15 years one-stop China custom CNC machining parts factory

0 |

Published by VMT at Jan 28 2026 | Reading Time:About 2 minutes

0 |

Published by VMT at Jan 28 2026 | Reading Time:About 2 minutes

In the market, whether you are sourcing raw materials for in-house machining or outsourcing part production to a manufacturing partner, it is rare to purchase "pure" 6061 aluminum (in its annealed or un-strengthened state). This is because the machinability, strength, and dimensional stability of untreated 6061 fail to meet the fundamental requirements of industrial manufacturing.

Almost invariably, 6061 aluminum is sold in tempered forms, most notably T6. And in the world of manufacturing and engineering, few materials are as ubiquitous and versatile as 6061 T6 aluminum. From high-end mountain bike frames and structural components of commercial aircraft to precision-machined electronics housings, what you are likely seeing is 6061-T6. After all, it represents the highest strength form of the 6061 alloy while retaining excellent characteristics such as lightweight, corrosion resistance, ease of machining, and weldability—all complemented by the cost advantages of a massive global supply chain.

In this comprehensive guide, we will dive deep into 6061-T6 aluminum—the most widely used and popular supply state of the 6061 alloy—detailing its properties, applications, and manufacturability (including its performance in CNC machining, welding, and bending).

6061 T6 aluminum is a precipitation-hardened aluminum alloy (Heat-Treatable Alloys as defined by the Aluminum Association), containing magnesium and silicon as its major alloying elements. It is standardized under various international specifications, most notably ASTM B209 for plates and ASTM B221 for extrusions.

The "6061" designation identifies its chemical composition within the 6000 series (Al-Mg-Si alloys), while "T6" denotes its temper—specifically, that it has been solution heat-treated and artificially aged to achieve its maximum strength. For 6061-T6 aluminum alloy, it highlights the following key characteristics that:

The "T" (Temper) represents different heat treatments to 6061 aluminum, which alters its mechanical properties and manufacturability. Below table shows differences of 6061-T6 aluminum with annealed (O) and other tempers:

Table 1: Comparing 6061-T6 with Annealed (O) and Other Tempers

| Performance/ Temper |

6061-O |

6061-T4 |

6061-T6 |

6061-T651 |

6061-T6511 |

| Tensile Strength |

125 MPa | 207 MPa | 310 MPa | 310 MPa | 310 MPa |

| Yield Strength |

55 MPa | 97 MPa | 276 MPa | 276 MPa | 276 MPa |

| Hardness |

30 HB | 65 HB | 95 HB | 95 HB | 95 HB |

| Elongation |

25-30% | 20-22% | 12-17% | 12-17% | 10-15% |

| Heat Treatment Process |

Full Annealing (Heated to 415°C then slow cooled). | Solutionizing + Natural Aging (Solution treated then stabilized at room temp). | Solutionizing + Artificial Aging (Solution treated then artificially hardened around 160-175°C). | Solutionizing + Stress Relieving (Stretching) + Artificial Aging. | Solutionizing + Straightening (Minor) + Artificial Aging (Similar to T651, but for extruded forms). |

| Performance |

Excellent Formability. Ideal for deep drawing and severe bending. | Good strength and decent ductility;general uses consider ductility. | Versatility;Good for welding, and machining | Best for CNC Machining; Stress-relieved prevents distortion. | Excellent for bars and tubes used in automated production. |

| Cost |

Base material cost. | Mid-range cost. | Affordable cost; most widely available. | Higher price than T6 for a more stress relieving step | Comparable to T651. |

The choice of temper defines the manufacturing compatibility of your project:

6061-T6 aluminum has excellent machinability, producing easily broken chips and a high-quality surface finish. It is a suitable material for CNC machining made into all kinds of parts like bicycle components, electronic housings, and other common industrial structural parts.

CNC machining involves using semi-automated devices like mills, lathes, and routers to remove material from a solid block to create a precise part. CNC Machining 6061-T6 aluminum can benefit your products manufacturing:

When it comes to sheet metal fabrication, the primary concern is whether 6061 T6 aluminum is bendable. The short answer is: Yes, but with caution.

Besides bending, sheet metal fabrication also includes drawing, punching, laser cutting, and welding. 6061-T6 is highly compatible with laser cutting, punching, and welding. However, due to its high hardness and reduced ductility, it has limited formability for processes like tight radius bending and deep drawing, where surface cracking may occur.

That is, 6061-T6 aluminum alloy has acceptable formability, but it is prone to cracking when the bending radius is too small. If you attempt to successfully bend 6061-T6, you can consider:

Aluminum 6061-T6 is highly weldable using standard methods like TIG (GTAW) or MIG (GMAW). It is a favorite in structural fabrication because it doesn't crack easily during the cooling process.

One trade-off you may consider is T6 strength can be decreased after welding. When you weld 6061-T6 aluminum alloy, the intense heat acts as a localized "annealing" process. This creates a Heat Affected Zone (HAZ) around the weld where the T6 strength can drop by as much as 30-50%. To restore original strength, the entire part would need to be re-heat-treated, though for many applications, the remaining strength is still sufficient.

No. 6061 is a wrought alloy, meaning it is designed to be worked in a solid state (rolled, extruded, or forged). If you melt 6061 to cast it, you lose the chemical uniformity and grain structure that gives it its strength. For casting needs, engineers typically use A356 aluminum, which offers similar properties but is specifically designed for the foundry.

One of the greatest advantages of 6061-T6 is its compatibility with surface finishes, especially good for anodizing:

Anodizing (Type II -Clear or Color)

This is the most common treatment. 6061-T6 takes anodizing exceptionally well, offering a durable, corrosion-resistant, and aesthetically pleasing finish. Consumer electronics, bicycle frames, decorative trim, and CNC-machined enclosures made by 6061 T6 aluminum usually choose this surface finish.

It is similar to Type II but performed at lower temperatures with higher current density. This produces a much thicker and denser oxide layer and usually results in a dark grey or bronze matte finish. This finish process is good for parts requiring high wear resistance like firearm components, hydraulic cylinders, aerospace gears, and high-friction industrial machinery.

It is using dry powder (polyester or epoxy) is electrostatically sprayed onto the part and then cured under heat to form a "skin." A thick and uniform layer is formed for the parts, and it is available in any color and various textures (glossy, matte, sand-texture). It covers minor machining marks or surface scratches.

This is a chemical dip that creates a thin protective film through a reaction with the aluminum, which is much thinner than anodizing. It appears yellow or clear, and its main benefit is corrosion protection while maintaining electrical conductivity. It also serves as an excellent primer base for painting. Aerospace internal structures, electronic chassis (where grounding is needed), and telecommunications equipment can apply this finish process.

Available in rods, bars, plates, and extrusions, 6061-T6 is used across almost every major industry for its good strength-to-weight ratio, durability, and machinability and weldability:

As the versatile alloy, 6061 T6 aluminum’s combination of high strength, excellent corrosion resistance, and superb machinability makes it the ideal candidate for most engineering projects. While it can’t be processed in large bending and casting, its performance in CNC machining and structural welding , it is highly suitable for its engineering value.

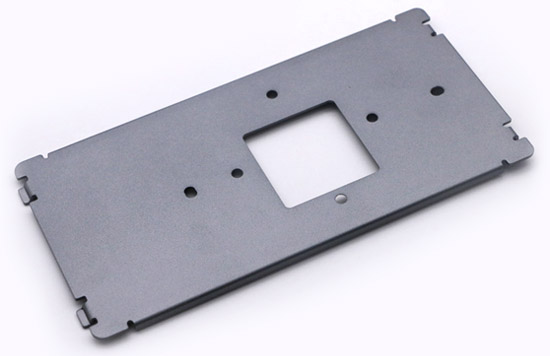

A European UAV manufacturer required a custom 6061 aluminum mounting bracket for its flagship gimbal. However, the high-precision camera brackets produced exhibited micro-jitters during flight, which directly degraded image quality. The root cause was identified in the previous supplier's manufacturing process: when standard 6061-T6 aluminum underwent extensive material removal, internal stress release caused a 0.15mm warpage, leading to an axial offset of the motor mounting position. Furthermore, the components had to withstand high-frequency mechanical vibrations while maintaining a superior aesthetic finish to match the premium brand positioning. Previous parts frequently showed color inconsistencies after anodizing and visible machining marks.

To address these challenges, VMT technical team developed a precision manufacturing plan. First, we upgraded the raw material to 6061-T651, which offers higher dimensional stability, utilizing its stress-relieved properties to eliminate deformation at the source. During production, we employed 15,000 RPM high-speed CNC cutting combined with a trochoidal milling strategy, reducing cutting forces by 30% and effectively controlling thermal deformation. To ensure a flawless surface, we replaced traditional manual sanding with a vibratory ceramic media finishing process, stabilizing the surface roughness at Ra 0.8 and providing an ideal substrate for subsequent anodizing.

Through these optimizations, the processing performance of the bracket exceeded the client's expectations. Data monitoring indicated that the flatness improved from 0.15mm to within 0.03mm (an 80% enhancement), eliminating physical jitter in the gimbal. Regarding aesthetic performance, the yield rate for anodized finished products rose from 88% to 98.5%, with no visible machining marks on the surface. The client was highly satisfied and has since placed an annual order of 5,000 units for this model with VMT.

Is 6061 T6 Aluminum RoHS Compliant?

Yes. Standard 6061-T6 aluminum is RoHS (Restriction of Hazardous Substances) compliant. It does not contain lead (unless specifically added in specialized variants), mercury, cadmium, or hexavalent chromium, making it safe for use in consumer electronics and global medical markets.

How strong is 6061 T6 aluminum?

It has a yield strength of 40,000 psi and an ultimate tensile strength of 45,000 psi. This makes it strong enough for structural frames but lightweight enough for flight.

Is 6061-T6 aluminum aircraft grade?

Yes. While 7075 is often called "the" aircraft grade due to higher strength, 6061-T6 is used extensively in aircraft for components where corrosion resistance and weldability are more critical than maximum strength.

Is 6061 aluminum good quality?

Absolutely. It is the gold standard for general-purpose aluminum. It is reliable, predictable during machining, and offers excellent longevity.

Why is T6 one of the Most Popular Aluminum 6061 Grades?

Because T6 provides the maximum mechanical strength for the alloy without making it too brittle to machine.

What metal is 6061?

It is a wrought aluminum alloy primary composed of Aluminum (approx. 97%), Magnesium (1.0%), and Silicon (0.6%), with small amounts of copper and chromium.

6061-T651 vs T6 & T6511: What’s the Difference?