15 years one-stop China custom CNC machining parts factory

465 |

Published by VMT at Sep 11 2024

465 |

Published by VMT at Sep 11 2024

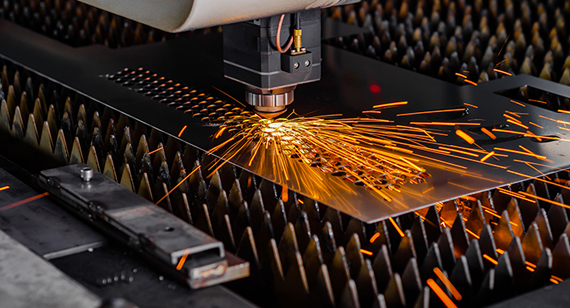

Sheet metal laser cutting is a critical manufacturing process used in a variety of industries for creating precise and intricate parts. This article delves into the fundamentals of sheet metal laser cutting, including the process, the types of lasers used, the materials suitable for laser cutting, and its advantages and disadvantages. Additionally, we explore common applications, alternative cutting methods, and essential tips for achieving high-quality results. For CNC machining factories and custom CNC machining services, laser cutting is an efficient and reliable solution that offers both precision and versatility.

Sheet metal laser cutting is a thermal cutting process that uses a concentrated laser beam to cut, engrave, or shape metal sheets. The process involves the use of high-energy laser beams that melt, burn, or vaporize material to create precise cuts. Laser cutting is known for its accuracy, ability to handle complex shapes, and high-speed operation, making it an essential technique for manufacturing precision CNC machining parts. The process is commonly used for metals such as steel, aluminum, copper, and brass, offering versatility for various industries.

The laser cutting process for sheet metal is highly efficient and relies on different methods to achieve precise cuts. Each method is designed for specific materials and cutting conditions:

Laser Beam Melting Cutting: In this process, the laser beam melts the material, and an inert gas such as nitrogen or argon blows away the molten metal from the cutting kerf. This method is commonly used for cutting stainless steel and aluminum, ensuring smooth, burr-free edges.

Laser Beam Sublimation Cutting: This technique uses high-energy laser beams to sublimate the material (turn it directly from solid to gas) without passing through a liquid state. It is ideal for cutting non-metallic materials and thin metals where precise edges are critical.

Laser Flame Cutting: Also known as reactive cutting, this process involves the use of an oxygen-assisted laser beam that burns the material. The heat from the laser and the chemical reaction with oxygen help in cutting thicker metals, such as carbon steel.

Several types of lasers are used for sheet metal cutting, each with unique characteristics that make them suitable for specific applications:

Fiber Laser: Fiber lasers are ideal for cutting reflective metals such as aluminum, copper, and brass. They offer high energy efficiency, fast cutting speeds, and excellent beam quality, making them popular in industrial CNC machining services.

CO2 Laser: CO2 lasers are versatile and suitable for cutting a wide range of materials, including non-metals like wood and plastic, in addition to metals. They are commonly used for precision engraving and cutting thin metals.

Crystal Laser (Nd or Nd): Crystal lasers use yttrium-aluminum-garnet (YAG) or yttrium-vanadate (YVO) as the laser medium. They are best suited for high-power applications, including cutting thicker metals or materials with high melting points. However, crystal lasers tend to be more expensive and have shorter lifespans compared to fiber and CO2 lasers.

Laser cutting offers extremely tight tolerances, typically ranging from ±0.1 mm to ±0.3 mm, depending on the material and the laser type. This high precision makes laser cutting suitable for complex and intricate designs that require detailed accuracy. The tight tolerances achievable with laser cutting also reduce the need for additional machining or finishing, making it ideal for CNC prototype machining and custom CNC machining.

The typical laser cutting tolerances for metals are:

The maximum thickness of metal that can be cut using a laser depends on the power of the laser and the type of metal. Fiber lasers can typically cut up to 25 mm (1 inch) of carbon steel, 20 mm of stainless steel, and 15 mm of aluminum. For thicker metals, alternative cutting methods such as plasma or water jet cutting may be required.

Laser cutting is compatible with a wide range of metals, each offering different characteristics:

Mild Steel (Carbon Steel): Laser cutting is widely used for mild steel due to its versatility and ease of cutting. Carbon steel can be cut with oxygen or nitrogen-assisted lasers, achieving clean, precise edges.

Stainless Steel: Stainless steel is ideal for laser cutting as it produces high-quality cuts with minimal heat-affected zones. Nitrogen-assisted lasers are commonly used to prevent oxidation during cutting.

Aluminum: Aluminum is a highly reflective metal, but fiber lasers are efficient in cutting it. Laser cutting aluminum is used in applications requiring high precision, such as aerospace and automotive industries.

Brass: Brass can be challenging to cut with CO2 lasers due to its reflective surface, but fiber lasers are highly effective. Laser-cut brass is used in decorative and electronic components.

Copper: Like brass, copper is best cut with fiber lasers due to its reflective nature. It is commonly used for electrical components and conductive materials.

Galvanized Steel: Laser cutting galvanized steel requires special considerations due to the zinc coating. However, it is commonly used in the construction and automotive industries for its corrosion resistance.

Titanium: Laser cutting titanium is possible with both fiber and CO2 lasers, making it ideal for aerospace and medical applications.

Nickel Alloys: Nickel alloys, including Inconel, can be laser cut with precision, offering excellent resistance to heat and corrosion.

Silver, Gold, Platinum: Precious metals like silver, gold, and platinum can also be cut using laser technology, mainly for jewelry making and electronics.

Zinc: Zinc-coated metals can be cut with lasers, but care must be taken to avoid contamination from the coating during the process.

Tin: Tin and tin alloys are suitable for laser cutting in specialized applications.

Laser cutting offers numerous advantages, making it a preferred method for sheet metal processing:

High Precision and Accuracy: Laser cutting achieves incredibly tight tolerances and smooth edges, making it ideal for precision CNC machining parts and complex designs.

Automated Process: Laser cutting systems are often fully automated, reducing the need for manual intervention and allowing for high-volume production with consistent quality.

Damage Prevention: The contactless nature of laser cutting prevents physical damage to the workpiece, reducing the risk of warping or distortion, particularly in delicate materials.

Compatible with Most Materials: Laser cutting is compatible with a wide range of metals, from mild steel and stainless steel to reflective materials like aluminum and brass.

Relatively Low Cost: While the initial investment in laser equipment can be high, the overall cost of laser cutting is relatively low due to its high efficiency and reduced waste.

High Versatility: Laser cutting is versatile and can be used for various applications, from engraving to cutting intricate shapes.

Low Energy Consumption: Compared to other cutting methods like plasma cutting, laser cutting consumes less energy while offering higher precision.

Despite its advantages, laser cutting also has some limitations:

Requires a Skilled Operator: While laser cutting machines are automated, they require skilled operators to set up the machines, ensure proper maintenance, and troubleshoot any issues that arise.

Limitation of Metal Thickness: While laser cutting can handle a wide range of metals, there are thickness limitations, particularly for thicker metals where alternative methods like plasma cutting may be more effective.

Release of Harmful Fumes and Gases: Laser cutting metals, especially coated or treated metals, can release harmful fumes. Proper ventilation and safety measures are required to protect operators and the environment.

High Initial Investment: The cost of purchasing and maintaining laser cutting machines can be high, particularly for small businesses or workshops.

To achieve the best results in sheet metal laser cutting, consider the following tips:

Choose the Right Material: Select materials compatible with laser cutting, considering factors such as thickness, reflectivity, and intended application.

Design with Software that Creates Vector Files: Laser cutters operate based on vector files (e.g., .DXF, .SVG). Ensure your designs are created in CAD or similar software that supports these formats for optimal results.

Remember the Cutouts: When designing parts, include appropriate cutouts to ensure clean separations between sections and reduce material waste.

Details Should Not Be Smaller Than the Metal Thickness: Ensure that intricate details are larger than the thickness of the material to avoid issues during cutting.

Minimum Distance Between Cutting Lines: Maintain an adequate distance between cutting lines to prevent warping, burning, or incomplete cuts.

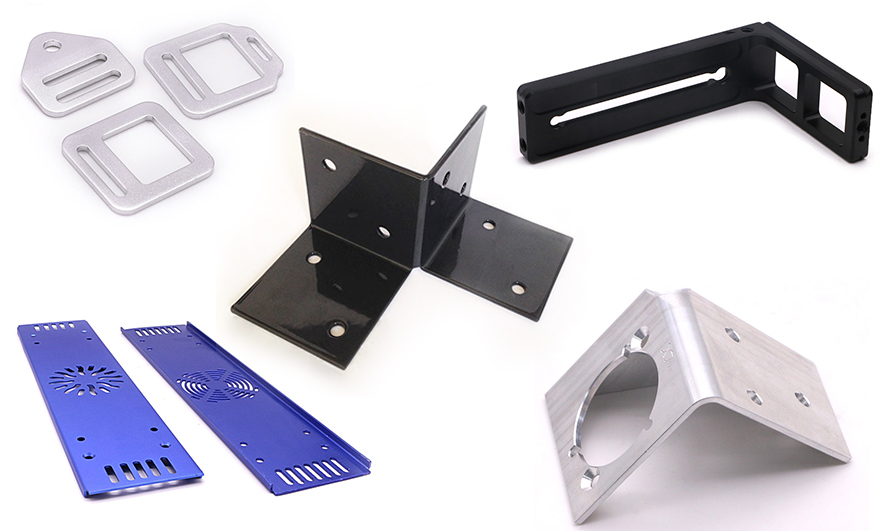

Laser-cut parts are used in a variety of industries due to their precision and versatility:

Medical Devices: Laser cutting is used to manufacture precise and intricate medical devices, such as surgical instruments and implantable components.

Jewelry Making: The high precision of laser cutting allows for the creation of intricate designs in precious metals, making it popular in the jewelry industry.

Interior Design: Decorative metal panels, lighting fixtures, and architectural elements are often laser-cut to achieve unique and intricate designs.

Aerospace Industry: In aerospace, laser cutting is used to manufacture lightweight yet durable components, ensuring the highest precision for safety-critical applications.

Automotive: Laser cutting is widely used for manufacturing automotive parts, including body panels, exhaust systems, and precision components.

Manufacturing: From brackets and enclosures to machine components, laser cutting is essential in the general manufacturing industry.

Electronics: Laser-cut parts are used in electronic enclosures, heat sinks, and precision components required for high-performance electronic devices.

Construction: The construction industry benefits from laser cutting in the production of structural components, beams, and custom metalwork.

While laser cutting is highly efficient, there are alternative metal-cutting processes:

Plasma Cutting: Plasma cutting uses a high-speed jet of hot plasma to cut through thick metals. It is ideal for cutting thick, conductive materials but lacks the precision of laser cutting.

Water Jet Cutting: Water jet cutting uses a high-pressure jet of water mixed with an abrasive material to cut through metals. This method is suitable for cutting thicker materials and does not generate heat, making it ideal for sensitive materials.

Mechanical Cutting: Mechanical cutting methods, such as sawing or shearing, are more traditional approaches to cutting metal but lack the precision and speed of laser cutting.

Sheet metal laser cutting is an invaluable process in modern manufacturing, offering unparalleled precision, speed, and versatility. While it has some limitations, such as thickness constraints and the need for skilled operation, its benefits far outweigh the disadvantages for most applications. Whether you're producing medical devices, automotive parts, or intricate jewelry designs, laser cutting offers a reliable and efficient solution. Understanding the process and its applications helps manufacturers and CNC machining factories leverage this technology for custom CNC machining services and CNC prototype machining.

How Thick a Metal Sheet Can Be Cut by Laser?

The maximum thickness depends on the type of laser and material, but most lasers can cut up to 25 mm of carbon steel and 15 mm of aluminum.

How Accurate is the Laser Cutting of Metal Sheet?

Laser cutting achieves high accuracy, typically within ±0.1 mm to ±0.3 mm, depending on the material and laser type.

What is the Maximum Thickness of Laser Cutting?

Fiber lasers can cut up to 25 mm for carbon steel, while thicker materials may require plasma or water jet cutting.

What Materials Should Never Be Cut by Laser?

Certain materials, such as PVC, can release harmful fumes when cut by laser. Additionally, highly reflective materials like copper require specialized lasers to prevent damage to the machine.

This detailed guide on sheet metal laser cutting covers everything from the process itself to its applications, advantages, and limitations, ensuring manufacturers can make informed decisions for their CNC machining parts. By understanding the technology and its benefits, CNC machining factories can optimize their production processes and deliver high-quality custom CNC machining services.