15 years one-stop China custom CNC machining parts factory

752 |

Published by VMT at Sep 13 2024

752 |

Published by VMT at Sep 13 2024

Medical plastics play a crucial role in modern healthcare, offering a combination of safety, versatility, and durability. These plastics are used in various medical devices, from surgical instruments to implants, due to their biocompatibility, ease of sterilization, and cost-effectiveness. As the healthcare industry grows, so does the demand for high-quality medical plastic materials, which are produced through precision CNC machining and injection molding techniques. This guide explores the types of medical plastics, their applications, and the advantages they offer to healthcare professionals and patients alike.

Medical plastics refer to specialized polymers designed for use in healthcare applications. These materials are engineered to meet strict standards for safety, durability, and sterilization, ensuring they can withstand the rigors of medical environments. Medical plastics are used in a wide range of devices, from simple syringes and tubing to complex surgical instruments and implants. The inherent flexibility of plastic, combined with its ability to be molded into complex shapes, makes it an ideal choice for creating lightweight, durable medical devices.

Yes, medical-grade plastics are safe when they meet stringent regulatory standards. These materials are carefully tested for biocompatibility to ensure that they do not cause adverse reactions when they come into contact with bodily tissues or fluids. Regulatory bodies such as the FDA (Food and Drug Administration) and ISO (International Organization for Standardization) provide guidelines for the testing and certification of medical plastics. Common safety considerations include the ability of the material to be sterilized without degradation, its non-toxicity, and its resistance to chemical interactions.

The demand for medical plastic products is expanding rapidly due to advancements in healthcare technology and the rising need for cost-effective, lightweight, and durable medical devices. The increased use of disposable medical products to reduce infection risks and improve patient safety has also driven growth in the medical plastics market. Additionally, the demand for plastic-based medical devices, such as diagnostic tools, surgical instruments, and prosthetics, is rising due to their versatility and the ease with which they can be customized through CNC machining and molding processes.

Polymers offer distinct advantages over traditional materials such as metal or glass in medical applications. Here are some key reasons why polymers are preferred:

Inherent Properties: Polymers are inherently lightweight, corrosion-resistant, and flexible, making them ideal for a wide range of medical applications. They can be easily molded into complex shapes and designs, ensuring that medical devices are comfortable for patients and easy to use for healthcare professionals.

Excellent Manufacturing Performance: Polymers can be processed through various manufacturing techniques, including injection molding and CNC machining. This versatility enables the production of high-precision parts in large volumes, reducing production costs and lead times.

Recyclable: Many medical plastics are recyclable, contributing to sustainable healthcare practices. Recyclable polymers help reduce medical waste and offer an environmentally friendly alternative to single-use materials.

Several thermoplastics are commonly used in medical injection molding due to their durability, biocompatibility, and sterilization capabilities. Here are nine of the most commonly used medical plastics:

Polycarbonate (PC): Known for its strength, transparency, and high heat resistance, polycarbonate is commonly used for medical devices such as surgical instruments, oxygenators, and dialysis machines.

Polypropylene (PP): A lightweight, durable, and chemically resistant material, polypropylene is ideal for syringes, containers, and other disposable medical products.

Polyethylene (PE): Offering excellent biocompatibility and flexibility, polyethylene is used in tubing, catheters, and medical bags.

Polyvinyl Chloride (PVC): PVC is known for its chemical resistance and flexibility, making it suitable for blood bags, IV tubing, and catheters.

Acrylonitrile Butadiene Styrene (ABS): ABS is used in medical housings and devices that require impact resistance and strength, such as protective casings for diagnostic tools.

Polystyrene (PS): Used in disposable medical items such as petri dishes and test tubes, polystyrene is lightweight and easy to sterilize.

Polyethylene Terephthalate Glycol (PETG): Known for its clarity and impact resistance, PETG is widely used in medical packaging and drug delivery systems.

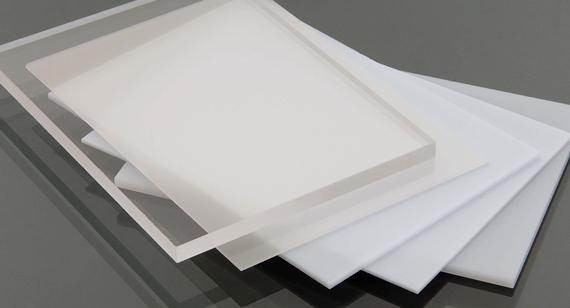

Polymethyl Methacrylate (PMMA): Also known as acrylic, PMMA is often used in dental applications and as a transparent material for medical devices like incubator enclosures.

Polyamide (PA): Nylon or polyamide is a durable, flexible material used in sutures, surgical meshes, and medical tubing due to its high tensile strength and biocompatibility.

Medical-grade plastics are chosen for their specific properties, making them suitable for critical healthcare applications. Some of the key properties include:

Biocompatibility: The ability of the plastic to be compatible with living tissues without causing adverse reactions or toxicity is critical for medical implants and devices that come into contact with the body.

Sterilization: Medical plastics must be able to withstand various sterilization methods, including autoclaving, gamma radiation, and chemical disinfection, without degrading or losing their properties.

Some Other Basic Properties of Medical Plastic Polymers:

Good Mechanical Properties: Medical plastics need to be strong, durable, and wear-resistant to ensure the longevity and reliability of medical devices.

Thermal Stability: The ability to maintain physical properties at high or low temperatures is essential for sterilization and use in surgical environments.

Good Optical Properties or Clarity: Transparency is important for certain medical devices such as diagnostic tools, where visibility is required.

Impermeability: Medical plastics used in containers, tubing, and packaging must be impermeable to gases, liquids, and other contaminants to maintain sterility.

Chemical Resistance: Medical plastics should resist degradation when exposed to chemicals, solvents, and bodily fluids to ensure durability and longevity.

Good Flame Retardancy: Fire safety is critical in medical settings, and many medical plastics are engineered to be flame-retardant.

Low Water Absorption: Medical plastics that absorb minimal water are more durable and maintain their integrity in wet or humid environments, such as in surgical instruments or implants.

Medical plastics provide several advantages over traditional materials, leading to widespread adoption in healthcare:

Easier to Sterilize: Medical plastics can be sterilized using various methods without degrading, ensuring that they remain safe for repeated use or in disposable products.

Versatility: Plastics can be molded into virtually any shape, making them ideal for a wide variety of medical applications, from tubing to complex surgical devices.

Enhanced Safety Features: Medical plastics are biocompatible and can be designed to minimize infection risk, improving patient safety during medical procedures.

Improved Quality of Life: Plastics are used in medical devices such as prosthetics and implants, improving mobility and function for patients.

Environmentally Friendly: Many medical plastics are recyclable, reducing waste and contributing to more sustainable healthcare practices.

Anti-Infection: Medical plastics can be treated with antimicrobial additives to prevent the spread of infection in healthcare settings.

Cost-Effective: Medical plastics are less expensive to produce and manufacture than traditional materials, making them a cost-effective option for medical devices.

Scope of Innovation: The adaptability of medical plastics allows for the development of new medical technologies and solutions that improve patient care.

Plastics are used in a wide range of medical products, providing durability, flexibility, and cost-effectiveness. Here are some common applications:

Surgical Instruments: Medical plastics are used to create catheters, cannulas, and other surgical instruments that are lightweight, sterile, and easy to use.

Sutures: Biodegradable plastics are used in sutures, which dissolve after a certain period, eliminating the need for removal.

Dental Instruments: Plastics are commonly used in dental tools such as tips, rubber clips, and cotton roll holders, providing a durable and lightweight alternative to metal.

IV Bags: Flexible plastics like PVC are used in IV bags to provide a sterile and durable solution for fluid delivery in hospitals.

Disposables: Plastics are the primary material used in disposable medical products such as syringes, reducing the risk of cross-contamination.

Sterilization Trays: Plastic trays are used for holding surgical instruments during sterilization procedures, ensuring that they remain sterile until use.

Medical Implants: Certain medical plastics are biocompatible and are used for implants, including joint replacements and dental prosthetics.

Anesthetic and Imaging Equipment: Plastics are commonly used in the housings and components of imaging machines and anesthesia delivery systems.

Tubing: Medical-grade plastics like PE and PVC are used in tubing for delivering fluids, oxygen, or medications to patients.

Prosthetics and Orthodontics: Lightweight and strong, medical plastics are ideal for creating customized prosthetic limbs and orthodontic appliances.

At VMT, we specialize in custom CNC machining and medical plastic part production. Whether you need precision components for medical devices or complex prototype machining for new innovations, our CNC machining factory is equipped to meet your needs. We provide high-quality medical-grade plastic parts that are tailored to meet the stringent requirements of the healthcare industry.

Medical plastics have revolutionized the healthcare industry by providing durable, flexible, and biocompatible materials that enhance the safety and effectiveness of medical devices. From surgical tools to prosthetics and implants, plastics have enabled innovation and cost-efficiency in healthcare. As demand for advanced medical products continues to grow, the role of medical plastics will only become more critical, offering countless possibilities for improving patient care and outcomes.

What is the best medical grade plastic?

The best medical grade plastic depends on the application. Common choices include polycarbonate for strength and clarity, polypropylene for disposables, and polyethylene for flexibility and durability.

How to know if a plastic is medical grade?

Medical grade plastics are certified to meet specific regulatory standards, such as FDA approval or ISO 10993 for biocompatibility. Manufacturers typically provide documentation verifying the material's compliance.

Which medical grade plastics are biocompatible?

Plastics such as polycarbonate, polyethylene, polypropylene, and PVC are biocompatible and commonly used in medical applications. Biocompatibility testing ensures that these materials are safe for contact with human tissues and fluids.

How are medical plastics made?

Medical plastics are typically produced through injection molding or CNC machining. These processes allow for the production of complex, high-precision parts that meet the exact specifications required for medical applications.

What kind of plastics are used in surgery?

Polycarbonate, polyethylene, and polypropylene are commonly used in surgical instruments, implants, and disposables due to their strength, flexibility, and sterilization capabilities.

What is surgical grade plastic?

Surgical grade plastic refers to plastics that meet the strict requirements for use in surgical instruments and implants. These plastics must be biocompatible, durable, and able to withstand sterilization processes.

What materials do plastic surgeons use?

Plastic surgeons often use medical grade silicone and polyethylene for implants and reconstructive surgeries, as well as biodegradable plastics for sutures and tissue scaffolding.

Medical plastics are essential to the modern healthcare landscape, offering unparalleled advantages in terms of safety, performance, and cost-effectiveness. As technology advances, the use of plastics in medical devices will continue to expand, providing even more opportunities for innovation and improved patient care.