15 years one-stop China custom CNC machining parts factory

180 |

Published by VMT at Sep 12 2024

180 |

Published by VMT at Sep 12 2024

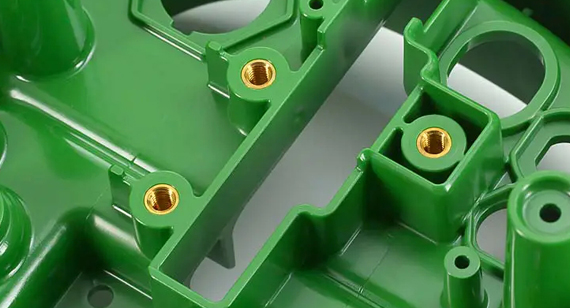

Insert molding is an advanced manufacturing process that combines metal or other components with plastic to create a single, durable part. Widely used in industries like automotive, aerospace, and medical devices, insert molding reduces assembly costs, enhances product design, and increases the strength of molded parts. This guide explores the insert molding process flow, key design considerations, and common applications, offering insight into its benefits and limitations for custom CNC machining and manufacturing. Whether for high-volume production or CNC prototype machining, insert molding is a versatile and efficient solution for integrating multiple materials into a single product.

Insert molding is a type of injection molding process that involves embedding a metal or non-plastic component (insert) into a mold, after which molten plastic is injected around the insert to form a single, integrated part. Unlike traditional molding, where only plastic is used, insert molding enables the creation of hybrid parts by combining plastic with other materials, such as metals or ceramics. The process improves product strength, reduces the need for post-assembly, and can enhance the functionality of the final product. It’s frequently used in industries requiring precision and durability, such as aerospace, automotive, and medical devices.

A wide range of materials can be used for insert molding, depending on the application and required properties:

Thermoplastics: These materials are versatile and commonly used in insert molding, including polypropylene (PP), nylon (PA), polycarbonate (PC), ABS, polyethylene (PE), and polyoxymethylene (POM). Thermoplastics are popular due to their ability to melt and re-solidify without degrading, making them ideal for mass production.

Thermosetting Plastics: Unlike thermoplastics, thermosetting plastics harden permanently after being molded. Common thermosetting materials include polyester, epoxy resin, melamine formaldehyde, and urea-formaldehyde resins. These materials are used when the product requires high heat resistance and structural integrity.

Elastomers: Elastomers, such as polyurethane and natural rubber, offer flexibility and elasticity, making them suitable for insert molding applications that require shock absorption, flexibility, and durability.

Insert molding is a multi-step process that integrates metal or non-plastic inserts into molded plastic components. Here’s a step-by-step breakdown of how the process works:

Step 1: Loading the Insert into the Mold

Inserts, which are often metallic or ceramic components, are placed into the mold before the plastic injection begins. There are two primary methods for loading inserts:

Automatic Insertion: In this method, robotic systems are used to load the inserts into the mold, ensuring precision and consistency. This approach is common in high-volume production environments.

Manual Insertion: For smaller production runs or custom parts, inserts may be manually placed into the mold. Although more labor-intensive, manual insertion allows for flexibility in part design and is often used for CNC prototype machining.

Step 2: Injecting Molten Plastic into the Mold

Once the insert is secured in place, molten plastic is injected into the mold cavity. The plastic surrounds the insert, creating a bond between the insert and the plastic. The key is to control the temperature and injection pressure to ensure the plastic flows smoothly around the insert without causing deformation or misalignment.

Step 3: Opening the Mold and Removing the Molded Part

After the plastic has cooled and solidified around the insert, the mold is opened, and the molded part is carefully removed. This step requires precise control to avoid damaging the insert or the plastic.

Step 4: Separating the Molded Part from the Gate

Once removed from the mold, the part is separated from the gate (the point where the plastic was injected). This may involve cutting or trimming any excess plastic to achieve the desired shape and finish.

Step 5: Post-Processing

After molding, additional processing may be required to refine the part. Common post-processing steps include:

Deburring: Removing any excess material or sharp edges left over from the molding process.

Heat Treatment: Strengthening the part by applying controlled heating and cooling processes.

Surface Treatment: Improving the part’s appearance or performance by applying coatings, painting, or polishing.

Humidity Control: In some cases, controlling humidity is essential to prevent warping or deformation of the plastic.

To ensure successful insert molding, certain factors must be considered during the design and planning stages:

Insert Types: Inserts can range from threaded metal fasteners to electronic components. Choosing the right type of insert for your application is essential for ensuring compatibility with the molding process and achieving the desired functionality.

Insert Locations: The placement of inserts within the mold is critical. Incorrect positioning can lead to misalignment, weak bonds, or damage to the insert. Careful planning is needed to ensure the insert remains securely in place during molding.

Closing the Gap Between Metal Parts and Inserts: Gaps between the metal insert and the surrounding plastic can weaken the bond. Proper mold design and injection pressure control are needed to minimize gaps and ensure a strong bond.

Choosing the Right Material and Molding Conditions: The selection of materials (both for the insert and the plastic) and the molding conditions (temperature, pressure, and cycle time) must be optimized for the specific application.

Choosing the Right Mold: Mold design is critical for achieving accurate and consistent results. The mold must be designed to accommodate both the insert and the plastic, ensuring proper flow and cooling.

Cost: Insert molding typically involves higher upfront costs due to the complexity of the mold and the need for precise insert placement. However, the reduction in post-assembly costs often makes insert molding more cost-effective in the long run.

Production Volume: Insert molding is ideal for medium to high production volumes. The process can be automated for high-volume runs, while smaller batches can be produced with manual insertion.

Pros of Injection Molded Inserts

Insert molding offers several advantages, particularly in reducing assembly time and improving part quality:

Reduce Assembly Costs: By integrating inserts directly into the molding process, manufacturers eliminate the need for secondary assembly operations, reducing labor and production costs.

Reduce Size and Weight: Insert molding allows for the creation of lightweight, compact parts by embedding metal components within plastic, reducing overall size and weight without sacrificing strength.

Increase Design Flexibility: Insert molding provides design freedom by allowing the combination of different materials in a single component, improving functionality and aesthetics.

Increase Design Reliability: Because the insert is securely embedded within the plastic, insert molding results in stronger, more reliable parts. This is particularly useful for parts subjected to mechanical stress or wear.

Cons of Injection Molded Inserts

Despite its advantages, insert molding has some challenges:

High Mold Cost and Complexity: Insert molding requires specially designed molds that can accommodate both the insert and the molten plastic. This increases the initial cost of mold development.

Injection Molded Insert Materials Are Incompatible with the Molding Process: Certain materials may not bond well with plastic or may deform under the heat and pressure of the molding process. Careful material selection is essential to avoid this issue.

Injection Molded Insert Positioning Is Inaccurate: If inserts are not accurately positioned, the final part may have defects, misalignments, or weak bonds.

Inserts Increase Cycle Time: The need to place inserts into the mold increases the overall cycle time, particularly for manual insertion, slowing down production in high-volume scenarios.

Insert molding is widely used in industries where high performance, durability, and precision are essential:

Aerospace: In aerospace, insert molding is used for lightweight, high-strength components that must withstand extreme conditions. Embedded metal fasteners, sensors, and connectors are common applications.

Automotive: Insert molding is used to produce various automotive components, including dashboards, door handles, and electrical housings. These parts require durability, heat resistance, and integration of metal inserts for structural integrity.

Medical Devices: Medical device manufacturing benefits from insert molding for parts that combine plastic and metal, such as surgical instruments, implants, and diagnostic equipment. Insert molding ensures sterility, strength, and precision.

Consumer Electronics: Insert molding is used to manufacture electronic housings, connectors, and switches that require precise placement of metal inserts for electrical conductivity.

Defense: Insert molding is employed in the defense industry for producing durable, lightweight components that integrate multiple materials, such as communication equipment and weapon systems.

Custom CNC machining plays a critical role in insert molding by producing precision inserts that meet specific requirements. Whether it's creating complex geometries or achieving tight tolerances, CNC machining ensures that the inserts fit perfectly into the molding process. CNC machining factories can collaborate with manufacturers to produce custom inserts for various applications, from aerospace to medical devices.

Insert molding and overmolding are both used to combine multiple materials into a single part, but they differ in their approach. Insert molding involves placing a pre-made insert into the mold before injecting plastic, while overmolding involves molding a second layer of material over an existing part. Overmolding is often used for adding a soft grip to a rigid part, while insert molding is focused on embedding metal or other components into the plastic.

Insert molding is a versatile and efficient manufacturing process that offers numerous benefits, including cost reduction, increased design flexibility, and improved part reliability. By understanding the process flow, design considerations, and potential challenges, manufacturers can optimize their use of insert molding in a wide range of industries. Whether for CNC prototype machining or large-scale production, insert molding is an essential technique for producing high-performance, multi-material parts.

What is the Difference Between Insert Molding and Overmolding?

Insert molding involves embedding an insert into the mold before injecting plastic, while overmolding involves applying a second layer of material over an existing part.

How to Design for Insert Molding?

Design for insert molding should account for insert positioning, material compatibility, and the flow of molten plastic around the insert.

Why Are Inserts Important in Injection Molding?

Inserts provide structural support, improve functionality, and allow the integration of multiple materials into a single part, reducing the need for secondary assembly.

What Are the Commonly Used Inserts in Insert Injection Molding?

Common inserts include metal fasteners, threaded inserts, electronic components, and bushings.

What is the Tolerance of Insert Molding?

Tolerances for insert molding vary depending on the materials used and the complexity of the design, but tight tolerances can be achieved with precision CNC machining.

What Materials Are Used for Insert Molding?

Common materials include thermoplastics like polypropylene and nylon, as well as thermosetting plastics and elastomers.

What is the Temperature for Insert Molding?

Insert molding temperatures depend on the plastic material used, typically ranging from 200°C to 300°C for thermoplastics.

What Should the Molding Depth Under the Insert Be?

The molding depth should be sufficient to provide a strong bond between the insert and the plastic, ensuring structural integrity.

Insert molding offers manufacturers a flexible and efficient way to produce high-quality, multi-material parts. By leveraging custom CNC machining services and optimizing the molding process, companies can meet the demands of industries such as automotive, aerospace, and medical devices.