15 years one-stop China custom CNC machining parts factory

146 |

Published by VMT at Oct 05 2024

146 |

Published by VMT at Oct 05 2024

Aluminum is a widely used material in industries such as aerospace, automotive, and construction due to its lightweight, corrosion resistance, and high strength-to-weight ratio. While it offers numerous advantages, welding aluminum is notoriously challenging. Welding aluminum requires special techniques, equipment, and knowledge to avoid issues such as oxidation, porosity, and cracking. Mastering aluminum welding is essential for achieving high-quality, durable welds, particularly in CNC precision machining and fabrication.

This detailed guide will explore the complexities of aluminum welding, the challenges welders face, the most effective techniques, and essential preparation steps. We’ll also discuss considerations for ensuring successful post-weld processes and how VMT can simplify your aluminum welding process. By the end of this guide, you will have a comprehensive understanding of how to approach aluminum welding and overcome its unique difficulties.

Aluminum presents unique challenges in welding that differ significantly from materials like steel. Its properties, such as high thermal conductivity, low melting point, and a tendency to form an oxide layer, make aluminum more challenging to work with than other metals. Additionally, contamination and poor wire feeding can further complicate the process. Here's a breakdown of the specific reasons why welding aluminum can be difficult.

1. High Thermal Conductivity, Low Melting Point

Aluminum has a high thermal conductivity, meaning it absorbs heat rapidly. This characteristic makes it difficult to manage heat input during welding. If too much heat is applied, the metal can melt too quickly, leading to burn-through or distortion. On the other hand, if not enough heat is applied, achieving proper fusion can be challenging.

Aluminum also has a lower melting point than other metals, such as steel. This further complicates heat management, as the material can easily warp or burn if the welder is not careful. It requires precise control of temperature and technique.

2. Aluminum Oxide Layer

Aluminum forms a thin oxide layer on its surface when exposed to air. This aluminum oxide layer melts at a much higher temperature (about 2,000°C) than aluminum itself (660°C). If not removed before welding, the oxide layer can prevent proper fusion and lead to weak welds. The oxide layer also has insulating properties, making it harder to penetrate during welding.

3. Contamination

Aluminum is highly sensitive to contamination, whether from dirt, oils, or moisture. Even minor contamination can lead to weld defects like porosity or cracking. Preparing the metal surface through proper cleaning is crucial before starting any aluminum welding process.

4. Poor Wire Feeding Ability

When using MIG welding with aluminum, the wire is softer than steel, which can result in poor wire feeding and lead to issues like bird-nesting or tangling in the wire feed system. Specialized equipment, such as a spool gun, is often required for smooth wire feeding.

5. No Color Change

Unlike steel, which changes color as it heats up, aluminum does not provide visual cues about its temperature. This makes it harder for welders to judge when the material is reaching its melting point, increasing the risk of burn-through.

Welding aluminum comes with several challenges, including oxidation, porosity, and cracking, which can affect weld quality. Understanding these challenges is essential for avoiding defects and achieving strong, reliable welds.

1. Oxidation

Aluminum’s oxide layer must be removed before welding. If the oxide layer remains, it can interfere with weld fusion and cause weak joints. Specialized cleaning methods, such as using a stainless steel wire brush, are necessary to remove this layer.

2. Porosity

Porosity is a common issue in aluminum welding. It occurs when gases, such as hydrogen, become trapped in the weld pool. These gases form bubbles within the weld, weakening its structural integrity. Proper cleaning, controlling heat input, and selecting the right shielding gas can help minimize porosity.

3. Impurities

Contaminants like oil, dirt, and grease can cause inclusions or porosity in the weld. Ensuring the surface is free from impurities is crucial for clean, defect-free welds.

4. Thickness

Aluminum sheets and components come in various thicknesses, and thin sheets are particularly challenging to weld because they are more prone to burn-through. Thicker aluminum requires higher heat input, but the high thermal conductivity of aluminum can make it difficult to maintain the correct heat levels.

5. Hot Cracking

Hot cracking occurs when the weld cools too quickly, causing cracks in the weld bead. This is especially problematic in aluminum due to its high thermal conductivity and rapid cooling rates. Using the correct welding technique and filler metal can reduce the risk of hot cracking.

6. Thermal Conductivity

Aluminum’s high thermal conductivity makes it difficult to retain heat in the weld zone. As a result, controlling the weld pool and ensuring even heat distribution can be challenging. Preheating the aluminum or using higher heat input can help manage this issue.

Several welding techniques are suitable for aluminum, each with its advantages and challenges. The choice of technique depends on the specific requirements of the project, including the type of aluminum, the thickness of the material, and the desired weld quality.

1. Tungsten Inert Gas Welding (TIG)

TIG welding is one of the most commonly used methods for welding aluminum. It provides excellent control and produces high-quality welds, making it ideal for CNC precision machining and aluminum fabrication. TIG welding uses a non-consumable tungsten electrode to produce the weld, and argon gas is used as the shielding gas to protect the weld pool from contamination.

TIG is particularly effective for thin aluminum sheets and allows for precise welds with minimal defects. However, it requires a high level of skill due to the manual control involved.

2. Metal Inert Gas Welding (MIG)

MIG welding is another common method for aluminum. Unlike TIG, MIG uses a consumable wire electrode that melts to form the weld. It’s faster than TIG and is often used for thicker aluminum sections in industries like automotive and construction. MIG welding is easier to learn but requires special equipment to prevent feeding issues with the softer aluminum wire.

3. Electron Beam Welding

Electron beam welding (EBW) is used for high-precision welding of aluminum components, often in aerospace and automotive applications. It utilizes a focused beam of electrons to generate heat and create deep, narrow welds. EBW is conducted in a vacuum environment, making it ideal for applications that require minimal contamination.

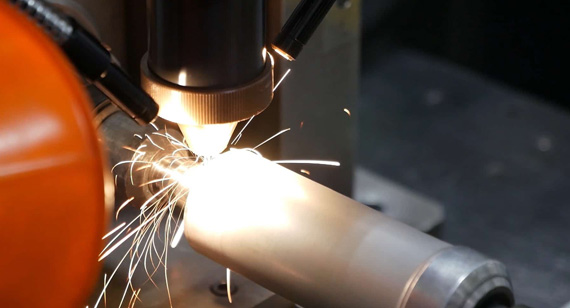

4. Laser Welding

Laser welding offers precision, speed, and deep penetration, making it suitable for welding complex aluminum parts. Laser beams can be tightly focused, resulting in minimal heat distortion, which is ideal for thin or delicate components. This method is used in CNC machining factories for high-quality welds on aluminum parts with tight tolerances.

5. Friction Stir Welding

Friction stir welding (FSW) is a solid-state welding technique that uses a rotating tool to join two pieces of aluminum. The heat generated by friction softens the metal, allowing the tool to stir the materials together. FSW is ideal for long, continuous welds in thick aluminum sections and is used in industries like shipbuilding and aerospace.

Preparation is critical to achieving a strong, defect-free aluminum weld. Proper cleaning, selecting the right filler, and choosing the correct welding method are all essential steps in the preparation process.

1. Cleaning is Important

Before welding, thoroughly clean the aluminum surface to remove the oxide layer, oils, and other contaminants. Use a stainless steel wire brush designed for aluminum and clean the surface just before welding to prevent the oxide layer from reforming.

2. Proper Welding Method

Choose the appropriate welding technique based on the type and thickness of the aluminum, as well as the project’s requirements. For thin sheets, TIG welding is usually preferred, while MIG welding is better suited for thicker materials.

3. Choose the Right Filler

Selecting the correct filler material is essential for aluminum welding. The filler metal should be compatible with the aluminum alloy being welded to prevent defects such as hot cracking.

4. Consider the Right Inert Gas

Use argon as the shielding gas for TIG welding and a mixture of argon and helium for MIG welding. Argon provides excellent coverage and minimizes oxidation, while helium increases heat input, which is beneficial for thicker aluminum.

1. Cleaning Metal

Always clean the aluminum just before welding to remove any contaminants or oxide layers. This ensures a stronger weld and reduces the risk of porosity or weak joints.

2. Proper Storage

Store aluminum materials in a dry, clean environment to prevent contamination from dirt, oil, or moisture. Keeping the metal clean and dry reduces the amount of cleaning required before welding.

3. Preheating Aluminum

Preheating the aluminum, especially thicker sections, can help reduce the risk of cracking and improve weld penetration. However, care must be taken not to overheat the metal, as this can cause distortion.

4. Higher Traverse Speeds

Aluminum welding generally requires faster welding speeds compared to other metals like steel. This helps to prevent burn-through and minimize heat distortion.

5. Using Tight Gun Angles

When MIG welding aluminum, use a tight gun angle to ensure better control over the weld pool and to avoid creating excessive spatter or defects.

6. “Push Welding” with MIG

For MIG welding, always push the torch rather than pull it. Pushing the torch provides better shielding gas coverage and produces a cleaner weld.

Post-weld processes are essential to ensure the longevity and strength of the aluminum weld. These processes include quality testing, heat treatment, aging, and surface preparation for finishing.

Inspect the weld for defects such as porosity, cracks, or incomplete fusion. Non-destructive testing methods like X-rays or ultrasonic testing can be used to verify the integrity of the weld.

2. Heat Treatment

Heat treatment after welding can help relieve internal stresses and improve the mechanical properties of the aluminum. This is especially important for alloys that are prone to cracking or distortion.

3. Aging

Some aluminum alloys benefit from aging processes to enhance their strength and durability after welding. This can be done through natural or artificial aging methods, depending on the alloy and application.

4. Surface Preparation

Post-weld surface preparation is crucial for achieving a smooth, clean finish. This can include grinding, polishing, or applying protective coatings to prevent corrosion and improve the appearance of the welded part.

At VMT, we specialize in providing CNC machining services and custom CNC machining solutions that include high-quality aluminum welding. Our expertise in aluminum CNC machining parts ensures that every component is welded with precision, durability, and attention to detail. Whether you’re working on CNC prototype machining or full-scale production, we have the experience and technology to make your welding process efficient and seamless.

Welding aluminum presents unique challenges that require specialized techniques and thorough preparation. Understanding the properties of aluminum, the challenges of oxidation and porosity, and the best welding methods can help you achieve strong, defect-free welds. With the right approach, including careful cleaning, choosing the appropriate filler and gas, and utilizing post-weld treatments, you can ensure high-quality welds that meet the demands of any project.

VMT offers the expertise and equipment necessary for high-quality aluminum welding CNC machining parts, ensuring the best results for your welding and machining needs.

Can aluminum be welded to other grades of aluminum or other materials?

Yes, but care must be taken to select compatible filler materials and welding techniques to avoid issues like cracking or weak welds.

What are some common applications for aluminum welding?

Aluminum welding is widely used in industries such as automotive, aerospace, marine, and construction for fabricating parts like frames, panels, and structural components.

What is the cheapest way to weld aluminum?

MIG welding is generally the most cost-effective method for aluminum welding, especially for thicker materials.

What is the best aluminum welder?

The best welder for aluminum depends on the application, but TIG and MIG welders are the most commonly used for precision aluminum welding.

What type of welding is used for aluminum?

TIG and MIG welding are the most commonly used methods for aluminum, but techniques like laser welding and friction stir welding are also used for specialized applications.

Is MIG or TIG better for aluminum?

TIG welding offers more precision and control, making it ideal for thinner materials, while MIG welding is faster and better suited for thicker aluminum sections.

Is MIG welding aluminum easy?

MIG welding aluminum can be challenging due to the metal’s properties, but with proper preparation and equipment, it is an effective method.

What aluminum cannot be welded with?

Some aluminum alloys, particularly those in the 2000 and 7000 series, are more difficult to weld due to their susceptibility to cracking.

Why is steel easier to weld than aluminum?

Steel has a higher melting point, lower thermal conductivity, and no oxide layer, making it easier to weld than aluminum.