15 years one-stop China custom CNC machining parts factory

296 |

Published by VMT at May 29 2025 | Reading Time:About 8 minutes

296 |

Published by VMT at May 29 2025 | Reading Time:About 8 minutes

Are you trying to decide which metal fabrication process best suits your production needs? With so many available options—each offering different capabilities—it’s easy to feel overwhelmed or make the wrong decision. Using the wrong process can lead to quality issues, higher costs, or even complete production failure.

But don’t worry. Once you understand the different types of metal fabrication processes, their advantages, limitations, and common applications, you’ll be able to make an informed decision that ensures efficiency, durability, and cost-effectiveness.

This guide breaks down each metal fabrication method, including casting, cutting, welding, forming, machining, and more—clearly and simply.

Metal fabrication processes include casting, cutting, forming, welding, machining, and stamping. Each process is chosen based on material type, part geometry, and production volume. CNC machining services and sheet metal fabrication are among the most common approaches for producing precise, durable, and cost-effective metal CNC machining parts.

Understanding the types of metal fabrication processes is essential for manufacturers, engineers, and buyers seeking durable and functional metal parts. Whether you're looking for large structural components or fine precision metal CNC machining parts, this guide will help you explore the right manufacturing method and understand why CNC machining factories and fabrication shops choose one process over another.

Key Points

Metal fabrication is a broad term that refers to the process of shaping, cutting, forming, and assembling metal into functional parts or structures. It combines various processes—each with unique equipment, tools, and skills—to turn raw metal into final products or components. In modern industries, metal fabrication often overlaps with metal CNC machining manufacturing, especially when high precision or complex geometries are required.

Choosing the right metal fabrication process depends on three main factors:

Below, we explore each method to help you match your needs with the right process.

Metal fabrication is not a single operation but a combination of several manufacturing processes. These methods transform raw materials—usually sheet metal or bar stock—into functional parts or end-use products. Each process is selected based on material type, thickness, desired geometry, production volume, and performance requirements. Whether you’re fabricating architectural frames or precise metal CNC machining parts, understanding each process ensures better design decisions, smoother production, and superior outcomes. Below is a breakdown of the most commonly used fabrication processes in modern metalworking.

Casting is one of the oldest fabrication methods, used to create complex or bulky shapes by pouring molten metal into a mold. Once cooled and solidified, the metal takes the shape of the cavity. Casting is ideal for manufacturing intricate geometries that are otherwise difficult or impossible to machine. It’s commonly used for components in the automotive, aerospace, and heavy machinery sectors. While casting can offer cost-efficiency for large production runs, it may require secondary processes like machining or finishing to meet tight tolerances.

Cutting

Cutting is typically the first step in sheet metal fabrication and is used to reduce large metal sheets or bars into manageable sizes or pre-defined shapes. The method chosen depends on the material thickness, required precision, and speed. Whether you’re preparing a flat pattern or cutting out complex geometries, cutting forms the foundation for subsequent forming, welding, or assembly operations. Common technologies include laser cutting, waterjet cutting, plasma cutting, and mechanical shearing.

Cutting: Types

There are several cutting techniques, each with specific benefits and ideal use cases. Choosing the right method can significantly impact the quality, cost, and production time of your metal fabrication project.

Water jet Cutting

Waterjet cutting uses a high-pressure jet of water mixed with abrasive particles to slice through metal without generating heat. This cold-cutting method preserves material integrity, making it suitable for heat-sensitive metals like titanium and hardened steel. It offers excellent precision and is widely used in aerospace and medical industries for complex and delicate parts.

Laser cutting is a high-speed, high-precision method that uses a focused laser beam to melt, burn, or vaporize material. It’s ideal for sheet metal fabrication projects requiring clean edges and intricate shapes. CNC machining factories favor laser cutting for its automation capabilities and its ability to handle stainless steel, carbon steel, and aluminum with minimal material waste.

Plasma Cutting

Plasma cutting utilizes a high-velocity jet of ionized gas (plasma) to conduct electricity and cut through electrically conductive materials like steel, aluminum, and brass. It’s faster than waterjet and suitable for cutting thick sheets with less focus on edge quality. Commonly used in construction, automotive, and repair work.

Torches

Oxy-fuel torches are a manual cutting solution where fuel gases and oxygen are used to generate a flame hot enough to melt and cut through metals. While slower and less precise than CNC-based methods, torch cutting is still used for simple, on-site operations, particularly in construction and maintenance.

Mechanical Cutters

Mechanical cutting includes guillotine shears, band saws, and punches. These tools physically separate metal using force, offering a cost-effective option for simple shapes and high-throughput environments. Mechanical cutting is frequently used in mass-production sheet metal fabrication for its speed and efficiency.

Punching is a method that uses a punch press to force a tool through metal, creating holes or cutouts. This process is especially efficient for repetitive patterns in thin sheet metals and is commonly used in creating brackets, enclosures, and panels. Punching can be automated and integrated with CNC technology for better consistency and precision.

Painting

Painting serves both functional and aesthetic purposes in metal fabrication. It protects metal surfaces from corrosion and environmental wear while also offering a customizable look. Industrial paints are chosen based on the application—powder coatings, primers, or high-durability finishes for outdoor or high-wear environments. Painting is often the final step after machining, cutting, or forming.

Drawing

Drawing makes use of tensile force in pulling metal through and inside tapered dies. This die transforms the metal to take a thinner shape by stretching it. You can draw at room temperature in a process called cold drawing. However, you can heat the workpiece to help in reducing the necessary force.

The process is also deep drawing whenever the depth of the final product is higher than or equal to its radius. Most times, it uses a suitable die setup to transform blank sheets into vessels having a box or cylindrical shape.

Bending reshapes flat metal sheets into angles or curves without removing material. It’s performed using press brakes or rolling machines and is fundamental in producing housings, frames, and enclosures. Bending must account for material type, thickness, and bend radius to avoid cracking or deformation. In sheet metal fabrication, bending is a core operation for customizing part geometry and achieving assembly-ready components.

Welding in Metal Fabrication: What Are the Different Types and How Are They Used?

Welding is a core process in metal fabrication that involves joining two or more metal parts by applying heat, pressure, or both. It’s crucial in everything from structural steelwork to precision assembly in metal CNC machining manufacturing. The choice of welding method depends on the material, joint configuration, performance requirements, and the intended application. In sheet metal fabrication, welding ensures that individual components become strong, unified structures, making it essential in industries like aerospace, automotive, construction, and more.

Whether you are manufacturing metal CNC machining parts or large-scale industrial frameworks, selecting the right welding technique impacts structural integrity, aesthetics, cost, and production time.

Different Types of Welding in Metal Fabrication

Fusion Welding

Fusion welding is one of the most common methods and involves melting the base metals to form a joint, with or without filler material. It’s widely used in CNC machining factories for everything from lightweight enclosures to heavy-duty equipment parts. Techniques under this category include arc welding, MIG, TIG, and plasma arc welding.

Solid-State Welding

Unlike fusion welding, solid-state welding joins metals without melting them. Instead, pressure, vibration, or diffusion bonds the materials at the molecular level. This method is ideal for high-precision applications where minimal distortion and clean joints are necessary, such as in aerospace and medical devices.

Manual Metal Arc Welding (SMAW)

Also known as stick welding, SMAW uses a consumable electrode coated with flux to create an arc between the electrode and the workpiece. It is a versatile, cost-effective method suitable for outdoor and heavy-duty fabrication tasks. While it's not commonly used in precision metal CNC machining parts, it remains indispensable in construction and structural applications.

Oxyacetylene Welding (OA)

This classic gas welding method uses a flame generated from burning oxygen and acetylene. It's ideal for cutting, brazing, and welding thin materials, particularly in maintenance and repair work. OA welding is still relevant for its portability and control in low-volume or prototype production runs.

Tungsten Inert Gas Welding (TIG)

TIG welding uses a non-consumable tungsten electrode and a separate filler material. It provides a clean, precise weld and is favored in industries requiring high aesthetic quality and fine detailing, such as CNC machining services for medical and electronic enclosures. TIG is ideal for thin materials like aluminum and stainless steel.

Gas Metal Arc Welding (MIG)

MIG welding uses a continuously fed wire as an electrode and shielding gas to protect the weld. It is fast, easy to automate, and suitable for medium to thick metals, making it popular in sheet metal fabrication and metal CNC machining manufacturing. MIG is often used for automotive frames, appliances, and general industrial parts.

Brazing

While technically different from welding, brazing joins metals by melting a filler metal that flows into the joint through capillary action. The base metals do not melt. Brazing is ideal for joining dissimilar metals and is used in plumbing, HVAC, and lightweight metal fabrication where mechanical strength without melting the workpieces is critical.

Flux-Cored Arc Welding (FCAW)

FCAW is similar to MIG welding but uses a tubular wire filled with flux. It can be used with or without shielding gas, making it suitable for outdoor and high-volume production environments. It’s commonly used in heavy sheet metal Machining and shipbuilding.

Plasma Arc Welding

This advanced process is a refinement of TIG welding, producing higher temperatures and more precise welds. Plasma arc welding is used in critical applications such as aerospace components and precision assemblies, often overlapping with high-end CNC machining services.

Submerged Arc Welding (SAW)

SAW involves a continuously fed electrode and a blanket of granular flux that covers the arc. This method minimizes spatter and enhances weld quality. It’s highly efficient for large, heavy welds in thick materials such as structural beams and industrial tanks.

Laser Beam Welding (LBW)

LBW uses a concentrated laser beam to melt and fuse materials. This high-precision, low-distortion method is excellent for metal CNC machining parts requiring clean, deep, and narrow welds. Laser welding is often used in electronics, medical devices, and precision automotive components.

What Is Forging in Metal Fabrication and When Should It Be Used?

Forging is one of the oldest and most reliable types of metal fabrication processes used in the manufacturing industry. It involves shaping metal using compressive forces, typically with a hammer or die. The process improves the internal structure of metals, enhances their strength, and increases fatigue resistance—making it especially valuable in industries such as aerospace, automotive, energy, and heavy machinery.

Forging is ideal for creating parts that require high strength, such as crankshafts, gears, and aerospace components. Unlike cutting or machining, forging does not remove material; it reconfigures it, resulting in minimal waste and superior mechanical properties. This is a significant advantage when working with expensive alloys or when producing components for safety-critical applications.

There are several types of forging used in metal CNC machining manufacturing, including open-die forging, closed-die forging (also known as impression-die forging), and seamless rolled ring forging. The method selected depends on part complexity, volume, and performance requirements.

While sheet metal fabrication often uses cutting and welding to form shapes, forging is about reshaping the entire internal grain structure of the metal, offering unmatched strength and durability. Forged parts often go through CNC machining services after forging to achieve final dimensional accuracy and surface finish, combining strength with precision.

What Is Extrusion in Metal Fabrication and Why Is It Important?

Extrusion is a metal fabrication process where a metal billet is forced through a die to create a continuous shape with a fixed cross-section. This method is commonly used to produce parts with uniform profiles such as rods, tubes, rails, and frames. In industries like construction, automotive, and electronics, extrusion is vital for manufacturing both structural and decorative components.

Extrusion offers several advantages: it allows for complex cross-sectional designs, delivers high production volumes, and minimizes waste. Metals commonly used in extrusion include aluminum, copper, brass, and magnesium—all of which are also prominent in sheet metal Machining and metal CNC machining parts. The choice of material affects the strength, corrosion resistance, and weight of the final product.

There are two main types of metal extrusion:

Extruded components often undergo secondary processes, such as CNC machining, cutting, or surface finishing, to achieve exact dimensions and performance characteristics. As part of a complete CNC machining services offering, extrusion allows manufacturers to produce high-quality components at scale, cost-effectively and with design flexibility.

What Is Machining in Metal Fabrication?

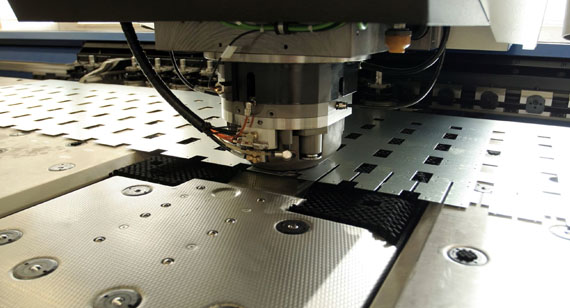

CNC Machining is a subtractive manufacturing process widely used in metal fabrication to create precision components by removing material from a workpiece using cutting tools. It plays a central role in metal CNC machining manufacturing, enabling the production of highly accurate and intricately shaped parts. Common in industries like aerospace, medical devices, and automotive, machining ensures components meet tight tolerances and strict surface finish requirements.

Unlike sheet metal fabrication, which shapes and joins thin materials, machining typically works with solid metal blocks. These are gradually cut and refined using high-speed rotary tools, drills, and lathes. CNC machining services have elevated this process by automating operations for improved repeatability, consistency, and efficiency.

Machining is ideal for metal CNC machining parts where precision is critical—such as engine components, gears, and medical implants. It is commonly used as a finishing step after casting, forging, or extrusion to fine-tune the geometry of a part.

The machining process encompasses several core operations, each suited to specific fabrication requirements. Understanding these helps engineers choose the right method based on part design, material, and functionality.

Each operation plays a unique role in metal CNC machining manufacturing, and many parts require a combination of these to reach their final form.

Types of Milling Operations in Metal Fabrication

Milling is one of the most diverse operations within CNC machining services, allowing for both simple and intricate geometries. Understanding the various types of milling operations can help manufacturers improve productivity and precision in metal fabrication.

Others: Includes slot milling, profile milling, and high-speed machining—all tailored for different design needs in metal CNC machining manufacturing.

What Is Metal Stamping in Fabrication?

Metal stamping is a process where flat sheet metal fabrication blanks are fed into a stamping press and shaped using a tool and die. This method is ideal for high-volume production of parts such as brackets, covers, and fasteners. Stamping operations include punching, embossing, coining, and bending.

It offers high repeatability and is cost-effective for mass production, especially when paired with automation. Although less flexible than CNC machining services, stamping excels in speed and cost for standardized parts with consistent geometry.

What Is Shearing in Metal Fabrication?

Shearing is a sheet metal fabrication technique used to cut straight lines on flat metal stock without melting or burning the material. It uses a blade to apply force perpendicular to the material, causing it to shear and separate. This process is quick, clean, and ideal for cutting large sheets into smaller, manageable sizes before secondary operations like machining or forming.

Shearing is commonly applied to aluminum, carbon steel, and stainless steel sheets. It creates clean edges with minimal burrs, reducing the need for post-Machining. It's often used in preparation for stamping, welding, or forming operations.

What Is Forming in Metal Fabrication?

Forming is a group of manufacturing processes that reshape metal fabrication materials without removing material. This includes bending, stretching, rolling, and pressing operations that permanently alter the shape of metal sheets or components.

Forming is essential in sheet metal fabrication, allowing flat materials to be transformed into structural or decorative parts. Techniques like roll forming and press brake forming are used to create U-channels, angles, and other profiles. Forming is usually employed before finishing and assembly and may be combined with CNC machining for tighter tolerances or added features.

Here's a clear, concise, and easy-to-understand table summarizing "Metal Fabrication: The Process", covering key processes used across metal fabrication, including sheet metal fabrication, metal CNC machining manufacturing, and other related operations.

| Process |

Description |

Applications |

| Casting |

Pouring molten metal into a mold to form complex shapes. | Engine blocks, complex machinery components. |

| Cutting |

Separating metal into desired shapes using various methods. | Prepares metal for further Machining in sheet metal fabrication or CNC machining services. |

| Punching |

Using a punch press to create holes or shapes in metal sheets. | Brackets, panels, enclosures. |

| Painting |

Applying a protective or decorative coating on metal surfaces. | Automotive bodies, appliances, and consumer goods. |

| Bending |

Deforming metal along a straight axis without changing its volume. | Sheet metal boxes, brackets, structural parts. |

| Welding |

Joining metals using heat, pressure, or filler materials. | Frames, structural supports, pipelines. |

| Forging |

Shaping metal using localized compressive forces, often with a hammer or die. | Tools, hardware, automotive parts. |

| Extrusion |

Forcing metal through a die to create long objects with a fixed cross-sectional profile. | Pipes, tubes, and structural bars. |

| Machining |

Removing material to achieve a precise geometry using machines. | Metal CNC machining parts in aerospace, electronics, and precision tooling. |

| Metal Stamping |

Forming metal into desired shapes using a die and press. | Automotive parts, tags, covers. |

| Shearing |

Cutting metal along a straight line, typically with a shear blade. | Trimming sheet metal to size before forming or welding. |

| Forming |

Shaping metal without removing material through methods like rolling or spinning. | Kitchenware, car parts, industrial components. |

Choosing the right material is a critical step in the metal fabrication process. The material selected directly impacts the performance, durability, cost, and overall manufacturability of the final product. Whether you are performing sheet metal fabrication or creating metal CNC machining parts, the base material determines factors such as corrosion resistance, strength, weight, and machinability. Below are the most commonly used metals in metal CNC machining manufacturing and fabrication processes.

Carbon Steel

Carbon steel is one of the most widely used materials in metal fabrication due to its affordability, strength, and ease of welding and forming. It’s ideal for structural applications, automotive parts, and construction projects. Available in various grades (low, medium, and high carbon), it can be tailored to meet specific strength and hardness requirements. It’s commonly used in CNC machining factories for robust, load-bearing components.

Aluminum is a lightweight, corrosion-resistant metal that is easy to machine and highly conductive. It’s frequently used in sheet metal fabrication and metal CNC machining parts for industries like aerospace, electronics, and transportation. Its high strength-to-weight ratio makes it an excellent choice for applications where both durability and low weight are essential. CNC machining aluminum yields precision parts with excellent surface finishes, ideal for high-performance components.

Bronze

Bronze, an alloy of copper and tin, is known for its excellent wear resistance and low friction properties. It’s often used in the production of bushings, bearings, and marine hardware. Bronze is particularly valuable in metal CNC machining manufacturing where its smooth machinability and resistance to corrosion are essential for creating durable, moving parts in industrial applications.

Brass Alloys

Brass, a copper-zinc alloy, is appreciated for its attractive appearance, corrosion resistance, and ease of machining. It’s often used in decorative applications, plumbing fittings, and musical instruments. CNC machining services frequently utilize brass due to its low friction properties and precision compatibility, making it suitable for high-end metal CNC machining parts that require both aesthetics and function.

Stainless Steel

Stainless steel is a staple in both sheet metal fabrication and CNC machining services due to its strength, corrosion resistance, and hygienic properties. It’s widely used in medical, food Machining, and chemical industries. Available in multiple grades (like 304 and 316), stainless steel is more difficult to machine than aluminum or brass, but its durability and resistance to rust make it a top choice for critical applications.

Copper

Copper is valued for its excellent electrical and thermal conductivity. It’s frequently used in electrical applications, wiring, and heat exchangers. Although it is soft and requires care during CNC machining, it produces highly precise parts when handled correctly. CNC machining factories working on electronic components or custom industrial parts often choose copper for its functional benefits.

Structural Steel

Structural steel includes various carbon steel shapes like I-beams, channels, and angles, designed to carry loads and provide structural integrity. It’s essential in construction, infrastructure, and large industrial equipment. This material is typically fabricated using sheet metal Machining methods like welding, cutting, and bending, and is sometimes refined using CNC machining services for holes, slots, or notches.

Titanium

Titanium is a premium metal used in high-performance industries such as aerospace, medical, and defense. It offers exceptional strength, corrosion resistance, and biocompatibility while being lighter than steel. Although titanium is more challenging to machine, advanced CNC machining factories are equipped to handle this material, delivering precision parts for mission-critical applications. Titanium’s superior performance characteristics make it a go-to material in specialized metal CNC machining manufacturing.

Below is a clear, professional, and easy-to-read table summarizing the Common Materials Used in Metal Fabrication. This table supports industries involved in sheet metal fabrication, metal CNC machining manufacturing, and those seeking reliable materials for CNC machining services and metal CNC machining parts production.

Table: Common Materials Used in Metal Fabrication

| Material |

Properties |

Typical Applications |

| Carbon Steel |

Strong, affordable, easy to weld and form. Available in low, medium, and high carbon grades. | Structural components, automotive frames, industrial equipment. |

| Aluminum |

Lightweight, corrosion-resistant, excellent thermal/electrical conductivity, easy to machine. | Aerospace parts, electronics housings, consumer products, CNC machining parts. |

| Bronze |

Good wear resistance, low friction, strong corrosion resistance. | Bearings, bushings, marine hardware. |

| Brass Alloys |

Aesthetic appeal, corrosion-resistant, excellent machinability. | Plumbing fittings, decorative parts, CNC machining services for luxury components. |

| Stainless Steel |

Highly durable, corrosion-resistant, hygienic, versatile across many grades. | Medical instruments, kitchenware, chemical tanks, sheet metal fabrication components. |

| Copper |

Exceptional conductivity, antimicrobial, malleable, corrosion-resistant. | Electrical parts, heat exchangers, electronic connectors. |

| Structural Steel |

Standardized shapes (I-beams, channels), great strength for load-bearing. | Building frames, industrial platforms, bridges. |

| Titanium |

High strength-to-weight ratio, corrosion-resistant, biocompatible, challenging to machine. | Aerospace, medical implants, military parts — often produced in metal CNC machining manufacturing. |

This material selection table is especially useful for engineers, buyers, and manufacturers determining the best material for their metal fabrication needs. Each material aligns with different project requirements, including precision, durability, conductivity, or weight, depending on the part’s function and operating environment.

In modern metal fabrication, technology plays a critical role in improving speed, precision, and production flexibility. From traditional operations to advanced digital integration, manufacturers now rely heavily on intelligent tools and systems to meet the complex demands of today's industries. Whether you're engaged in sheet metal fabrication or producing high-tolerance metal CNC machining parts, the right technologies are essential to optimize efficiency and ensure consistent quality. These technologies not only help minimize material waste and human error, but also reduce turnaround time, leading to faster delivery cycles and lower overall production costs. Let's explore the key technologies transforming how metal fabrication is performed across industries.

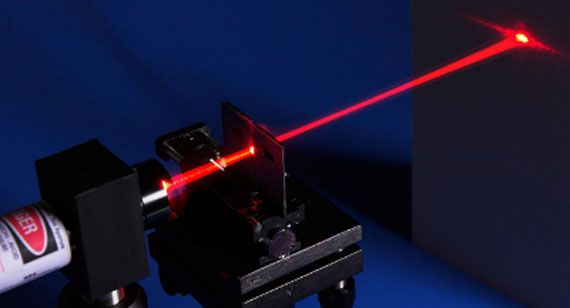

Laser Technology

Laser technology has revolutionized the field of metal fabrication with its ability to deliver fast, precise, and clean cuts across a wide range of materials. Laser cutting machines use a concentrated beam of light to slice through metals like carbon steel, aluminum, brass, and stainless steel with extreme accuracy. This non-contact cutting method ensures minimal material deformation and is ideal for intricate shapes, small holes, or detailed patterns in sheet metal Machining. In addition to cutting, laser technology is also used for engraving, marking, and welding applications. Due to its high efficiency and precision, it's a popular choice in CNC machining factories and custom fabrication shops alike. Laser systems often integrate with CAD/CAM software, further increasing automation and reducing lead times. Whether for prototyping or high-volume production, laser cutting enables cleaner edges and less post-Machining, which helps reduce manufacturing costs.

CAD Software

Computer-Aided Design (CAD) software is the digital backbone of modern metal fabrication. CAD allows engineers and designers to create accurate 2D and 3D models of parts before production begins, ensuring optimal design validation, functionality, and manufacturability. With CAD, fabrication professionals can simulate machining processes, visualize assembly fits, and detect potential flaws before any material is cut. In CNC machining services, CAD files are directly translated into machine code (via CAM software), enabling seamless, automated production. This results in fewer errors, better use of materials, and highly repeatable outcomes. CAD is especially crucial in metal CNC machining manufacturing, where tolerances and specifications are tight. The software supports fast design changes and prototyping, empowering clients to move from concept to production quickly. For companies looking to reduce development time and costs, integrating CAD software into the fabrication workflow is no longer optional—it's essential.

Plasma Cutting

Plasma cutting is a highly effective technology used in metal fabrication processes to cut through thick or conductive metals with speed and precision. The process involves directing a high-velocity jet of ionized gas (plasma) at the workpiece, which melts the material and blows away the molten metal to create a clean cut. Unlike laser cutting, plasma is particularly suited for thicker metals and heavier industrial tasks. It’s commonly used in sheet metal fabrication when cutting structural steel, stainless steel, or aluminum plates. Portable and cost-effective, plasma cutting systems are widely adopted in both small job shops and large-scale CNC machining factories. With advancements in CNC-integrated plasma cutters, the accuracy and repeatability of cuts have dramatically improved. Additionally, plasma cutting offers fast turnaround, making it ideal for time-sensitive fabrication projects.

Automation

Automation is at the heart of next-generation metal fabrication. It encompasses everything from robotic welding arms and material handling systems to fully integrated production lines controlled by smart software. The goal of automation is to increase productivity, ensure consistency, reduce labor costs, and eliminate human error. In CNC machining services, automated machines can run continuously with minimal supervision, dramatically improving throughput and reducing downtime. Automation also improves safety by removing operators from hazardous tasks such as heavy lifting, high-temperature welding, or sharp material cutting. Integrated sensors and monitoring systems ensure quality control in real-time, allowing for immediate adjustments and reduced scrap. As a result, metal CNC machining parts produced in automated environments offer superior quality and uniformity. For manufacturers dealing with large volumes or repetitive tasks, investing in automation is key to remaining competitive in the global market.

Metal fabrication is an essential process in the manufacturing world, shaping everything from small electronics housings to large construction structures. But like any industrial process, it has its pros and cons. Whether you are choosing sheet metal fabrication, metal CNC machining manufacturing, or a hybrid approach, understanding the advantages and disadvantages will help you select the right method for your specific needs. This section highlights the most critical aspects that decision-makers should consider when investing in metal fabrication services or choosing a reliable CNC machining factory. It’s all about finding the best balance between cost, performance, design flexibility, and production time.

Advantages of Metal Fabrication

Versatility

One of the biggest strengths of metal fabrication is its remarkable versatility. From creating simple brackets to complex enclosures, metal can be formed, cut, bent, machined, and welded into nearly any shape. Modern technologies like CNC machining services, laser cutting, and robotic welding further expand the possibilities, allowing designers and engineers to bring intricate designs to life. This adaptability makes metal fabrication suitable for diverse industries such as aerospace, automotive, construction, and electronics.

Competitively Priced

Thanks to advancements in CNC machining factories and automation, metal fabrication has become highly cost-effective, especially for medium to high production volumes. Materials such as aluminum, carbon steel, and stainless steel are widely available and affordable. In many cases, sheet metal Machining can reduce both material waste and labor costs, improving the total cost of ownership for fabricated parts.

Easy to Maintain

Another advantage of fabricated metal parts is their durability and ease of maintenance. Fabricated components often require less upkeep over time due to their resistance to corrosion, wear, and environmental damage—especially when surface-treated with coatings like powder coating, anodizing, or painting. These qualities translate to longer service life and lower maintenance costs, making metal CNC machining parts a smart long-term investment.

Disadvantages of Metal Fabrication

Initial Cost May Be Higher

While metal fabrication is cost-effective for large runs, the initial setup—especially in CNC machining—can be expensive. Custom tooling, advanced machinery, and CAD/CAM programming require upfront investment. For prototypes or small batches, this can drive up the per-unit cost significantly compared to plastic manufacturing or 3D printing.

Longer Time

Certain metal fabrication processes may take longer due to multiple production steps—cutting, bending, welding, finishing, and quality inspection. If you're on a tight schedule, this could be a drawback, especially when compared to faster prototyping methods like injection molding or additive manufacturing.

More Finishing Operations

Unlike injection-molded plastics that can come out of molds with finished surfaces, most fabricated metal parts require additional finishing steps. Deburring, grinding, polishing, and painting not only add time but also increase labor costs. Without proper surface treatment, metals can also rust or degrade over time.

Design Constraints

While metal CNC machining manufacturing offers high precision, it still faces limitations in producing complex internal geometries or parts with thin, flexible sections. Some designs may need to be adjusted to suit fabrication capabilities. Additionally, joining methods like welding or fastening may impose structural or aesthetic limitations on the final product.

Here's a clear and professional comparison table summarizing the advantages and disadvantages of metal fabrication, written in a concise and easy-to-understand format:

Advantages and Disadvantages of Metal Fabrication

| Category |

Advantages |

Disadvantages |

| Versatility |

Easily adapted to produce a wide range of shapes and parts across various industries. | Some complex geometries may still be limited depending on the fabrication method used. |

| Cost |

Cost-effective for medium to high production volumes; raw materials are widely available and affordable. | High initial setup and tooling costs for small batch runs or custom parts. |

| Durability |

Fabricated metal parts are strong, wear-resistant, and have a long service life. | Without proper finishing (e.g., coating), metals can corrode or oxidize over time. |

| Maintenance |

Easy to maintain due to resistance to environmental and mechanical wear. | Maintenance may require specialized tools or knowledge depending on the part complexity. |

| Production Speed |

High throughput when processes are optimized with CNC machining and automation. | Some processes involve multiple steps (e.g., cutting, welding, finishing) which can slow production. |

| Surface Finish |

Can be enhanced with coatings like anodizing, powder coating, or painting. | Often requires additional finishing steps, which adds time and labor costs. |

| Design Flexibility |

Can be used with CAD/CAM systems for high-precision custom designs. | Certain designs may need to be adjusted to fit machining or forming limitations. |

Metal fabrication plays a crucial role across a wide range of industries, serving as the backbone for manufacturing complex components, structural parts, and durable equipment. Whether it’s through sheet metal fabrication, metal CNC machining manufacturing, or other specialized processes, metal fabrication enables the creation of precise, reliable, and high-performance products. Understanding the diverse applications helps businesses and engineers choose the right fabrication method and materials for their specific needs. Below, we explore some of the key industries where metal fabrication is indispensable.

Aerospace

In aerospace, metal fabrication is critical for producing aircraft frames, engine components, landing gear, and control surfaces. High strength-to-weight ratios, dimensional accuracy, and reliability are vital here, making CNC machining and advanced metal forming technologies indispensable for meeting strict safety and performance standards.

The automotive industry relies heavily on metal fabrication for manufacturing chassis parts, engine components, exhaust systems, and body panels. Processes like stamping, welding, and CNC machining ensure parts are durable, precise, and optimized for mass production, supporting everything from everyday vehicles to high-performance cars.

Construction

Metal fabrication supports the construction sector by providing steel beams, frames, cladding, and custom architectural components. These fabricated metal parts offer the necessary strength, flexibility, and corrosion resistance for building infrastructure ranging from commercial buildings to bridges and residential homes.

Shipbuilding

In shipbuilding, metal fabrication is essential for hull construction, decks, piping systems, and machinery mounts. The ability to work with heavy metals and large sheet metal sections while maintaining tight tolerances ensures that ships are seaworthy, safe, and built to withstand harsh marine environments.

Hardware Manufacturing

Metal fabrication enables the production of a wide range of hardware, including fasteners, hinges, brackets, and locks. Precision machining and forming techniques ensure these parts meet exact specifications for functionality and durability in consumer products and industrial equipment.

Mining

The mining industry uses fabricated metal parts for heavy-duty machinery, conveyor systems, structural supports, and wear-resistant components. Fabrication processes deliver rugged and reliable parts that can endure extreme operational conditions and abrasive environments.

Defense and Military

Military applications demand high-strength, reliable components such as armored vehicle parts, weapon systems, and communication equipment housings. Metal fabrication’s precision and material versatility make it ideal for meeting stringent military standards and complex design requirements.

Energy

Metal fabrication supports the energy sector by producing components for oil rigs, pipelines, wind turbines, and power plants. The ability to work with specialized metals and apply advanced coatings helps ensure durability and safety in energy infrastructure.

In electronics, metal fabrication is used for manufacturing housings, heat sinks, connectors, and precision parts. CNC machining services and sheet metal Machining ensure high-quality finishes and dimensional accuracy necessary for sensitive electronic assemblies.

Here's a clear and professional table summarizing the applications of metal fabrication across various industries:

| Industry |

Applications of Metal Fabrication |

| Aerospace |

Aircraft frames, engine components, landing gear, control surfaces requiring high strength, precision, and safety standards. |

| Automotive |

Chassis parts, engine components, exhaust systems, body panels produced via stamping, welding, and CNC machining for durability. |

| Construction |

Steel beams, frames, cladding, architectural components offering strength, corrosion resistance, and flexibility in infrastructure. |

| Shipbuilding |

Hulls, decks, piping systems, machinery mounts built with large metal sections maintaining tight tolerances for marine conditions. |

| Hardware Manufacturing |

Fasteners, hinges, brackets, locks requiring precise machining and forming for functionality and longevity in various products. |

| Mining |

Heavy machinery parts, conveyor systems, structural supports designed to endure abrasive and harsh operational environments. |

| Defense and Military |

Armored vehicle parts, weapon system components, communication equipment housings meeting stringent standards and complex designs. |

| Energy |

Oil rigs, pipelines, wind turbines, power plant components fabricated with specialized metals and coatings for durability. |

| Electronics |

Housings, heat sinks, connectors, precision parts requiring high-quality finishes and dimensional accuracy for sensitive devices. |

This table provides a quick overview to understand where metal fabrication processes like sheet metal fabrication, metal CNC machining manufacturing, and related services are most commonly applied.

Choosing the right metal fabricator is a critical decision that can significantly impact the quality, cost, and timeline of your manufacturing projects. Whether you require sheet metal fabrication, metal CNC machining parts, or complex assemblies, selecting a skilled and reliable fabricator ensures your product meets specifications and performs as expected. Here are the key factors to consider when choosing a metal fabricator:

1. Expertise and Capabilities

Evaluate the fabricator’s technical expertise and the range of metal fabrication processes they offer. A versatile fabricator should provide multiple services such as cutting, welding, machining, forming, and finishing. Check if they have experience with the specific materials and techniques your project requires, such as aluminum or stainless steel fabrication, CNC machining services, or advanced welding methods.

Quality is paramount in metal fabrication. Look for fabricators with robust quality control systems and industry certifications (e.g., ISO 9001). Ask about their inspection processes, testing equipment, and adherence to industry standards. A good fabricator will provide documentation to prove the quality and consistency of their work.

3. Technology and Equipment

Modern, well-maintained equipment is essential for precision and efficiency. Check if the fabricator uses up-to-date machinery like CNC machines, laser cutters, or automation technologies. Advanced equipment can improve turnaround times, reduce errors, and expand the range of parts they can produce.

4. Capacity and Lead Time

Consider the fabricator’s production capacity and how it aligns with your project size and timeline. Some fabricators specialize in small-batch or prototype work, while others excel in high-volume production. Confirm their ability to meet your deadlines without compromising quality.

5. Customer Service and Communication

Strong communication is vital throughout the fabrication process. Choose a fabricator who is responsive, transparent, and willing to collaborate. A good partner will provide clear quotes, regular updates, and be open to discussing design or process adjustments.

6. Cost and Value

While cost is important, it should not be the sole deciding factor. Focus on the overall value, which includes quality, reliability, and service. Sometimes paying slightly more upfront can save costs related to rework, delays, or poor-quality parts in the long run.

For businesses seeking dependable CNC machining factories or comprehensive metal fabrication services, considering these factors will guide you toward the best manufacturing partner.

In today’s competitive manufacturing landscape, finding a reliable partner for metal fabrication and metal CNC machining manufacturing is essential to ensuring high-quality products and on-time delivery. VMT stands out as a premier provider of comprehensive metal fabrication Machining services, combining advanced technology, skilled craftsmanship, and customer-focused solutions to meet diverse industry needs.

Comprehensive Capabilities

VMT offers a full spectrum of metal fabrication services, including sheet metal fabrication, CNC machining, welding, cutting, bending, and finishing. Whether you require intricate CNC machining parts with tight tolerances or large-scale sheet metal assemblies, VMT’s expertise and state-of-the-art equipment ensure precision and consistency. Their service portfolio is designed to handle both prototyping and full production runs efficiently.

Advanced Technology and Equipment

At VMT, the integration of cutting-edge machinery and software guarantees superior quality and productivity. The company utilizes advanced CNC machines, laser cutting systems, waterjet cutters, and automated welding equipment to deliver accurate and repeatable results. Their investment in automation and CAD/CAM software enhances design accuracy and accelerates production timelines.

Quality Assurance and Compliance

Quality control is deeply embedded in VMT’s manufacturing process. With rigorous inspections at every stage, adherence to international standards, and continuous improvement initiatives, VMT ensures every product meets customer specifications and industry regulations. This commitment to excellence has earned them a reputation for reliability among clients across aerospace, automotive, electronics, and other demanding sectors.

Customer-Centric Approach

Understanding that every project has unique requirements, VMT prioritizes communication and collaboration. Their experienced team works closely with clients to provide tailored solutions that optimize cost, material use, and lead time. From initial design consultation to final delivery, VMT maintains transparency and responsiveness, fostering long-term partnerships.

Sustainability and Innovation

VMT is also committed to sustainable manufacturing practices, minimizing waste through efficient material utilization and adopting eco-friendly processes where possible. Their innovation-driven mindset encourages continuous adoption of new technologies to meet evolving market demands.

For companies seeking trusted CNC machining services and robust metal fabrication capabilities, VMT offers a reliable, high-quality solution. To explore more about specific fabrication processes and how VMT can support your projects, visit our pages on CNC Machining Operations and Sheet Metal Fabrication Processes.

Understanding the various types of metal fabrication processes and their applications is crucial for making informed decisions in manufacturing. Whether you choose sheet metal fabrication or metal CNC machining manufacturing, each method offers distinct advantages tailored to different design complexities, materials, and production volumes. CNC machining excels in producing high-precision, complex parts with excellent surface finishes, ideal for prototypes and low to medium volumes. In contrast, sheet metal fabrication offers cost-effective solutions for larger parts and higher production runs, focusing on efficiency and material utilization.

Choosing the right metal fabrication process depends on factors such as part geometry, material properties, and functional requirements. Modern technologies like laser cutting, CAD software, and automation have significantly improved both CNC machining and sheet metal fabrication, enhancing precision, speed, and scalability. However, each method carries inherent advantages and limitations, and understanding these will help optimize your production strategy.

At VMT, we combine advanced equipment, skilled craftsmanship, and customer-focused services to provide comprehensive metal fabrication and CNC machining solutions. By partnering with experienced fabricators, you can ensure your projects meet the highest standards of quality, cost-efficiency, and timely delivery.

To deepen your understanding of metal fabrication and explore how different processes can meet your specific needs, we invite you to explore our detailed articles on Metal Fabrication Processes, CNC Machining Services, and Sheet Metal Fabrication. Making the right choice today sets the foundation for manufacturing success tomorrow.

1. What is the difference between steel fabrication and metal fabrication?

Steel fabrication specifically refers to the process of cutting, shaping, and assembling steel materials into finished products or structures. Metal fabrication is a broader term that includes working with a variety of metals such as aluminum, copper, brass, stainless steel, and more, not just steel. Steel fabrication is a subset of metal fabrication, focused exclusively on steel.

2. What is the difference between fabrication and Machining?

Fabrication generally refers to the overall manufacturing steps that transform raw materials into finished products, including cutting, bending, welding, and assembling. Machining often describes specific operations within fabrication, such as machining or heat treating. Machining is part of the fabrication workflow.

3. What is the principle of fabrication?

The principle of fabrication is to convert raw metal materials into functional, precise parts or assemblies through various mechanical and chemical operations. This includes shaping, cutting, joining, and finishing, all while maintaining the required dimensional accuracy and structural integrity.

4. What tools are used in the metal fabrication process?

Common tools include CNC machines (milling, turning, drilling), cutting tools (laser cutters, plasma cutters, waterjet cutters), bending machines, welding equipment, grinders, shears, and stamping presses. Software tools like CAD/CAM systems are also crucial for design and process control.

5. Does fabrication also mean welding?

Welding is one of the many operations within the fabrication process. Fabrication includes welding, but also cutting, forming, machining, and finishing. Welding joins metal parts, which is essential for assembling components in many fabrication projects.

6. How is metal removed during metal cutting?

Metal removal during cutting occurs through mechanical or thermal methods. Mechanical cutting uses tools like saws or shears to physically separate material, while thermal cutting (such as laser or plasma cutting) uses intense heat to melt or burn through the metal.

7. How is metal fabrication different from steel fabrication?

Metal fabrication encompasses all types of metals, including steel, aluminum, brass, and others, involving various processes. Steel fabrication focuses exclusively on steel materials. Techniques may overlap, but steel fabrication often involves processes suited for steel’s unique properties.

8. What is the process of metal fabrication?

Metal fabrication includes steps such as designing, cutting, forming, assembling (welding or fastening), and finishing. Each stage transforms the raw material closer to the final product, ensuring it meets functional and dimensional requirements.

9. What are the basics of metal fabrication?

The basics include understanding the material properties, selecting appropriate fabrication methods (cutting, bending, welding), preparing designs, and maintaining quality control to produce parts that meet specifications.

10. What are the three types of metal fabrication?

The three primary types of metal fabrication are:

11. Which steel is best for fabrication?

Mild carbon steel (often referred to as “mild steel”) is the most commonly used steel for fabrication due to its excellent weldability, machinability, and cost-effectiveness. Stainless steel is preferred when corrosion resistance is critical. The choice depends on the application requirements such as strength, corrosion resistance, and finish.