15 years one-stop China custom CNC machining parts factory

338 |

Published by VMT at Feb 26 2025 | Reading Time:About 8 minutes

338 |

Published by VMT at Feb 26 2025 | Reading Time:About 8 minutes

Laser cutting aluminum is becoming an increasingly popular method for manufacturers and designers looking to create precise, intricate, and high-quality parts. If you're involved in CNC machining, you may already know that aluminum presents certain challenges due to its thermal properties and reflective nature. But what if there was a way to achieve flawless, efficient cuts, even with these challenges? Laser cutting might be the perfect solution. In this article, we will break down how laser cutting aluminum works, the various machine options available, and why it’s considered a game-changer in CNC machining.

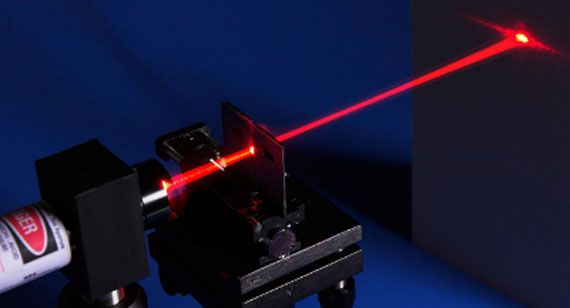

Laser cutting aluminum involves directing a powerful laser beam to melt and cut through the material. With the right parameters and settings, this technique allows for precise, clean cuts, which are crucial for producing custom CNC machining parts. Whether you're dealing with aluminum sheets, profiles, or components, laser cutting ensures superior quality and high production efficiency for your CNC machining services.

Now that we understand why laser cutting aluminum is so popular, let’s dive deeper into the technology behind it. How does laser cutting work in practice, and what are the essential steps to ensure you achieve the perfect cut? From material preparation to machine calibration and post-processing, there are several factors that play a role in delivering high-quality results. Let’s explore the process step by step to ensure your next project is a success.

Laser cutting aluminum is a process that uses a focused laser beam to melt and vaporize the material in a controlled manner, creating a clean, precise cut. This technique can be used to cut through various thicknesses of aluminum, from thin sheets to thicker profiles, with exceptional accuracy. In CNC machining, laser cutting is particularly valuable because it offers the precision needed for complex shapes and fine details, which is difficult to achieve with traditional cutting methods like saws or shears.

Aluminum, a lightweight and versatile material, has properties that make it ideal for laser cutting. However, its high reflectivity and thermal conductivity can pose challenges when compared to other materials like steel. Therefore, the laser cutting process for aluminum requires careful consideration of settings, such as laser power and feed speed, to ensure the best results.

Yes, aluminum can be effectively cut with a laser, but the process requires more precise control compared to cutting other materials like steel. The high reflectivity of aluminum can cause issues with the laser beam, making it less efficient. However, using fiber lasers and adjusting parameters like assist gas flow and power density can overcome these challenges. By doing so, laser cutting aluminum can produce sharp, smooth edges, making it ideal for various applications in the aerospace, automotive, and manufacturing industries.

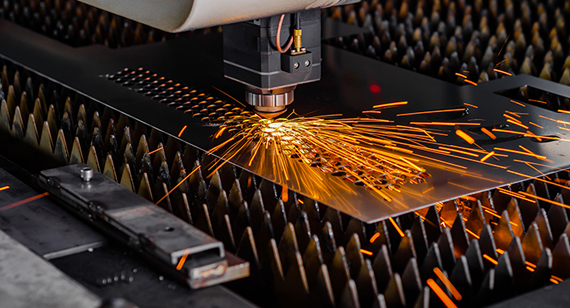

Laser cutting of aluminum is a precise and efficient process that utilizes a focused laser beam to cut through aluminum material, allowing for intricate designs and high-quality edges. The process is widely used in industries such as aerospace, automotive, and manufacturing, as it offers speed, accuracy, and the ability to handle complex shapes. Below, we’ll explore how laser cutting works, including the necessary steps, programming, and precautions to ensure optimal results when cutting aluminum.

Laser cutting of aluminum involves focusing a laser beam onto the material’s surface, where it melts and vaporizes the material to create precise cuts. The process can be adjusted for different thicknesses and types of aluminum, ensuring the best results for various applications. The laser used is often a fiber laser, known for its high efficiency and ability to cut reflective materials like aluminum.

One of the key challenges in laser cutting aluminum is managing the high reflectivity of the material, which can cause the laser beam to scatter or lose power. To combat this, laser cutting of aluminum involves optimizing several parameters, such as the laser’s power, assist gas flow, and focus. Proper calibration ensures that the process remains efficient and that the cuts are clean and accurate.

Machine Programming

Before starting the cutting process, the CNC machine must be properly programmed. This involves inputting the design into a CAD (Computer-Aided Design) software, which translates the blueprint into machine-readable commands. The machine programming defines the cutting path, the laser speed, and the intensity of the beam required for each section of the cut. This level of detail ensures that the aluminum is cut precisely according to the design specifications.

CNC programming software typically allows manufacturers to simulate the cutting process, helping to identify any potential issues such as incomplete cuts or unnecessary material wastage before actual cutting begins. Machine programming is a critical step in ensuring that the laser cutting process is as accurate and efficient as possible.

Different Cutting Modes

Laser cutting machines for aluminum operate in several modes, each suited to a specific application. Some of the primary cutting modes include:

Each cutting mode requires adjustments to the laser’s power, speed, and assist gas, depending on the material thickness and desired cut type.

Cutting Parameters

The key to achieving a high-quality cut in aluminum lies in controlling the cutting parameters. These parameters include:

Correctly setting and adjusting these parameters is crucial for ensuring that the laser cutting process is both efficient and effective.

Material Properties

The properties of aluminum itself have a significant impact on the laser cutting process. The key properties to consider when laser cutting aluminum include:

Adjusting the laser parameters based on these properties ensures the best possible cutting performance.

Job Queues

Job queues refer to the sequence of tasks that the CNC machine will perform during the laser cutting process. If multiple parts need to be cut from a single sheet of aluminum, the machine can be programmed to follow an efficient cutting sequence that minimizes waste and reduces the time spent between each cut. Organizing the job queue ensures that the cutting process runs smoothly and that the material is used efficiently.

Material Loading

Once the CNC machine is programmed and the cutting path is defined, the next step is loading the aluminum material onto the machine. Proper material loading is essential for ensuring accuracy during the cutting process. The aluminum sheet must be securely placed and aligned on the cutting bed to avoid any shifts that could affect the final cut.

By carefully considering material orientation and thickness during loading, manufacturers can avoid common issues like misalignment or incomplete cuts.

Preventing Potential Issues During Cutting

To prevent potential issues during the laser cutting process, several factors must be considered:

By paying attention to these key factors, you can avoid common laser cutting issues and achieve optimal results.

Conclusion

Laser cutting aluminum offers numerous benefits, including precision, efficiency, and the ability to handle complex shapes. By understanding the key elements involved in the process, such as machine programming, cutting parameters, and material properties, you can ensure that your CNC machining projects are successful. Whether you're cutting thin sheets or thick aluminum profiles, knowing how to optimize these factors will result in high-quality parts and faster production times.

Calibrating the Laser

Calibrating the laser is a critical step in the laser cutting process. Proper calibration ensures that the laser beam is focused accurately and has the correct power to cut through aluminum effectively. A well-calibrated laser results in smoother cuts, fewer errors, and more efficient operations. Misalignment, incorrect settings, or an unfocused beam can lead to poor cut quality, increased production costs, and wasted materials. Therefore, calibration is essential for ensuring the highest precision and the best performance in laser cutting operations.

For aluminum, higher power densities are often required due to its high reflectivity and thermal conductivity. A laser that has too low a power density may struggle to cut through thicker aluminum sheets, while a laser that has too high a power density could result in over-melting or excessive dross buildup on the edges. Ensuring the right balance of power density is key to achieving smooth, accurate cuts.

The laser’s focus is typically adjusted based on the thickness of the aluminum being cut. Thinner materials require a finer focus, while thicker sheets of aluminum may need a slightly wider focus to ensure a clean, through-cut. Regular checks and recalibration of the focus point are necessary to maintain optimal cutting performance throughout the production run.

Calibrating the assist gas flow rate is crucial because too little gas will result in poor material removal, leading to rough cuts and potential thermal issues. Too much gas can cause instability in the cutting process or waste energy. Ensuring the correct assist gas flow, combined with the right laser power and focus, is key to achieving smooth, high-quality cuts.

Feed Speed

Feed speed refers to how quickly the laser cutting head moves across the material. The feed speed directly affects the quality and efficiency of the cutting process. If the feed speed is too fast, the laser may not have enough time to cut through the material, leading to incomplete cuts and poor edges. Conversely, if the feed speed is too slow, it may result in excessive heat buildup, leading to rough edges or material distortion.

To calibrate feed speed properly, it must be matched with both the laser power and the material thickness. Thicker aluminum materials require slower feed speeds to ensure the laser has enough time to melt or vaporize the material thoroughly. Calibrating the feed speed to work in harmony with other cutting parameters is essential for producing high-quality cuts efficiently.

Laser Power

Laser power determines the intensity of the beam and is directly linked to the cutting ability of the laser. For aluminum, adjusting the laser power based on material thickness and cutting speed is essential. A higher power setting may be needed for thicker materials to ensure the laser can penetrate deeply and cleanly.

Proper calibration ensures the laser power is adequate to cut through the material without causing damage. Too little power can result in incomplete cuts, while too much power can cause excess heat, burn marks, or unwanted oxidation. Ensuring that laser power is well-calibrated for each specific job is necessary for maintaining optimal cutting quality.

Cutting Head

The cutting head holds the laser optics and directs the laser beam onto the material. The cutting head must be aligned properly to ensure the laser beam hits the material at the right angle, producing clean, accurate cuts. Misalignment of the cutting head can lead to off-center cuts, inaccurate shapes, or uneven cutting depth.

In addition to alignment, the cutting head also needs to be maintained regularly to ensure optimal performance. The nozzle through which the assist gas flows should be free of obstructions and properly aligned to direct gas efficiently. Calibration of the cutting head, including ensuring correct nozzle positioning, is crucial for achieving precision and avoiding cutting defects.

Post-Processing

After the laser cutting process is complete, post-processing is often required to refine the cuts, remove unwanted material, and prepare the final product for use. This step involves a series of operations designed to improve the finish of the cut edges, remove excess material like dross, and ensure the parts meet quality standards. Proper post-processing can significantly enhance the final appearance and function of the aluminum parts, making them suitable for their intended applications.

Removing Dross: Dross is the residue that forms along the edges of a laser cut due to the vaporization of the material. In aluminum, dross can be particularly problematic if not properly managed. If left unremoved, dross can affect the surface finish of the part, creating imperfections and interfering with further processing steps.

To remove dross effectively, a variety of methods can be employed, including mechanical scraping, sandblasting, or using a secondary laser pass. The choice of method depends on the part’s design, thickness, and required finish. Regular calibration and fine-tuning of the laser parameters, such as assist gas flow and power, can help minimize dross formation in the first place, reducing the need for extensive post-processing.

Edge Smoothing: Edge smoothing is an essential part of post-processing that improves the surface finish of the cut. Laser cutting, particularly when cutting thicker materials, can leave rough or uneven edges. Edge smoothing involves removing any burrs, jagged edges, or oxidation that may have occurred during cutting.

Several techniques can be used for edge smoothing, including mechanical deburring, chemical treatments, or polishing. For aluminum, chemical treatments like anodizing or passivation can help improve the appearance and provide additional corrosion resistance. Edge smoothing not only improves the aesthetics of the cut but also enhances the part’s functionality by ensuring smooth surfaces that fit together more precisely in assembly.

Additional Processing: Beyond removing dross and smoothing edges, additional post-processing steps may be required depending on the part’s final use. These steps could include:

By carefully handling post-processing tasks, manufacturers can ensure that the final product is of the highest quality and meets all functional and aesthetic requirements.

Conclusion

Laser cutting of aluminum is a highly precise, efficient process that offers numerous benefits, including speed, accuracy, and the ability to cut complex shapes. Proper calibration of the laser, including adjusting parameters such as power density, focus, assist gas, and feed speed, is critical to achieving the best results. Post-processing steps like dross removal, edge smoothing, and additional finishing ensure that the final aluminum parts meet the required standards for quality and functionality. By understanding and fine-tuning the laser cutting process, manufacturers can achieve high-quality aluminum CNC machining parts for a wide range of applications.

Laser cutting of aluminum has come a long way since its inception in the late 1960s. Initially, lasers were used for research and basic material processing. However, as technology advanced, laser cutting became a highly efficient and versatile method for cutting metals, particularly aluminum. Over time, innovations in laser technology—such as the development of fiber lasers, CO2 lasers, and solid-state lasers—have revolutionized the way manufacturers cut and process aluminum, offering more precision, speed, and flexibility.

In the early stages, laser cutting was mostly limited to materials like steel and other metals with lower reflectivity. However, with improvements in laser beam power and processing technology, lasers became capable of cutting reflective metals like aluminum. Today, laser cutting is a critical part of many industries, from aerospace and automotive to manufacturing and electronics.

There are three main types of laser cutting machines used to cut aluminum: fiber laser cutting machines, CO2 laser cutting machines, and solid-state lasers. Each type offers distinct advantages and challenges, depending on the material properties, cut quality, and production needs.

Laser cutting technology has evolved over time, and each laser type has its strengths and weaknesses when it comes to cutting aluminum. Below, we’ll explore each of these laser types, examining their features, benefits, and challenges, as well as their suitability for cutting aluminum.

Fiber Laser Cutting Machines

Fiber laser cutting machines are one of the most advanced and widely used systems for cutting aluminum. These machines use a fiber-optic cable to deliver laser light, which is then focused on the material. Fiber lasers have rapidly become the preferred choice for cutting metals due to their superior efficiency and ability to cut reflective materials like aluminum.

Fiber Laser Cutting Machine Features:

Challenges:

While fiber lasers are highly efficient and fast, they do have some challenges when cutting aluminum:

CO2 Laser Cutting Machines

CO2 laser cutting machines are one of the oldest and most commonly used types of lasers for cutting various materials, including aluminum. These machines use a carbon dioxide gas mixture to produce a highly concentrated laser beam. CO2 lasers are often used for a variety of industrial cutting applications, including those involving metals, plastics, and ceramics.

CO2 Laser Cutting Machine Features:

Applications:

Despite the challenges, CO2 lasers are still used in a variety of applications where the cutting quality of aluminum is crucial. They are commonly employed in industries such as:

Solid State Lasers

Solid-state lasers are a newer category of lasers used for cutting aluminum and other materials. These lasers use solid-state materials like Nd:YAG (neodymium-doped yttrium aluminum garnet) to generate the laser beam. While not as common as fiber or CO2 lasers, solid-state lasers are gaining popularity due to their beam quality and efficiency.

Solid-State Laser Features:

Applications:

Solid-state lasers are used in specialized applications, including:

Challenges:

Despite their advantages, solid-state lasers do have some limitations:

Conclusion

Laser cutting of aluminum has evolved significantly over the years, with fiber lasers, CO2 lasers, and solid-state lasers offering unique features that make them suitable for various applications. Fiber lasers are ideal for high-speed, high-precision cutting, while CO2 lasers remain useful for cutting thinner aluminum sheets and are still widely used due to their reliability. Solid-state lasers, although less common, offer exceptional beam quality and energy efficiency, making them ideal for specialized tasks. Understanding the characteristics, strengths, and challenges of each laser type is essential for choosing the best technology for your aluminum cutting needs.

Laser cutting aluminum is a sophisticated and highly efficient process that requires careful attention to various material properties and cutting parameters. To achieve precise, clean cuts, it’s important to consider the specific challenges aluminum presents, such as its oxide films, thermal conductivity, and reflectivity. Understanding these material-specific characteristics and how they interact with laser technology is essential to optimizing the cutting process.

Aluminum is one of the most commonly laser-cut materials, thanks to its lightweight, corrosion-resistant properties. However, its unique characteristics—such as high reflectivity, thermal conductivity, and the formation of oxide films—pose specific challenges that need to be addressed during the cutting process. By understanding these properties and optimizing the laser cutting settings, manufacturers can achieve high-quality cuts with minimal waste and efficient production times.

Aluminum Oxide Films

One of the main challenges when laser cutting aluminum is the formation of aluminum oxide films on the material’s surface. Aluminum naturally forms a thin oxide layer when exposed to air, which provides excellent corrosion resistance. However, this oxide film can interfere with the laser cutting process by reflecting a portion of the laser energy, reducing cutting efficiency.

To overcome this, laser cutting machines for aluminum typically employ assist gases like nitrogen or oxygen to blow away the oxide layer and prevent it from hindering the cut. Nitrogen is commonly used to create clean, oxide-free cuts, while oxygen can be used for faster cutting at the expense of leaving rougher edges. Special attention to the assist gas type and pressure is crucial for minimizing the effects of aluminum oxide films.

Viscosity and Thermal Conductivity

Aluminum has high thermal conductivity, which means it dissipates heat quickly. This is beneficial in preventing overheating but can pose challenges during laser cutting, especially with thicker materials. The rapid dissipation of heat from the cutting zone requires the laser to provide enough energy to maintain a consistent cut. The combination of this high thermal conductivity and the material’s low viscosity (which allows it to flow easily when melted) requires precise control of laser parameters to ensure smooth and clean cuts.

Additionally, aluminum’s high thermal conductivity means that the cut must be performed at high speeds to prevent heat buildup in the material. This is crucial for achieving a clean cut and preventing distortion or warping of the material.

Assist Gas Flow and Laser Focusing

To optimize the laser cutting process for aluminum, the flow of assist gas and the focus of the laser beam are crucial factors. Assist gases, such as nitrogen or oxygen, help cool the cutting area, remove molten material, and reduce oxidation. The gas flow must be calibrated to ensure that it supports the cutting process without causing turbulence, which could lead to uneven cutting.

The focus of the laser beam is equally important. A well-focused laser ensures that the energy is concentrated on the material, providing a precise and clean cut. If the laser is not properly focused, the beam will scatter, reducing cutting efficiency and leading to poor-quality edges. Regular calibration of both the assist gas and laser focus is necessary to achieve the best results when cutting aluminum.

Optimizing the laser cutting process for aluminum involves adjusting several key factors:

By carefully considering these factors and adjusting the machine parameters, manufacturers can optimize the cutting process to achieve precise and high-quality results.

An aluminum laser cutting machine is made up of several key components that work together to perform the cutting process. These components include:

The main parameters for laser cutting aluminum include:

By adjusting these parameters, you can optimize the laser cutting process for aluminum, achieving the best balance between quality and efficiency.

The cutting tolerances for aluminum laser cutting typically range from ±0.1mm to ±0.3mm, depending on the thickness of the material, the cutting machine’s precision, and the complexity of the cut. For thinner aluminum sheets, tolerances can be tighter, while thicker materials may require slightly looser tolerances. The cutting process itself, including parameters like laser power, focus, and assist gas flow, can also affect the final tolerance. Achieving tight tolerances is essential for high-precision parts used in industries like aerospace, automotive, and electronics.

Laser cutting machines can cut aluminum sheets of varying thicknesses, with the maximum thickness depending on the type of laser and its power. For fiber laser cutting machines, typical maximum cutting thickness ranges from 12mm to 25mm, while CO2 lasers can handle aluminum sheets up to 20mm thick. Thicker sheets may require multiple passes or a higher-power laser to achieve clean cuts. The thickness that can be effectively cut will also depend on the specific machine configuration and the quality of the cutting edge required.

The best grades of aluminum for laser cutting depend on the application and desired outcomes. Some of the most commonly used aluminum grades for laser cutting include:

Choosing the right aluminum grade depends on the specific project requirements, such as strength, corrosion resistance, and machinability.

Conclusion

Laser cutting aluminum is a highly efficient and precise method for producing custom parts. By understanding and optimizing the key factors such as material properties, cutting parameters, and machine settings, manufacturers can achieve high-quality results. With the right machine and optimal conditions, laser cutting can handle aluminum sheets of various thicknesses and grades, making it ideal for a wide range of industries. Whether you are cutting thin sheets for electronics or thicker materials for structural components, laser cutting provides a versatile solution for achieving precision and efficiency.

Laser cutting aluminum is a popular method in the manufacturing and production industries due to its precision, efficiency, and versatility. However, like any process, it has its set of challenges. In this article, we’ll explore both the advantages and the challenges associated with laser cutting aluminum, helping you make informed decisions about using this cutting technology for your CNC machining projects.

Laser cutting aluminum offers several benefits, including precision, speed, and flexibility in creating custom CNC machining parts. However, aluminum's unique properties, such as high reflectivity and thermal conductivity, can create challenges during the cutting process. By understanding both the advantages and challenges, manufacturers can optimize laser cutting parameters and achieve high-quality results while overcoming obstacles effectively.

Advantages of Laser Cutting Aluminum

Laser cutting aluminum provides several significant advantages that make it a preferred choice for various industries, from aerospace to automotive and beyond. Let’s take a closer look at these benefits:

High Precision

One of the most significant advantages of laser cutting aluminum is its exceptional precision. Laser cutting can achieve tolerances as tight as ±0.1 mm or better, which is crucial for manufacturing parts that require high accuracy. This level of precision is particularly beneficial for cutting intricate shapes and fine details in aluminum, which would be challenging to achieve using traditional cutting methods. Laser cutting allows for repeatability, ensuring each part is cut with the same accuracy, which is essential for large-scale production.

Speed

Laser cutting is a fast and efficient process. The high-speed operation of laser cutters allows manufacturers to produce large quantities of aluminum parts in a relatively short period. This speed is especially valuable when producing thin to medium-gauge aluminum materials, where laser cutting can be 2 to 3 times faster than other conventional methods, such as punching or mechanical cutting. The faster cutting times can significantly reduce production costs, especially in high-volume manufacturing.

Versatility

Laser cutting aluminum is highly versatile. It can cut through a wide range of aluminum thicknesses, from thin sheets (as thin as 0.2 mm) to thicker materials (up to 25 mm or more, depending on the machine and settings). Additionally, laser cutting can be used for various applications, including engraving, etching, and cutting complex designs or custom parts. The versatility of laser cutting enables it to be used in multiple industries, from aerospace and automotive to electronics and signage.

Other Advantages

Beyond the core benefits of precision, speed, and versatility, laser cutting offers additional advantages:

While laser cutting aluminum offers numerous advantages, it does come with its own set of challenges. Manufacturers need to address these issues to ensure optimal cutting results. Below are some of the most common challenges:

High Reflectivity

Aluminum’s high reflectivity is one of the main challenges when laser cutting. The reflective surface causes a significant portion of the laser energy to bounce off, reducing the cutting efficiency. This results in slower cutting speeds and potential energy loss, requiring adjustments to the laser power and assist gas settings. Fiber lasers are more effective at handling reflective materials than CO2 lasers, but even fiber lasers require careful calibration to prevent energy loss and achieve clean cuts.

Thermal Conductivity

Aluminum’s high thermal conductivity presents another challenge. It dissipates heat quickly, making it difficult to maintain the necessary cutting temperature in the material. The rapid heat transfer means that a laser cutter must deliver consistent and controlled energy to the cutting zone. Thicker aluminum materials require more power and slower feed speeds to compensate for the heat dissipation, which can result in slower cutting speeds compared to other materials.

Cost

One of the main considerations when using laser cutting is the cost. Laser cutting machines, especially high-powered fiber lasers, come with a significant upfront investment. Additionally, the operational costs, such as maintenance, consumables (laser tips, lenses, assist gases), and electricity, can add up. The cost of operation is influenced by the thickness of the aluminum being cut, with thicker materials requiring more power and longer cutting times. This can make laser cutting more expensive than traditional methods in some cases, particularly for low-volume projects.

Additional Challenges

In addition to the core challenges of reflectivity and thermal conductivity, there are other considerations when laser cutting aluminum:

Laser cutting aluminum can be considered expensive, especially when compared to traditional cutting methods like mechanical cutting or shearing. The high upfront costs for laser cutting machines, the need for specialized training, and the ongoing costs for maintenance, consumables, and power usage contribute to the overall expense.

However, despite these costs, laser cutting aluminum offers significant advantages in terms of precision, speed, and versatility, making it a worthwhile investment for many manufacturers, particularly for complex or high-precision parts. Additionally, the speed and efficiency of laser cutting can reduce production times, which helps offset the high initial costs in high-volume operations.

In the long run, laser cutting may be more cost-effective for certain projects, especially when part complexity, accuracy, and production speed are key considerations. For large-scale manufacturers or industries where precision is critical (like aerospace or medical device manufacturing), the cost of laser cutting can be justified by the quality and efficiency it offers.

Conclusion

Laser cutting aluminum is an advanced and efficient process that provides many advantages, such as high precision, speed, and versatility. However, challenges such as high reflectivity, thermal conductivity, and the associated costs must be carefully managed. Understanding these advantages and challenges allows manufacturers to optimize their laser cutting processes, ensuring they achieve the best results while maintaining cost-effectiveness.

Laser cutting aluminum is an essential technology across various industries due to its precision, speed, and versatility. The ability to achieve high-quality cuts with minimal material wastage makes it ideal for producing complex parts with tight tolerances. From aerospace to electronics, many industries rely on laser cutting to meet their production needs. Let’s explore some of the major industries that use lasers to cut aluminum and why this technology is crucial for their operations.

Laser cutting has become the go-to solution for manufacturers in several key industries, particularly for materials like aluminum, which require precise cutting and high efficiency. The flexibility of laser cutting technology allows it to be adapted to a wide range of applications, from structural components to intricate parts for consumer electronics. Whether it's for large-scale manufacturing or high-precision requirements, laser cutting delivers results that are fast, accurate, and cost-effective. Below are the primary industries that use lasers for cutting aluminum and how they benefit from this advanced technology.

Aerospace

In the aerospace industry, precision and reliability are paramount, and laser cutting aluminum provides both. Aircraft parts, from fuselages to wing components, often require cutting aluminum alloys to exact specifications to ensure strength, weight reduction, and durability. The high-precision capability of laser cutting allows aerospace manufacturers to cut complex designs and profiles, ensuring that each part fits within tight tolerances for performance and safety. The reduced material wastage associated with laser cutting also helps optimize costs in this high-stakes industry.

Laser cutting is also beneficial for creating intricate internal geometries and lightweight structural parts that need to withstand high-stress conditions. Given the demanding standards of the aerospace sector, laser cutting is one of the most reliable ways to meet these needs.

The automotive industry uses laser cutting extensively, especially for manufacturing parts such as chassis, body panels, engine components, and structural parts. The precision of laser cutting ensures that parts are consistently produced to exact specifications, which is critical for vehicle safety, performance, and assembly.

In modern automotive production, reducing weight while maintaining strength is crucial for improving fuel efficiency and performance. Laser cutting is ideal for achieving lightweight, durable parts made from aluminum, while its precision also helps reduce the amount of finishing and secondary processing needed. The automotive industry also benefits from the high-speed capabilities of laser cutting, enabling fast production times and cost-effective large-scale manufacturing.

Construction

In construction, laser cutting is used to fabricate a wide range of aluminum components, such as structural beams, window frames, doors, and other architectural elements. Aluminum's corrosion resistance, lightweight properties, and aesthetic appeal make it an ideal material for construction, and laser cutting allows for precise shapes and intricate designs that are often required in modern architecture.

Laser cutting ensures that aluminum parts meet the exact specifications needed for building projects, whether it's for structural integrity or aesthetic appeal. The ability to cut aluminum sheets into customized shapes with high precision also allows for more complex and flexible design possibilities in both residential and commercial buildings.

Other Industries

Beyond aerospace, automotive, and construction, there are several other industries that benefit from the ability to laser cut aluminum.

Manufacturing

Laser cutting plays a crucial role in the manufacturing of parts and components across various sectors. It’s used to create everything from small, intricate machine components to large panels for industrial equipment. The manufacturing industry relies on laser cutting for its ability to produce highly accurate, repeatable parts, which are essential for efficient assembly and production.

Design

The design industry, including fields such as interior design and product design, frequently uses laser cutting for creating customized, intricate aluminum parts. Designers use aluminum for its aesthetic qualities as well as its lightweight nature, and laser cutting enables the creation of precise, detailed patterns for artistic or functional pieces. This is often used in the creation of signage, decorative elements, and even furniture, where precision and a clean finish are critical.

Energy

The energy sector, including solar and wind power, also utilizes laser cutting to fabricate components made from aluminum. For instance, aluminum parts used in solar panel frames or wind turbine structures require the strength and durability that laser cutting can provide, especially in harsh environments. The ability to cut aluminum with precision helps improve the overall efficiency and performance of energy production systems.

The electronics industry uses laser cutting to create parts for devices such as smartphones, laptops, and other consumer electronics. Laser cutting allows for the production of thin, complex aluminum parts that are essential for modern electronics. It is particularly important for creating lightweight enclosures, heat sinks, and other components where precision and a clean finish are essential for both aesthetic and functional purposes.

While laser cutting aluminum offers numerous advantages, it’s important to understand and optimize several factors to ensure the best results. In addition, avoiding common mistakes during the process can prevent issues like poor cut quality, material wastage, and costly rework.

Laser cutting aluminum requires careful consideration of several key factors. Properly adjusting the machine settings, choosing the right assist gas, and maintaining the correct cutting parameters are essential for achieving clean, precise cuts. Additionally, it’s important to be aware of common mistakes that can occur during the process, as these can result in poor cut quality or inefficiencies. Let’s explore the main factors to consider and mistakes to avoid when laser cutting aluminum.

Key Factors to Consider Include:

Common Mistakes to Avoid Include:

Conclusion

Laser cutting aluminum is a highly effective process that offers numerous advantages, such as high precision, speed, and versatility. However, to achieve the best results, it is important to carefully consider factors like material thickness, assist gas type, and laser power, while avoiding common mistakes such as incorrect focus, insufficient assist gas flow, and improper cutting speed. By understanding these key factors and optimizing the cutting process, manufacturers can ensure that their aluminum parts are produced efficiently, with excellent quality, and meet the specific requirements of their respective industries.

Laser cutting aluminum is a highly precise and efficient method that allows manufacturers to create custom parts and components quickly and with excellent accuracy. Whether you're working with thin sheets for electronics or thicker panels for structural components, laser cutting can deliver consistent, high-quality results. This guide will walk you through the steps for preparing and executing a successful aluminum laser cutting job, from selecting the right aluminum grade to fine-tuning your machine settings.

Laser cutting aluminum involves using a focused laser beam to cut through the material. This process provides the precision needed for intricate designs and parts with tight tolerances. It’s used extensively in industries like aerospace, automotive, and electronics. However, achieving the best results requires careful preparation and an understanding of how aluminum behaves during the cutting process. In this guide, we’ll cover the steps you need to take before and during the cutting process to ensure clean, precise cuts.

Preparing to Laser Cut Aluminum

Before starting the laser cutting process, there are several critical steps to ensure the material and machine are set up correctly. Proper preparation is essential for achieving optimal results and avoiding common cutting issues like poor quality, excessive heat, or material distortion.

Choosing the Right Aluminum Grade and Thickness

The first step in preparing to cut aluminum is selecting the appropriate aluminum grade and thickness for your project. Different aluminum grades have varying properties, such as strength, corrosion resistance, and machinability, so it’s essential to choose one that meets the requirements of your specific application.

Aluminum Grades: Some common grades for laser cutting include:

Thickness: The thickness of the aluminum sheet will determine the laser power and cutting speed required. Thin sheets (0.2 mm to 3 mm) require lower power and faster speeds, while thicker sheets (5 mm to 25 mm or more) need higher power and slower speeds to ensure a clean cut. Understanding the thickness will help you calibrate the machine for the best results.

Calibrating Laser Settings

Once the material is chosen, the next step is to calibrate the laser cutting machine to ensure that the laser beam is operating at optimal parameters. Correct calibration is essential for achieving precise, clean cuts and avoiding issues like excessive heat buildup or incomplete cuts.

Power Levels and Speeds

The power level of the laser determines how much energy is delivered to the aluminum, and the feed speed controls how quickly the laser head moves across the material. Both factors need to be adjusted according to the material thickness and type.

Focus and Beam Quality

The focus of the laser is critical for achieving precision. A laser that is too focused can create a narrow cutting area, potentially missing parts of the material. Conversely, an unfocused beam can produce wide cuts that are inaccurate.

Preparing the Cutting Table

Proper setup of the cutting table is crucial for achieving consistent cuts and preventing material movement during the process. The cutting table holds the aluminum sheet in place and supports the material during the laser cutting operation. Here are the key components to focus on when preparing the cutting table:

Support Rods

Support rods or rollers help keep the aluminum sheet stable during cutting. Ensuring that the material is well-supported across its entire surface is essential to prevent any warping, bending, or shifting. Support rods are particularly important when cutting larger or thicker sheets of aluminum, as they help maintain alignment throughout the process.

Nozzle and Cutting Head

The nozzle and cutting head are responsible for directing the laser beam and assist gases (such as nitrogen or oxygen) to the material’s surface. It’s crucial to check that the nozzle is clean and free from any obstructions that could interfere with the cutting process.

Test Run

Before proceeding with the full production run, it’s always a good idea to perform a test run. A small test cut will allow you to verify that the laser settings, material alignment, and cutting parameters are correct. During the test, check the cut quality, edge smoothness, and overall precision to ensure that everything is functioning as expected.

Performing a test cut can help identify any potential issues early on, such as incorrect focus, power settings, or material alignment, allowing for quick adjustments before beginning the full production.

Conclusion

Laser cutting aluminum is a highly effective method for achieving precise, clean cuts with minimal material waste. However, to ensure optimal results, proper preparation is essential. By choosing the right aluminum grade and thickness, calibrating your laser settings for power, speed, focus, and beam quality, and preparing the cutting table for stability, you can achieve high-quality, accurate cuts every time. A test run before the full production process further ensures that the setup is correct, allowing you to confidently proceed with the cutting operation. By following these steps, you can maximize the efficiency and quality of your laser cutting aluminum process.

Laser cutting aluminum is a highly precise and effective method used across various industries. However, like all cutting processes, it comes with certain safety risks due to the high temperatures, laser radiation, and potentially hazardous fumes generated during the process. Following proper safety protocols ensures the safety of operators and helps maintain a productive work environment.

Laser cutting involves using high-powered lasers to cut through materials such as aluminum, and the process requires special safety measures. Ensuring the protection of workers while maintaining optimal productivity is essential. Below, we outline some essential safety tips to follow when operating a laser cutting machine, particularly for aluminum, to ensure both safety and effective operation.

Always Wear Protective Gear

The first line of defense when laser cutting aluminum is the protective gear worn by operators. As with any industrial machinery, safety should be the primary concern.

Ensure Proper Ventilation

Proper ventilation is critical when laser cutting aluminum. The cutting process generates heat and fumes, especially if any coating or material other than pure aluminum is being cut. Ensuring that the area is well-ventilated helps prevent the buildup of potentially harmful gases and maintains a safe environment for operators.

The design stage plays a significant role in ensuring the laser cutting process runs smoothly and produces high-quality results. Here are a few key design tips to consider when preparing to cut aluminum.

When designing parts for laser cutting, it’s important to keep in mind the limitations and strengths of the process. Laser cutting is well-suited for intricate, detailed designs, but certain considerations must be made when working with thicker aluminum materials. Below are some essential design tips that can help optimize your laser cutting process and ensure that your designs are both feasible and efficient to cut.

Avoid Complex Designs on Thicker Sheets

Thicker aluminum sheets require more laser power to cut and may result in longer cutting times. To avoid complications and inefficiencies, try to avoid overly complex designs when working with thicker sheets. The more intricate the design, the slower the cutting process may be, and more energy is required to cut through the material.

For thicker aluminum sheets (more than 6mm), it’s advisable to keep the design simpler to minimize the risk of excessive heat buildup, potential material warping, and slower production times. Instead, break down complex designs into simpler shapes or components that can be cut efficiently.

Complexity and Detail

Laser cutting excels at cutting detailed and intricate designs, particularly on thinner aluminum sheets. For designs requiring fine details or small holes, laser cutting can produce excellent results with high precision. However, it’s essential to take into account the material thickness and the laser’s ability to handle fine details.

When working with thinner aluminum (less than 3mm), you can incorporate more complexity into your designs, as the laser can cut these with high speed and accuracy. For detailed cutouts, fine lines, or patterns, laser cutting can achieve results that are difficult to match with traditional cutting methods.

CAD Software

Using computer-aided design (CAD) software is essential for creating the correct design files for laser cutting. CAD software allows for accurate and precise modeling of parts, helping to ensure that the designs are optimized for laser cutting. CAD files are typically saved as vector-based formats (such as DXF, SVG, or AI files), which are directly interpretable by laser cutting machines.

Additionally, CAD software allows designers to visualize the final cut before production, identify any potential issues with the design, and make adjustments to ensure smoother cutting operations. For more complex designs, CAD software also allows for the organization of parts on a cutting sheet, minimizing material waste.

Precise Programming with CAD Software

Once the design has been finalized in CAD software, the next step is programming the laser cutting machine to execute the design. Precise programming ensures that the laser cutter follows the correct path, cutting at the optimal speed and power.

File Types

When preparing CAD files for laser cutting, ensure that the file format is compatible with the laser cutter. The most common file formats for laser cutting are DXF (Drawing Exchange Format), SVG (Scalable Vector Graphics), and AI (Adobe Illustrator). These formats allow the cutting machine to interpret the vector paths and instructions for each part of the design.

Each file type has specific settings for laser cutting, including parameters for line thickness, cutting paths, and engraving instructions, so it is essential to ensure that the file is correctly prepared for the laser cutter.

Templates

For repetitive or large-scale cutting projects, using templates within CAD software can help streamline the design process. Templates allow designers to quickly replicate common shapes or patterns, saving time and reducing the chances of errors. Templates also help optimize the arrangement of parts on the material to reduce waste and improve material efficiency.

Additional Tips

In addition to the considerations above, here are a few additional tips to ensure successful laser cutting:

Conclusion

Laser cutting aluminum offers numerous advantages, including precision, speed, and versatility. By following the right safety procedures, preparing your design with the right software, and optimizing cutting parameters, you can ensure that your laser cutting projects run smoothly. With careful preparation and attention to detail, you can take full advantage of the precision and efficiency that laser cutting provides while avoiding common pitfalls. Whether you are a professional or a hobbyist, understanding these safety and design tips will help you achieve excellent results every time.

Laser cutting aluminum is a precise and efficient method for creating intricate parts, but the cost of the process can vary depending on several factors. These factors include the complexity of the project, the efficiency of the laser cutting machine, material costs, post-processing needs, and geographic location. Understanding these elements can help businesses and manufacturers estimate the overall cost of laser cutting aluminum and determine if this cutting method fits within their budget.

Laser cutting is one of the most accurate and efficient methods for cutting aluminum, but it is important to consider various factors that can influence the overall cost of the process. Whether you're cutting small, intricate components for electronics or larger structural parts for construction, each job will have a different cost structure. Let’s dive into the different factors that influence the cost of laser cutting aluminum.

Project Complexity

The complexity of the design plays a significant role in the cost of laser cutting. Intricate designs with fine details, small holes, or curves require more precision and time to cut, which increases the cost of the project. The more complex the design, the longer the cutting process will take, leading to higher labor and machine operating costs. Additionally, intricate cuts may require specialized settings for the laser cutter, further contributing to the cost.

For simpler, more straightforward designs, the cutting process is faster and requires fewer adjustments, making it more cost-effective. Therefore, if you're working with a straightforward shape, you can expect lower costs compared to highly detailed or customized designs.

Laser Cutter Efficiency

Laser cutter efficiency is another factor that influences the cost of cutting aluminum. More advanced laser cutters, particularly fiber lasers, are faster and more efficient at cutting through aluminum, which reduces overall production time and costs. These machines typically offer better energy efficiency and higher cutting speeds, making them ideal for high-volume production.

Older or less efficient machines, such as CO2 lasers, may take longer to cut through aluminum, leading to higher operating costs. Additionally, the quality of the cuts may not be as high, which may require more post-processing to achieve the desired finish, increasing the overall cost.

Material Costs

Material costs also factor into the price of laser cutting aluminum. The cost of aluminum itself can vary based on factors such as the grade of aluminum, thickness, and quality. For example, high-strength aluminum alloys or specialized grades of aluminum may cost more than standard grades. Additionally, thicker aluminum sheets require more power and time to cut, further increasing material costs.

It’s important to choose the right aluminum grade for your project to balance cost and performance. While higher-quality materials may be more expensive upfront, they may offer superior durability and longevity, making them a more cost-effective choice in the long run.

Post-Processing

In many cases, laser cutting doesn’t result in a completely finished part. Post-processing operations like deburring, edge smoothing, anodizing, or polishing may be required to achieve the desired quality and finish. These additional steps can add to the overall cost of the project, especially if multiple treatments are necessary.

For example, aluminum parts cut by laser often require additional work to remove dross (residual molten material) or smooth rough edges, which takes extra time and resources. Be sure to account for any post-processing steps when estimating the total cost of a laser cutting project.

Geography

The location of the laser cutting service also plays a role in the cost. Costs can vary depending on the region, as labor rates, facility overheads, and energy prices can differ. Additionally, shipping costs can be a significant factor if materials or finished parts need to be transported across large distances.

In general, laser cutting services in areas with higher operating costs (such as urban centers) may charge more for their services. Conversely, services located in regions with lower overhead costs may offer more competitive pricing. It’s important to consider the geographic location when comparing quotes from different laser cutting services.

The price of an aluminum laser cutting machine varies greatly depending on the features, performance, and capabilities of the machine. Laser cutters range in price from affordable, entry-level models to high-end industrial machines, and understanding these differences is important when considering the initial investment.

The cost of purchasing an aluminum laser cutting machine can vary widely based on factors such as laser type, power, and brand. For small-scale operations, a lower-cost, less powerful laser cutter might be sufficient, while larger manufacturers may require high-performance machines capable of handling large volumes and thick materials. Let's take a look at some of the main factors that affect the cost of these machines.

Features and Performance

The features and performance capabilities of a laser cutting machine play a crucial role in determining its cost. Machines with advanced features like high cutting speeds, higher power, automated systems, and precision control tend to be more expensive. Additionally, more powerful machines that can handle a variety of materials and thicknesses are generally priced higher.

Brands

The brand of the laser cutter also influences its price. Well-known brands that specialize in high-quality industrial machinery tend to have higher prices, but they also offer better reliability, customer support, and advanced features. Some of the leading brands in the laser cutting market include Trumpf, Bystronic, and Amada. These companies are known for their cutting-edge technology and higher prices, while more affordable brands like Raycus or Baofeng may offer entry-level machines at a lower cost.

Laser Power

Laser power is another critical factor in determining the price of a laser cutting machine. More powerful lasers can cut through thicker aluminum more efficiently, but they come with a higher price tag. Fiber lasers typically have higher efficiency and can handle thicker materials than CO2 lasers, making them more expensive.

Maintenance and Consumables

In addition to the initial purchase cost, laser cutters have ongoing maintenance and consumables costs. Regular maintenance, such as cleaning and replacing parts, is necessary to keep the machine in optimal condition. Consumables like laser lenses, nozzles, and assist gases also add to the operational cost. Consumables are typically priced based on the machine's usage, material thickness, and production volume.

Add-ons and Upgrades

Additional features and upgrades—such as automated material loading, enhanced cooling systems, or high-performance cutting heads—can increase the price of a laser cutting machine. These upgrades often improve the overall efficiency, cut quality, and versatility of the machine, but they also contribute to a higher purchase cost.

Choosing the best aluminum laser cutter depends on your specific needs, such as cutting speed, precision, and the volume of materials you need to cut. Below are some key qualities to consider when selecting a laser cutter:

When evaluating aluminum laser cutters, it’s important to assess factors like cutting speed, precision, ease of use, and maintenance requirements. The right laser cutter will offer a balance of these qualities to meet your business needs and budget. Let’s take a closer look at what makes a laser cutter "the best" for cutting aluminum.

High Cutting Speeds

For high-volume production, cutting speed is a critical factor. The best laser cutters are capable of cutting aluminum at high speeds without sacrificing precision. Fiber laser cutters are known for their fast cutting speeds and ability to handle complex designs efficiently.

Precision and Accuracy

Precision is paramount in industries like aerospace, automotive, and electronics, where parts require exact measurements and tight tolerances. The best aluminum laser cutters offer exceptional accuracy, consistently producing high-quality cuts with minimal deviation.

Easy to Use

User-friendly interfaces and intuitive software make laser cutting machines more accessible and easier to operate. Machines with simple setups and clear instructions can reduce training time and increase productivity.

Low Maintenance

Maintenance is a crucial consideration when choosing a laser cutter. The best machines are designed for easy maintenance, with readily available parts and simple cleaning procedures. Machines with low maintenance costs and longer service intervals offer better long-term value.

While laser cutting is an excellent method for aluminum, there are other cutting technologies that might be more suitable depending on your needs.

Other cutting methods such as water jet cutting, plasma cutting, and mechanical cutting are commonly used for aluminum in certain applications. Each method has its strengths and weaknesses, and understanding the differences will help you choose the best cutting process for your project.

Water Jet Cutting

Water jet cutting uses a high-pressure stream of water mixed with abrasive particles to cut through aluminum. This method does not generate heat, making it ideal for cutting heat-sensitive materials. Water jet cutting offers smooth edges but can be slower than laser cutting, especially on thicker materials.

Plasma Cutting

Plasma cutting uses a high-temperature plasma jet to cut through aluminum. While faster than water jet cutting, plasma cutting is less precise than laser cutting, and the heat generated can cause rougher edges. Plasma cutting is typically used for thicker materials where precision is less critical.

Mechanical Cutting

Mechanical cutting, such as sawing or shearing, is often used for larger cuts and less intricate designs. This method is slower than laser cutting and may not offer the same level of precision, but it can be more cost-effective for basic cuts on thicker aluminum materials.

Conclusion

Laser cutting aluminum is an efficient, precise, and versatile method that is widely used across industries. While it can be more expensive upfront compared to other cutting methods, the advantages in terms of speed, precision, and cut quality make it a worthwhile investment for high-precision work. When considering an aluminum laser cutter, it's essential to factor in the machine’s cutting speed, precision, and maintenance costs. Additionally, evaluating alternatives like water jet cutting, plasma cutting, and mechanical cutting can provide a more comprehensive understanding of the best options for your specific cutting needs.

Can you cut aluminum with a laser?

Yes, aluminum can be cut with a laser. However, due to aluminum’s high reflectivity, special care needs to be taken when cutting it with a laser. Fiber lasers are commonly used for aluminum because they offer better efficiency and accuracy with reflective materials. CO2 lasers can also cut aluminum, but they are less efficient compared to fiber lasers.

How thick aluminum can a laser cutter cut?

Laser cutters can typically cut aluminum sheets up to 25mm thick, depending on the laser power and the machine’s capabilities. For thinner materials, cutting speeds are faster and the laser can cut through with ease. However, for thicker materials, more power and slower cutting speeds are needed to achieve clean, precise cuts. Fiber lasers can generally cut through thicker aluminum sheets more effectively than CO2 lasers.

What settings should I use to laser cut aluminum?

The ideal settings for laser cutting aluminum depend on factors like material thickness, the type of laser, and the desired cut quality. Some of the key settings to adjust include:

Testing the settings on a small section of the material can help fine-tune these parameters.

What is the best laser for cutting aluminum?

Fiber lasers are generally considered the best for cutting aluminum, especially when high precision and efficiency are required. Fiber lasers are more efficient than CO2 lasers for cutting reflective materials like aluminum, offering better beam absorption, faster cutting speeds, and less energy loss. This makes them ideal for applications requiring clean cuts and faster production times.

Can a 10W laser cut aluminum?

A 10W laser is not typically powerful enough to cut aluminum efficiently, especially thicker sheets. For laser cutting aluminum, you generally need a laser with at least 500W to 1kW of power for cutting thin aluminum. Higher-power lasers (2kW to 5kW or more) are better suited for thicker aluminum sheets.

What materials should you never cut with a laser cutter?

While lasers are versatile tools, there are some materials that should not be cut due to safety concerns or damage to the laser cutter:

Always ensure that the material you are cutting is laser-compatible to avoid hazardous fumes or damage to the machine.

What should you never try to cut with a laser cutter?

You should never attempt to cut materials that can cause dangerous fumes, fires, or damage to the machine. These include:

Always check the material compatibility before cutting with a laser.

What are the disadvantages of laser cutting?

While laser cutting offers many advantages, there are some disadvantages to consider:

What is the thickest material a laser cutter can cut?

The thickest material a laser cutter can cut depends on the type of laser and its power. For most laser cutters:

Fiber lasers can typically cut materials up to 25mm thick for metals like aluminum, though more powerful machines can handle thicker materials.

CO2 lasers can handle slightly less thickness for aluminum, typically cutting up to 20mm efficiently.

However, for very thick materials beyond 25mm, other methods like plasma cutting or waterjet cutting may be more effective.

What are the 5 types of lasers?

The five main types of lasers used in industrial cutting are:

What is the difference between a laser and a laser?

The term "laser" generally refers to a light amplification by stimulated emission of radiation. However, when comparing one laser to another, the difference lies in factors like the laser’s medium (e.g., CO2, fiber, or diode), wavelength, power, and application. The key differences often involve the laser's ability to cut or engrave certain materials, as well as its efficiency and cutting speed.

What can the most powerful laser do?

The most powerful lasers, particularly those used in industrial applications (such as high-power fiber lasers), can cut through very thick materials like steel, aluminum, and titanium. These lasers are capable of cutting through materials up to several inches thick and can perform high-precision cutting for large-scale manufacturing, aerospace, and automotive industries. High-power lasers are also used in welding, drilling, and additive manufacturing processes.

What is the best laser for cutting aluminum?

The fiber laser is generally considered the best for cutting aluminum due to its high efficiency with reflective materials. Fiber lasers provide faster cutting speeds, better precision, and reduced energy consumption compared to other laser types, such as CO2 lasers. They are ideal for cutting aluminum in both thin and thick materials, offering excellent edge quality and minimal heat-affected zones.

How thick aluminum can a laser cut?

As mentioned earlier, a laser can typically cut aluminum sheets up to 25mm thick. However, the maximum thickness depends on the power of the laser. Fiber lasers are more effective at cutting thicker aluminum compared to CO2 lasers, which are typically better suited for thinner materials.

What is used to cut aluminum?

Laser cutting, plasma cutting, water jet cutting, and mechanical cutting (such as sawing or shearing) are all commonly used to cut aluminum. Each method has its advantages, depending on the material thickness, cut quality, and production volume. Laser cutting is the most precise method, ideal for intricate designs and high-quality cuts. Plasma cutting is faster and more economical for thicker sheets, while water jet cutting is useful for materials that can’t withstand the heat generated by other methods. Mechanical cutting is often used for simpler cuts in thicker aluminum sheets.