15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

321 |

Published by VMT at Oct 28 2024 | Reading Time:About 2 minutes

321 |

Published by VMT at Oct 28 2024 | Reading Time:About 2 minutes

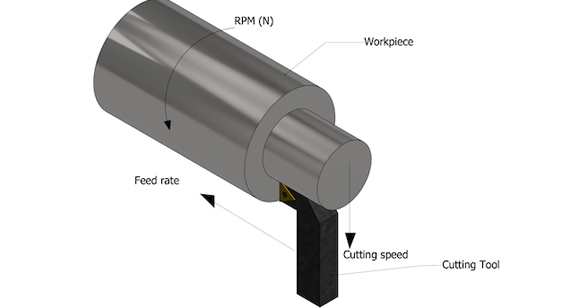

CNC machining is a cornerstone of modern manufacturing, enabling the precise fabrication of complex parts from various materials. Two crucial parameters that significantly affect the machining process are feed rate and cutting speed. Understanding the differences between these two concepts is vital for optimizing machining operations, enhancing productivity, and ensuring the longevity of tools. This guide will explore the definitions, optimal selections, and importance of feed rate and cutting speed in CNC machining, providing clarity for both novice and experienced machinists.

CNC machining refers to the automated control of machining tools via a computer. This technology allows for the precise shaping and cutting of materials like metal, plastic, and wood. CNC machines operate by following programmed instructions, translating them into precise movements that shape materials to specified dimensions. The ability to program complex geometries makes CNC machining invaluable in industries ranging from aerospace to medical device manufacturing. The accuracy, repeatability, and efficiency of CNC machining enable manufacturers to produce high-quality parts at scale.

The feed rate is the speed at which the cutting tool moves through the material during machining. Typically expressed in units such as inches per minute (IPM) or millimeters per minute (MPM), the feed rate is a critical parameter that influences the quality of the finished part, tool wear, and overall productivity. A higher feed rate can increase production speed but may lead to poorer surface finishes and increased tool wear. Conversely, a lower feed rate can enhance surface quality but may result in longer machining times.

Selecting the optimal feed rate is essential for achieving a balance between productivity and quality. Several factors influence this decision:

Productivity: Higher feed rates can lead to increased production rates, making it a critical consideration for manufacturers aiming to meet tight deadlines.

Surface Treatment: The required surface finish of the machined part directly affects the feed rate. Parts requiring a smoother finish may necessitate a slower feed rate to minimize tool marks.

Feed Rate Limitations: Not all machines can handle the same feed rates. Machine specifications and capabilities often dictate the maximum achievable feed rate.

Cutting Tool Geometry: The design of the cutting tool, including its shape and material, impacts how effectively it can handle varying feed rates. Certain geometries perform better at specific feed rates.

Machine Tool Capabilities: Different CNC machines have varying capabilities regarding feed rates. Understanding the limits of the machine can prevent inefficiencies and equipment damage.

Cutting speed refers to the speed at which the cutting edge of the tool moves relative to the workpiece. It is typically measured in surface feet per minute (SFM) or meters per minute (MPM). Cutting speed is a crucial factor in determining the efficiency of the machining process and significantly influences tool life and the quality of the machined surface.

Choosing the right cutting speed is critical for maximizing tool life and ensuring effective machining. Key factors influencing the selection of cutting speed include:

Workpiece Hardness: The hardness of the material being machined greatly affects the cutting speed. Harder materials typically require lower cutting speeds to prevent tool wear.

Cutting Tool Strength: The material and design of the cutting tool also dictate the appropriate cutting speed. High-speed steel (HSS) tools, for example, have different cutting speed requirements compared to carbide tools.

Tool Life: Increasing cutting speed can enhance productivity but may reduce tool life. It is essential to find a balance that maintains acceptable tool longevity while optimizing machining efficiency.

Understanding and controlling feed rate and cutting speed are critical for several reasons:

Efficiency: Properly optimizing these parameters ensures efficient machining, reducing cycle times and increasing productivity.

Quality: The quality of the finished part is closely linked to feed rate and cutting speed. Incorrect settings can lead to poor surface finishes or dimensional inaccuracies.

Tool Longevity: Tools experience varying levels of wear depending on the feed rate and cutting speed. Proper settings can enhance tool life, reducing costs associated with frequent tool changes.

While feed rate and cutting speed are both essential parameters in CNC machining, they refer to different aspects of the machining process.

Cutting Speed

Cutting speed is concerned with how fast the cutting edge of the tool moves across the material. It primarily affects the heat generated during the cutting process and the rate of tool wear.

Cutting Speed Considerations in CNC Machining

When determining cutting speed, several considerations come into play:

Material Being Cut: Different materials have varying optimal cutting speeds. Understanding the properties of the workpiece is crucial for setting the right speed.

Cutting Tool Material: The material composition of the cutting tool plays a significant role in determining the maximum allowable cutting speed.

Tool Life: Maintaining an optimal cutting speed can prolong tool life and reduce overall machining costs.

Feed Rate

Feed rate considerations are equally important in the CNC machining process. Factors influencing feed rate include:

Tool Type: Different tools have different optimal feed rates based on their geometry and cutting capabilities.

Workpiece Finish: The desired finish quality of the part will dictate the appropriate feed rate, with smoother finishes often requiring slower rates.

Cutting Width: The width of the cut also affects the feed rate, as wider cuts may require adjustments to maintain effective machining.

TPI Use: Threads per inch (TPI) can influence the choice of feed rate, particularly in operations involving threading.

The following chart of cutting speed and feed rate provides a more visual understanding of the differences:

| Parameter |

Cutting Speed |

Feed Rate |

| Generatrix and Directrix |

Directrix is generated by the cutting speed |

Generatrix is generated by feed rate |

| Units of Motion and Short Form |

Measured in meters per minute (m/min) or feet per minute (ft/min) and denoted by Vc |

Measured in meters per revolution (mpr) or inches per revolution and denoted by s or f |

| Chip Direction |

No effect on deviating from the orthogonal chip direction |

Affect the actual chip flow direction |

| Cutting Force and Power Consumption |

Influence the cutting force and power consumption |

Not influence the cutting force and power consumption |

| Surface Roughness and Scallop Marks |

Not directly related to the scalloping or marks produced on the machined surface |

Directly related to the scalloped marks on the finished surface |

| Cutting Temperature, Tool Life and Tool Wear |

Greatly impacted |

Less impacted |

Determining the correct feed rate and cutting speed involves several calculations and considerations:

Other Important Considerations: Factors such as spindle speed limitations and the specific CNC machine's capabilities must be taken into account.

Spindle Speed Limitations: The maximum spindle speed of the machine can restrict the achievable cutting speeds.

Non-linear Paths: Machining operations involving non-linear paths may require adjustments to the feed rate to maintain surface quality.

Cutting Speed and Feed Rate Interaction: The interaction between cutting speed and feed rate can significantly influence the overall machining process. Understanding this relationship is crucial for optimizing operations.

In CNC machining, the feed rate and cutting speed are two of the most critical parameters that impact productivity, part quality, and tool life. Understanding their differences, optimal selections, and the various factors influencing them is essential for any machinist or engineer aiming to optimize machining operations. By carefully balancing these elements, manufacturers can improve efficiency, reduce costs, and enhance the quality of their machined parts. Partnering with a precision CNC machining provider like VMT ensures that these parameters are expertly managed for optimal results.

What is the difference between feed and cutting force?

Feed force is the force used to advance the cutting tool, while cutting force is the force required to remove material.

What is the difference between cutting speed and feed rate?

Cutting speed is the speed of the cutting edge relative to the material, whereas feed rate is the speed at which the tool moves through the material.

Are cutting speed and feed rate the same?

No, they are distinct parameters with different implications for the machining process.

What is the relationship between cutting force and cutting speed?

Higher cutting speeds can increase cutting force due to increased heat and friction, impacting tool wear and efficiency.

What two factors determine cutting speed?

The cutting speed is determined by the material being machined and the cutting tool's properties.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!