15 years one-stop China custom CNC machining parts factory

1043 |

Published by VMT at Oct 06 2024

1043 |

Published by VMT at Oct 06 2024

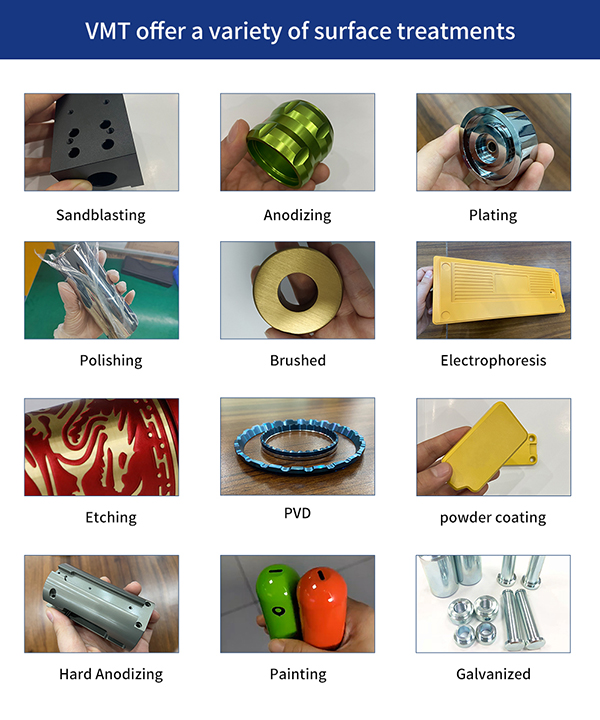

In the world of CNC precision machining, surface treatments like plating are essential for enhancing the durability, corrosion resistance, and overall performance of metal components. Among the many plating options available, hard chrome and chemical nickel plating are two popular methods that offer different benefits and characteristics. Selecting the right plating process depends on the application, the environment, and the desired performance characteristics of the component.

This article provides an in-depth comparison between hard chrome plating and chemical nickel plating by exploring the processes involved, their specific applications, the advantages and disadvantages of each, and how to determine the best plating solution for your project. Whether you're working on hard chrome CNC machining parts or chemical nickel CNC machining parts, understanding these surface treatments will help you make informed decisions that meet your needs.

Hard chrome plating, also known as industrial chrome plating, is a process where a layer of chromium is electroplated onto a metal surface. The chromium layer provides several key advantages, including exceptional hardness, wear resistance, and corrosion protection. Unlike decorative chrome, which is primarily used for aesthetic purposes, hard chrome is intended to extend the lifespan of metal components, making it ideal for high-wear industrial applications.

Hard chrome plating is commonly applied to steel and other alloys to increase the surface hardness and reduce friction, making it suitable for parts like hydraulic cylinders, crankshafts, and machine tools. The process results in a bright, smooth, and highly reflective surface that can withstand harsh operating environments.

The process of hard chrome plating involves several key stages, including cleaning, activation, electroplating, and finishing. Each of these steps is crucial to achieving a durable and uniform chrome layer that enhances the performance of the machined part.

The Hard Chrome Plating Process Includes the Following Steps:

Cleaning

Before the plating process begins, the metal surface must be thoroughly cleaned to remove any contaminants like dirt, oils, or oxidation. This is typically done through chemical cleaning, abrasive blasting, or electrolytic degreasing. Proper cleaning ensures a smooth surface and helps the chromium layer adhere properly to the substrate.

Activation

After cleaning, the part is activated by immersing it in an acid solution, such as sulfuric acid. The activation process helps prepare the surface for the electroplating step by removing any residual oxide layers that could interfere with adhesion.

Electroplating

In the electroplating step, the part is immersed in a plating bath containing a chromium solution. An electrical current is passed through the solution, causing chromium ions to be deposited onto the metal surface. The thickness of the chrome layer can be controlled by adjusting the current and plating time.

Finishing

Once the desired thickness of chrome is achieved, the part is removed from the plating bath and rinsed thoroughly. After rinsing, additional finishing steps like polishing or grinding may be performed to achieve the required surface smoothness and precision. The final product is a hard, smooth, and highly reflective chrome layer.

Applications of Hard Chrome Plating

Hard chrome plating is widely used in industries that require high durability and wear resistance. The following are some key applications where hard chrome plating is commonly used:

Aerospace

In the aerospace industry, hard chrome plating is applied to critical components such as landing gear, hydraulic systems, and turbine engines. The plating provides excellent wear resistance and protects parts from corrosion caused by harsh environmental conditions.

Hard chrome plating is used on various automotive components, including piston rings, cylinder liners, and crankshafts. These parts endure significant friction and wear, and hard chrome’s durability helps extend their lifespan.

Marine

In the marine industry, hard chrome is applied to components exposed to saltwater, such as propeller shafts and pumps. The corrosion resistance offered by chrome plating helps protect these parts from rust and degradation in marine environments.

Machine Tools

Machine tools, such as cutting tools, dies, and molds, benefit from hard chrome plating due to its ability to reduce friction and wear. This results in longer tool life and reduced maintenance costs.

Polishing chrome plating is a crucial step in maintaining its reflective and smooth finish. To polish chrome, first clean the surface using soap and water to remove any dirt or grease. Next, apply a metal polish or chrome-specific polish to a soft cloth and gently buff the surface in circular motions. Use a microfiber cloth for the final wipe-down to achieve a high-gloss, mirror-like finish.

Chemical nickel plating, also known as electroless nickel plating, is a process that deposits a layer of nickel-phosphorous alloy onto a metal surface without the use of an electric current. Unlike hard chrome plating, which requires electroplating, chemical nickel plating relies on a chemical reaction between the metal substrate and the plating solution. This process provides uniform coverage, even on complex or irregularly shaped parts, and enhances properties such as corrosion resistance, wear resistance, and hardness.

Chemical nickel plating is ideal for applications that require excellent corrosion protection and uniform thickness, making it suitable for industries such as electronics, automotive, and aerospace.

The chemical nickel plating process involves several stages, including cleaning, pretreatment, immersion in plating tanks, and the use of chemical reducing agents to deposit the nickel layer. Each step ensures a consistent, high-quality finish.

The Application Process of Electroless Nickel Plating Generally Includes the Following Stages:

Thorough Cleaning

Before the plating begins, the metal surface must be thoroughly cleaned to remove any contaminants, such as oils, dirt, and oxides. Proper cleaning is essential to ensure a smooth and uniform nickel layer.

Pretreatment

After cleaning, the metal is pretreated with an acid or alkaline solution to activate the surface. This step helps to ensure that the nickel will adhere properly to the substrate.

Plating Tanks

The metal part is immersed in a plating tank containing a solution of nickel salts and a reducing agent. The chemical reaction between the metal surface and the reducing agent causes the nickel to deposit evenly onto the part.

Chemical Reducing Agents

The reducing agent, typically sodium hypophosphite, reacts with the nickel ions in the plating solution, causing them to be deposited onto the metal surface. The reaction continues until the desired thickness is achieved, which is typically between 0.0001 to 0.005 inches.

Electroless nickel plating is used across a wide range of industries due to its corrosion resistance, uniformity, and ability to coat complex parts. Common applications include:

Cleaning nickel-plated surfaces requires using non-abrasive cleaners to prevent scratching or damaging the nickel layer. Mild soap and water or specialized nickel-cleaning solutions are typically recommended. After cleaning, dry the surface with a soft cloth to prevent water spots.

While both hard chrome and electroless nickel plating offer enhanced durability and corrosion resistance, there are several key differences between the two processes. Understanding these differences will help in choosing the right plating method for specific applications.

1. Hardness

Hard chrome plating is renowned for its extreme hardness, typically measuring between 68 and 72 HRC (Rockwell Hardness Scale). This makes it ideal for applications that require high wear resistance, such as in heavy machinery. In contrast, electroless nickel plating has a hardness of around 45 to 55 HRC, though this can be increased through heat treatment.

2. Durability

Both plating methods offer excellent durability, but hard chrome is superior in applications where extreme wear resistance is critical. Electroless nickel plating, however, provides uniform coverage, which enhances durability in more intricate parts.

3. Corrosion Resistance

Electroless nickel plating offers better corrosion resistance compared to hard chrome, particularly in environments exposed to chemicals or saltwater. This makes electroless nickel plating a better option for applications such as marine or chemical processing equipment.

4. Appearance

Hard chrome plating has a bright, reflective finish, making it visually appealing for decorative purposes. Electroless nickel plating, on the other hand, has a matte to semi-bright appearance, which may be preferred for industrial or functional applications.

5. Coefficient of Friction

Hard chrome plating provides a lower coefficient of friction, reducing wear in moving parts. Electroless nickel plating has a higher coefficient of friction, which may not be ideal for parts that require smooth movement.

6. Conductivity

Electroless nickel plating provides better electrical conductivity than hard chrome, making it ideal for electronic components.

7. Price

Hard chrome plating tends to be more expensive than electroless nickel plating due to the more complex electroplating process and the materials involved.

Both hard chrome and electroless nickel plating come with their own set of challenges. Below are common issues and solutions for each process.

Common Hard Chrome Plating Problems and Solutions

Blistering: Caused by poor surface preparation. Ensure proper cleaning and activation before plating.

Burned Plating: Occurs when the current density is too high. Reduce the amperage during the plating process.

Crack Spots: Caused by excessive stress in the chromium layer. Use lower current densities and adjust plating parameters.

Common Electroless Nickel Plating Problems and Solutions

Metallic Contamination: Results in dull or uneven plating. Regularly filter the plating solution to remove contaminants.

Organic Contamination: Can lead to poor adhesion. Ensure the cleaning process removes all organic materials before plating.

Dull Deposits: Caused by improper bath chemistry. Regularly monitor and adjust the chemical balance in the plating bath.

Choosing between hard chrome and electroless nickel plating depends on the specific requirements of your application. Factors like wear resistance, corrosion protection, and part geometry should be considered.

1. Wear

For applications requiring extreme hardness and wear resistance, hard chrome plating is the better choice, especially for parts exposed to heavy friction.

2. Environment

Electroless nickel plating is better suited for environments with high moisture or chemical exposure, providing superior corrosion resistance.

3. Movement

If your part involves movement, the low coefficient of friction provided by hard chrome plating may be ideal to reduce wear and extend part life.

4. Shape

For complex or irregularly shaped parts, electroless nickel plating offers uniform thickness and coverage, ensuring all surfaces are equally protected.

Hard chrome plating offers several key advantages, particularly in industries requiring high-performance components. Below are the main reasons to choose hard chrome plating.

Superior Hardness: With a hardness of up to 72 HRC, hard chrome provides exceptional wear resistance for heavy-duty applications.

Lower Coefficient of Friction: Hard chrome reduces friction, which is ideal for parts subjected to constant movement or sliding contact.

Conductivity: Hard chrome is an excellent conductor, making it suitable for electrical and thermal applications.

Versatile: Hard chrome can be applied to a wide range of metals and alloys, making it adaptable for various industries.

Low Temperature Applications: Hard chrome can be used in applications exposed to cold temperatures without compromising performance.

Electroless nickel plating provides unique benefits, particularly in environments requiring corrosion protection and uniform coverage. Here are the reasons to choose electroless nickel plating:

Excellent Corrosion Resistance: Electroless nickel plating provides superior protection against corrosion, especially in harsh environments.

Uniformity: The electroless process ensures an even layer of nickel, making it perfect for intricate and irregular shapes.

Versatile: Suitable for a variety of metals, electroless nickel plating is versatile and adaptable to different industries.

Affordable: Electroless nickel plating is typically more cost-effective than hard chrome, especially for parts that require uniform coatings.

Customizable Surface Treatments: Depending on the desired outcome, the process can be customized to achieve specific surface properties, including hardness and brightness.

At VMT, we specialize in CNC machining services and surface treatments, offering both hard chrome and electroless nickel plating for a wide range of CNC machined parts. Whether you need enhanced wear resistance, corrosion protection, or a uniform finish, our team provides top-quality, custom plating solutions to meet your specific needs. From CNC prototype machining to large-scale production, we ensure precision and quality at every stage.

What types of chrome plating are there?

There are two main types of chrome plating: hard chrome (industrial chrome) and decorative chrome, with hard chrome offering superior wear resistance.

What types of nickel plating are there?

Nickel plating can be performed using electroplating or electroless (chemical) plating, with the latter offering uniform coverage and better corrosion resistance.

What is the difference between nickel plating and chemical nickel plating?

Nickel plating uses electrical current to deposit nickel, while chemical (electroless) nickel plating relies on a chemical reaction, offering uniform coatings.

What is the difference between hard chrome plating and chemical nickel plating?

Hard chrome provides superior hardness and wear resistance, while chemical nickel plating offers better corrosion resistance and uniform coverage.

Which is better, chrome plating or nickel plating?

The choice depends on the application. Hard chrome is better for wear resistance, while electroless nickel is better for corrosion protection.

Is chemical nickel plating expensive?

Chemical nickel plating is generally more cost-effective than hard chrome, especially for parts with complex geometries.

Why is chemical plating better than electroplating?

Chemical plating offers uniform coverage without the need for electrical current, making it ideal for parts with intricate shapes.

Which is more expensive, nickel or chromium?

Hard chrome plating tends to be more expensive due to its complexity and higher material costs.

Will chemical nickel plating rust?

Chemical nickel plating provides excellent corrosion resistance and does not rust easily, especially when used in the appropriate environment.

What is the difference between chrome plating and electroplating?

Chrome plating is a specific type of electroplating that deposits a layer of chromium, while electroplating refers to the general process of depositing a metal using an electrical current.

What is the difference between electroplating and chemical plating?

Electroplating uses electrical current to deposit metal, while chemical plating uses a chemical reaction to achieve the same result without electricity.

What is the difference between hard chrome plating and flash chrome plating?

Hard chrome plating applies a thicker, more durable layer of chrome, while flash chrome plating applies a thin decorative layer primarily for aesthetic purposes.