15 years one-stop China custom CNC machining parts factory

274 |

Published by VMT at Aug 13 2025 | Reading Time:About 6 minutes

274 |

Published by VMT at Aug 13 2025 | Reading Time:About 6 minutes

Many industries — from aerospace and medical to electronics — choose titanium for its exceptional performance. Yet, one question often confuses engineers, machinists, and product designers: Is titanium magnetic? The answer matters more than you might think. In applications like MRI machines, high-tech sensors, or precision CNC machined parts, even a small amount of magnetism could cause interference or failure. Unfortunately, there’s a lot of misunderstanding online — some claim titanium is magnetic, others say it’s completely nonmagnetic. Without clear knowledge, you risk selecting the wrong material, leading to increased costs, safety hazards, and project delays. This guide will break down the truth, explaining titanium’s magnetic properties, why it behaves that way, and how it affects CNC machining services.

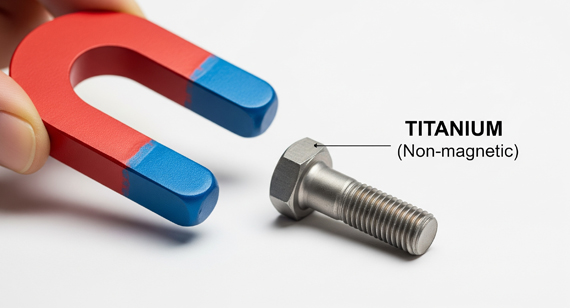

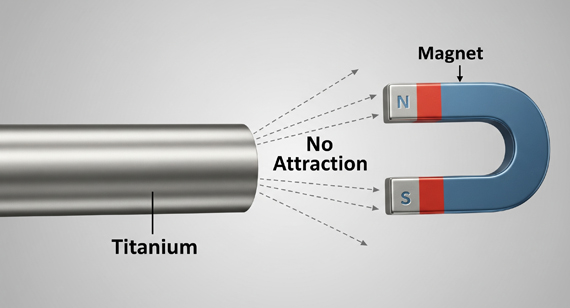

Titanium is not magnetic under normal conditions. It is a weakly magnetic (diamagnetic) metal, meaning it is not attracted to magnets. Its atomic structure prevents strong magnetic alignment, making it ideal for applications like medical implants, aerospace components, and precision CNC machined parts that require minimal magnetic interference.

Now that we know titanium is generally nonmagnetic, it’s time to understand why. This knowledge will help you make informed material choices for engineering projects, especially when working with CNC machining factories that produce titanium CNC machined parts for high-performance industries. Let’s break down what titanium is, how magnetism works in metals, and how different titanium grades and alloys behave.

Pure titanium is nonmagnetic, but the story changes slightly with alloys. Alloying titanium with other metals can introduce trace magnetic responses, though still far weaker than steel or nickel alloys. For example, titanium alloys used in aerospace may contain aluminum or vanadium, which do not make it strongly magnetic, but alloying with small amounts of iron can increase magnetic susceptibility slightly. In practice, even titanium alloys remain safe for MRI use and sensitive equipment, provided their composition is controlled. When CNC machining titanium alloys, manufacturers must consider these variations to ensure the final product meets magnetic interference requirements.

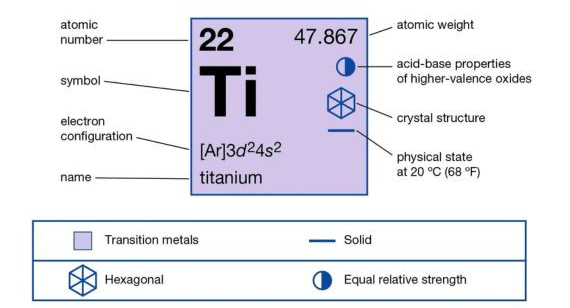

Titanium is classified as diamagnetic, meaning it slightly repels magnetic fields instead of attracting them. This behavior is due to its electron configuration — the paired electrons in titanium’s atomic orbitals do not allow the alignment needed for ferromagnetism. As a result, magnets have little to no effect on titanium. This makes it ideal for industries where magnetism could cause problems, such as electronics manufacturing, precision optical systems, and certain defense applications.

Titanium is a strong, lightweight, corrosion-resistant metal with the symbol Ti and atomic number 22. Discovered in the late 18th century, it has become one of the most sought-after materials for advanced engineering applications. It offers an excellent strength-to-weight ratio, high resistance to seawater corrosion, and stability at high temperatures. Titanium’s biocompatibility also makes it a top choice for surgical implants. In CNC machining factories, titanium CNC machined parts are valued for their durability and performance in demanding environments.

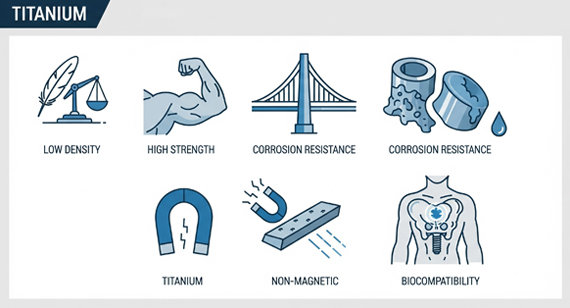

Titanium is valued across multiple industries because it combines several unique properties that are rarely found in a single metal. Its nonmagnetic nature makes it ideal for use in environments where magnetic interference could cause operational failures, such as in medical imaging or precision electronic systems. At the same time, titanium offers excellent corrosion resistance, which ensures long-term durability even in harsh marine or chemical conditions. Its biocompatibility allows it to be used safely inside the human body, while its heat resistance makes it suitable for high-temperature aerospace and industrial processes. Finally, titanium is significantly lighter than steel, yet strong enough to withstand extreme mechanical stress. These characteristics, taken together, explain why titanium CNC machined parts are in high demand among aerospace, medical, defense, and automotive manufacturers. When you partner with professional CNC machining services, you can fully leverage these advantages to optimize both performance and lifespan of your components.

Nonmagnetic

One of titanium’s most defining characteristics is its nonmagnetic behavior. Classified as a diamagnetic metal, titanium does not attract magnets and is unaffected by most magnetic fields. This is crucial in applications such as MRI machines, sensitive laboratory instruments, and defense equipment, where even minimal magnetic interference could disrupt functionality or accuracy. For CNC machining factories producing titanium CNC machined parts, this property means they can create components that will operate safely in magnetic-sensitive environments without additional shielding or isolation measures. Unlike ferromagnetic metals like steel, titanium’s electron configuration prevents the magnetic alignment that causes attraction, ensuring stable performance even near powerful magnets. This makes it a go-to material for surgical tools, spacecraft parts, and specialized sensors.

Corrosion-Resistant

Titanium is exceptionally corrosion-resistant, thanks to a thin but robust oxide layer that forms naturally on its surface. This oxide film acts as a protective barrier against oxygen, chlorides, and various acids, making titanium ideal for use in seawater, chemical processing plants, and biomedical implants. Unlike many metals that degrade over time, titanium maintains its integrity for decades, even in aggressive environments. For CNC machining services, this means titanium CNC machined parts can be used in marine propeller shafts, offshore drilling equipment, and desalination systems without the need for heavy anti-corrosion coatings. In medical applications, this corrosion resistance ensures that implants will not leach harmful metals into the body. From a cost perspective, titanium’s corrosion resistance reduces the need for frequent replacement, lowering lifetime project expenses.

Biocompatible

Titanium’s biocompatibility makes it one of the most widely used metals for surgical implants, dental tools, and prosthetics. The human body does not reject titanium because it is inert and non-toxic, meaning it will not trigger allergic reactions or cause long-term irritation. Over time, bone can even grow and bond directly to titanium surfaces, a process called osseointegration, which is critical for stable joint replacements and dental implants. CNC machining factories can produce highly precise titanium CNC machined parts for medical applications, ensuring tight tolerances and smooth finishes that promote healing and reduce infection risks. This property also benefits wearable technology, medical instruments, and body-contact devices where skin compatibility is essential.

Heat-Resistant

Titanium maintains its mechanical strength and structural integrity at temperatures up to 600°C (1,112°F), outperforming many other metals in high-heat environments. This makes it indispensable for aerospace components such as jet engine blades, exhaust systems, and spacecraft structures. In industrial settings, titanium CNC machined parts are used in furnaces, heat exchangers, and chemical reactors, where both heat and corrosion resistance are required. The combination of high heat tolerance and low thermal expansion ensures that titanium components remain dimensionally stable under temperature fluctuations, improving reliability and service life. For CNC machining services, this means that parts designed for high-temperature performance can be produced without worrying about premature thermal degradation.

Lightweight

Titanium has a density of about 4.5 g/cm³, roughly 60% that of steel but with comparable tensile strength. This means engineers can design components that are just as strong as steel parts but significantly lighter, improving energy efficiency and reducing fuel consumption in vehicles, aircraft, and ships. For CNC machining factories, this property is particularly valuable when producing aerospace and automotive titanium CNC machined parts, where every gram of weight saved translates to performance gains and cost reductions in operation. In wearable medical devices, lightweight titanium improves patient comfort without compromising durability. Additionally, its low density simplifies installation and handling, reducing labor costs in assembly.

summarizing the Titanium Properties section so readers can quickly compare each characteristic — perfect for your CNC machining article.

Table: Key Properties of Titanium

| Property |

Description |

Benefits for CNC Machined Parts |

Typical Applications |

| Nonmagnetic |

Diamagnetic metal, not attracted to magnets. | Safe for magnetic-sensitive environments without shielding. | MRI equipment, surgical tools, aerospace sensors. |

| Corrosion-Resistant |

Naturally forms an oxide layer that protects against rust and chemical attack. | Long service life in aggressive environments, minimal maintenance. | Marine shafts, offshore drilling equipment, chemical reactors. |

| Biocompatible |

Inert and non-toxic, does not cause allergic reactions. | Ideal for medical implants and tools requiring skin or tissue contact. | Hip joints, dental implants, prosthetics, wearable medical devices. |

| Heat-Resistant |

Maintains strength at temperatures up to 600°C (1,112°F). | Reliable performance in high-heat conditions; stable dimensions. | Jet engine blades, heat exchangers, furnace parts. |

| Lightweight |

Density ~60% that of steel with comparable strength. | Reduces weight in designs without sacrificing durability; improves efficiency. | Aerospace structures, automotive performance parts, portable medical devices. |

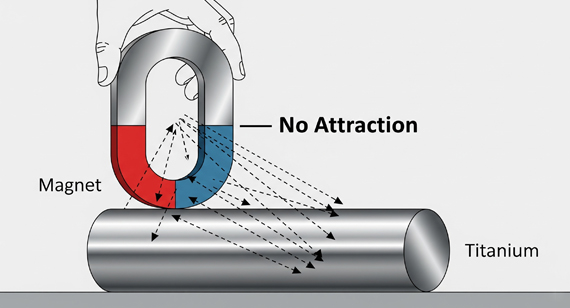

One of the most important physical characteristics of titanium is its nonmagnetic behavior. This property makes it an ideal choice for environments where magnetic interference can cause operational problems or safety risks. In industries such as medical imaging, aerospace, and precision electronics, even a slight magnetic response from a material can distort equipment readings or compromise performance. Titanium avoids these issues because it does not align its electrons in response to an external magnetic field. For CNC machining factories, this means titanium CNC machined parts can be used in specialized applications like MRI-compatible tools, navigation systems, and high-precision scientific instruments without the need for additional shielding. Understanding why titanium is nonmagnetic helps engineers make informed material choices and avoid unexpected design failures.

Diamagnetism

Titanium is classified as diamagnetic, which means it creates a very weak repelling force when exposed to an external magnetic field. This occurs because all the electrons in titanium atoms are paired, so their magnetic moments cancel out, preventing strong attraction. Diamagnetism is a fundamental property and is not affected by normal operating conditions like temperature changes or atmospheric pressure. For industries that require zero or near-zero magnetic interference, titanium’s diamagnetism ensures that parts will remain stable even when placed near powerful magnets. In CNC machining services, this property allows the creation of precision parts that function reliably in magnetic resonance imaging, microelectronic manufacturing, and aerospace navigation systems.

Weak Magnetic Moment

A magnetic moment is the measure of how strongly a material responds to a magnetic field. Titanium has an extremely weak magnetic moment because its atomic structure lacks unpaired electrons, which are responsible for generating strong magnetic responses in ferromagnetic metals like iron, nickel, and cobalt. Even when placed in a strong magnetic field, titanium’s response is negligible and temporary. This weak magnetic moment is especially important for equipment calibration — components made from titanium will not distort readings or create interference in magnetically sensitive systems. CNC machining factories that work with titanium can confidently produce high-precision parts for laboratory and defense equipment knowing the magnetic signature will remain minimal.

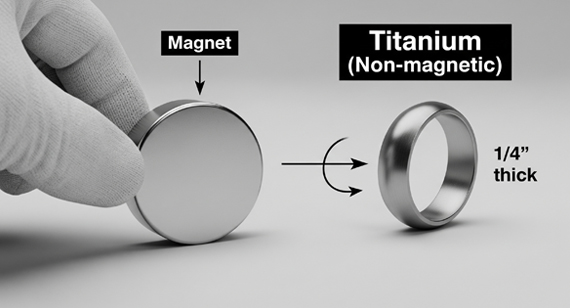

Not Attracted by Magnets

In practical terms, titanium is not attracted by magnets. Even strong rare-earth magnets like neodymium will have no noticeable pull on pure titanium or standard titanium alloys. This makes it a perfect material for surgical instruments used in MRI suites, where any magnetic attraction could pose serious safety hazards. In industrial applications, titanium’s lack of magnetic attraction allows it to be used in precision instruments without risk of magnetic field distortion. For CNC machining services, producing nonmagnetic titanium CNC machined parts eliminates the need for special coatings or isolators to reduce magnetic interference. This simplifies design and can lower production costs for industries where magnetic neutrality is a requirement.

summarizing the Titanium’s Nonmagnetism section so readers can quickly grasp the key points.

Table: Summary of Titanium’s Nonmagnetic Properties

| Aspect |

Description |

Relevance for CNC Machined Parts |

| Diamagnetism |

Titanium slightly repels magnetic fields due to paired electrons. | Ensures compatibility with MRI equipment, aerospace sensors, and precision instruments. |

| Weak Magnetic Moment |

Minimal response to magnetic fields; lacks unpaired electrons that create strong magnetism. | Prevents interference in calibration-sensitive and navigation systems. |

| Not Attracted by Magnets |

Even strong neodymium magnets have virtually no effect on pure titanium or standard alloys. | Eliminates need for magnetic shielding, reducing design complexity and costs. |

| Application Benefit |

Nonmagnetic behavior remains stable under normal operating conditions. | Reliable performance in medical, aerospace, electronics, and defense applications. |

Titanium is diamagnetic, not paramagnetic. This distinction is important because these two types of magnetism behave very differently. Paramagnetic materials have unpaired electrons in their atomic structure, which allows them to be weakly attracted to magnetic fields. Diamagnetic materials, on the other hand, have all their electrons paired, causing their magnetic moments to cancel each other out. Instead of being attracted, diamagnetic materials slightly repel magnetic fields. Titanium’s electron configuration places it firmly in the diamagnetic category, meaning it does not exhibit measurable attraction to magnets under normal conditions.

In practical terms, this diamagnetic property makes titanium an ideal choice for environments where even a weak magnetic pull could cause problems — for example, inside MRI machines, precision navigation equipment, or sensitive scientific instruments. CNC machining factories that produce titanium CNC machined parts for such applications can guarantee that the components will not distort magnetic fields or affect device accuracy.

It’s worth noting that while pure titanium is completely diamagnetic, some titanium alloys may show trace paramagnetic behavior if alloying elements like iron are present in significant quantities. However, these effects are still minimal compared to ferromagnetic metals such as steel. This is why material certification and composition verification are essential steps when ordering titanium components from CNC machining services.

Titanium’s magnetic behavior depends not only on its atomic structure but also on its processing, surface treatments, and alloy composition. While pure titanium is consistently diamagnetic, certain modifications and coatings may introduce materials with different magnetic properties. For engineers, product designers, and CNC machining factories, understanding these variations is essential for selecting the right titanium type for magnetic-sensitive applications. In CNC machining services, precise material choice ensures that titanium CNC machined parts meet both functional and safety requirements without introducing unwanted magnetic responses. Below, we examine pure titanium, anodized titanium, PVD-coated titanium, and titanium alloys to understand how each type behaves around magnets.

Pure Titanium

Pure titanium, typically in Grades 1 through 4, is entirely diamagnetic and does not attract magnets. This makes it ideal for use in medical, aerospace, and electronic applications where magnetic interference must be avoided. Because its magnetic susceptibility is extremely low, pure titanium CNC machined parts can be safely used in MRI rooms, precision measurement instruments, and navigation systems without affecting accuracy. In CNC machining factories, pure titanium is favored for its predictable and stable performance in these environments.

Pure Titanium Anodizing (Anodized Materials)

Anodizing titanium is a surface treatment process that uses an electrolytic bath to create an oxide layer, producing vibrant colors without adding foreign metals. Since anodizing only changes the oxide thickness and does not introduce magnetic materials, the nonmagnetic nature of titanium remains unchanged. CNC machining services often anodize titanium CNC machined parts for aesthetic purposes, corrosion resistance, or to create color-coded components for medical instruments. This process is common in aerospace, marine, and consumer electronics, where both visual appearance and nonmagnetism are required.

Pure Titanium PVD (Physical Vapor Deposition)

Physical Vapor Deposition (PVD) is a coating process that can enhance wear resistance, change color, or improve surface hardness. While PVD itself does not alter titanium’s internal magnetic behavior, the coating material can. For example, if a PVD process applies a titanium nitride (TiN) layer, the part remains nonmagnetic. However, if a magnetic material such as chromium or nickel is deposited, the outer surface may exhibit slight magnetic attraction even though the core titanium is diamagnetic. CNC machining factories working with titanium often use PVD for decorative or functional purposes, but in magnetic-sensitive applications, the coating composition must be carefully selected.

Titanium Alloys

Titanium alloys, such as Ti-6Al-4V (Grade 5), are widely used in aerospace, medical, and automotive industries due to their strength and durability. While most titanium alloys remain weakly diamagnetic, some alloying elements — particularly iron, cobalt, or nickel — can introduce slight paramagnetic behavior. In most cases, this effect is too small to cause problems, but for extreme magnetic sensitivity, such as in MRI-compatible tools, high-purity titanium grades may be preferred. CNC machining services must account for these differences, especially when producing titanium CNC machined parts that will operate in magnetic field-sensitive environments.

Here’s a clear, professional comparison table for Types of Titanium and Its Magnetic Properties:

Table: Magnetic Properties of Different Titanium Types

| Titanium Type |

Magnetic Behavior |

Cause/Notes |

CNC Machining Considerations |

| Pure Titanium (Grades 1–4) |

Diamagnetic (nonmagnetic) | All electrons paired; no magnetic attraction. | Ideal for MRI-safe tools, aerospace sensors, and precision instruments. |

| Pure Titanium Anodizing |

Diamagnetic (nonmagnetic) | Oxide layer only; no introduction of magnetic materials. | Safe for color-coded, corrosion-resistant, nonmagnetic components. |

| Pure Titanium PVD (Nonmagnetic Coating) |

Diamagnetic (nonmagnetic) | Coating material is nonmagnetic (e.g., TiN, ZrN). | Suitable for wear resistance and decorative finishes without changing magnetic properties. |

| Pure Titanium PVD (Magnetic Coating) |

Slight magnetic response (if present) | Coating contains magnetic metals (e.g., Ni, Cr, Co). | Avoid magnetic coatings in MRI-compatible or magnetic-sensitive environments. |

| Titanium Alloys (e.g., Ti-6Al-4V) |

Weakly diamagnetic to slightly paramagnetic | Alloying elements like Fe, Ni can introduce minimal magnetic response. | Verify alloy composition when designing for extreme magnetic neutrality. |

The reason titanium is nonmagnetic lies in its atomic structure and electron configuration. Titanium atoms have all their electrons paired, which means their magnetic moments cancel each other out. In magnetic materials like iron, unpaired electrons align in the presence of a magnetic field, creating attraction. Titanium’s paired electrons prevent this alignment, making it diamagnetic—it actually produces a very weak opposing magnetic field when placed near a magnet. This microscopic resistance to magnetism is so minimal that it is undetectable without sensitive scientific instruments.

From a manufacturing standpoint, this property is critical. Titanium CNC machined parts will not interfere with magnetic fields, making them ideal for medical implants, MRI-compatible tools, aerospace navigation systems, and sensitive electronic instruments. In CNC machining services, knowing that titanium won’t cause electromagnetic interference helps engineers design parts for highly specialized environments. For industries that require precision and safety, nonmagnetic metals like titanium are often the only acceptable choice.

It’s worth noting that titanium’s nonmagnetic behavior is inherent to pure titanium. However, alloys with iron, nickel, or cobalt can introduce a slight paramagnetic effect. This is why CNC machining factories often verify both material composition and magnetic susceptibility before approving titanium components for magnetic-sensitive applications.

In its pure form, titanium is not attracted to magnets. Because it is a diamagnetic material, it slightly repels magnetic fields rather than being drawn toward them. This repulsion is extremely weak—so weak that you wouldn’t feel or see any effect without using precise laboratory instruments. In practical terms, holding a magnet near pure titanium will produce no visible movement or attraction. This is one of the reasons titanium is favored for MRI-safe medical devices, aerospace components, and precision measuring tools.

However, there’s an important exception. If titanium is alloyed with elements like iron, nickel, or cobalt, even in small amounts, it can show slight paramagnetic properties, meaning it could exhibit minimal attraction to a strong magnet. Similarly, if titanium surfaces are coated (such as with a PVD layer containing magnetic metals), the outer coating—not the titanium itself—may respond to magnets. In CNC machining services, this distinction is crucial when producing titanium CNC machined parts for magnetic-sensitive industries.

For engineers and buyers, the key takeaway is simple: pure titanium won’t stick to a magnet, but alloys or coatings can change that. This means your CNC machining factory must confirm the exact material composition if nonmagnetic behavior is essential for your project.

Titanium’s nonmagnetic behavior does not directly influence the cutting, shaping, or finishing processes in CNC machining. Machining performance is determined more by factors like hardness, thermal conductivity, and work-hardening tendency than by magnetic properties. Since titanium is diamagnetic, its lack of magnetic attraction neither hinders nor improves the mechanical cutting process in CNC machining factories.

However, its nonmagnetic nature does affect the industries and applications that choose titanium CNC machined parts. In sectors such as aerospace, electronics, and medical technology, magnetic neutrality is a key design requirement. For example, MRI-compatible surgical tools must be entirely nonmagnetic to avoid safety risks and imaging interference. This means CNC machining services often handle titanium to meet these niche requirements, especially when producing parts that operate in high-magnetic-field environments.

In some cases, titanium’s nonmagnetism indirectly influences workholding strategies. Magnetic chucks—often used for holding ferrous metals—cannot be used with titanium. CNC machining factories instead rely on mechanical clamps, vacuum fixtures, or custom-designed jigs to secure titanium workpieces during milling or turning. This requires careful planning to prevent part movement, especially when machining thin-walled or delicate components.

While pure titanium is naturally diamagnetic and unaffected by typical magnetic fields, certain conditions can slightly influence its magnetic behavior. For CNC machining factories producing titanium CNC machined parts for magnetic-sensitive applications, understanding these factors is essential. This ensures the final product maintains its required nonmagnetic characteristics, especially in industries such as aerospace, medical, and electronics.

1. Pressure

Extreme mechanical pressure—far beyond what is seen in normal machining—can slightly alter titanium’s crystal structure. In laboratory settings, ultra-high pressure can affect electron movement and cause minimal changes in magnetic susceptibility. While standard CNC machining pressures are far too low to cause this effect, components used in deep-sea or high-pressure aerospace environments may require post-manufacturing testing.

2. Temperature

High temperatures can temporarily affect the movement of electrons in titanium. When titanium is heated above certain thresholds (e.g., during welding or high-speed machining without proper cooling), there can be minor and reversible changes in its magnetic response. Proper coolant use in CNC machining services prevents these effects and maintains the material’s stability.

Note: Overheating titanium not only risks dimensional accuracy but may also compromise surface integrity.

3. Impurities

Even trace amounts of magnetic impurities—such as iron, nickel, or cobalt—can give titanium a weak paramagnetic property. These can enter the material during extraction, smelting, or even through cross-contamination in CNC machining workshops. Using certified titanium from reputable suppliers greatly reduces this risk.

4. Alloying Elements

Titanium alloys, like Ti-6Al-4V, are widely used for their strength and corrosion resistance, but some alloying elements can introduce slight magnetic responses. For example, iron increases strength but also adds a minimal paramagnetic effect. When producing MRI-compatible titanium CNC machined parts, CNC machining factories must select grades that avoid or minimize such elements.

Here’s the comparison table for Factors Affecting Titanium’s Nonmagnetic Properties:

Table: Influence of Different Factors on Titanium’s Magnetic Properties

| Factor |

Effect on Magnetism |

Level of Impact |

CNC Machining Consideration |

| Pressure |

Ultra-high pressure can slightly alter electron structure, changing susceptibility. | Very Low | Not a concern in normal CNC machining; may matter in deep-sea or aerospace stress testing. |

| Temperature |

Extreme heat can cause minor, reversible changes in magnetic response. | Low | Use coolants during machining to prevent overheating and property changes. |

| Impurities |

Trace iron, nickel, or cobalt can introduce slight paramagnetism. | Medium | Source titanium from certified suppliers; avoid cross-contamination in machining. |

| Alloying Elements |

Some alloy metals (iron, cobalt) increase magnetic susceptibility. | Medium-High | Choose Grade 1 or 2 titanium for MRI or magnetic-sensitive applications. |

Titanium’s unique combination of nonmagnetic behavior, high strength-to-weight ratio, corrosion resistance, and biocompatibility makes it a material of choice across a variety of industries. For CNC machining factories, this versatility means titanium CNC machined parts are in constant demand—from medical devices to aerospace components. Below are the key industries where titanium’s properties bring unmatched advantages.

Power Generation

Titanium is heavily used in power plants, especially in seawater-cooled condensers and heat exchangers. Its corrosion resistance in marine environments makes it ideal for nuclear and thermal power facilities. CNC machining services produce titanium turbine blades, pumps, and valve components that must perform under high stress and resist long-term degradation.

Titanium’s biocompatibility and nonmagnetic nature make it the gold standard for surgical implants, dental fixtures, and orthopedic devices. MRI compatibility is a major reason surgeons choose titanium over stainless steel. CNC machined parts in this sector include bone screws, joint replacements, and surgical instruments that require precision and absolute reliability.

Aerospace

Aerospace engineering relies on titanium for its strength-to-weight advantage, heat resistance, and ability to withstand high stress. Nonmagnetic behavior helps avoid interference with onboard navigation and communication systems. CNC machining factories often produce titanium airframe parts, landing gear components, and jet engine elements.

In electronics, titanium is valued for being nonmagnetic and corrosion-resistant, ensuring sensitive devices aren’t disrupted by magnetic interference. Titanium CNC machined parts are used in casings for sensors, connectors, and high-performance computing systems where electromagnetic stability is vital.

Industrial

Chemical processing plants, desalination facilities, and marine engineering projects all benefit from titanium’s resistance to corrosion and high temperatures. CNC machining services provide custom titanium valves, fittings, and pressure vessel parts for these demanding environments.

In high-performance automotive engineering, titanium is used for exhaust systems, suspension components, and fasteners to reduce weight while maintaining durability. Nonmagnetic properties are less critical here, but its combination of lightness and strength delivers a competitive advantage. CNC machining factories often serve racing teams and luxury car manufacturers with precision titanium parts.

Here’s the summary table for Applications of Titanium:

Table: Applications of Titanium and CNC Machined Parts

| Industry |

Key Benefits of Titanium |

Common CNC Machined Parts Produced |

| Power Generation |

Corrosion resistance in seawater, high strength at elevated temperatures | Turbine blades, condenser tubes, heat exchanger plates, pump components |

| Medical |

Biocompatible, nonmagnetic, MRI safe, corrosion-resistant | Bone screws, dental implants, joint replacements, surgical instruments |

| Aerospace |

High strength-to-weight ratio, heat resistance, nonmagnetic | Airframe components, landing gear parts, jet engine blades, fasteners |

| Electronics |

Nonmagnetic, corrosion-resistant, EMI-safe | Sensor housings, connectors, device casings, shielding components |

| Industrial |

Chemical resistance, high-temperature durability | Valves, fittings, pressure vessel parts, desalination components |

| Automotive |

Lightweight, strong, high-performance durability | Exhaust systems, suspension components, performance fasteners |

At VMT, we specialize in precision titanium CNC machining parts tailored to meet the highest industry standards. Whether you require components for aerospace, medical devices, electronics, or automotive applications, our advanced CNC machining services combine cutting-edge technology with expert craftsmanship to deliver superior quality. We understand the unique challenges titanium presents—from its strength and corrosion resistance to its nonmagnetic properties—and we leverage our extensive experience to produce parts that excel in performance and reliability.

Our CNC machining factories employ state-of-the-art equipment capable of handling pure titanium grades as well as complex titanium alloys. We work closely with you to select the appropriate titanium material and machining parameters, ensuring your parts meet strict tolerance, surface finish, and nonmagnetic requirements. This attention to detail is crucial for applications where magnetic neutrality is a must, such as MRI-compatible medical tools and aerospace navigation components.

At VMT, quality assurance is paramount. Every titanium CNC machined part undergoes rigorous inspection, including dimensional checks, surface quality tests, and material certification reviews. We also offer post-processing services like anodizing and PVD coatings while carefully preserving the inherent nonmagnetic properties of titanium.

Choosing VMT means partnering with a trusted CNC machining service provider that understands titanium’s complexities and your industry demands. Contact us today to discuss your project needs and discover how our titanium CNC machining expertise can help you achieve outstanding results.

Titanium stands out as a remarkable metal thanks to its unique combination of being nonmagnetic, corrosion-resistant, biocompatible, lightweight, and heat-resistant. These properties make titanium an essential material across industries such as aerospace, medical, electronics, and automotive, where performance and reliability are critical. For CNC machining services and factories, understanding titanium’s magnetic behavior and its impact on machining processes ensures that parts meet stringent quality and functional requirements.

Choosing titanium for your next project means benefiting from components that won’t interfere with sensitive magnetic environments, offer exceptional durability, and deliver lightweight strength. Whether you require pure titanium or specialized alloys, partnering with an experienced CNC machining provider like VMT guarantees precision, quality, and expertise throughout the manufacturing process.

By considering factors such as alloy composition, surface treatments, and machining conditions, you can maximize titanium’s advantages while minimizing costs and ensuring magnetic neutrality. As demand for titanium CNC machined parts grows in cutting-edge sectors, investing in the right materials and machining services is more important than ever.

For reliable, high-quality titanium CNC machining parts that meet your industry’s exacting standards, trust VMT to deliver excellence every time.

No, titanium does not rust like iron or steel because it naturally forms a protective oxide layer that prevents corrosion. This corrosion resistance makes titanium CNC machined parts ideal for marine, medical, and industrial environments.

Does titanium conduct electricity? Can metal detectors detect titanium?

Titanium is a good conductor of electricity but not as conductive as copper or aluminum. Metal detectors can detect titanium, though sometimes with less sensitivity than ferrous metals because titanium is nonmagnetic and has different conductivity properties.

Is surgical titanium magnetic?

Surgical-grade titanium is typically nonmagnetic or only very weakly magnetic, making it safe for use in environments like MRI machines. This is why titanium is preferred over stainless steel for implants and surgical instruments.

Is titanium safe for MRIs?

Yes, titanium is safe for MRI scans due to its nonmagnetic and biocompatible nature. Titanium implants and tools will not interfere with the imaging process or pose safety risks.

Does titanium attract magnets?

Pure titanium does not attract magnets. It is diamagnetic, meaning it slightly repels magnetic fields. However, some titanium alloys or coated materials might show weak magnetic responses if they contain magnetic elements.

Does surgical titanium conduct electricity?

Yes, surgical titanium conducts electricity, but its conductivity is moderate compared to highly conductive metals. This property does not affect its safety or performance in medical applications.

Is titanium antimagnetic?

Titanium is considered antimagnetic or diamagnetic because it does not retain magnetic properties or get attracted to magnets. This makes it suitable for applications requiring magnetic neutrality.

Will surgical-grade titanium set off metal detectors?

Surgical-grade titanium can set off metal detectors, but often with less intensity than ferrous metals. Its detection depends on the size and shape of the implant or device.

Is 100% titanium magnetic?

No, 100% pure titanium is not magnetic. It is diamagnetic and will not be attracted to magnets under normal conditions.

Is titanium more expensive than gold?

Generally, titanium is less expensive than gold by weight, but costs vary based on purity, form, and processing. Titanium’s strength-to-weight ratio and durability often make it more cost-effective for industrial uses.

Is titanium stronger than stainless steel?

Titanium typically has a higher strength-to-weight ratio than stainless steel, meaning it can be stronger while being lighter. This makes titanium preferable for aerospace, medical, and automotive applications.

How do you know if it’s genuine titanium?

Authentic titanium can be verified through certifications from suppliers, magnetic testing (it should be nonmagnetic), density measurements, and professional lab analysis such as X-ray fluorescence (XRF).