15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

164 |

Published by VMT at Jun 03 2024

164 |

Published by VMT at Jun 03 2024

Overview

In the expansive world of manufacturing, CNC machining and injection molding are two critical production methods. Each has its unique advantages and limitations, suitable for different production needs. This article aims to explore the differences between CNC machining and injection molding in depth to help businesses or individuals choose the most appropriate processing method based on their specific requirements.

I. CNC Machining

CNC machining is a technology that uses computer-controlled machines to process parts. By following pre-programmed instructions, CNC machines cut, drill, mill, and perform other operations to manufacture high-precision parts.

Advantages of CNC Machining

High Precision: CNC machining achieves micron-level precision, meeting the production demands for high-accuracy parts.

High Production Efficiency: CNC machining can perform multiple processes continuously, reducing manual intervention and improving production efficiency.

High Automation: The CNC machining process is highly automated, reducing the impact of human factors on product quality.

Short Production Preparation Time: CNC machining requires only a program change to adjust production, minimizing time for tooling and fixture changes.

Diverse Material Selection: CNC machining is suitable for processing various metal, non-metal, and composite materials.

Disadvantages of CNC Machining

High Equipment Cost: CNC machining equipment is expensive, requiring significant initial investment.

High Technical Threshold: CNC machining requires specialized programming and operational skills, demanding high technical expertise from personnel.

Low Flexibility for Small Batch Production: CNC machining is suitable for large-scale production. For small batch, multi-variety production, the cost is higher.

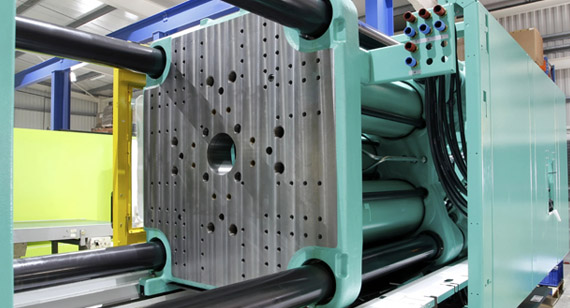

II. Injection Molding

Injection molding is a process where molten plastic is injected into a mold and solidifies into the desired part upon cooling. It is widely used in the production of plastic products.

Advantages of Injection Molding

Fast Production Speed: Injection molding can produce a large number of parts in a short time, meeting the needs of large-scale production.

Ability to Process Complex Shapes: Injection molding can produce parts with complex shapes and good surface quality.

Wide Material Selection: Injection molding is suitable for processing various plastic materials, including thermoplastics and thermosetting plastics.

Low Manufacturing Cost: Injection molding can achieve automated production, reducing labor costs and improving production efficiency.

Disadvantages of Injection Molding

High Mold Cost: Injection molding requires mold production, which is costly and time-consuming to replace.

Product Quality Depends on Mold Design: Unreasonable mold design can lead to quality issues, such as bubbles and shrinkage.

Limited Material Selection: Injection molding is mainly suitable for plastic materials and not applicable to metals, ceramics, etc.

III. CNC Machining vs. Injection Molding: Main Differences

Material Diversity and Selection

CNC machining is applicable to various metals, non-metals, and composite materials, while injection molding is mainly suitable for plastic materials. Thus, CNC machining offers greater flexibility in material selection.

Tolerances

CNC machining achieves micron-level precision, while injection molding is limited by mold precision and material properties, resulting in larger tolerances. Therefore, CNC machining is more advantageous for high-precision parts.

Design Flexibility and Limitations

CNC machining can produce parts with various complex shapes and allows for easy design modifications. Injection molding, however, requires mold production, making design changes more costly and less flexible. However, injection molding is ideal for mass production of identical parts.

Time Efficiency from Prototype to Production

CNC machining can quickly produce prototype parts directly from CAD models. Injection molding requires mold production and testing, which extends the time from prototype to production. Therefore, CNC machining offers higher time efficiency during the product development phase.

Production Volume

CNC machining is suitable for small-batch, multi-variety production, whereas injection molding is better for large-scale production. The choice of processing method depends on the production volume.

Final Product Quality and Precision

CNC machining can produce high-precision, high-quality parts. Injection molding, limited by mold precision and material properties, generally results in lower precision and quality. However, injection molding can produce parts with good surface quality and achieve automated production, reducing the impact of human factors on product quality.

Tool Life and Maintenance Requirements

CNC machining tools have a limited lifespan and require regular replacement and maintenance. Injection molding requires mold and injection machine maintenance to ensure normal operation. Both methods have their own maintenance requirements.

Cost Efficiency for Different Production Volumes

For small-batch production, CNC machining is more cost-efficient. For large-scale production, injection molding is more cost-effective. Therefore, a cost-benefit analysis based on production volume is essential when choosing a processing method.

IV. Similarities Between CNC Machining and Injection Molding

Precision and Accuracy

While CNC machining and injection molding differ in precision, both can achieve high levels of accuracy. CNC machining uses computer control for micron-level precision, while injection molding optimizes mold design and process parameters to improve accuracy.

Ability to Process Complex Geometries

Both CNC machining and injection molding can handle complex geometries. CNC machining uses programmed control for multi-axis machining, creating intricate surfaces and holes. Injection molding uses mold design to produce complex plastic parts.

Material Variety

Despite differences in material selection, both methods support various materials. CNC machining processes metals, plastics, wood, and more. Injection molding primarily processes plastic materials.

Design Modification

Both methods offer design modification flexibility. CNC machining can change programs for design adjustments, while injection molding can adapt molds to design changes, though at a higher cost.

Importance in Product Development

CNC machining and injection molding play vital roles in product development. CNC machining quickly produces prototype parts for design verification, while injection molding rapidly produces sample parts for market testing and customer feedback.

V. Choosing VMT’s CNC Machining and Injection Molding Services

As a professional CNC machining parts manufacturer, VMT provides high-quality CNC machining and injection molding services. With advanced equipment and an experienced technical team, we deliver precise, efficient machining services. Whether you need metal parts or plastic products, VMT is dedicated to serving you.

VI. Additional Comparisons of CNC Machining and Injection Molding

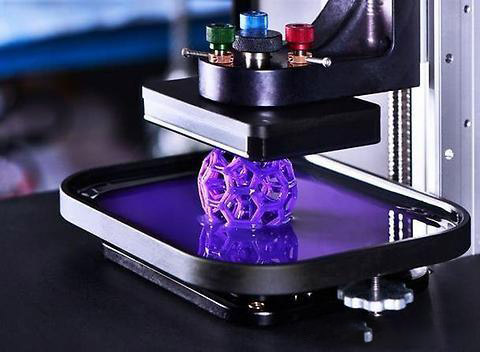

CNC machining and 3D printing differ in principles, material selection, and precision. CNC machining removes material to create parts, suitable for various materials. 3D printing adds material layer by layer, suitable for plastics, metals, and more. CNC machining typically offers higher precision.

CNC Machining vs. Traditional Machining

CNC machining provides higher automation and precision compared to traditional machining, which relies on manual operation and experience, influencing precision and efficiency.

Injection Molding vs. Die Casting

Injection molding and die casting differ in principles, material selection, and production costs. Injection molding uses molten plastic; die casting uses molten metal or alloy. Injection molding is for plastics, die casting for metals. Injection molding usually has lower costs.

Injection Molding vs. Extrusion Molding

Injection molding and extrusion molding are key plastic processing methods, differing in principles, product shapes, and applications. Injection molding produces complex plastic parts, while extrusion molding produces continuous profiles like pipes and rods.

Compression Molding vs. Injection Molding

Compression molding and injection molding differ in principles, mold design, and product precision. Compression molding heats plastic in a mold under pressure, while injection molding injects molten plastic into a mold to cool. Injection molding generally offers higher precision.

Blow Molding vs. Injection Molding

Blow molding and injection molding are plastic processing methods with different principles and applications. Blow molding creates hollow products by blowing molten plastic into a mold; injection molding creates solid products by injecting molten plastic into a mold. Blow molding produces bottles and containers; injection molding produces a wide range of plastic parts.

VII. Conclusion

CNC machining and injection molding are vital processing methods with differences in material selection, precision, and production volume. Choosing the right method depends on product needs, cost efficiency, and other factors. As a professional CNC machining parts manufacturer, VMT provides high-quality CNC machining and injection molding services to meet various processing needs.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!