.

Some DFM Techniques for Sheet Metal Fabrication

Design for Manufacturing (DfM) is a manufacturing-oriented design method aimed at improving the efficiency and quality of the manufacturing process by optimizing product design. In sheet metal fabrication, using some DfM techniques can significantly improve the manufacturability and performance of the product. Here are some commonly used DfM techniques in sheet metal fabrication:

Simplified Design: Avoid overly complex designs to reduce processing steps and costs. Simplifying designs can be achieved by reducing unnecessary details, merging similar components, or using standardized parts.

Optimal Material Usage: Consider material utilization during the design process to avoid waste. By optimizing the shape and size of parts, the amount of material used can be reduced while maintaining the strength and function of the parts.

Selection of Appropriate Manufacturing Processes: Choose suitable manufacturing processes based on the characteristics and requirements of the product. For example, for parts requiring high precision and surface quality, high-precision machining equipment such as laser cutting or CNC punching machines can be used; for parts requiring large-scale production, automated production lines can be used to improve production efficiency.

Consideration of Assembly Processes: Consider the assembly process of the parts during the design process to ensure that the parts are easy to assemble and disassembl. Through reasonable assembly design and the use of standardized interfaces, assembly difficulty and cost can be reduced.

Allowance for Tolerances and Clearances: Reserve appropriate tolerances and clearances during the design process to cope with uncertainties and errors in the manufacturing process. This ensures the stability and consistency of parts during manufacturing.

Do You Need Top-Tier Sheet Metal Manufacturing?

With the intensification of market competition and the increasing demands of consumers for product quality, enterprises increasingly need to rely on top-tier sheet metal manufacturing to provide high-quality and efficient sheet metal processing services. Top-tier sheet metal manufacturers typically have the following characteristics:

Advanced Machining Equipment and Technology: They use advanced CNC machining equipment and technology to ensure machining accuracy and efficiency.

Strict Quality Control System: They establish a sound quality control system to ensure the stability and consistency of product quality.

Professional Technical Team: They have a professional technical team capable of providing one-stop services from design to production for customers.

Flexible Customization Services: They can provide flexible customization services according to customer needs and requirements to meet personalized demands.

Good After-Sales Service: They provide comprehensive after-sales service to ensure that customers receive timely technical support and solutions during use.

Conclusion

Sheet metal fabrication, as an essential part of modern manufacturing, is becoming increasingly prominent in its application scope and importance. By gaining in-depth knowledge of sheet metal fabrication, including its definition, processes, types of techniques, material selection, surface treatment options, design considerations, and DfM techniques, we can better master sheet metal fabrication technology and improve the quality and performance of products. At the same time, choosing top-tier sheet metal manufacturing is crucial to ensuring product quality and efficiency. Therefore, in the field of CNC machined parts manufacturing, we should focus on the development and application of sheet metal fabrication technology to meet the constantly changing market demands.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!