15 years one-stop China custom CNC machining parts factory

293 |

Published by VMT at Jul 18 2024

293 |

Published by VMT at Jul 18 2024

Metal sheet welding is a crucial aspect of CNC machining part manufacturing. By employing welding techniques, separate metal sheets are joined together to meet various mechanical and structural requirements. This article provides an in-depth look at common welding methods, techniques, types of metals used in welding, tips, and factors to consider when selecting a welding method. It aims to offer readers comprehensive and professional knowledge.

Metal sheet welding refers to the process of joining two or more metal sheets into a single unit through heating or pressure, creating atomic bonds between them. This process is widely used in CNC machining part manufacturing, especially in industries like automotive, aerospace, construction, and electronics.

MIG Welding (Metal Inert Gas Welding)

MIG welding uses a continuous wire feed as the electrode and an inert gas (such as argon, helium, or their mixtures) to shield the arc and molten pool. This method is suitable for various metals, including carbon steel, alloy steel, stainless steel, aluminum, and magnesium. The advantages of MIG welding are its fast welding speed and high deposition rate, making it ideal for automated production.

TIG Welding (Tungsten Inert Gas Welding)

TIG welding employs a non-consumable tungsten electrode and an arc between the electrode and the workpiece to melt the metal. An inert gas (such as argon or helium) is used to shield the weld area. TIG welding is particularly suitable for welding thin metal sheets and reactive metals like aluminum, magnesium, titanium, and zirconium. It offers high weld quality but has a relatively slower welding speed.

Stick Welding (Shielded Metal Arc Welding)

Stick welding is one of the earliest and most widely used arc welding methods. It uses a coated consumable electrode as both the arc and filler metal source. The arc between the electrode and the workpiece generates the heat needed for welding. Stick welding equipment is simple and flexible, making it suitable for short welds and hard-to-reach areas. It can use various electrodes to accommodate different metals.

Plasma Arc Welding

Plasma arc welding uses a compressed arc (called a transferred arc) between the electrode and the workpiece. This method is suitable for butt welds without beveling, ensuring full penetration and uniform weld seams. Plasma arc welding is efficient and produces high-quality welds, but it requires complex equipment and precise control of welding parameters.

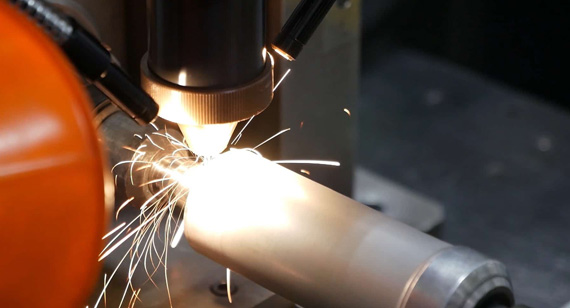

Electron Beam and Laser Welding

Electron beam welding uses a concentrated beam of high-speed electrons to generate heat on the workpiece surface, typically performed in a vacuum. Laser welding employs a focused beam of high-power coherent monochromatic light to provide the heat source for welding. Both methods allow precise energy control and are suitable for welding precision microdevices and hard-to-weld metals.

Gas Welding

Gas welding uses the heat from the chemical reaction or combustion of a fuel gas mixed with an oxidizing gas to weld. While simple and flexible, gas welding is less efficient and has a larger heat-affected zone. It is best suited for welding thin sheets and small workpieces.

Common metals used in metal sheet welding include carbon steel, stainless steel, aluminum alloys, and copper alloys. Different metals have different melting points, thermal conductivities, and coefficients of thermal expansion, requiring appropriate welding methods and parameters.

Flat Surface

For flat metal surfaces, MIG, TIG, or stick welding methods can be chosen. These methods can produce uniform and aesthetically pleasing weld seams on flat surfaces.

Horizontal Surface

Welding on a horizontal surface is relatively easy to control. MIG or TIG welding methods can be chosen to ensure stable welding quality.

Vertical Surface

Welding on a vertical surface requires careful control of the molten pool to prevent drips. TIG or stick welding can be chosen, with appropriate techniques like crescent or triangular weaving.

Overhead Surface

Welding on an overhead surface is challenging due to spatial limitations. Automated MIG or laser welding can be chosen to improve welding efficiency and quality.

Fillet and Groove Welds

Fillet and groove welds require attention to the shape and size of the weld. TIG or stick welding, with appropriate weaving techniques, can be chosen to control the shape and size of the weld.

Use the Correct Metal Technology

Select the appropriate welding method and technique based on the type, thickness, and position of the metal to ensure welding quality.

Choose the Filler Metal

Choose the appropriate filler metal based on the composition and properties of the base material to improve the mechanical properties and corrosion resistance of the weld.

Use Skip Welding

Skip welding can be used for long welds to reduce welding distortion and stress.

Use Tack Welding

Tack welding can preliminarily fix the metal sheets together before formal welding, helping maintain alignment and stability during subsequent welding and reducing distortion.

Run Tests on the Metal

It is essential to perform test welds before batch welding. Test welding can verify the reasonableness of welding parameters (such as current, voltage, welding speed, etc.) and observe the shape and quality of the weld, allowing timely adjustments to the welding process.

Use Small Diameter Wire

For welding thin metal sheets, using small diameter wire can reduce heat input, lower the risk of welding distortion and burn-through, and help create aesthetically pleasing welds.

Use Small Electrodes

In TIG welding, selecting the appropriate size of tungsten electrode is crucial for controlling the stability of the welding arc and molten pool. A small electrode can provide a more concentrated and stable arc, helping achieve high-quality welding.

Clamp the Backing Plate

Using a backing plate or clamp to secure the workpiece during welding can prevent movement and distortion, ensuring accuracy and consistency of the weld.

Use High-Argon Shielding Gas

For situations requiring high-purity shielding gas (such as TIG welding), selecting high-argon shielding gas (such as pure argon or argon with a small amount of hydrogen) can reduce oxidation and contamination of the welding area, improving weld quality.

Assembly and Joint Design

Proper assembly and joint design are key to ensuring welding quality. Different types of joints, such as butt joints, lap joints, T-joints, corner joints, and edge joints, should be selected and designed according to actual needs to ensure the strength and sealing of the weld.

Butt Joint: Used for high-tension applications.

Lap Joint: Used for applications requiring sealing but not high strength.

T-Joint: Common in structural connections.

Corner Joint: Used for changing direction or shear force applications.

Edge Joint: Used for making enclosed structures.

Adjust the Heat Input

Properly adjust the heat input according to the thickness and material of the metal sheet to avoid overheating, burn-through, and lack of fusion defects. By adjusting parameters such as welding current, voltage, and speed, the heat input can be controlled to ensure weld quality.

Choose the Right Company

For complex metal sheet welding projects, choosing a CNC machining company with extensive experience and professional expertise is crucial. Such a company can provide comprehensive services from design to welding, ensuring smooth project completion and high-quality delivery.

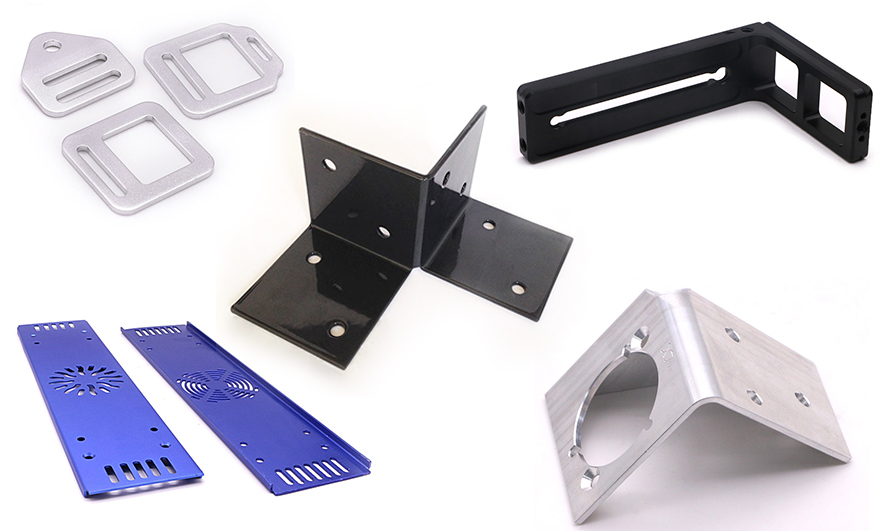

Metal sheet welding is an indispensable part of CNC machining part manufacturing. By selecting the appropriate welding methods and techniques, welding quality and efficiency can be ensured. VMT, as your custom metal sheet welding partner, has advanced equipment and a professional team to provide high-quality CNC machining services and welding solutions.

As a leading company in the CNC machining part manufacturing field, VMT is committed to providing high-quality custom metal sheet welding services. We have advanced welding equipment and a professional technical team capable of handling various complex and precise welding tasks. Whether thin sheet welding, medium-thick sheet welding, or large structure welding, we can provide precise solutions and quality service.

VMT's advantages include:

Advanced Equipment: We use the latest CNC welding equipment and automated production lines to ensure the stability and precision of the welding process.

Professional Technology: Our technical team has extensive welding experience and expertise, capable of handling various welding challenges and difficulties.

Customized Services: We provide customized welding solutions and services based on specific customer needs and conditions, ensuring customer expectations and requirements are met.

Strict Quality Control: We implement strict quality control processes and standards to ensure each welding process meets industry standards and customer requirements.

Choosing VMT as your custom metal sheet welding partner will bring you high-quality, efficient, and reliable welding solutions, supporting your project's successful implementation and delivery.

Which welding method is used for sheet metal?

Sheet metal welding can use various methods, including MIG welding, TIG welding, stick welding, plasma arc welding, electron beam and laser welding, and gas welding. The choice of welding method depends on the type of metal, thickness, welding position, and required welding quality and efficiency.

Which is better for sheet metal welding, TIG or MIG?

TIG and MIG welding have their advantages and are suitable for different welding scenarios. TIG welding is ideal for welding thin and reactive metals, offering high weld quality but slower speed. MIG welding is suitable for welding various metals, providing fast welding speed and high deposition rate, though the weld quality might be slightly lower than TIG welding. Therefore, the choice between TIG and MIG welding should be based on specific needs and conditions.

What welding machine is best for welding sheet metal?

Choosing the right welding machine for sheet metal depends on several factors, including the welding method, type of metal, thickness, welding position, and production requirements. Generally, CNC welding machines are widely used in sheet metal welding due to their high precision, efficiency, and flexibility. When selecting a welding machine, factors like welding process parameters, equipment stability, and control systems should also be considered.

Can a MIG welder be used for sheet metal?

Yes, MIG welding is widely used for sheet metal welding. MIG welding provides fast welding speed and high deposition rate, suitable for welding various metals, including carbon steel, stainless steel, and aluminum. Additionally, MIG welding can achieve good welding quality and aesthetic appearance, making it one of the common methods in sheet metal welding.

How thin can you weld with MIG?

MIG welding can be used to weld very thin metal sheets, even as thin as 0.6mm (24 gauge). When welding thin metal sheets with MIG welding, attention should be paid to controlling the welding parameters, such as reducing the welding current and voltage, and using a small diameter wire to avoid excessive heat input and welding defects like burn-through and warping.

What is the welding thickness of metal plates?

The welding thickness of metal plates can range from a few millimeters to tens of millimeters or even thicker. The specific welding thickness depends on factors such as welding method, equipment capacity, welding process parameters, and the material and performance of the metal plate. In practical applications, it is necessary to select the appropriate welding method according to specific needs and conditions.

What is the best way to weld metal plates?

There is no fixed answer to the best way to weld metal plates, as it depends on a combination of factors, including the type of metal, thickness, welding position, required welding quality, production efficiency, and cost. Here are some guidelines to help choose the most suitable welding method:

For thin metal plates: TIG welding is ideal for welding thin metal plates because it can accurately control heat input and provide high-quality welds. In addition, laser welding is also very suitable for welding thin plates due to its high precision and low heat-affected zone.

For medium and thick metal plates: MIG welding performs well in welding medium and thick metal plates due to its high efficiency and deposition rate. However, for occasions requiring higher weld quality, stick welding or plasma arc welding can also be considered.

For large or heavy structures: In these cases, automated and semi-automated welding methods, such as CNC MIG welding or robotic welding systems, can significantly improve production efficiency and welding quality.

For special metals or alloys: Some metals or alloys may require specific welding methods due to their unique physical and chemical properties. For example, aluminum alloys are usually welded using MIG or TIG, while stainless steel may be welded using TIG, MIG, or stick welding.

Cost considerations: When choosing a welding method, cost factors also need to be considered. Including equipment investment, consumables costs, maintenance costs, and labor costs. For large-scale production, it is particularly important to choose a cost-effective welding method.

In summary, the best method for welding metal plates should be selected and evaluated based on the specific situation. In practical applications, it may be necessary to combine multiple welding methods and techniques to meet different needs and conditions.

Summary

Sheet metal welding is an important part of CNC machining parts manufacturing. Choosing the right welding method and technique is essential to ensure welding quality and efficiency. This article introduces six common sheet metal welding methods, types of metals used in welding, surface factors to consider when selecting a welding method, twelve tips for welding sheet metal, and the advantages of VMT as a custom sheet metal welding partner. I hope these contents can help readers better understand and apply sheet metal welding technology and provide strong support for CNC machining parts manufacturing.