15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

151 |

Published by VMT at Jan 29 2024

151 |

Published by VMT at Jan 29 2024

Introduction:

In CNC machining factories, the use of quality inspection equipment and control methods is a crucial means to ensure the quality of CNC machined parts. By employing advanced quality inspection equipment and scientific quality control methods, factories can conduct comprehensive and accurate inspections and controls of the quality of CNC machined parts. This article will introduce commonly used quality inspection equipment and control methods in CNC machining factories.

I. Quality Inspection Equipment:

Coordinate Measuring Machine (CMM):

CMM is a high-precision measuring device capable of inspecting the dimensions, shapes, and positional accuracy of CNC machined parts. By moving the measuring probe in three mutually perpendicular directions, it accurately measures the actual dimensions of parts, comparing them with design drawings to ensure machining accuracy meets requirements.

Optical Microscope:

Optical microscopes are used to observe the surface microstructures, materials, and defects of CNC machined parts. By magnifying observations, surface roughness, scratches, corrosion, and other subtle issues can be detected, facilitating the timely identification and resolution of potential quality concerns.

Profile Projector:

A profile projector measures the surface profile and texture of CNC machined parts. By measuring the amplitude and wavelength of surface micro-fluctuations, it evaluates surface machining quality and mechanical performance.

Ultrasonic Testing Device:

Ultrasonic testing devices utilize the propagation characteristics of ultrasonic waves in materials to detect internal defects and cracks in CNC machined parts. By emitting and receiving ultrasonic waves, issues within the parts that are difficult to detect with conventional methods can be identified.

Material Testing Machine:

Material testing machines are used to test the material properties of CNC machined parts, such as tensile, compression, and bending properties. Simulating stress-strain conditions under actual working conditions, they evaluate indicators such as material strength, plasticity, and toughness.

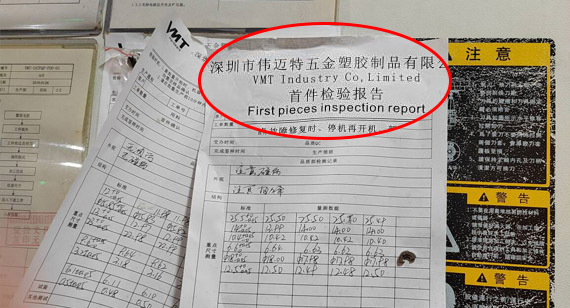

First Article Inspection:

Conduct inspections on the first CNC machined part of each batch or after a shift change to ensure equipment, process parameters, etc., are in a stable state. By comparing the first article with design drawings, issues can be promptly discovered and adjusted to avoid batch defects.

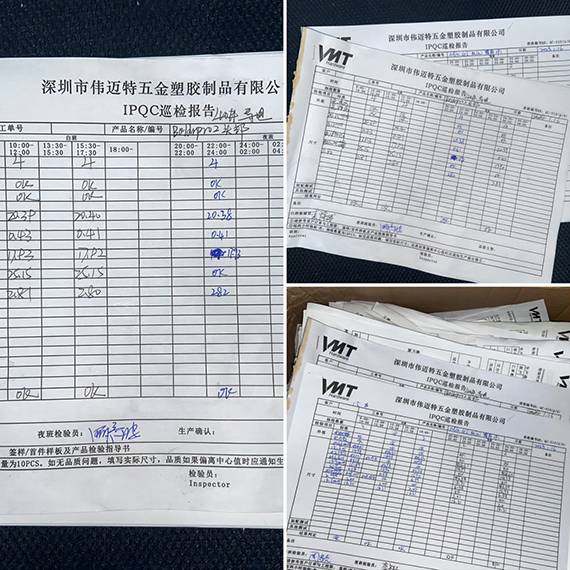

In-Process Inspection:

Regularly inspect CNC machined parts during the production process to ensure quality stability. Inspection personnel can periodically sample parts, checking key dimensions, surface quality, internal defects, and providing timely feedback to guide production adjustments.

Sampling Inspection:

Conduct sampling inspections on CNC machined parts based on statistical principles to assess the overall quality level. By determining a reasonable sampling plan and acceptance criteria, the factory can scientifically evaluate the quality of parts and take corresponding measures for improvement.

Process Control:

Monitor the CNC machining process in real-time to ensure stable process parameters and normal equipment operation. By collecting and analyzing process data, deviations and trends can be detected promptly, and corrective measures can be taken.

Quality Traceability:

Establish a quality traceability system for CNC machined parts, recording and tracing the production process of each part. By recording key process parameters, inspection data, etc., it becomes easier to investigate and analyze quality issues, ensuring timely resolution.

Continuous Improvement:

Apply quality tools and methods such as Statistical Process Control (SPC), Failure Mode and Effect Analysis (FMEA), etc., for continuous improvement of the CNC machining process. By statistically analyzing production data, identifying potential issues, and formulating improvement measures, the quality level of CNC machined parts can be continuously enhanced.

Employee Training:

Conduct regular training sessions on quality awareness and skill enhancement for employees to elevate their attention to quality control and operational skills. Through training, employees can proficiently use quality inspection equipment and control methods effectively in their practical work.

Communication and Collaboration:

Strengthen communication and collaboration between departments to ensure timely transmission and handling of quality information. By regularly organizing quality meetings and cross-departmental collaborations, information sharing and teamwork can be promoted, collectively raising the quality level of CNC machined parts.

Quality Assessment and Evaluation:

Establish quality assessment standards and methods, regularly assessing and evaluating the quality management work of each department. Through objective evaluations of departmental performance in quality control, outstanding departments and individuals can be recognized, while deficiencies are identified for improvement.

Customer Feedback:

Pay attention to customer feedback and suggestions, promptly collecting and analyzing customer evaluations and requirements for CNC machined parts. Adjust quality standards and control methods based on customer feedback to meet customer needs and adapt to market changes. Maintain good communication with customers to enhance customer satisfaction and loyalty.

Conclusion:

In conclusion, CNC machining factories can effectively ensure the quality level of CNC machined parts by utilizing advanced quality inspection equipment and scientific control methods. The rational application of these equipment and methods enables comprehensive monitoring and management of the CNC machining process, facilitating the timely detection and resolution of potential issues, ensuring the qualification rate and stability of the final products. Moreover, factories should continuously optimize and refine their quality control systems, enhance their quality management capabilities, and embrace technological innovation to adapt to evolving market demands and technological trends.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!