15 years one-stop China custom CNC machining parts factory

149 |

Published by VMT at Aug 11 2025 | Reading Time:About 6 minutes

149 |

Published by VMT at Aug 11 2025 | Reading Time:About 6 minutes

When designing CNC machined parts, choosing the right material is critical. Many buyers ask, “Is iron magnetic?” because magnetic properties can influence everything from motor performance to precision alignment. The problem is, not all iron behaves the same way — and misunderstanding this could lead to expensive redesigns or failed product performance. The frustration comes when a project requires strong magnetism, yet the chosen iron alloy has weak or no magnetic response due to impurities, heat treatment, or alloying elements.

The solution? Understanding how iron’s atomic structure, domain alignment, and environmental factors affect its magnetism. In this guide, VMT CNC machining experts explain exactly when iron is magnetic, why it sometimes isn’t, and how to select the right grade for your CNC machined parts. You’ll also learn how CNC machining services can precisely shape magnetic iron into functional components while controlling cost and performance.

Tip: Always confirm the material’s magnetic requirements during the design stage — changing the material later can increase costs and delay production.

Yes, iron is magnetic because it is a ferromagnetic metal. Its unpaired electrons and aligned magnetic domains make it strongly attracted to magnets. Pure iron and many iron-based alloys retain magnetism, but some stainless steels and high-temperature conditions can reduce or eliminate this property.

Knowing that iron is generally magnetic is just the first step — understanding why it is magnetic helps you choose the right type for CNC machining projects. In the next sections, we’ll cover atomic structure, ferromagnetism, alloy effects, and even how to magnetize iron for permanent use. For buyers looking into iron CNC machined parts, this knowledge ensures the final product meets both mechanical and magnetic specifications. If you’re also considering non-magnetic metals for precision parts, check out our stainless steel CNC machining guide.

Tip: If your design involves moving magnetic fields, consider tolerance effects — magnetism can subtly influence CNC machined part alignment in sensitive assemblies.

Yes — iron is magnetic because it is a ferromagnetic metal, meaning its atomic structure allows the magnetic moments of its electrons to align in the same direction. This alignment creates strong magnetic fields, making pure iron and most iron alloys strongly attracted to magnets.

However, not all iron-based materials behave the same. Pure iron, low-carbon steels, and many alloy steels are strongly magnetic, but factors like temperature (above its Curie point of ~770°C), alloying with non-magnetic elements (such as chromium or nickel in certain stainless steels), and heat treatment can reduce or eliminate its magnetism.

In CNC machining, this property is important because magnetic behavior can influence material handling, assembly, and application performance. For example:

Tip: When ordering iron CNC machined parts from CNC machining factories, always specify whether magnetic properties are required. This ensures the correct iron grade is sourced and processed to meet your functional needs.

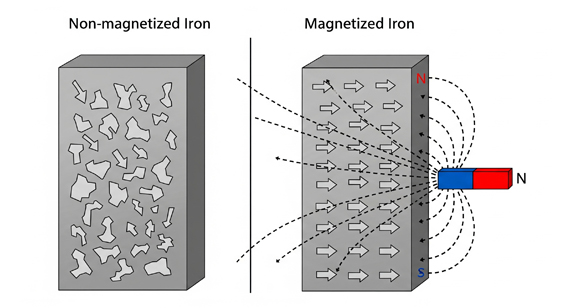

Iron sometimes has magnetic properties because of its electron configuration and the way its atoms are arranged — but these factors can change depending on temperature, alloy composition, and processing. At the atomic level, iron has unpaired electrons in its outer shell. These unpaired electrons produce small magnetic moments, and when many atoms align their magnetic moments in the same direction, the material becomes ferromagnetic.

In pure iron at room temperature, the magnetic domains (groups of aligned atoms) are naturally oriented in a way that makes the metal strongly magnetic. However, this alignment can be disrupted. For example, heating iron above its Curie temperature (~770°C) causes the domains to lose alignment, making the material non-magnetic. Similarly, alloying iron with non-magnetic elements — such as chromium or nickel — can break the domain alignment, reducing or eliminating magnetic properties.

For CNC machining services, this means not all iron CNC machined parts will behave the same magnetically. If a part must work in a magnetic environment (like in electric motors, sensors, or magnetic clamping systems), the chosen iron alloy must retain its ferromagnetism after processing. This is why CNC machining factories often test materials to confirm their magnetic performance before production.

Tip: If your project requires stable magnetism, avoid high-temperature processes or excessive alloying that could alter the iron’s magnetic domain structure.

Ferromagnetism in iron is the result of microscopic physical properties that make it strongly attracted to magnets and capable of becoming a permanent magnet itself. These properties stem from the way electrons are arranged, how their spins align, and how magnetic domains interact within the crystal structure. However, ferromagnetism is not guaranteed in all iron-based materials — it can be enhanced, reduced, or eliminated depending on environmental and material conditions.

In CNC machining, this knowledge matters because magnetism can influence how iron CNC machined parts are handled, assembled, or used in electrical applications. Choosing the wrong alloy or processing method could lead to parts that fail magnetic performance requirements. For example, an alloy steel with excessive non-magnetic elements may machine well but be unsuitable for electromagnetic devices.

Tip: Always ask your CNC machining services provider to confirm the magnetic specifications of the material before finalizing production.

Atomic Structure

The root cause of magnetism in iron lies in its electron configuration. Iron atoms have unpaired electrons in their 3d orbitals. These unpaired electrons act like tiny magnets, each producing a magnetic moment. When many atoms in a solid have unpaired electrons, the potential for ferromagnetism increases significantly.

In pure iron, these unpaired electrons allow the magnetic moments to interact strongly through a phenomenon called exchange coupling, aligning in the same direction. This is why pure iron shows strong magnetism compared to many other metals. CNC machining factories working with pure or low-alloy iron often choose it for applications where both mechanical strength and magnetic responsiveness are essential.

Spin Alignment

Each unpaired electron in iron spins, generating a magnetic field. In ferromagnetic materials, these spins tend to align in the same direction due to quantum mechanical exchange forces. This spin alignment amplifies the overall magnetic field, making iron strongly magnetic.

In some iron alloys, however, spin alignment is disrupted by crystal lattice changes or alloying elements, leading to weaker magnetism. For example, certain stainless steels have iron atoms, but the crystal structure prevents consistent spin alignment, making them nearly non-magnetic. For CNC machined parts that need predictable magnetic properties, controlling the alloy composition and post-processing heat treatments is essential.

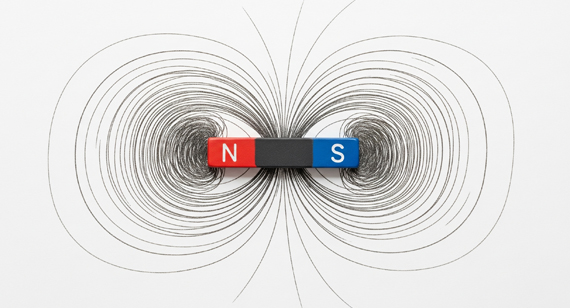

Domain Alignment

Even if electron spins align locally, they do so in small regions called magnetic domains. In an unmagnetized piece of iron, these domains point in random directions, canceling each other’s fields. When an external magnetic field is applied, the domains reorient to align in the same direction, producing strong magnetism.

For iron CNC machined parts in applications like motors, solenoids, or magnetic clamps, domain behavior determines performance. Machining stress, cold working, or improper annealing can disrupt domain boundaries, affecting how easily a part can be magnetized. CNC machining factories often apply stress-relief heat treatments to restore optimal domain alignment.

Curie Temperature

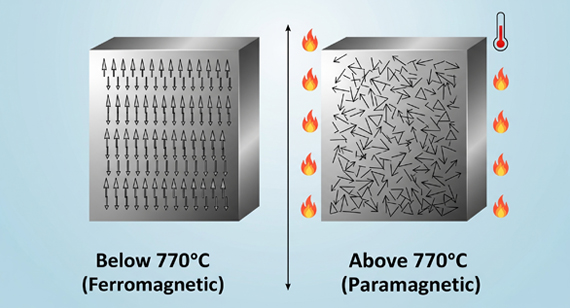

Iron retains its ferromagnetism only below its Curie temperature, about 770°C (1,418°F). Above this temperature, thermal vibrations disrupt domain alignment, and the material becomes paramagnetic — weakly attracted to magnetic fields.

This is crucial in manufacturing: welding, heat treating, or high-speed machining can temporarily or permanently alter magnetic properties if temperatures exceed the Curie point. For CNC machining services producing precision magnetic components, controlling heat input during processing is essential to prevent magnetism loss.

Impurities and Alloying Elements

Pure iron is highly magnetic, but real-world materials often contain impurities or deliberate alloying elements. Adding carbon, manganese, chromium, or nickel can alter the crystal lattice, electron configuration, and domain behavior. While some alloys maintain strong magnetism (like low-carbon steels), others, such as austenitic stainless steels, are essentially non-magnetic.

In CNC machining, the alloy choice impacts not just magnetism but also machinability, corrosion resistance, and strength. Buyers needing magnetic CNC machined parts should clearly specify both magnetic performance and mechanical requirements, as some alloys trade magnetism for other properties. CNC machining factories often guide customers to the right material grade based on a balance of all these needs.

Iron is one of the most well-known ferromagnetic metals, and its strong magnetic properties are the foundation of many modern engineering applications. At the atomic level, its unpaired electrons and naturally aligned magnetic domains give it an exceptional ability to generate and retain a magnetic field. This is why iron is a primary material in electromagnets, transformers, electric motors, and magnetic storage devices.

In pure form, iron exhibits the strongest ferromagnetism, but many common engineering grades — such as low-carbon steels — maintain most of these properties while improving strength and machinability. On the other hand, alloying iron with non-magnetic elements, such as nickel or chromium, can reduce or eliminate ferromagnetism. For example, while martensitic stainless steels are moderately magnetic, austenitic stainless steels are mostly non-magnetic due to their crystal structure.

For iron CNC machined parts, the presence or absence of magnetism can be a decisive factor in selecting the material. Components for motors, sensors, or magnetic clamping systems require strong ferromagnetism, while others — such as medical instruments or electronic housings — may require minimal magnetic interference. CNC machining services can shape both magnetic and non-magnetic iron alloys with precision, but the material choice must match the application’s performance requirements.

While pure iron is strongly ferromagnetic, its alloys can show very different magnetic properties depending on their chemical composition and crystal structure. In many cases, alloying improves strength, wear resistance, or corrosion resistance, but it can also reduce magnetism. This is why engineers and buyers of iron CNC machined parts must consider both mechanical and magnetic performance when selecting materials.

CNC machining services can work with a wide range of iron alloys, but each behaves differently in applications involving magnetism — from strong electromagnetic devices to components requiring low magnetic interference. Understanding the magnetism of different iron alloys helps avoid costly redesigns and ensures the part performs as expected in service.

Carbon Steel

Carbon steels are iron alloys containing carbon as the primary strengthening element. They typically retain strong ferromagnetism because their microstructure remains largely similar to pure iron, with unpaired electrons and aligned domains. Low-carbon steels, such as AISI 1018, are especially popular for magnetic applications due to their high permeability and ease of magnetization.

For CNC machined parts, carbon steels offer an excellent balance of magnetic strength, machinability, and affordability. They are widely used in motor parts, electromagnetic cores, and fixtures where magnetic clamping is required. However, higher carbon content can make the steel harder and more brittle, which might require slower machining speeds or additional processing.

Alloy Steel

Alloy steels contain additional elements like manganese, molybdenum, chromium, or nickel to enhance specific mechanical properties. While many alloy steels remain magnetic, higher concentrations of certain elements — particularly austenite-stabilizing elements like nickel — can weaken or eliminate ferromagnetism.

In CNC machining, alloy steels are often chosen for their superior strength, wear resistance, and toughness. For example, 4140 alloy steel retains moderate magnetism while providing exceptional mechanical performance. This makes it suitable for gears, shafts, and other high-stress magnetic components.

Stainless steel’s magnetism varies widely depending on its crystal structure. Ferritic and martensitic stainless steels (e.g., 430 and 410) are magnetic, while austenitic stainless steels (e.g., 304, 316) are generally non-magnetic due to their face-centered cubic structure.

For CNC machining services, this is a critical distinction. If you need corrosion-resistant parts that are also magnetic — such as for marine electromagnetic devices — ferritic stainless steel is a better choice than austenitic grades. On the other hand, non-magnetic stainless steel is preferred for medical devices or sensitive electronics where magnetic interference must be avoided.

Tool Steel

Tool steels are high-carbon steels alloyed with elements like tungsten, molybdenum, and vanadium for extreme hardness and wear resistance. Many tool steels remain magnetic, though their high alloy content can slightly reduce magnetic strength compared to pure carbon steels.

For CNC machined parts, tool steels are often used in dies, molds, and cutting tools where magnetism is not the primary property but can still be beneficial in magnetic holding systems during machining.

Cast Iron

Cast iron is an iron-carbon alloy with a higher carbon content (over 2%), giving it excellent wear resistance and vibration damping. It is generally magnetic because its matrix is iron-based, but the graphite content can slightly reduce its overall magnetic permeability.

In CNC machining, cast iron is used for machine bases, housings, and heavy-duty components. While it is machinable, its brittleness requires careful handling. For applications needing both structural stability and moderate magnetism, cast iron can be a cost-effective choice.

Maraging Steel

Maraging steels are unique iron-nickel alloys known for ultra-high strength and toughness achieved through aging heat treatments. Despite their high nickel content, they remain ferromagnetic due to their martensitic structure after processing.

In CNC machining services, maraging steels are used in aerospace, tooling, and high-performance engineering applications. Their combination of strength and magnetism makes them ideal for specialized magnetic assemblies where mechanical integrity is critical.

summarizing the Magnetism of Iron Alloys section, with CNC machining relevance included.

| Iron Alloy |

Magnetic Property |

Reason for Magnetism or Lack |

CNC Machining Applications |

Notes & Tips |

| Carbon Steel |

Strongly magnetic | Retains pure iron’s ferromagnetic structure with unpaired electrons | Motor parts, electromagnetic cores, magnetic fixtures | Low-carbon steel is ideal for high magnetism and easy machining |

| Alloy Steel |

Variable (moderate to strong) | Alloying with Mn, Mo, Cr may retain magnetism; Ni can reduce it | Gears, shafts, magnetic structural components | Confirm exact grade before production |

| Stainless Steel |

Ferritic & martensitic: magnetic; Austenitic: mostly non-magnetic | Ferritic/martensitic = BCC or martensitic structure; Austenitic = FCC structure disrupting spin alignment | Marine magnetic parts, corrosion-resistant components | Always check the grade — don’t assume stainless is magnetic |

| Tool Steel |

Magnetic (slightly reduced) | High alloy content slightly disrupts domain alignment | Dies, molds, cutting tools | Confirm magnetic retention after heat treatment |

| Cast Iron |

Magnetic (lower permeability) | Graphite phase reduces overall magnetic performance | Machine bases, housings, heavy-duty parts | Avoid for applications needing high permeability |

| Maraging Steel |

Magnetic | Martensitic structure after aging retains ferromagnetism despite high Ni content | Aerospace, tooling, high-strength magnetic parts | Magnetism can shift after prolonged high-heat exposure |

The Curie temperature of iron is approximately 770°C (1,418°F). Below this point, iron maintains its ferromagnetic properties because the magnetic domains remain aligned. Above this temperature, thermal energy becomes strong enough to disrupt domain alignment, causing iron to lose its ferromagnetism and become paramagnetic — weakly attracted to magnetic fields.

This phenomenon is critical in both engineering design and manufacturing. For example, iron CNC machined parts used in motors, transformers, or electromagnetic assemblies must remain below their Curie temperature during operation to retain magnetic functionality. Exceeding this threshold — even temporarily — can permanently change the material’s microstructure and reduce magnetism.

From a CNC machining perspective, processes such as welding, heat treating, or high-speed cutting can generate localized temperatures exceeding the Curie point. If not controlled, this heat can weaken or eliminate the magnetism of the final component. CNC machining factories often manage this risk through coolant use, optimized cutting parameters, and post-process magnetic testing.

Magnetic permeability is a measure of how easily a material can support the formation of a magnetic field within itself. Iron, especially in its pure form or as low-carbon steel, has very high magnetic permeability, making it one of the best materials for guiding and amplifying magnetic fields. This is why it is widely used in electromagnets, transformers, motors, and magnetic shielding.

High magnetic permeability means that iron can concentrate magnetic flux efficiently, reducing energy loss in electromagnetic systems. However, permeability is not constant — it varies with factors like alloy composition, mechanical stress, and temperature. For example, adding nickel or chromium can lower permeability, while heat treatment can restore or enhance it.

In CNC machining services, understanding permeability is crucial when manufacturing iron CNC machined parts for applications like solenoid cores or precision magnetic jigs. Material selection should balance mechanical properties with the desired magnetic performance. CNC machining factories often source specific electrical-grade iron or specialized steels to ensure maximum permeability for industrial clients.

Iron’s strong ferromagnetic properties make it an excellent base material for manufacturing permanent magnets. By manipulating its magnetic domains through controlled processes, engineers can create components that retain magnetism for extended periods. Permanent magnets made from iron or iron alloys are widely used in motors, sensors, electronic devices, and industrial holding systems.

For CNC machining services, the challenge is producing iron CNC machined parts with precise dimensions and surface finishes while ensuring the material is suitable for magnetization. This often requires selecting the right grade of iron, applying the correct magnetizing process, and verifying magnetic performance before shipment.

Choosing the Right Iron Material

Not all iron grades respond equally well to magnetization. Pure iron and low-carbon steels typically achieve the highest permanent magnet strength due to their high permeability and low coercivity. In contrast, high-alloy steels or stainless steels may resist magnetization or lose it quickly.

For CNC machined parts intended to be permanent magnets, materials like ARMCO pure iron or specific electrical steels are often chosen. These materials allow for deep magnetic saturation and stable domain alignment. The chosen alloy should match not only magnetic performance but also mechanical and environmental requirements.

Exposure to a Strong Magnetic Field

To magnetize iron, it must be exposed to a strong external magnetic field, typically created by passing high current through a coil surrounding the part. This field forces the magnetic domains in the iron to align in the same direction, creating a strong, unified magnetic field within the material.

For precision CNC machined parts, this process is often done after all machining is completed, to avoid heat or stress changes that could weaken magnetism. CNC machining factories that handle magnetized parts may need to use non-magnetic tooling or fixtures to prevent accidental demagnetization during handling.

Magnetic Domain Alignment

The goal of magnetization is to align the microscopic magnetic domains so that their magnetic moments point in the same direction. In unmagnetized iron, these domains are randomly oriented, canceling each other’s fields. The external magnetic field reorients them, producing strong, permanent magnetism.

Mechanical stress, high temperatures, or physical impacts can disturb this alignment, reducing magnet strength. This is why parts that need to retain magnetism must be designed with both structural integrity and environmental protection in mind.

Maintaining Magnetization

Once magnetized, iron can retain its magnetic properties for years if protected from conditions that disturb domain alignment. These include high heat, strong opposing magnetic fields, or physical shock. Coatings and surface treatments can also help prevent corrosion, which can indirectly weaken magnetic performance over time.

In industrial applications, maintaining magnetization may involve environmental controls, protective housings, or regular performance checks. CNC machining services can incorporate these design considerations directly into the manufacturing process.

In some cases, heat treatment can enhance a magnetized iron part’s stability. Controlled heating followed by cooling can relieve internal stresses that might otherwise cause gradual loss of magnetism. However, heating above the Curie temperature will demagnetize the part completely.

For CNC machining factories, this step must be precisely managed, especially for high-performance magnets in aerospace or medical devices. Heat treatment schedules are typically tailored to the specific alloy and application.

Testing

After magnetization, parts must be tested to confirm they meet the required magnetic strength and field direction. Testing methods include using a gaussmeter, pull-force testing, or flux mapping. This ensures the magnetized iron CNC machined parts will perform as intended in their final application.

Testing is especially important for critical components in motors, medical devices, or precision instruments, where magnetic performance is directly tied to functionality. CNC machining services often provide this as part of their quality control process.

Ferromagnetism in iron and its alloys is a complex phenomenon influenced by many internal and external factors. Understanding these influences is critical for engineers and buyers working with iron CNC machined parts to ensure the desired magnetic performance throughout the component’s lifecycle. Factors such as crystal structure, temperature, alloying elements, mechanical stress, grain size, and external magnetic fields all play a role in strengthening or weakening ferromagnetism.

In CNC machining services, controlling these factors during material selection and processing helps prevent unexpected magnetic failures and reduces production costs by minimizing rework.

Crystal Structure

The arrangement of atoms in a metal’s crystal lattice greatly impacts its magnetic properties. Iron’s body-centered cubic (BCC) structure at room temperature allows unpaired electrons to align their spins efficiently, producing strong ferromagnetism. However, when iron changes to a face-centered cubic (FCC) structure — as in austenitic stainless steels — spin alignment is disrupted, and magnetism decreases significantly.

For CNC machining factories, knowing the crystal structure helps determine whether the iron alloy will be magnetic after machining. This is especially important for applications like electric motors or magnetic sensors, where the wrong crystal phase could lead to weak or inconsistent magnetism.

Temperature

Temperature is one of the most significant external factors affecting ferromagnetism. Iron loses its ferromagnetic properties when heated above its Curie temperature (~770°C), as thermal energy randomizes magnetic domain alignment. Even temperatures below the Curie point can reduce magnetic strength by increasing atomic vibrations.

During CNC machining, excessive heat from cutting, grinding, or welding can temporarily or permanently degrade magnetic performance. Proper cooling and heat management are essential to preserving magnetism in iron CNC machined parts.

Alloying Elements

Adding different elements to iron alters its magnetic behavior. For instance, nickel and chromium are common alloying elements that can stabilize non-magnetic crystal phases or interrupt spin alignment. This effect is evident in stainless steels: austenitic grades containing high nickel and chromium are typically non-magnetic, while ferritic and martensitic grades with less of these elements remain magnetic.

Alloying improves corrosion resistance, strength, or hardness but may compromise magnetism. Therefore, balancing these factors is key when selecting materials for CNC machining services focused on magnetic applications.

Mechanical Stress

Mechanical stress, such as bending, machining-induced strain, or impact, can distort the crystal lattice and disrupt magnetic domain alignment. This stress reduces the overall magnetization of the iron part, potentially impairing its performance in magnetic assemblies.

CNC machining processes generate mechanical stress, especially during heavy cutting or cold working. To mitigate this, many CNC machining factories perform stress-relief heat treatments or recommend annealing to restore magnetic properties after machining.

Grain Size

The size of the grains in the iron’s microstructure influences how easily magnetic domains form and move. Smaller grains can hinder domain wall movement, reducing magnetic permeability and coercivity. Conversely, larger grains facilitate better domain alignment and stronger ferromagnetism.

Control of grain size is often achieved through heat treatment and controlled cooling. CNC machining factories familiar with magnetic materials will guide customers to specify appropriate thermal processing to optimize grain size and magnetic performance.

Magnetic Field

External magnetic fields can influence the magnetization state of iron parts. Exposure to strong fields can permanently magnetize a part or alter its domain structure. Conversely, alternating or opposing fields can demagnetize or weaken ferromagnetism over time.

In applications like electric motors or magnetic sensors, understanding and managing these effects is vital. CNC machining services must consider the part’s final operating environment to recommend suitable materials and finishes.

summarizing the Factors Affecting Ferromagnetism with CNC machining relevance and tips included:

| Factor |

Effect on Ferromagnetism |

CNC Machining Considerations |

Tips |

| Crystal Structure |

BCC (iron, ferritic steels) promotes strong magnetism; FCC (austenitic steels) reduces it | Select alloys with suitable crystal phases for magnetic parts | Confirm crystal structure when ordering alloys |

| Temperature |

Above Curie temperature (~770°C), iron loses magnetism; elevated heat reduces magnetic strength | Manage machining heat via coolant and cutting parameters | Avoid overheating during machining |

| Alloying Elements |

Elements like Ni, Cr may disrupt magnetism; alloying balances corrosion and strength with magnetism | Choose alloys balancing mechanical and magnetic requirements | Communicate magnetic specs clearly to supplier |

| Mechanical Stress |

Stress distorts lattice and domain alignment, reducing magnetism | Consider stress-relief heat treatment post-machining | Request annealing or stress relief if magnetism is critical |

| Grain Size |

Larger grains favor magnetic domain movement; smaller grains reduce permeability | Specify heat treatments controlling grain size | Ask about thermal processing for optimal grain size |

| Magnetic Field |

Strong fields can magnetize parts; alternating fields may demagnetize | Consider operational magnetic environment when selecting materials | Discuss final environment with CNC machining factory |

Iron’s strong ferromagnetic properties make it indispensable in numerous industrial and technological applications. From electromagnets to electric motors, iron and its alloys provide the foundation for devices that rely on controlled magnetic fields. For engineers and buyers sourcing iron CNC machined parts, understanding these applications helps ensure the right material and machining services are selected to meet both magnetic and mechanical requirements.

Electromagnets

Electromagnets use iron cores to amplify magnetic fields generated by electric currents. The high magnetic permeability of iron concentrates magnetic flux, resulting in strong, controllable magnetic forces used in cranes, magnetic locks, and industrial separators.

CNC machining services play a key role in shaping iron cores to precise dimensions, ensuring optimal magnetic performance and mechanical fit. The choice of iron grade and post-machining heat treatments directly affect the electromagnet’s strength and durability.

Transformers

Transformers rely on laminated iron cores to efficiently transfer electrical energy between circuits. Iron’s ferromagnetism reduces energy loss by directing magnetic flux, improving efficiency and reducing heat generation.

In manufacturing, CNC machining factories produce precisely shaped core components from electrical-grade iron or silicon steel alloys. Maintaining material integrity and low residual stress during machining is critical to preserving magnetic permeability.

Electromotors

Electric motors use iron components, such as stators and rotors, to generate motion through magnetic fields. The ferromagnetic iron core enhances the motor’s magnetic flux, improving efficiency and torque output.

CNC machining of iron parts for electromotors demands tight dimensional accuracy and surface finish to ensure magnetic and mechanical performance. The correct iron alloy choice also affects heat resistance and longevity.

Magnetic Storage Tools

Iron’s magnetic properties are utilized in data storage devices like hard drives and magnetic tapes, where tiny magnetic regions store digital information. Precision machining of iron and iron-alloy parts contributes to the reliability and performance of these storage tools.

CNC machining services enable the production of intricate, small-scale magnetic components essential for modern electronics. Material selection and machining precision directly influence data integrity and device lifespan.

summarizing the Magnetic Applications of Iron, with CNC machining considerations and tips included:

| Application |

Role of Iron’s Magnetism |

CNC Machining Relevance |

Tips |

| Electromagnets |

Iron cores amplify magnetic fields for strong, controllable force | Precision shaping of iron cores for optimal performance | Specify magnetic & mechanical tolerances clearly |

| Transformers |

Laminated iron cores direct magnetic flux, improving efficiency | Low-stress machining of electrical-grade iron cores | Request magnetic testing and low-stress machining |

| Electromotors |

Iron stators & rotors enhance magnetic flux for motor torque | Tight dimensional accuracy and surface finish required | Partner with factories experienced in magnetic components |

| Magnetic Storage Tools |

Magnetic regions in iron store digital data | Precision machining of small-scale magnetic parts | Specify surface finish and magnetic requirements clearly |

Understanding “Is iron magnetic?” is essential for selecting the right materials and manufacturing processes in industries relying on iron CNC machined parts. Iron’s inherent ferromagnetism, influenced by factors such as atomic structure, alloy composition, and temperature, makes it invaluable in applications ranging from electromagnets and transformers to electric motors and magnetic storage tools.

When sourcing CNC machined parts from CNC machining factories, clear communication of both magnetic and mechanical requirements ensures that the correct iron grades and machining processes are applied. This not only guarantees optimal magnetic performance but also prevents costly rework and delays.

By partnering with experienced CNC machining services, customers can benefit from precise machining, material expertise, and thorough quality control — all critical to producing high-performance magnetic components that meet today’s demanding standards.

Is Iron Attracted to a Magnet? Yes or No?

Yes, iron is strongly attracted to magnets due to its ferromagnetic properties. This makes it one of the most commonly used materials in magnetic applications, including iron CNC machined parts.

Which Metals Are Nonmagnetic?

Metals like copper, aluminum, gold, silver, and austenitic stainless steels (e.g., 304, 316) are generally nonmagnetic. Choosing the right metal is important in CNC machining when magnetism must be minimized.

Is Iron in Food Magnetic?

The iron present in food is typically in ionic or molecular form and is not magnetic. It does not respond to magnets like metallic iron does.

Does Gold Attract a Magnet?

No, gold is a nonmagnetic metal and is not attracted to magnets.

Is Diamond Magnetic? Is Magnesium Magnetic?

Diamonds are nonmagnetic because they are made of carbon atoms in a tightly bonded structure without unpaired electrons. Magnesium is weakly paramagnetic and does not exhibit ferromagnetism.

Aluminum is nonmagnetic. It is often used in applications where magnetic interference must be avoided.

Bronze is generally nonmagnetic, but some bronze alloys may show weak magnetic responses due to impurities.

Stainless steel’s magnetism depends on its type. Ferritic and martensitic stainless steels are magnetic, while austenitic stainless steels (commonly used in food and medical industries) are mostly nonmagnetic.

Does Iron Lose Its Magnetism?

Iron can lose magnetism if heated above its Curie temperature (~770°C), subjected to strong opposing magnetic fields, or physically stressed.

Is a Screw Magnetic?

Most screws made from carbon steel or certain stainless steels are magnetic. However, screws made from austenitic stainless steel or nonmagnetic alloys will not be attracted to magnets.

Is a Magnet Made of Pure Iron?

Pure iron can be magnetized but is rarely used alone for permanent magnets. Instead, iron alloys or specially treated materials are preferred for durability and stronger magnetic retention in manufacturing.