15 years one-stop China custom CNC machining parts factory

196 |

Published by VMT at Aug 15 2025 | Reading Time:About 6 minutes

196 |

Published by VMT at Aug 15 2025 | Reading Time:About 6 minutes

When engineers and procurement specialists search for aluminum 6061 materials, they often encounter three confusing terms: 6061-T6, 6061-T651, and 6061-T6511. While they may look similar on paper, choosing the wrong one for CNC machining projects can lead to dimensional instability, reduced strength, or unnecessary machining costs.

The frustration comes from technical jargon—heat treatments, stress relief processes, and mechanical property variations—that are rarely explained clearly for real-world manufacturing needs.

The good news is that with the right knowledge, you can choose the correct 6061 alloy variant, improve 6061 CNC machined parts quality, and save on production costs. This guide breaks down each type, their properties, and their best applications in CNC machining services.

6061-T6 is heat-treated aluminum without stress relief, 6061-T651 is stress-relieved T6 for improved stability, and 6061-T6511 is stress-relieved with controlled straightness for extruded shapes. Choosing depends on dimensional tolerance needs, part size, and machining requirements.

Understanding the difference between 6061-T6, T651, and T6511 is not just a matter of technical curiosity—it’s a cost and quality decision. The right choice affects machinability, strength, and final tolerance stability.

In the sections below, we’ll compare chemical composition, mechanical properties, and physical performance to help engineers, designers, and buyers select the right alloy for their aluminum CNC machined parts. For deeper insights on aluminum alloys, you can also explore related guides on our website about 7075-T6 vs. 6061-T6 and MIC-6 cast aluminum plates, which offer different strengths for CNC machining projects.

What is 6061-T6?

6061-T6 is a heat-treated aluminum alloy from the aluminum 6061 family, known for its balanced strength, corrosion resistance, and machinability. The “T6” designation means the material is solution heat-treated and artificially aged to achieve maximum strength.

However, it has not undergone stress-relief stretching, which means residual stresses from heat treatment can remain in the material. In CNC machining, these stresses can cause dimensional changes after milling, particularly for large, thin, or asymmetrical parts.

This variant is commonly used for structural frames, automotive parts, and aerospace components where high strength-to-weight ratio is essential but extreme dimensional stability is not critical.

What is 6061-T651?

6061-T651 is essentially 6061-T6 that has undergone stress relief by stretching. The “51” suffix indicates that after heat treatment, the aluminum is stretched to relieve internal stresses before being machined.

This makes it a preferred choice in CNC machining factories for projects requiring tight tolerances and minimal post-machining distortion. It is particularly beneficial for precision components, aerospace fittings, and large aluminum CNC machined parts where dimensional accuracy is critical.

What is 6061-T6511?

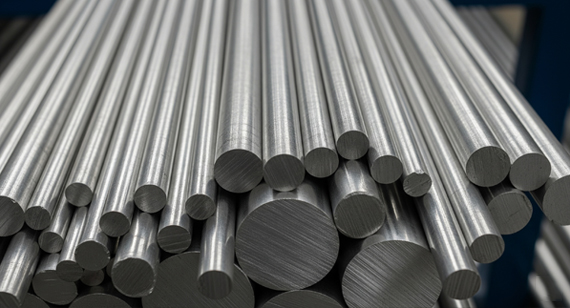

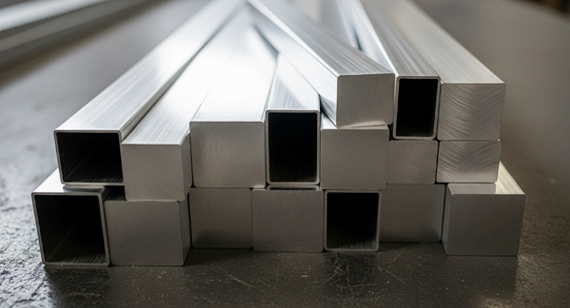

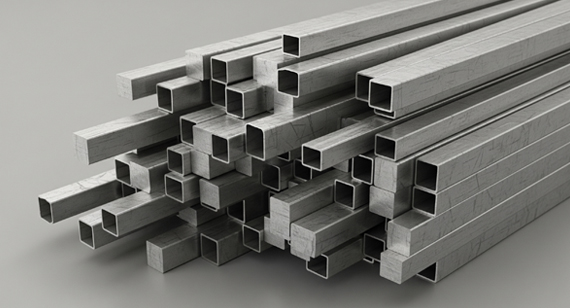

6061-T6511 is a variant of T651, primarily applied to extruded shapes such as bars, rods, and profiles. After heat treatment and stress relief, it undergoes a controlled straightening process to meet precise dimensional tolerances for extrusions.

This makes T6511 ideal for applications like automotive chassis, machine tool components, and structural frames where straightness and stability are essential, but the parts originate from extruded stock.

At first glance, 6061-T6, 6061-T651, and 6061-T6511 aluminum may appear identical—they share the same base alloy, aluminum 6061, and nearly identical chemical composition. However, their mechanical performance, dimensional stability, and suitability for CNC machining can differ significantly due to variations in post-heat-treatment processes.

The main distinction lies in stress relief and straightness control. 6061-T6 is the baseline, strong but with residual stresses; 6061-T651 adds stretching to remove those stresses; and 6061-T6511 combines stretching with precise straightening for extrusions. Choosing incorrectly can cause machining distortion, assembly issues, and unexpected project delays.

For customers sourcing aluminum CNC machined parts through CNC machining services, understanding these differences ensures parts meet tolerance requirements without costly rework. This section will start by comparing their chemical composition, which forms the foundation of their mechanical and physical behavior.

Chemical Composition

Aluminum 6061—regardless of whether it is T6, T651, or T6511—shares the same nominal chemical makeup. The alloy is primarily aluminum, with magnesium and silicon as the main alloying elements, plus trace amounts of copper, iron, and other elements to fine-tune performance.

Typical chemical composition for 6061 series alloys is:

While all three tempers—6061-T6, 6061-T651, and 6061-T6511—share this composition, their different tempering and stress-relief treatments result in distinct mechanical property profiles, which we will examine next.

Chemical Composition

While 6061-T6, 6061-T651, and 6061-T6511 share the same aluminum 6061 base alloy, their mechanical properties differ because of tempering and stress-relief processes, not chemical makeup.

Here’s the typical chemical composition of aluminum 6061:

| Element |

Percentage (%) |

Function in Alloy |

| Aluminum (Al) |

95.8 – 98.6 | Provides lightweight structure, corrosion resistance, and base metal properties. |

| Magnesium (Mg) |

0.8 – 1.2 | Improves strength, corrosion resistance, and forms Mg₂Si with silicon. |

| Silicon (Si) |

0.4 – 0.8 | Enhances hardness and wear resistance by forming Mg₂Si. |

| Copper (Cu) |

0.15 – 0.40 | Increases strength but slightly reduces corrosion resistance. |

| Chromium (Cr) |

0.04 – 0.35 | Improves toughness and resistance to stress corrosion cracking. |

| Iron (Fe) |

≤ 0.70 | Usually an impurity; can influence machinability. |

| Zinc (Zn) |

≤ 0.25 | Minimal effect in 6061; may influence anodizing appearance. |

| Titanium (Ti) |

≤ 0.15 | Refines grain structure, enhancing overall mechanical performance. |

Mechanical Properties

Even though 6061-T6, 6061-T651, and 6061-T6511 have identical chemical compositions, their mechanical properties vary because of stress relief and straightening processes.

These differences directly affect CNC machining performance, dimensional stability, and final part quality. For example, the tensile strength of 6061-T6 is similar to T651, but the stress relief in T651 reduces the likelihood of distortion after machining. T6511 has comparable strength to T651 but with improved straightness for extrusions, making it ideal for long aluminum CNC machined parts such as structural frames and machine components.

Choosing the wrong variant can mean extra rework, higher costs, and longer lead times—especially for parts requiring tight tolerances from CNC machining factories.

Mechanical Property Comparison Table

| Property |

6061-T6 |

6061-T651 |

6061-T6511 |

| Hardness |

High | High | High |

| Shear Strength (MPa) |

~207 | ~207 | ~207 |

| Elastic Modulus (GPa) |

68.9 | 68.9 | 68.9 |

| Fatigue Strength (MPa) |

~96.5 | ~96.5 | ~96.5 |

| Brinell Hardness (HB) |

95 | 95 | 95 |

| Yield Strength (MPa) |

~276 | ~276 | ~276 |

| Elongation at Break (%) |

12 | 12 | 12 |

| Tensile Strength (MPa) |

~310 | ~310 | ~310 |

| Elongation (Rp0.2/MPa) |

~276 | ~276 | ~276 |

| Ductility (%) |

Moderate | Moderate | Moderate |

Physical Properties

While mechanical properties define how an alloy handles stress and load, physical properties dictate its performance in thermal, electrical, and environmental conditions. For 6061-T6, 6061-T651, and 6061-T6511, these physical characteristics are largely identical, since they share the same aluminum 6061 chemical composition.

However, understanding these parameters is crucial for CNC machining services—especially when parts will be exposed to heat, electrical currents, corrosive environments, or welding operations. A designer choosing material for aluminum CNC machined parts must account for these properties to ensure long-term reliability.

Thermal Conductivity (W/m·K)

All three temper variants offer high thermal conductivity, typically around 167 W/m·K, making them suitable for heat sinks, engine components, and electronic housings.

Electrical Conductivity (%)

With an electrical conductivity of about 43% IACS, aluminum 6061 conducts electricity well enough for bus bars, enclosures, and electronic frames, though not as well as pure aluminum.

Melting Range (°C)

The alloy melts between 582–652°C, providing adequate thermal tolerance for most manufacturing processes, but care must be taken in high-temperature operations like forging.

At around 2.70 g/cm³, aluminum 6061 is lightweight, making it ideal for aerospace, automotive, and structural CNC machined parts.

Coefficient of Thermal Expansion (μm/m·°C)

The expansion rate is 23.6 μm/m·°C, meaning that thermal changes can slightly alter dimensions—important when designing precision assemblies.

The solidus point is around 582°C, and the liquidus at 652°C, defining its processing temperature limits.

Corrosion Resistance

Aluminum 6061 has excellent corrosion resistance, especially in atmospheric and marine environments, making it popular for outdoor CNC machined components.

Wear Resistance

While not as hard as some alloys, it offers moderate wear resistance, which can be enhanced with surface treatments like anodizing.

Oxidation Resistance

Forms a natural oxide layer that resists further oxidation, ideal for parts without heavy chemical exposure.

Welding

Highly weldable using TIG or MIG methods, though mechanical strength in the weld zone may decrease without post-weld heat treatment.

Non-magnetic, suitable for sensitive electronic equipment housings where magnetism could interfere with operation.

Formability

Good formability in the T6 condition; excellent in the annealed state before final heat treatment.

Machinability (Annealing)

In the T6 and T651 conditions, machinability is rated as good, producing clean finishes for aluminum CNC machined parts.

Physical Properties Comparison Table

| Property |

6061-T6 |

6061-T651 |

6061-T6511 |

| Thermal Conductivity (W/m·K) |

~167 | ~167 | ~167 |

| Electrical Conductivity (% IACS) |

~43 | ~43 | ~43 |

| Melting Range (°C) |

582–652 | 582–652 | 582–652 |

| Density (g/cm³) |

2.70 | 2.70 | 2.70 |

| Coefficient of Thermal Expansion |

23.6 | 23.6 | 23.6 |

| Melting Point (°C) |

~582–652 | ~582–652 | ~582–652 |

| Corrosion Resistance |

Excellent | Excellent | Excellent |

| Wear Resistance |

Moderate | Moderate | Moderate |

| Oxidation Resistance |

High | High | High |

| Welding |

Excellent | Excellent | Excellent |

| Magnetic Properties |

Non-magnetic | Non-magnetic | Non-magnetic |

| Formability |

Good | Good | Good |

| Machinability (Annealing) |

Good | Good | Good |

Strength

When it comes to structural performance, 6061-T6, 6061-T651, and 6061-T6511 share similar ultimate tensile and yield strengths, since their base alloy and heat treatment levels are the same. The typical tensile strength is about 310 MPa, and the yield strength is around 276 MPa for all three.

However, while raw strength is nearly identical, T651 and T6511 deliver more consistent strength across the entire workpiece due to stress-relief processes. This consistency becomes critical in CNC machining services, where removing material can cause non-stress-relieved plates or bars to distort, weakening certain sections.

For heavy-duty load-bearing aluminum CNC machined parts—such as aerospace brackets, automotive suspension components, and industrial machine frames—T651 or T6511 often outperform T6 in maintaining long-term shape and load capacity.

Dimensional Stability Comparison

Dimensional stability refers to a material’s ability to maintain its exact measurements after machining, temperature changes, or long-term use.

For CNC machining factories producing tight-tolerance aerospace panels, precision jigs, or long mechanical arms, choosing T651 or T6511 minimizes rework time and scrap rates.

Vibration Damping

Aluminum 6061 is not known for exceptional vibration damping compared to materials like cast iron, but temper choice can still influence performance in sensitive applications.

Because 6061-T651 and 6061-T6511 undergo stress relief, they tend to exhibit slightly improved vibration stability after machining, especially in parts with thin walls or extended spans. This stability benefits precision measuring equipment frames, CNC machine tooling components, and aerospace sensor housings where vibration can reduce accuracy or service life.

While damping properties are primarily governed by the base aluminum alloy’s modulus of elasticity (68.9 GPa), reducing internal stress also helps maintain tight fits and alignment under vibratory loads.

Heat treatment plays a crucial role in defining the performance characteristics of 6061 aluminum alloys. While 6061-T6, 6061-T651, and 6061-T6511 share the same chemical composition, they undergo slightly different processing methods, resulting in variations in residual stress, dimensional stability, and machinability. Understanding these distinctions helps engineers, designers, and procurement teams choose the optimal temper for CNC machining applications.

6061-T6 Alloy

The 6061-T6 temper is achieved by solution heat treating the alloy, followed by artificial aging. The solution heat treatment dissolves soluble phases into a solid solution, while the artificial aging process precipitates fine Mg₂Si particles to increase strength. This results in high tensile strength, good corrosion resistance, and balanced machinability.

However, T6 retains residual stresses from the quenching process, which can cause warping during machining—an important consideration for high-precision CNC parts.

Key Heat Treatment Steps:

6061-T651 Alloy

6061-T651 is essentially the T6 temper with an additional stress-relief stretching step. After solution heat treatment and artificial aging, the alloy is stretched by approximately 1.5–3% to reduce internal stresses. This extra process minimizes the risk of distortion during machining, making T651 the preferred choice for high-precision and large CNC aluminum parts.

While mechanical strength is nearly identical to T6, the improved dimensional stability makes T651 more reliable for critical aerospace, defense, and mold-making applications.

Key Heat Treatment Steps:

6061-T6511 Alloy

6061-T6511 follows the same heat treatment sequence as T651 but applies to extruded products rather than plate or rolled material. The “11” designation indicates that the product has been stress-relieved by stretching after solution heat treatment and artificially aged, but in the form of bars, rods, or shapes.

For CNC machining, T6511 is often used when long extrusions are needed for structural components, as it combines good machinability with improved stability over T6.

Key Heat Treatment Steps:

Heat Treatment Comparison for 6061-T6, 6061-T651, and 6061-T6511

| Temper Designation |

Heat Treatment Process |

Stress Relief |

Straightening / Stretching |

Typical Applications |

| 6061-T6 |

Solution heat treated and artificially aged | No stress relieving after aging | No stretching or straightening | General-purpose structural parts, aerospace fittings, automotive components |

| 6061-T651 |

Solution heat treated, stress relieved by stretching, then artificially aged | Yes – stress relieved by stretching | Minimal distortion due to stretching | Precision CNC machined parts, tooling plates, aerospace components requiring tight tolerances |

| 6061-T6511 |

Solution heat treated, stress relieved by stretching, straightened, then artificially aged | Yes – stress relieved by stretching | Extrusion straightened for better dimensional control | Long CNC machined extrusions, structural profiles, marine hardware |

When selecting aluminum for CNC machining parts, 6061 in its different tempers — T6, T651, and T6511 — offers a balance of strength, machinability, and corrosion resistance. Each variant undergoes specific heat treatment and stress-relieving processes, resulting in differences in mechanical performance, stability, and application suitability. Understanding their advantages and disadvantages helps engineers, procurement specialists, and CNC machining factories choose the right material for each project.

Advantages of 6061-T6, 6061-T651, and 6061-T6511

While all three share the same chemical composition, their tempering process influences performance. Here’s a breakdown of their benefits.

6061-T6 Alloy

6061-T651 Alloy

6061-T6511 Alloy

Disadvantages of 6061-T6, 6061-T651, and 6061-T6511

Despite their popularity, each temper has certain drawbacks that may impact cost, production efficiency, or performance in specific applications.

6061-T6 Alloy

6061-T651 Alloy

6061-T6511 Alloy

Here’s the comparison table for the advantages and disadvantages of 6061-T6, 6061-T651, and 6061-T6511:

| Alloy Type |

Advantages |

Disadvantages |

| 6061-T6 |

- High tensile and yield strength - Good corrosion resistance - Excellent machinability in heat-treated condition - Suitable for welding with proper precautions |

- Susceptible to slight distortion after machining due to residual stresses - Lower dimensional stability than T651/T6511 - May require stress relief for critical tolerance parts |

| 6061-T651 |

- All advantages of T6 plus stress-relief stretching for higher dimensional stability - Reduced risk of warping after machining - Good balance of strength, corrosion resistance, and machinability |

- Slightly more expensive than T6 - Limited availability in certain shapes - Mechanical properties marginally lower than T6 due to stress-relief |

| 6061-T6511 |

- All advantages of T651 plus straightening for extruded profiles - Excellent dimensional stability and minimal warping in long sections - Ideal for CNC-machined extrusion parts |

- Typically limited to extruded forms only - Higher cost compared to T6 - Mechanical properties slightly reduced compared to T6 |

Here’s a clear breakdown of 6061-T6 and 6061-T6511 interchangeability in a CNC machining context:

| Aspect |

6061-T6 |

6061-T6511 |

Interchangeability Notes |

| Form Availability |

Plate, sheet, extrusions, bar | Extrusions only (with stress relief + straightening) | They can be interchangeable only when extrusions are used, since T6511 is an extrusion-specific temper. |

| Strength |

Higher tensile and yield strength than T6511 by a small margin | Slightly lower tensile and yield strength due to stress relief | The strength difference is usually negligible for most CNC parts unless maximum strength is critical. |

| Dimensional Stability |

Prone to minor warping after machining due to residual stresses | Much better dimensional stability after machining | For precision CNC parts, T6511 is preferred; swapping T6 for T6511 could improve stability. |

| Weldability & Corrosion Resistance |

Good weldability and corrosion resistance | Same as T6 | Fully interchangeable in terms of corrosion and welding performance. |

| Machinability |

Good, but residual stresses may cause movement after machining | Very good, minimal movement after machining | In CNC machining, T6511 is often chosen over T6 for better post-machining stability. |

| Cost & Availability |

Slightly lower cost, wider availability | Slightly higher cost, limited to extrusions | Interchangeable if design allows extrusion profiles and budget permits. |

Summary:

Alloy 6061 is one of the most widely used aluminum alloys in CNC machining services due to its excellent strength-to-weight ratio, corrosion resistance, and machinability. Within this family, the 6061-T6, 6061-T651, and 6061-T6511 tempers each have unique processing characteristics, making them suitable for specific industries and applications. Understanding where each alloy excels helps manufacturers, engineers, and procurement teams choose the right material for their CNC machining projects.

Applications of 6061-T6 Alloy

The 6061-T6 temper is heat-treated and artificially aged, offering high strength and good corrosion resistance, making it versatile for a wide range of industries. Common applications include:

Applications of 6061-T651 Alloy

The 6061-T651 temper is similar to T6 but has undergone stress-relieving by stretching, reducing internal stresses and improving dimensional stability—ideal for precision CNC machining. Common applications include:

Applications of 6061-T6511 Alloy

The 6061-T6511 temper has the same mechanical properties as T651 but is typically supplied as extruded products and is stress-relieved by stretching after solution heat treatment. This makes it particularly suited for elongated and complex shapes. Applications include:

Here’s a clean, well-structured table comparing the applications and uses of 6061 T6, 6061 T651, and 6061 T6511:

| Alloy Type |

Main Applications |

Key Applications |

Typical Use Cases |

| 6061-T6 | Versatile structural and mechanical parts where high strength and corrosion resistance are required. | Aircraft Components |

Wing structures, fuselage parts, landing gear supports |

| Automotive Components |

Engine parts, suspension arms, chassis components | ||

| Sporting Equipment |

Baseball bats, archery bows, climbing gear | ||

| Door & Window Fixtures |

Sliding door frames, high-strength window frames | ||

| Gardening Tools |

Handles, tool heads, reinforced parts | ||

| Marine/Ship Parts |

Masts, hull fittings, gangways | ||

| Pipes & Tubing |

Hydraulic tubing, fuel lines, structural pipes | ||

| Bicycle Frames |

Road bike frames, mountain bike frames | ||

| Frames & Structures |

Support beams, architectural frames | ||

| Industrial Equipment Frames |

Conveyor frames, machine frames | ||

| Electronic Equipment Enclosures |

Durable casings for outdoor electronics | ||

| 6061-T651 | Precision-machined parts requiring excellent dimensional stability after heat treatment. | Machinery Parts |

Shafts, gears, machine bases |

| Aircraft Components |

Landing gear parts, brackets, ribs | ||

| Automotive Parts |

Performance car components, off-road vehicle parts | ||

|

Bicycles & Bicycle Frames |

High-performance frames, racing frames | ||

| Structural Frames |

Bridges, load-bearing structures | ||

| Fittings & Pipes |

High-pressure fittings, marine pipelines | ||

| Marine Applications |

Hull reinforcements, deck structures | ||

| Consumer Products |

Durable handles, protective casings | ||

| 6061-T6511 | Profiles and extrusions where excellent machinability, corrosion resistance, and weather resilience are needed. | Automotive Body Panels |

Lightweight yet rigid panels, door skins |

| Frames & Chassis |

Racing chassis, lightweight structural frames | ||

| Electronic Enclosures |

Weatherproof housings, industrial control panels | ||

| Machinery/Equipment Enclosures |

Machine guards, precision housing frames | ||

| Machine Tools & Parts |

Tool holders, precision fixtures | ||

| Signages/Displays |

Outdoor signs, display structures | ||

| Medical Equipment |

Imaging equipment frames, wheelchair parts | ||

| Transportation Structures |

Bus frames, railway car panels | ||

| Severe Weather Enclosures |

Outdoor telecom boxes, marine electronics housings |

Cost and Pricing Overview

The cost of 6061 aluminum alloys—whether T6, T651, or T6511—depends on several factors, including raw material prices, dimensions, machining complexity, order volume, and any special surface treatments. In general, 6061-T6 is the most widely available and therefore often the most competitively priced, while T651 and T6511 may cost slightly more due to additional processing and dimensional stability requirements.

6061-T6 Pricing

As the most common heat-treated variant of 6061 aluminum, T6 is generally the most affordable choice. Its price per kilogram or pound is typically 5–10% lower than T651 or T6511. Customers often select T6 for large-scale projects such as aircraft frames, automotive parts, or marine structures where strength and corrosion resistance are needed without strict flatness tolerances. Bulk orders can lead to further discounts, especially from CNC machining factories with direct supplier relationships.

6061-T651 Pricing

T651 undergoes stress-relieving after heat treatment, which ensures superior flatness and dimensional stability—especially important for precision CNC machined parts. This extra processing generally adds a 5–15% price premium over T6. Buyers in aerospace, defense, and high-precision manufacturing often consider the added cost justified by the reduced risk of warping during machining, which ultimately saves rework and material waste.

6061-T6511 Pricing

T6511 is similar to T651 but applies specifically to extruded profiles. Its pricing depends not only on size and thickness but also on the complexity of the extrusion shape. Intricate profiles with tight tolerances tend to be more expensive. T6511 often costs slightly more than T651 when custom tooling is required, but for standard extrusion shapes, pricing is comparable. Many CNC machining factories source T6511 for long structural parts, frames, and transport applications where both machinability and weather resistance are critical.

Additional Cost Factors

Beyond alloy type, costs can be affected by:

Here’s a clear comparison table for 6061 T6, T651, and T6511 Cost and Pricing:

| Alloy Type |

Relative Cost |

Factors Influencing Price |

Typical Market Position |

Common Purchase Form |

Notes |

| 6061-T6 |

Low to Medium | Standard heat treatment; widely available; lower machining stress relief requirement | Most cost-effective for general use | Sheets, plates, extrusions, bars | Economical option for mass production where extreme precision is not required |

| 6061-T651 |

Medium | Additional stress relieving process; better dimensional stability; slightly higher machining cost | Mid-range pricing due to improved stability | Plates, blocks | Often preferred for precision machining, justifying the slight cost increase |

| 6061-T6511 |

Medium to High | Stress relieved and mechanically straightened; higher processing cost for extrusions | Higher price point in extrusion market | Extrusions, rods, bars, tubes | Price reflects enhanced straightness and machining consistency |

Here’s a comparison table for 6061 T6, T651, and T6511: Different Stock Shapes:

| Alloy Type |

Common Stock Shapes |

Typical Size Range |

Notes on Availability |

| 6061-T6 |

Sheets, plates, bars, tubes, angles, channels, extrusions | Thin sheets (<1"), plates up to several inches thick, various bar diameters | Most versatile form availability; widely stocked in standard shapes |

| 6061-T651 |

Plates, blocks | Typically >0.5" thick up to large plate sizes | Primarily supplied as stress-relieved plate for machining; rarely in thin sheet form |

| 6061-T6511 |

Extruded bars, rods, tubes, shapes | Small to medium diameters and profiles | Focused on long extrusions with high straightness and stability; ideal for structural or precision parts |

Aluminum 6061 is one of the most versatile alloys, but its performance depends heavily on the temper — T6, T651, and T6511. Each has distinct manufacturing processes and mechanical properties, making them suitable for different applications. Understanding when to use each variant helps engineers, designers, and procurement managers make cost-effective and performance-driven choices.

When to Use Aluminum 6061-T651?

Aluminum 6061-T651 is stress-relieved by stretching after heat treatment, which reduces internal stresses and minimizes distortion during machining. It is the preferred choice for thick plates and precision-machined parts where stability and accuracy are critical. This makes it ideal for aerospace structural components, precision tooling plates, and heavy-duty machinery frames. If your project requires minimal warping during machining, T651 is often the go-to option.

When to Use Aluminum 6061-T6?

Aluminum 6061-T6 is the standard solution heat-treated and artificially aged version without stress relief stretching. It offers an excellent balance of strength, corrosion resistance, and machinability, making it a cost-effective option for general-purpose applications such as automotive parts, bicycle frames, sporting goods, and marine fittings. Choose T6 when you need versatility, availability in various shapes, and moderate strength at a lower cost compared to stress-relieved tempers.

When to Use Aluminum 6061-T6511?

Aluminum 6061-T6511 is similar to T651 but produced in extruded forms like bars, rods, tubes, and custom profiles. It is straightened after stretching, offering high dimensional stability for long-length extrusions. This makes it ideal for structural frames, machine tool components, transportation parts, and architectural extrusions. If your design involves long, precise, and straight aluminum profiles, T6511 is the best option.

Here’s the comparison table for Aluminum 6061-T6, 6061-T651, and 6061-T6511:

| Temper |

Key Features |

Best For |

Common Applications |

| 6061-T6 |

Heat-treated and artificially aged; no stress relief; widely available; good balance of strength, corrosion resistance, and machinability | General-purpose projects needing moderate strength at lower cost | Automotive parts, bicycle frames, sporting goods, marine fittings, door and window frames |

| 6061-T651 |

Same as T6 but stress-relieved by stretching; reduced internal stress; minimal distortion during machining | Precision-machined parts requiring high dimensional stability | Aerospace structural components, precision tooling plates, heavy-duty machinery frames |

| 6061-T6511 |

Stress-relieved like T651 but in extruded form; straightened for accuracy; ideal for long profiles | Long-length structural and mechanical components needing high straightness | Structural frames, machine tool components, transportation parts, architectural extrusions |

When it comes to precision, durability, and efficiency in aluminum parts manufacturing, VMT CNC Machining Services stands out as a trusted partner for global clients. Specializing in 6061-T6, 6061-T651, and 6061-T6511 aluminum alloys, VMT delivers high-quality aluminum CNC machining parts that meet strict industrial standards and customer-specific requirements.

Our advanced CNC machining factories are equipped with multi-axis machining centers, enabling us to handle everything from small, intricate components to large structural frames. Each aluminum part is produced with tight tolerances, excellent surface finishes, and consistent quality, ensuring optimal performance in applications such as aerospace, automotive, marine, and industrial machinery.

Whether you require custom aluminum prototypes or large-volume production runs, VMT offers end-to-end CNC machining services — from material selection and engineering design support to precision manufacturing, finishing, and quality inspection. Our expertise with 6061 aluminum alloys ensures your parts maintain superior strength, corrosion resistance, and machinability, while also offering cost-effective production.

Choosing VMT means choosing reliability, precision, and efficiency. We are committed to delivering aluminum CNC machining parts that not only meet but exceed your expectations.

Selecting the right aluminum alloy temper — whether 6061-T6, 6061-T651, or 6061-T6511 — is critical to achieving optimal performance, cost efficiency, and durability in CNC machined parts. Each offers unique advantages: T6 for balanced strength and machinability, T651 for improved stress relief and dimensional stability, and T6511 for extruded profiles with enhanced straightness.

By understanding these differences, engineers, designers, and procurement specialists can make informed decisions that align with their project’s technical and budgetary requirements.

At VMT CNC Machining Services, we combine material expertise with precision manufacturing to deliver high-quality aluminum CNC machining parts that meet the demands of industries from aerospace to automotive. Our advanced CNC machining factories ensure every component is crafted with tight tolerances, excellent surface finishes, and consistent quality.

When your project demands precision, reliability, and performance, VMT is your trusted partner for 6061 aluminum CNC machined parts — from concept to final delivery.

1. What is the difference between 6061-T651 and 6061-T6511?

Both are heat-treated, stress-relieved versions of 6061 aluminum. The difference lies in manufacturing: T651 is produced from plate, while T6511 comes from extruded profiles and is additionally straightened after stretching for better dimensional accuracy.

2. What is the difference between T6 and T651?

T6 is solution heat-treated and artificially aged to achieve maximum strength. T651 undergoes the same process but is stress-relieved by stretching to reduce internal stresses, making it less prone to warping during machining.

3. What is the difference between 6061-T651 and 7075-T651?

6061-T651 offers excellent corrosion resistance and weldability, while 7075-T651 provides significantly higher strength but lower corrosion resistance. The choice depends on whether strength or environmental durability is more important.

4. What is the difference between T6 and T61 heat treatments?

T6 involves full artificial aging after solution heat treatment, whereas T61 is a variation with a slightly different aging process, resulting in slightly different mechanical properties.

5. What is 6061-T651 aluminum used for?

It is widely used for precision CNC machined parts in aerospace, automotive, marine, and structural applications requiring high strength, stability, and corrosion resistance.

6. Is 6061-T6511 machinable?

Yes. 6061-T6511 aluminum is highly machinable, especially for long extruded profiles where dimensional stability and straightness are critical.

7. What is the equivalent material for 6061-T6?

International equivalents include AlMg1SiCu in Europe and A96061 in UNS designation. Properties can vary slightly depending on manufacturing standards.

8. Is 6061-T6511 heat treated?

Yes. 6061-T6511 undergoes solution heat treatment, artificial aging, and stress-relieving by stretching.

9. What does T6 stand for in aluminum?

It means the alloy has been solution heat-treated and artificially aged for maximum strength.

10. Is 6061-T6511 weldable?

Yes, it has excellent weldability using MIG or TIG welding, although post-weld heat treatment may be necessary to restore strength in the heat-affected zone.

11. Can 6061-T651 be bent?

Yes, but it requires a larger bend radius compared to softer tempers to prevent cracking.

12. Is 6061-T6 expensive?

It is cost-effective compared to aerospace-grade aluminum like 7075, offering a strong balance between performance and price.

13. Is T651 better than T6?

Not necessarily “better,” but T651 is preferred when machining large parts due to reduced risk of distortion.

14. Is 6061-T651 aluminum strong?

Yes, with a tensile strength around 45,000 psi, it offers excellent structural performance for a wide range of applications.

15. Is 6061-T6 forged or cast?

It is typically produced as a wrought alloy, meaning it is rolled or extruded rather than cast.

16. What is the strongest aluminum alloy?

7075-T6 is among the strongest, with significantly higher strength than 6061, but lower corrosion resistance.

17. Is 6061-T6 the same as T6511?

No. While they share the same base alloy, T6511 is extruded and stress-relieved, whereas T6 refers to the heat treatment only, without specifying the manufacturing process.