15 years one-stop China custom CNC machining parts factory

242 |

Published by VMT at Aug 15 2025 | Reading Time:About 6 minutes

242 |

Published by VMT at Aug 15 2025 | Reading Time:About 6 minutes

In CNC machining, choosing the wrong material for your project can cause unexpected problems—especially if magnetism becomes a factor you didn’t plan for. Imagine designing precision metal CNC machined parts for a medical device, only to discover they interfere with MRI equipment. Or producing high-tolerance components for an aerospace project, only to have magnetic attraction disrupt delicate sensors. This is why understanding which metals are magnetic isn’t just about science—it’s a critical step in avoiding costly production errors. Magnetism affects everything from design feasibility to assembly processes, and even final applications. In industries served by CNC machining services and CNC machining factories, it can impact tooling, quality control, and performance in the field. Knowing the magnetic properties of metals before placing an order is the first safeguard against these issues.

Metals that are magnetic include iron, cobalt, nickel, most steels, and certain rare earth metals. These materials exhibit ferromagnetism, meaning they are strongly attracted to magnets and can become magnets themselves.

Magnetism in metals is more than just a laboratory curiosity—it’s a defining characteristic that can determine whether your project succeeds or fails. In the next sections, we’ll break down what magnetism really means, the science behind it, and which metals will respond to a magnet. We’ll also explore non-magnetic metals, practical uses for magnetic materials, and how all of this directly impacts metal CNC machined parts production. Whether you’re designing precision components for electronics, medical devices, or heavy industry, this guide will help you make informed choices.

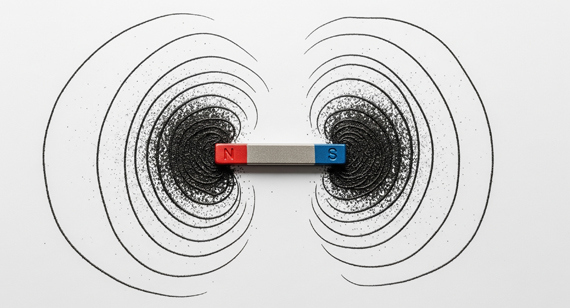

At its core, magnetism is the physical phenomenon where certain materials exert an attractive or repulsive force on others due to the motion of electric charges—primarily electrons. In metals, this is influenced by electron spin and alignment within the material’s atomic structure. When the magnetic fields of individual atoms align in the same direction, the metal becomes magnetic. This behavior is strongest in ferromagnetic materials, which can retain magnetization even after an external magnetic field is removed. In CNC machining applications, understanding magnetism isn’t just about basic physics—it informs material selection, tool design, and post-processing considerations. For example, magnetic materials can attract fine metal chips during machining, affecting surface finish and requiring extra cleaning steps. Knowing these fundamentals helps engineers and machinists anticipate potential production challenges.

Ferromagnetic metals are metals that can be strongly magnetized and remain magnetic even after the external magnetic field is removed. This property is called ferromagnetism, and it is the most powerful and commonly encountered type of metal magnetism. At the atomic level, ferromagnetism occurs when a large number of electrons in a material have their spins aligned in the same direction, creating a strong and unified magnetic field. Unlike weakly magnetic (paramagnetic) or repelling (diamagnetic) materials, ferromagnetic metals can become permanent magnets. The most well-known examples are iron, cobalt, and nickel, along with many of their alloys. Some steels—especially carbon steel and low-alloy steel—are also ferromagnetic because they contain a high proportion of iron.

In CNC machining services and CNC machining factories, ferromagnetic metals require special handling. They can attract fine metal chips during machining, cause unintended magnetic interference with precision instruments, and sometimes influence tool wear. On the other hand, their magnetic properties can be an advantage in applications such as magnetic fixtures, magnetic sensors, or components that must interact with other magnets. In manufacturing metal CNC machined parts, understanding whether your chosen alloy is ferromagnetic ensures you avoid costly mistakes—especially in industries like electronics, aerospace, or medical devices, where unintended magnetism could disrupt performance.

When we talk about which metals are magnetic, we’re usually referring to metals that display ferromagnetism—the strongest and most practical type of metal magnetism. These metals can be magnetized and will remain magnetic even when the external magnetic field is removed. In CNC machining, this property is important because it can affect how materials behave during processing, assembly, and use. For example, a magnetic material might attract small metal chips during machining, influence the operation of nearby sensors, or be intentionally used for magnetic fastening systems. Whether you’re designing metal CNC machined parts for electronics, automotive components, or industrial equipment, understanding a metal’s magnetic properties helps you avoid costly production mistakes.

Magnetic Metals

Iron is the most widely recognized ferromagnetic metal. It’s naturally magnetic and forms the base for many alloys, including most steels. Its high magnetic permeability makes it ideal for electromagnetic applications like transformers, motors, and generators. In CNC machining, iron-based parts are common in heavy machinery and structural applications, but they require careful handling due to rust susceptibility.

Cobalt

Cobalt is less common than iron but has strong magnetic properties and excellent temperature resistance. It’s often used in specialized magnets, high-speed steels, and aerospace alloys. Cobalt’s magnetism remains stable even in high-heat environments, making it useful for CNC-machined components in turbines or motors.

Nickel

Nickel is ferromagnetic and corrosion-resistant, making it suitable for applications requiring both durability and magnetism. It’s used in coins, plating, and special alloys like permalloy. In CNC machining, nickel alloys are popular for precision parts in electronics and marine equipment.

Steel

Most steels are magnetic because they’re primarily iron-based. However, magnetic behavior varies by type—carbon steel and ferritic stainless steels are magnetic, while austenitic stainless steels (like 304) are generally non-magnetic. Knowing your steel grade is critical before machining.

Rare Earth Metals

Metals like neodymium and samarium are extremely magnetic and are used to create powerful permanent magnets. These materials are less common in CNC machining but may be incorporated into components for high-performance motors or electronics.

Other Metals

Some metals, like gadolinium, exhibit magnetism under certain conditions (e.g., low temperatures). While rarely used in CNC machining, they are important in niche scientific and industrial applications.

Magnetic Compounds and Alloys

Compounds and alloys can also exhibit strong magnetic properties if they contain significant amounts of iron, cobalt, or nickel. These base elements provide the atomic structure necessary for ferromagnetism, while the added elements in the alloy can enhance or modify other properties such as corrosion resistance, hardness, and heat tolerance. In CNC machining services and CNC machining factories, working with magnetic alloys is common, especially for industrial equipment, motors, and precision tools. Understanding their magnetic behavior ensures the correct machining approach, prevents unwanted interference in sensitive assemblies, and allows engineers to leverage magnetism where it’s beneficial.

Common Magnetic Alloys

Various Types of Steel

Carbon steel, alloy steel, and certain grades of stainless steel—especially martensitic and ferritic—are magnetic because they have a high iron content. These steels are widely used in structural components, gears, and machinery parts produced by CNC machining.

Wide Varieties of Stainless Steel

Not all stainless steels are non-magnetic. Ferritic (400-series) and martensitic stainless steels are magnetic, making them suitable for knife blades, shafts, and magnetic fasteners. However, austenitic stainless steels (300-series) are generally non-magnetic unless cold-worked.

Ferrites

Ferrites are ceramic-like compounds made from iron oxide combined with other metallic elements. They are magnetic but non-conductive, making them ideal for electronic components such as transformer cores, inductors, and antenna rods.

Alnico

An alloy of aluminum, nickel, and cobalt, Alnico produces strong permanent magnets with excellent temperature stability. It’s used in electric guitar pickups, sensors, and industrial equipment.

Permalloy

A nickel–iron alloy with extremely high magnetic permeability, permalloy is widely used in electrical and electronic applications, such as magnetic shielding, sensors, and transformers.

Tip: When ordering CNC machined parts made from magnetic alloys, ensure the machinist is aware of the material’s specific composition. Small alloying changes can significantly alter magnetic performance, affecting how the part interacts with other components in the system.

Not all metals—or their alloys—are magnetic. In fact, many of the most commonly used engineering and decorative metals are non-magnetic due to their atomic structures. These materials typically lack the electron alignment required for ferromagnetism. In CNC machining services and CNC machining factories, non-magnetic metals are often chosen for applications where magnetic interference must be avoided, such as in electronics, medical imaging devices, and precision instruments. They are also valuable when weight reduction, corrosion resistance, or specific mechanical properties are more important than magnetism. Understanding which alloys are non-magnetic can help you make better material decisions for your metal CNC machined parts, ensuring both functionality and cost-effectiveness.

Copper

Copper is a non-magnetic, highly conductive metal widely used in wiring, heat exchangers, and precision components. In CNC machining, its softness and machinability make it a go-to material for electrical parts.

An alloy of copper and zinc, brass is non-magnetic and corrosion-resistant. It’s common in decorative fittings, precision valves, and musical instruments. Brass machines well, producing smooth finishes without sparking.

Lightweight, corrosion-resistant, and non-magnetic, aluminum is used extensively in aerospace, automotive, and marine industries. It’s ideal for CNC machined parts that require strength-to-weight optimization without magnetic interference.

Lead

Lead is non-magnetic, dense, and soft. While less common in modern applications due to health concerns, it’s still used in radiation shielding and specialty counterweights.

Gold

Gold is non-magnetic, highly corrosion-resistant, and an excellent conductor. It’s used in electronics for plating contacts and in high-value decorative applications.

Silver

Non-magnetic and the best electrical conductor of all metals, silver is used in high-performance electronics, conductors, and jewelry.

Titanium is non-magnetic, lightweight, and exceptionally strong. It’s a preferred material for aerospace, medical implants, and marine parts produced in CNC machining factories.

Tungsten

Though very dense and hard, tungsten is non-magnetic. It’s often used for cutting tools, counterweights, and military applications.

Zinc

Zinc is non-magnetic and corrosion-resistant, often used in galvanizing steel or making die-cast components for hardware and electronics.

summarizing magnetic vs non-magnetic metals and alloys from the sections we’ve covered so far.

| Category |

Metal / Alloy |

Magnetic? |

Notes & Common CNC Applications |

| Pure Metals | Iron | ✅ Yes | Strongly ferromagnetic; used in structural components, gears, machinery parts. |

| Cobalt | ✅ Yes | Heat-resistant magnetic metal; used in turbines, high-speed tools. | |

| Nickel | ✅ Yes | Corrosion-resistant magnetic metal; used in electronics, marine parts. | |

| Copper | ❌ No | Excellent electrical conductor; used in wiring, heat exchangers, electrical contacts. | |

| Aluminum | ❌ No | Lightweight, corrosion-resistant; used in aerospace, automotive, marine. | |

| Lead | ❌ No | Dense, soft; used in radiation shielding, counterweights. | |

| Gold | ❌ No | Corrosion-resistant, highly conductive; used in electronics, decorative parts. | |

| Silver | ❌ No | Best electrical conductor; used in high-performance electronics, jewelry. | |

| Titanium | ❌ No | Lightweight, strong; used in aerospace, medical, marine CNC machined parts. | |

| Tungsten | ❌ No | Dense, hard; used in cutting tools, counterweights. | |

| Zinc | ❌ No | Corrosion-resistant; used in galvanizing, die-casting. | |

| Alloys | Steel (carbon & alloy) | ✅ Yes | Most grades are magnetic except some stainless steels; used in machinery, tools. |

| Stainless Steel (ferritic & martensitic) | ✅ Yes | Magnetic stainless grades used in cutlery, shafts, fasteners. | |

| Stainless Steel (austenitic) | ❌ No | Non-magnetic unless cold-worked; used in food processing, medical parts. | |

| Ferrites | ✅ Yes | Non-conductive ceramic-like magnetic material; used in electronics. | |

| Alnico | ✅ Yes | Strong permanent magnet alloy; used in sensors, speakers, guitar pickups. | |

| Permalloy | ✅ Yes | High magnetic permeability; used in magnetic shielding, transformers. | |

| Brass | ❌ No | Corrosion-resistant, decorative; used in valves, fittings, instruments. |

Metals become magnetic when their atomic structures allow for the alignment of unpaired electron spins, creating a unified magnetic field within the material. This behavior is rooted in quantum mechanics, where electrons possess a property called spin that produces a magnetic moment. In most materials, these magnetic moments cancel out because electrons are paired or randomly oriented. In ferromagnetic metals such as iron, cobalt, and nickel, the electron spins naturally align in the same direction within regions called magnetic domains. When an external magnetic field is applied, these domains align further, producing strong and lasting magnetism.

The key factor in metal magnetism is the crystal structure of the metal. For example, body-centered cubic (BCC) and face-centered cubic (FCC) structures influence how easily electrons can align. This explains why certain stainless steels—despite being iron-based—are non-magnetic: austenitic stainless steels have an FCC structure that disrupts magnetic ordering, while ferritic and martensitic stainless steels have structures conducive to magnetism.

In CNC machining services and CNC machining factories, knowing what makes a metal magnetic helps in process planning. Magnetic materials can attract fine chips during milling or turning, potentially affecting surface finish and dimensional accuracy. They may also interact with nearby sensors or electronic components. Conversely, magnetism can be an advantage for fixturing parts during machining or creating functional magnetic components.

When metals are magnetized, they generally fall into one of three categories of magnets, each with distinct properties and industrial uses. Knowing the difference is important in CNC machining services and CNC machining factories, as the choice of magnet type can influence material selection, part design, and assembly methods.

1. Permanent Magnet

A permanent magnet retains its magnetic field indefinitely without needing an external power source. This occurs when the magnetic domains inside a ferromagnetic metal (such as iron, cobalt, nickel, or certain alloys like Alnico) remain locked in alignment after being magnetized. Permanent magnets are used in motors, generators, magnetic clamps, sensors, and consumer electronics. CNC-machined permanent magnet housings or precision fixtures often require tight tolerances to maintain consistent magnetic performance.

2. Temporary Magnet

A temporary magnet becomes magnetic only when exposed to an external magnetic field and loses its magnetism once that field is removed. Soft iron is a good example—it magnetizes quickly but does not hold magnetism. This property is useful in applications like electromagnetic cranes or magnetic workholding in machining, where you need strong magnetism only during operation and no residual attraction afterward.

3. Electromagnet

An electromagnet generates a magnetic field when an electric current flows through a coil of wire wrapped around a ferromagnetic core (usually soft iron). By controlling the current, you control the magnetic strength. Electromagnets are used in industrial lifting, MRI machines, and CNC automation systems for magnetic tool changers or robotic handling. CNC-machined components for electromagnets must often meet high precision standards to ensure optimal magnetic field efficiency.

A common misconception is that magnetic metals are automatically stronger than non-magnetic ones. In reality, magnetism and mechanical strength are unrelated properties—a metal’s strength depends on its atomic bonding, crystal structure, and alloy composition, not whether it’s magnetic. For example, iron is strongly magnetic but not as strong as tungsten, which is non-magnetic yet has a much higher tensile strength. Similarly, titanium is non-magnetic but offers exceptional strength-to-weight performance, making it a top choice in aerospace and medical CNC machined parts.

In CNC machining services and CNC machining factories, selecting a magnetic or non-magnetic metal should be based on the part’s functional requirements. If the application needs magnetic attraction (e.g., a magnetic sensor housing or magnetic workholding), ferromagnetic metals like carbon steel or ferritic stainless steel might be ideal. However, if the component must resist magnetic interference—such as in electronics, navigation systems, or MRI-compatible equipment—non-magnetic metals like aluminum, brass, or austenitic stainless steel are the better choice.

It’s also worth noting that some of the hardest and most wear-resistant metals—like certain tool steels—can be either magnetic or non-magnetic depending on heat treatment and alloying. Thus, engineers must weigh magnetic behavior alongside strength, corrosion resistance, machinability, and cost.

Yes, metal detectors can detect non-magnetic metals, even though they don’t have ferromagnetic properties. This is because most metal detectors work on the principle of electromagnetic induction, not by detecting permanent magnetism. When the detector’s coil generates an alternating magnetic field, it induces small electrical currents—called eddy currents—in conductive materials. These eddy currents create their own magnetic fields, which the detector senses. The stronger the electrical conductivity of the metal, the easier it is to detect.

Non-magnetic metals like aluminum, copper, brass, silver, and gold are often even easier to detect than some magnetic metals because they are excellent conductors. That’s why metal detectors can find aluminum cans, gold jewelry, and copper wiring without any problem. On the other hand, stainless steels, which can be either magnetic or non-magnetic, are sometimes harder to detect due to lower electrical conductivity.

In CNC machining services and CNC machining factories, understanding this principle matters in quality control, security, and recycling processes. For instance, if a manufacturing line needs to ensure no stray metal fragments contaminate a batch of food or pharmaceuticals, the detection equipment must be calibrated to sense both magnetic and non-magnetic metals. Similarly, in scrap sorting, detection systems must distinguish between different types of metals for efficient recycling.

Metals can respond to magnetic fields in different ways depending on their atomic structure and electron configuration. These responses are categorized into five main types of magnetism, each with unique characteristics and applications.

1. Ferromagnetism

Definition: The strongest form of magnetism where magnetic moments of atoms align in the same direction, creating a strong, permanent magnetic field.

Examples: Iron (Fe), Cobalt (Co), Nickel (Ni), and some rare earth metals like Neodymium.

Key Features:

2. Paramagnetism

Definition: Weak attraction to external magnetic fields caused by unpaired electrons, but the material loses magnetism when the field is removed.

Examples: Aluminum, Platinum, Magnesium.

Key Features:

3. Diamagnetism

Definition: Weak repulsion from magnetic fields due to paired electrons that produce no net magnetic moment.

Examples: Copper, Silver, Gold, Bismuth.

Key Features:

4. Ferrimagnetism

Definition: Magnetic moments in the material align in opposite directions but are unequal, resulting in a net magnetic effect.

Examples: Magnetite (Fe₃O₄), Ferrites used in electronics.

Key Features:

5. Antiferromagnetism

Definition: Magnetic moments align in opposite directions and cancel each other out, resulting in no net magnetism.

Examples: Manganese Oxide (MnO), Chromium.

Key Features:

Here’s a clear comparison table for the 5 types of metal magnetism:

| Type of Magnetism |

Magnetic Behavior |

Examples of Metals / Materials |

Magnetic Strength |

Key Characteristics |

| Ferromagnetism |

Strong attraction to magnets; can become permanently magnetized | Iron, Cobalt, Nickel, Steel, Alnico | Very strong | Magnetic domains align easily; retains magnetism |

| Paramagnetism |

Weak attraction to magnets; loses magnetism when external field is removed | Aluminum, Platinum, Magnesium | Weak | Magnetic moments align only in presence of a field |

| Diamagnetism |

Weak repulsion from magnets | Copper, Gold, Bismuth, Silver | Very weak (repulsive) | Induced magnetic field opposes the applied field |

| Ferrimagnetism |

Strong magnetism due to unequal opposing magnetic moments | Ferrites, Magnetite (Fe₃O₄) | Strong | Magnetic moments are opposed but unequal, causing net magnetism |

| Antiferromagnetism |

No net magnetism due to equal and opposite magnetic moments | Manganese, Chromium, Hematite (Fe₂O₃ above certain temp) | None (overall) | Magnetic moments cancel each other out completely |

Magnetic metals have a wide range of practical and creative applications. For instance, they can be used to temporarily attach objects to other ferromagnetic surfaces, which is common in tools, fixtures, and signage. In navigation, they form the basis of a compass, where magnetized metal aligns with Earth’s magnetic field.

In the world of audio technology, magnetic metals are essential for building speakers and microphones, and for pickups on electric guitars, which convert string vibrations into electrical signals. They also play a key role in data storage, from traditional magnetic tape to modern hard drives, where magnetic fields record and retrieve digital information.

Everyday conveniences like magnetic strips on credit or debit cards rely on them, while industrial uses include electrical motors, moving large scrap metal such as cars with powerful lifting magnets, and even advanced transportation like magnetic levitation trains.

In healthcare, magnetic metals enable magnetic resonance imaging (MRI), a critical diagnostic tool. They also play a role in electrical power generation, where magnets convert mechanical motion into electricity. And of course, they can be found in toys, adding a fun and interactive element to play.

| Application |

Description / Purpose |

| Temporarily attach objects |

Hold tools, notes, or other items to ferromagnetic surfaces without permanent fasteners. |

| Compass creation |

Use magnetized metal to align with Earth’s magnetic field for navigation. |

| Speakers and microphones |

Convert electrical signals into sound (or vice versa) using magnetic fields. |

| Magnetic data storage |

Store information on tapes, hard drives, and other magnetic media. |

| Toys |

Magnetic building sets, puzzles, and novelty gadgets. |

| Electric guitar pickups |

Detect string vibrations and convert them into electrical signals. |

| Magnetic strips on cards |

Store secure data for transactions and identification. |

| Electric motors |

Convert electrical energy into mechanical motion. |

| Scrap metal handling |

Lift and transport heavy ferromagnetic objects like cars. |

| Magnetic levitation trains |

Use magnetic repulsion/attraction for frictionless travel. |

| Electrical power generation |

Rotate magnetic fields to induce electric current. |

| MRI machines |

Use strong magnetic fields for non-invasive medical imaging. |

Magnetic metals are fundamental to many industries and technologies because of their unique ability to generate and respond to magnetic fields. From everyday electronics to advanced medical equipment, these metals enable critical functions that keep modern life running smoothly. Understanding their diverse uses can help engineers and designers choose the right materials for metal CNC machined parts, ensuring optimal performance and reliability.

Magnetic metals are integral in electronic components such as transformers, inductors, and sensors. Their magnetic properties allow for efficient signal transmission, electromagnetic interference shielding, and precise control of electrical currents. They’re also essential in data storage devices like hard drives, where magnetic fields encode information.

Navigation Equipment

Compasses and other navigation tools rely on ferromagnetic metals to detect Earth’s magnetic field. Magnetic materials are also used in magnetometers and gyroscopes for accurate positioning in aerospace, marine, and automotive navigation systems.

In medicine, magnetic metals enable technologies like magnetic resonance imaging (MRI), which uses powerful magnets to produce detailed internal body images without radiation. They’re also found in implantable devices and magnetic sensors that monitor physiological parameters.

Transportation

Magnetic metals play key roles in electric motors, generators, and braking systems within vehicles and trains. Magnetic levitation trains use magnets for frictionless movement, increasing speed and efficiency. Additionally, they’re employed in magnetic sensors for vehicle safety and performance monitoring.

Car Batteries

Certain magnetic alloys are components in car batteries and electric vehicle motors, contributing to energy storage and conversion efficiency. These metals help improve battery lifespan and power output, supporting the shift toward sustainable transportation.

Scrapyards

In recycling, magnetic metals are separated from non-magnetic materials using powerful magnets. This process allows scrapyards to efficiently sort and process metal waste, supporting circular economy practices and reducing environmental impact.

Here’s a clear and concise table summarizing the uses of magnetic metals:

| Application |

Description |

| Electronic Devices |

Used in transformers, inductors, sensors, and magnetic data storage like hard drives. |

| Navigation Equipment |

Essential for compasses, magnetometers, and gyroscopes in aerospace, marine, and automotive navigation. |

| Medical Devices |

Key component in MRI machines, implantable devices, and magnetic sensors monitoring health. |

| Transportation |

Used in electric motors, generators, magnetic levitation trains, and vehicle safety sensors. |

| Car Batteries |

Magnetic alloys contribute to energy storage and conversion in batteries and electric motors. |

| Scrapyards |

Powerful magnets separate magnetic metals from other materials for recycling and sorting. |

Magnetization can significantly influence the cost of metals and metal components, especially in metal CNC machined parts manufacturing. Materials that exhibit strong magnetic properties—like high-grade ferromagnetic alloys and rare earth magnets—often require more complex extraction, refining, and processing methods, which increase their base price. For example, rare earth metals such as neodymium and samarium, prized for their powerful permanent magnetism, are more expensive due to limited supply and specialized processing.

Moreover, magnetized metals may need additional handling during CNC machining to mitigate magnetic interference. Magnetic materials can attract metal chips and debris, complicating cleanup and potentially causing wear on cutting tools, which raises manufacturing costs. Also, parts intended to retain specific magnetic properties often demand tighter machining tolerances and specialized heat treatments, both of which add to production time and expense.

In contrast, non-magnetic metals generally cost less and are easier to machine, but they may require more frequent testing or coatings to meet application demands, which can offset initial savings. Additionally, when magnetic properties are critical to a component’s function—such as in motors, sensors, or medical devices—investing in high-quality magnetic materials is essential despite the higher price to ensure performance and longevity.

Understanding which metals are magnetic and how their magnetism influences material behavior is crucial for making informed decisions in CNC machining services and manufacturing. Metals like iron, cobalt, and nickel—and many of their alloys—offer strong ferromagnetic properties that make them invaluable in electronics, medical devices, transportation, and more. Meanwhile, non-magnetic metals such as aluminum, copper, and titanium provide alternatives when magnetic interference must be avoided or specific mechanical properties are required.

Knowing the type of magnetism a metal exhibits—whether ferromagnetic, paramagnetic, or diamagnetic—helps engineers select the right material for both performance and cost-effectiveness. Additionally, the magnetization state affects not only the function of the part but also manufacturing complexity and pricing. Clear communication of magnetic requirements to your CNC machining factory can prevent costly errors and ensure your project runs smoothly from design to final product.

For more detailed insights on selecting the best metals for your metal CNC machined parts, and to explore related topics like stainless steel grades and alloy properties, feel free to explore our comprehensive resources and contact our CNC machining experts.

What metals have the strongest magnets?

The metals with the strongest magnets are primarily rare earth metals like neodymium and samarium, as well as traditional ferromagnetic metals such as iron, cobalt, and nickel. Alloys made from these elements, such as Alnico and rare earth magnets, exhibit exceptionally strong magnetic fields.

What metals are not attracted to magnets?

Non-magnetic metals include copper, brass, aluminum, lead, gold, silver, titanium, tungsten, and zinc. These metals either have no unpaired electrons or atomic structures that prevent magnetic alignment, so they do not exhibit ferromagnetism and are not attracted to magnets.

Is stainless steel magnetic?

It depends on the stainless steel grade. Ferritic and martensitic stainless steels are magnetic, while austenitic stainless steels (like 304 and 316) are generally non-magnetic unless cold-worked or stressed. The magnetic behavior relates to their crystal structures.

Does a magnet attract silver?

No, silver is non-magnetic and is not attracted to magnets. It exhibits diamagnetism, meaning it weakly repels magnetic fields.

Does a magnet attract copper?

No, copper is also non-magnetic and not attracted to magnets. Like silver, it exhibits diamagnetism and is weakly repelled by magnetic fields.

Which metal is most easily attracted to a magnet?

Iron is the metal most easily and strongly attracted to magnets due to its high ferromagnetic properties and magnetic permeability.

How can I test if an object is magnetic without a magnet?

If you don’t have a magnet, you can test magnetism indirectly by observing if the object attracts small iron filings or affects a compass needle’s direction. Another method is to use a metal detector designed to detect ferromagnetic metals.

Which jewelry metals are non-magnetic?

Common non-magnetic jewelry metals include gold, silver, platinum, and titanium. These metals are favored for their appearance and corrosion resistance, as well as their lack of magnetic response.

Which metals cannot be magnetized?

Metals that cannot be magnetized include those with no unpaired electrons or atomic arrangements preventing magnetic domain formation, such as copper, aluminum, gold, silver, and most austenitic stainless steels.

Is galvanized steel magnetic?

Yes, galvanized steel is typically magnetic because it’s usually made from carbon steel coated with a thin layer of zinc. The underlying steel retains its ferromagnetic properties.

Can a magnet attract stainless steel?

It depends on the stainless steel type. Magnetic grades like ferritic and martensitic stainless steels are attracted to magnets, whereas austenitic stainless steels are generally not unless they have been cold-worked or contain impurities.