15 years one-stop China custom CNC machining parts factory

122 |

Published by VMT at Jul 17 2024

122 |

Published by VMT at Jul 17 2024

In the field of CNC machining part manufacturing, corrosion resistance is a key factor in determining the quality and longevity of parts. To meet the requirements for corrosion resistance in different application scenarios, it is crucial to select the appropriate metal materials and post-treatment techniques. This article will discuss 17 corrosion-resistant options for parts from the perspective of common corrosion-resistant metal materials and enhancing corrosion resistance through post-treatment, and will address common questions about corrosion-resistant materials.

Stainless Steel

What is Stainless Steel?

Stainless steel is a group of alloy steels known for their corrosion resistance, high-temperature resistance, and aesthetic appeal. Its corrosion resistance is mainly due to a dense chromium oxide passive layer formed on the surface of the steel. Stainless steel is widely used in aerospace, chemical, medical, and food processing industries.

Austenitic Stainless Steel

Austenitic stainless steel, also known as 300 series stainless steel, is the most common type of stainless steel. This type of stainless steel contains high levels of chromium and nickel, providing good corrosion resistance, toughness, and weldability. The most common grades are 304 and 316 stainless steel. 316 stainless steel has enhanced corrosion resistance due to the addition of molybdenum, making it particularly suitable for corrosive environments like seawater.

Martensitic Stainless Steel

Martensitic stainless steel, usually referred to as 400 series stainless steel (e.g., 420A), has high hardness and strength but relatively lower corrosion resistance. These steels do not contain nickel and have higher carbon content, making them suitable for applications requiring high strength and wear resistance.

Ferritic Stainless Steel

Ferritic stainless steel, also part of the 400 series (e.g., 430A), has high chromium content (up to 27%) to enhance corrosion resistance but low carbon content to improve toughness. Ferritic stainless steel is suitable for applications requiring moderate corrosion resistance and good toughness.

What is Duplex Stainless Steel?

Duplex stainless steel is a special type of stainless steel containing both ferritic and austenitic microstructures. It combines the corrosion resistance of ferritic stainless steel with the toughness of austenitic stainless steel, offering excellent mechanical properties and corrosion resistance. Typical duplex stainless steel grades include 2205 (22% chromium, 5% nickel, and 3% molybdenum) and S32750 (25% chromium, 7% nickel, and 4% molybdenum), widely used in harsh environments such as the oil and gas industry.

High-Temperature Alloys

What are High-Temperature Alloys?

High-temperature alloys are a group of materials that maintain excellent mechanical properties and corrosion resistance in high-temperature environments. They are widely used in aerospace and energy industries.

Nickel-Based High-Temperature Alloys

Nickel-based high-temperature alloys have high strength and excellent corrosion resistance, making them the most common type of high-temperature alloys. They are typically cheaper and have good machinability compared to cobalt-based high-temperature alloys.

Cobalt-Based High-Temperature Alloys

Cobalt-based high-temperature alloys have higher melting points and excellent thermal corrosion resistance, making them suitable for extreme high-temperature environments. However, their high cost limits widespread use.

Iron-Based High-Temperature Alloys

Iron-based high-temperature alloys offer high strength and corrosion resistance at room temperature and are cost-effective, suitable for high-temperature applications with cost considerations.

What is Aluminum?

Aluminum is a lightweight, corrosion-resistant metal widely used in aerospace, automotive, and construction industries. Its surface forms a dense aluminum oxide passive layer, protecting it from corrosion.

1xxx Series

The 1xxx series aluminum has high purity (99%+), providing optimal corrosion resistance, suitable for most general applications.

3xxx Series

The 3xxx series aluminum, with manganese as the primary alloying element, has similar corrosion resistance to the 1xxx series but higher strength.

5xxx Series

The 5xxx series aluminum, with magnesium as the primary alloying element, offers excellent corrosion resistance and good machinability, particularly suitable for welding applications.

What are Copper Alloys?

Copper alloys are a group of alloys with copper as the base, combined with other elements. They offer good electrical and thermal conductivity and corrosion resistance.

Bronze

Bronze is a copper-tin alloy with good corrosion resistance, especially suitable for applications involving seawater contact. Adding small amounts of silicon can further enhance its corrosion resistance.

Brass

Brass is a copper-zinc alloy with good machinability and electrical conductivity. Adding small amounts of tin improves its corrosion resistance, though increasing zinc content reduces corrosion resistance.

What is Titanium?

Titanium is a lightweight, high-strength metal with excellent corrosion resistance and biocompatibility. Its corrosion resistance comes from a passive oxide layer that forms on its surface, which can quickly regenerate in the presence of oxygen or moisture. Titanium is widely used in aerospace, medical, and petrochemical industries.

When selecting corrosion-resistant materials, cost is an important consideration. High-performance materials like titanium alloys and stainless steel offer excellent corrosion resistance and mechanical properties, but they are relatively expensive. For non-critical parts or cost-sensitive applications, lower-cost materials such as aluminum and brass can be chosen. However, it is important to note that cost considerations should include not only the material itself but also processing difficulty, maintenance costs, and total long-term costs. For example, although the initial investment for stainless steel might be higher, its superior corrosion resistance and long lifespan can significantly reduce maintenance and replacement frequency, thus saving costs in the long run.

Additionally, material selection should be based on specific application scenarios and performance requirements. In some extreme environments, such as high temperatures, high pressures, or highly corrosive media, choosing slightly more expensive but better-performing materials might be more economically reasonable. Therefore, a comprehensive cost-benefit analysis is crucial before making decisions.

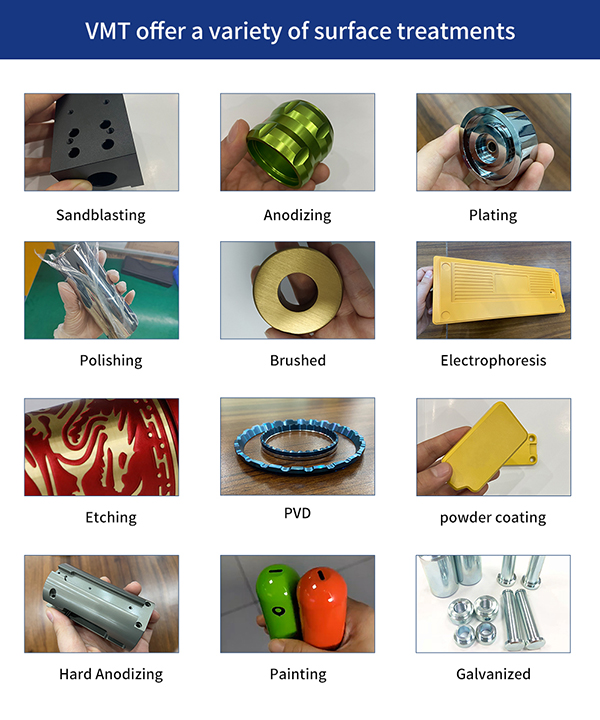

In addition to selecting appropriate corrosion-resistant metal materials, post-treatment techniques can significantly enhance the corrosion resistance of parts. Here are some common post-treatment methods:

Anodizing

Anodizing is an electrochemical process that forms a dense oxide layer on the metal surface. For aluminum and its alloys, anodizing greatly enhances corrosion resistance and wear resistance. This oxide layer is not only hard and corrosion-resistant but can also be colored to enhance aesthetics.

Painting

Painting is a simple and effective anti-corrosion method. By applying one or more layers of anti-corrosion paint to the part surface, direct contact between the metal and the environment is prevented, thereby preventing corrosion. Different types of anti-corrosion paints have varying levels of corrosion resistance, making the selection of appropriate paint crucial for improving the part's corrosion resistance.

Electroplating

Electroplating deposits a thin metal or alloy layer on the metal surface. This forms a uniform, dense protective layer, enhancing corrosion resistance and wear resistance. Common electroplating materials include chromium, nickel, and zinc. The electroplated layer protects the base metal from corrosion and improves the part's appearance and surface properties.

Surface Polishing

Surface polishing does not directly improve corrosion resistance but by removing surface roughness and defects, it reduces the attachment and penetration of corrosive media, indirectly enhancing corrosion resistance. Additionally, a smooth surface is easier to apply subsequent anti-corrosion treatments.

In CNC machining part manufacturing, selecting appropriate corrosion-resistant metal materials and post-treatment techniques is crucial for ensuring part quality and longevity. From stainless steel, duplex stainless steel, high-temperature alloys to aluminum, copper alloys, and titanium, each material offers unique corrosion resistance and suitability for various applications. Additionally, post-treatment techniques such as anodizing, painting, electroplating, and surface polishing can further enhance part corrosion resistance. When choosing materials and post-treatment methods, it is important to consider cost, performance requirements, and application scenarios comprehensively to achieve optimal economic benefits and usage effects.

What is the best corrosion-resistant coating?

There is no single "best" corrosion-resistant coating as the optimal choice depends on specific application scenarios, environmental conditions, and performance requirements. For example, in marine environments, zinc or aluminum coatings might be more effective, whereas high-temperature environments may require coatings with high-temperature stability.

What is the most corrosion-resistant material?

The most corrosion-resistant material depends on the specific application scenario. In some extremely corrosive environments, such as strong acid or strong alkaline solutions, titanium alloys may offer the best corrosion resistance. However, in other environments, such as marine or chloride environments, stainless steel or duplex stainless steel might be more suitable.

Which materials are corrosion-resistant?

Several materials offer good corrosion resistance, including but not limited to stainless steel (austenitic, martensitic, ferritic, duplex stainless steel), high-temperature alloys (nickel-based, cobalt-based, iron-based), aluminum and its alloys, copper alloys (bronze, brass), and titanium. The choice of material depends on the specific application needs and environmental conditions.

Understanding the corrosion resistance properties of different materials and how to enhance corrosion resistance through post-treatment techniques is crucial in CNC machining part manufacturing. This knowledge helps produce more reliable and durable parts, meeting the demands of various complex and harsh environments.