15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

172 |

Published by VMT at Oct 07 2021

172 |

Published by VMT at Oct 07 2021

In the manufacturing industry, CNC machining and injection molding are commonly used processing techniques. What are CNC machining and injection molding? What is the difference between them? This article will tell you about CNC machining and injection molding related knowledge.

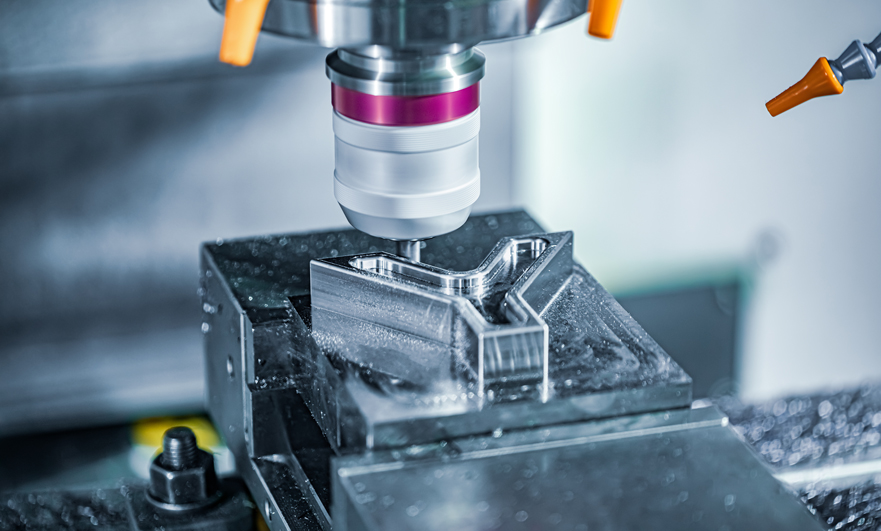

CNC machining:

The control system issues instructions to make the tool perform various movements that meet the requirements for subtractive processing. Since it is controlled by a computer, you can expect very good results, although it does produce a lot of leftovers.

Injection molding:

The material is injected into the mold for additive processing, which is accomplished by melting the raw material and pressing it into the mold under high pressure, and repeating the process again with the same mold.

The difference between CNC machining and injection molding

The difference in speed:

CNC machining is a computer program that can be processed to complete parts quickly, while injection molding requires a lot of time for injection molding modeling, which is slightly slower than CNC machining.

The difference in price:

CNC machining is the best choice in the case of a large number of parts. It has a volume advantage and usually has an advantage between a few to more than a hundred parts. The actual cost of each part of an injection molded part is cheaper than machining. When it comes to injection molding, creating a mold is expensive.

Material distinction

CNC machining can process a variety of materials. If high-performance plastics or specific plastics are required, this may be a very important determining factor. Generally speaking, harder plastics are easier to process than soft materials. Injection molding has many advantages, but there are indeed deficiencies in the materials that can be used. The injection molding process requires it to melt the original material into a liquid form before proceeding. In fact, there are not many suitable materials.

The difference in surface treatment

Using CNC machining, you can get tighter tolerances and better surface finish, but with injection molding, you can get repeatability for each batch. You can make one million identical parts with one mold with minimal wear.

Summarize

There are differences between CNC machining and injection molding in terms of speed, price, materials, surface treatment, and so on. Please carefully consider each element before selecting the required process for processing and manufacturing parts. Wrong decisions may bring you a lot of unnecessary CNC machining costs.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!