15 years one-stop China custom CNC machining parts factory

502 |

Published by VMT at Aug 12 2025 | Reading Time:About 6 minutes

502 |

Published by VMT at Aug 12 2025 | Reading Time:About 6 minutes

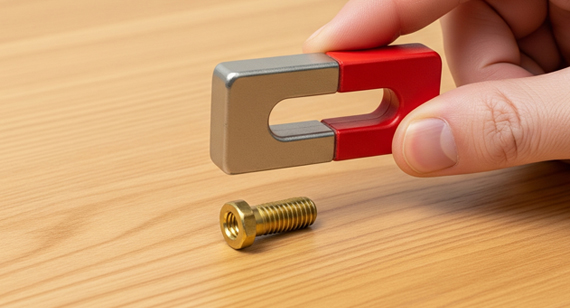

When working with brass CNC machined parts, customers often wonder: Is brass magnetic? This question arises because brass is widely used in industries where magnetic interference can cause performance issues — such as electronics, marine components, and precision instruments. The problem is that many people assume all metals are magnetic, which can lead to costly design mistakes. In reality, the magnetism of brass is a nuanced topic influenced by its composition and processing. Without understanding these factors, engineers risk choosing the wrong material for their CNC machining projects, resulting in wasted resources and delays. The good news? Brass is generally non-magnetic, but there are exceptions that every designer and manufacturer should know before committing to production.

Brass is generally non-magnetic because it is an alloy of copper and zinc, both of which are non-ferromagnetic. However, trace impurities or mechanical processing can induce slight magnetism. To ensure non-magnetic performance in brass CNC machined parts, choose high-purity alloys and verify properties before production.

While the short answer is “no,” brass is not magnetic under normal conditions, there are cases where it may exhibit weak magnetic behavior. Understanding why brass is usually non-magnetic — and when it might become magnetic — helps engineers, designers, and procurement specialists make the right decisions for CNC machining projects. Let’s break down the science behind brass’s magnetic properties and its implications in various industries.

Brass is typically classified as a non-ferromagnetic material. This means it does not naturally attract magnets and will not retain magnetic fields when removed from a magnetic source. The reason lies in its composition: brass is a copper-zinc alloy, and neither copper nor zinc contains the unpaired electrons necessary for ferromagnetism. In CNC machining services, this property makes brass an ideal choice for components where magnetic interference must be avoided, such as in electrical connectors, marine compasses, and precision measuring instruments.

However, not all brass behaves identically. Small variations in alloy composition, mechanical working, and impurities can alter its magnetic behavior slightly. While this change is often negligible in real-world applications, certain high-precision fields, such as aerospace or medical devices, require complete certainty about a part’s magnetic profile before use.

No — brass is not a ferromagnetic material. Ferromagnetism occurs when a material’s atoms have unpaired electrons in their outer shells and these electrons align in the same direction, creating a strong, permanent magnetic field. Metals such as iron, cobalt, and nickel show this property. Brass, however, is an alloy of copper and zinc, and neither of these base metals has the electronic structure needed for ferromagnetism.

In its purest form, brass exhibits diamagnetic or weakly paramagnetic behavior. This means it either slightly repels a magnetic field (diamagnetism) or has a very faint attraction that disappears once the magnetic field is removed (paramagnetism). For most CNC machining applications, brass is effectively considered non-magnetic, making it ideal for precision components in electronics, navigation systems, and sensitive instrumentation where magnetic interference must be avoided.

That said, brass can sometimes appear weakly magnetic. This typically happens when it contains trace ferromagnetic impurities such as iron or when it is bonded to a ferromagnetic substrate, like in brass-plated steel. Manufacturing processes such as cold working can also slightly align atomic structures, increasing magnetic susceptibility — though not to the point of true ferromagnetism.

Brass, in its pure form, cannot be permanently magnetized because it is not ferromagnetic. Unlike iron or cobalt, brass lacks the atomic structure needed to maintain an internal magnetic field. However, under certain conditions, brass may display weak or temporary magnetism. This phenomenon often surprises engineers and customers who expect brass CNC machined parts to be entirely non-magnetic. The causes are usually related to impurities, processing effects, or the use of brass coatings over magnetic metals. Understanding these scenarios is critical for industries where magnetic neutrality is essential, such as aerospace, medical devices, and high-precision electronics.

1. Trace Impurities

Even high-grade brass alloys can contain minute amounts of ferromagnetic metals, such as iron, nickel, or cobalt, introduced during the smelting process or from recycled feedstock. These impurities can slightly alter the alloy’s magnetic behavior. Although the effect is usually negligible in everyday applications, precision industries may find such interference unacceptable. That’s why CNC machining services handling aerospace, defense, or scientific instruments often use certified virgin brass stock to eliminate the risk of magnetic contamination.

2. Induced Magnetism

When brass is exposed to a strong magnetic field for an extended time, it may exhibit induced magnetism. This effect is temporary and disappears once the magnetic field is removed, but it can be enough to disrupt ultra-sensitive equipment. Cold working, such as rolling or hammering, can also slightly increase brass’s magnetic susceptibility by changing its crystal structure. For most applications, this change is inconsequential, but in industries like scientific research or satellite manufacturing, even a tiny magnetic influence can be problematic.

3. Brass-Plated Steel

Sometimes, parts marketed as “brass” are actually brass-plated steel. In this case, the steel core is ferromagnetic, meaning it will strongly attract a magnet even though the outer layer looks like brass. This is common in decorative fixtures, hardware, or cost-reduced components where appearance is prioritized over performance. For CNC machined parts requiring non-magnetic properties, using brass-plated steel would be a serious error, as it would completely fail in magnetic-sensitive environments.

summarizing the three main reasons brass might show magnetic behavior:

| Cause |

Description |

Magnetic Effect |

CNC Machining Tip |

| Trace Impurities |

Presence of small amounts of ferromagnetic metals (iron, nickel, cobalt) introduced during alloying or from recycled materials. | Weak and often negligible magnetism. | Request material certification to ensure high-purity brass for critical parts. |

| Induced Magnetism |

Brass temporarily influenced by strong magnetic fields or altered by cold working (rolling, hammering, bending). | Temporary or slightly increased magnetic susceptibility. | Use stress-relief annealing after cold working to reduce residual magnetism. |

| Brass-Plated Steel |

A thin brass coating applied over a ferromagnetic steel core. | Strong magnetism from the steel beneath. | Perform a magnet test to detect hidden steel before production. |

Magnetism refers to the ability of a material to respond to a magnetic field. In materials science and CNC machining applications, understanding the different types of magnetism is essential for selecting the right material for performance-sensitive parts. Brass CNC machined parts are typically classified as diamagnetic or weakly paramagnetic, but never ferromagnetic under normal conditions. Knowing the distinction between these magnetic categories helps engineers prevent interference in electronics, navigation, and medical devices.

Diamagnetism

Diamagnetism is the weakest form of magnetism. In diamagnetic materials, the electrons are paired, and their magnetic moments cancel out, causing the material to slightly repel a magnetic field. This effect is very small and often undetectable without sensitive instruments. Pure copper and pure zinc — the main constituents of brass — are diamagnetic, which explains why brass is generally non-magnetic. Diamagnetic materials do not retain any magnetism once the magnetic field is removed, making them excellent for precision instruments that must remain magnetically neutral.

Paramagnetism

Paramagnetic materials have some unpaired electrons, which align with an external magnetic field, causing weak attraction. However, this magnetism disappears once the external field is removed. Brass can show slight paramagnetic behavior if it contains trace amounts of ferromagnetic impurities or undergoes certain mechanical processing. While the effect is minimal, it can matter in aerospace, defense, or medical CNC machining projects where even a weak attraction is undesirable.

Ferromagnetism

Ferromagnetism is the strongest and most familiar form of magnetism. Ferromagnetic materials, such as iron, cobalt, and nickel, have unpaired electrons that align over large regions called domains, producing strong, permanent magnetic fields. Brass is not ferromagnetic, so it will not exhibit this property under normal circumstances. However, brass-plated steel or contaminated brass alloys may appear ferromagnetic because of the underlying or embedded ferromagnetic material.

Three types of magnetism:

| Type of Magnetism |

Electron Structure |

Magnetic Behavior |

Retains Magnetism After Field Removal? |

Examples |

Brass Classification |

| Diamagnetism |

All electrons paired | Slightly repels magnetic fields | No | Copper, Zinc, Bismuth | Pure brass is generally diamagnetic |

| Paramagnetism |

Some unpaired electrons | Weakly attracted to magnetic fields | No | Aluminum, Platinum, Magnesium | Brass with impurities or after cold working may show weak paramagnetism |

| Ferromagnetism |

Many unpaired electrons aligned in domains | Strongly attracted to magnetic fields | Yes | Iron, Nickel, Cobalt | Brass is never ferromagnetic, but brass-plated steel is |

Brass generally falls into the diamagnetic category because its main components — copper and zinc — both have all electrons paired in their atomic orbitals. This means they do not generate a permanent magnetic field and, in fact, slightly repel external magnetic fields. For most CNC machining applications, this property ensures that brass CNC machined parts remain magnetically neutral, making them ideal for use in sensitive environments such as medical devices, navigation equipment, and electronic enclosures.

However, brass can occasionally show weak paramagnetism under specific conditions. This typically happens when the alloy contains trace amounts of ferromagnetic impurities like iron or nickel. Even small amounts of these metals can introduce unpaired electrons, which align with an applied magnetic field and create a faint attraction. While the effect is temporary and disappears once the field is removed, it can still interfere with high-precision instruments.

From a CNC machining services perspective, understanding whether brass is purely diamagnetic or has slight paramagnetic tendencies is crucial in industries where electromagnetic interference must be avoided. The choice of brass grade, alloy purity, and manufacturing process — including whether the brass has undergone cold working — can influence its final magnetic properties.

While brass is generally classified as a non-magnetic alloy, several factors can subtly influence its magnetic behavior. These influences are important for engineers, designers, and procurement teams in industries where magnetic neutrality is crucial — such as aerospace, marine navigation, medical devices, and precision electronics. Even minor changes in composition or processing can shift brass from being purely diamagnetic to weakly paramagnetic. For CNC machining services, understanding these factors helps ensure that brass CNC machined parts meet performance expectations without costly post-production rework.

Composition

Brass’s magnetism depends heavily on its alloy composition. Since pure copper and zinc are diamagnetic, brass made from high-purity versions of these metals will also be diamagnetic. However, different grades of brass contain varying amounts of additional elements, such as lead (for machinability) or tin (for corrosion resistance). These extra elements typically do not cause magnetism, but if ferromagnetic metals like iron or nickel are added — even in trace amounts — they can introduce weak magnetic behavior.

Presence of Impurities

Unintentional impurities often come from recycled feedstock or contamination during the alloying process. Ferromagnetic elements such as iron, cobalt, or nickel are the most likely to affect magnetism. Even if these impurities are present in tiny percentages, they can be enough to create a measurable magnetic response. This is especially important in industries where components must pass stringent electromagnetic compatibility (EMC) testing.

Mechanical Deformation

Physical deformation, such as bending, rolling, or hammering, can change the internal structure of brass. This may slightly increase its magnetic susceptibility, especially if the material already contains trace ferromagnetic impurities. Although the change is usually negligible in everyday products, it can matter in high-sensitivity applications.

Processing and Heat Treatment

Processing methods such as annealing or stress relief can influence brass’s magnetic behavior. Heat treatment can relax internal stresses and restore the random atomic arrangement, reducing any induced magnetism caused by prior mechanical work. On the other hand, improper heat treatment may concentrate impurities and slightly enhance magnetic response.

Cold Working

Cold working — machining, rolling, or shaping brass at room temperature — increases dislocation density in the crystal lattice. This can alter how the material interacts with magnetic fields, especially if impurities are present. The effect is typically small but can be measured in sensitive applications.

Temperature

Temperature changes can temporarily influence magnetic susceptibility. Brass may show slightly different behavior at very low or very high temperatures, although the changes are minimal compared to ferromagnetic materials. In extreme environments, however, this effect may still be relevant.

Internal Crystal Structure

The atomic arrangement in brass depends on its composition and processing history. Any distortion or alteration in the crystal structure — due to mechanical stress, impurities, or temperature — can subtly affect magnetic properties. Maintaining a uniform crystal structure through careful manufacturing helps ensure consistent non-magnetic behavior.

Magnetic Field Strength

While brass is non-magnetic under normal conditions, exposure to a very strong magnetic field can induce a temporary magnetic moment. The effect disappears once the field is removed, but it can be problematic for extremely sensitive applications.

summarizing the important factors affecting brass magnetism:

| Factor |

How It Affects Magnetism |

CNC Machining Tip |

| Composition |

Pure copper and zinc are diamagnetic; adding ferromagnetic metals like iron or nickel can introduce weak magnetism. | Specify high-purity brass grades with certified composition. |

| Presence of Impurities |

Contamination from recycled feedstock or alloying may add ferromagnetic elements. | Use virgin brass stock from reputable CNC machining factories. |

| Mechanical Deformation |

Bending, rolling, or hammering can slightly increase magnetic susceptibility. | Plan post-processing to restore optimal non-magnetic performance. |

| Processing and Heat Treatment |

Proper annealing relieves stresses and reduces induced magnetism; poor treatment can increase it. | Discuss heat treatment protocols with your CNC machining service provider. |

| Cold Working |

Increases dislocation density in the crystal lattice, slightly affecting magnetic response. | Use controlled machining or apply stress-relief annealing afterward. |

| Temperature |

Extreme temperatures can cause small changes in magnetic behavior. | Test parts under actual operating temperature conditions. |

| Internal Crystal Structure |

Alterations in crystal arrangement affect magnetic interaction. | Maintain consistent processing for stable performance across batches. |

| Magnetic Field Strength |

Strong fields can induce temporary magnetism. | Avoid storing parts near powerful magnets in sensitive applications. |

Accurately determining the magnetic properties of brass is essential for industries where magnetic neutrality is critical — such as aerospace, defense, medical devices, and precision electronics. While brass is generally considered non-magnetic, impurities, cold working, or plating over ferromagnetic metals can alter its magnetic response. In CNC machining services, verifying the magnetism of brass CNC machined parts helps prevent costly project delays caused by failed compliance tests. Testing methods range from simple visual inspections to highly sophisticated laboratory measurements, each suited for different accuracy requirements.

Testing Brass and Its Magnetic Properties

There is no single “best” method to test brass magnetism; the right choice depends on the precision needed, the budget, and the application. Below are the most common techniques, from basic shop-floor checks to advanced scientific analysis.

Visual Inspection

Visual inspection involves checking for signs that the part might not be pure brass — for example, areas where the surface coating has worn off, revealing a different core material (like steel). This is not a definitive magnetic test, but it can help detect brass-plated ferromagnetic metals.

Magnetic Susceptibility Measurement

This method uses instruments to measure how much a material becomes magnetized when exposed to a magnetic field. It provides a quantitative value of magnetic response, making it more precise than simple magnet tests.

Hall Effect Sensor

A Hall effect sensor detects magnetic fields by measuring voltage changes across a conductor. By placing a sensor near the brass part, you can determine whether it produces or alters a magnetic field.

Vibrating Sample Magnetometer (VSM)

VSM testing involves vibrating a sample in a magnetic field and measuring the induced voltage in nearby detection coils. This is a laboratory-grade method capable of mapping detailed magnetic properties across the sample’s volume.

SQUID Magnetometer

The Superconducting Quantum Interference Device (SQUID) magnetometer is one of the most sensitive magnetic measurement tools available. It can detect extremely weak magnetic fields, making it indispensable for scientific research or ultra-sensitive component manufacturing.

Eddy Current Testing

Eddy current testing uses electromagnetic induction to detect differences in conductivity and magnetic permeability. It is widely used for non-destructive testing in CNC machining factories to verify alloy composition and detect defects without damaging the part.

Hysteresis Measurement

This method measures how a material’s magnetization changes as the magnetic field is cycled. Since pure brass shows almost no hysteresis, any detected loop suggests impurities or contamination.

X-ray Magnetic Circular Dichroism (XMCD)

XMCD is a synchrotron-based technique that uses polarized X-rays to investigate magnetic properties at the atomic level. It provides unmatched detail but is reserved for advanced research and is not practical for regular manufacturing inspections.

summarizing brass magnetism testing methods:

| Testing Method |

Accuracy |

Cost |

Best Use Case |

CNC Machining Tip |

| Visual Inspection |

Low | Very Low | Quick check for brass-plated steel or surface wear | Always follow with a magnet or instrument test for confirmation |

| Magnetic Susceptibility Measurement |

Medium-High | Medium | Quantitative evaluation of weak magnetism | Ideal for EMC-compliant brass CNC machined parts |

|

Hall Effect Sensor |

High | Medium | Detecting very weak magnetic fields | Useful for aerospace and defense CNC machining projects |

| Vibrating Sample Magnetometer (VSM) |

Very High | High | Detailed material property mapping | Best for R&D and alloy verification before mass production |

| SQUID Magnetometer |

Ultra High | Very High | Ultra-sensitive detection for research | Overkill for most CNC machining; used in scientific labs |

| Eddy Current Testing |

High | Medium | Non-destructive quality control | Great for large-scale inspection at CNC machining factories |

| Hysteresis Measurement |

High | High | Detecting ferromagnetic contamination | Effective for confirming alloy purity in critical parts |

| X-ray Magnetic Circular Dichroism (XMCD) |

Ultra High | Very High | Atomic-level magnetic property analysis | Reserved for material science research, not typical production |

Here’s the table for Simple Magnetic Testing of Brass:

| Step Category |

Details |

| Materials Required |

Brass Sample: A small piece, such as a rod, sheet, or fitting.

Magnet: A small, strong permanent magnet (e.g., neodymium magnet). Non-Metallic Surface: A clean piece of paper, a wooden table, or plastic surface to avoid interference from other metals. |

| Preparing the Brass Sample |

Ensure the brass piece is clean, free of dust, oil, or coatings that might interfere with testing. Wipe with a dry cloth. |

| Preparing the Magnet |

Use a magnet strong enough to detect very weak attraction if present. Avoid touching it to steel objects before the test to prevent contamination. |

| Attraction Test |

1. Place the brass sample on the non-metallic surface. 2. Slowly bring the magnet close to the brass without touching at first. 3. Observe if the brass moves or is drawn toward the magnet. 4. If no movement is detected, lightly touch the magnet to the brass and feel for any pull. |

| Interpreting the Results |

No Attraction: The brass is likely pure and non-magnetic. Weak Attraction: Could indicate trace magnetic impurities or contamination. Strong Attraction: Suggests the brass contains a significant amount of ferromagnetic material (or it is brass-plated steel). |

simple magnetic testing and advanced laboratory testing for brass:

| Test Type |

Method |

Equipment Needed |

Procedure |

Interpretation |

| Simple Magnetic Test |

Attraction Observation | Small strong magnet (e.g., neodymium), brass sample, non-metallic surface |

1. Place brass on a clean non-metallic surface. 2. Bring magnet close without touching. 3. Observe if brass moves. 4. Lightly touch magnet to brass if no movement is seen. |

No Attraction: Likely pure, non-magnetic brass. Weak Attraction: Possible magnetic impurities. Strong Attraction: Brass-plated steel or high ferromagnetic content. |

| Advanced Magnetic Susceptibility Test |

Magnetic Susceptibility Measurement | Laboratory magnetometer or Gaussmeter |

1. Place brass sample in device chamber. 2. Measure magnetic field response under controlled conditions. 3. Compare to baseline for pure brass. |

Near-zero reading: Confirms non-magnetic. Small reading: Minor paramagnetic impurities. Large reading: Alloy contains ferromagnetic elements. |

| Eddy Current Testing |

Non-destructive alloy verification | Eddy current tester, probe, reference brass sample |

1. Calibrate tester with known brass sample. 2. Pass probe over test sample. 3. Record and compare conductivity and response. |

Matches reference brass: Non-magnetic and correct composition. Different reading: Alloy variation or contamination. |

| X-ray Fluorescence (XRF) Analysis |

Composition Analysis | Portable XRF analyzer |

1. Aim device at brass sample. 2. Trigger scan to detect elemental composition. 3. Review for iron or other magnetic metals. |

No iron detected: True non-magnetic brass. Iron detected: Source of magnetic response. |

Brass, in its pure form, cannot be magnetized because it is not a ferromagnetic material. It is an alloy primarily made of copper and zinc, both of which are diamagnetic metals—meaning they naturally repel magnetic fields rather than attract them. As a result, a strong magnet will generally not stick to brass.

However, there are a few scenarios where brass may show weak or apparent magnetism:

In summary, pure brass cannot be permanently magnetized, but contamination, special processing, or a different core material can make it appear magnetic.

Non-magnetic brass is valued in industries where magnetic interference must be avoided and where corrosion resistance, machinability, and aesthetic appeal are equally important. Its unique combination of non-magnetic properties, electrical conductivity, and durability makes it a preferred choice for specialized engineering and design applications.

Electrical and Electronic Components

Because brass is non-magnetic and an excellent conductor of electricity, it is widely used in connectors, terminals, and switch components. In sensitive electronics, avoiding magnetic interference is crucial for maintaining signal clarity and preventing electromagnetic distortion. Brass components are also favored for their ability to be precision-machined into complex shapes without losing strength.

Marine and Nautical

Brass resists corrosion from saltwater, making it a staple material for ship fittings, navigational instruments, and underwater hardware. Its non-magnetic nature ensures it doesn’t interfere with navigational compasses, an essential safety factor for marine applications. For CNC machining factories, this property makes brass a reliable choice for producing custom marine-grade parts.

Aerospace Industry

In aerospace engineering, even small amounts of magnetic interference can disrupt navigational and communication systems. Non-magnetic brass is used in instrument housings, connectors, and precision fittings that require both strength and electromagnetic neutrality. Additionally, its lightweight properties make it an excellent alternative to ferromagnetic metals.

Medical environments demand materials that are safe for use near sensitive imaging equipment like MRI machines. Brass’s non-magnetic properties allow it to be used for surgical tools, diagnostic device components, and implant accessories without affecting magnetic imaging or causing safety hazards. CNC machining services often produce custom brass parts for this sector.

Brass Instruments

Musical instruments like trumpets, trombones, and saxophones take advantage of brass’s acoustic qualities, corrosion resistance, and ease of shaping. While the non-magnetic property isn’t critical in this application, it contributes to the instrument’s long-term durability and performance without risk of magnetic interference.

Here’s your table for Applications and Practical Uses of Non-Magnetic Brass:

| Application Area |

Why Brass Is Used |

Examples |

| Electrical and Electronic Components |

Non-magnetic, excellent electrical conductivity, corrosion-resistant | Connectors, terminals, switches, electrical contacts |

| Marine and Nautical |

Resistant to saltwater corrosion, non-magnetic for navigation safety | Ship propellers, marine fittings, compass housings |

| Aerospace Industry |

Lightweight, corrosion-resistant, non-magnetic to avoid interference with avionics | Aircraft instrumentation housings, fasteners |

| Medical Devices |

Non-magnetic to avoid MRI interference, corrosion-resistant, biocompatible | Surgical tools, MRI-safe equipment parts |

| Brass Instruments |

Acoustic properties, durability, and corrosion resistance | Trumpets, trombones, tubas, saxophones |

Besides brass, several other metals are naturally non-magnetic due to their atomic structure and electron arrangement, meaning they do not attract magnets or retain magnetic fields.

Aluminum is one of the most widely used non-magnetic metals. Known for its lightweight properties and resistance to corrosion, it is extensively applied in aerospace, automotive, construction, and packaging industries. Its non-magnetic nature also makes it suitable for applications where magnetic interference must be avoided.

Copper is another non-magnetic metal, widely recognized for its excellent electrical and thermal conductivity. It is commonly used in electrical wiring, plumbing, and electronics manufacturing. Its lack of magnetism ensures stable performance in sensitive electronic systems.

Silver is also non-magnetic and is highly valued for its conductivity and reflectivity. It is used in jewelry, electronics, and high-quality mirrors. Similarly, gold is non-magnetic and is prized in jewelry, aerospace technology, and high-end electronics for its resistance to corrosion and oxidation.

Lead is non-magnetic and is most often used in radiation shielding, batteries, and as ballast weights in various industries. Tin, also non-magnetic, is commonly used for coating steel to prevent corrosion and in soldering materials for electronics.

Zinc remains non-magnetic and is primarily applied in galvanizing steel to improve corrosion resistance, as well as in the production of batteries and die-cast components. Platinum, although weakly magnetic in some rare forms, is generally considered non-magnetic and is valued for jewelry, catalytic converters, and laboratory equipment.

Titanium is a strong, lightweight, and non-magnetic metal, making it ideal for aerospace parts, medical implants, and marine hardware where magnetic fields could cause operational issues. Lastly, austenitic stainless steel is typically non-magnetic due to its face-centered cubic (FCC) crystal structure, making it a preferred material for food processing equipment, surgical tools, and decorative applications.

Here’s a clean table for Common Non-Magnetic Metals Besides Brass:

| Metal |

Magnetic Property |

Key Reasons for Being Non-Magnetic |

Common Uses |

| Aluminum |

Non-magnetic | Atomic structure lacks unpaired electrons | Aircraft parts, automotive components, packaging |

| Copper |

Non-magnetic | Diamagnetic nature resists magnetic fields | Electrical wiring, plumbing, electronics |

| Silver |

Non-magnetic | Diamagnetic, highly conductive | Jewelry, electronics, mirrors |

| Gold |

Non-magnetic | Atomic structure prevents magnetism | Jewelry, electronics, aerospace |

| Lead |

Non-magnetic | Diamagnetic, dense structure | Radiation shielding, weights |

| Tin |

Non-magnetic | Diamagnetic, low unpaired electrons | Coating for steel, solder |

| Zinc |

Non-magnetic | Diamagnetic, stable electron configuration | Galvanizing steel, batteries |

| Platinum |

Non-magnetic (weakly magnetic in some forms) | Stable electron configuration | Jewelry, catalysts |

| Titanium |

Non-magnetic | Low magnetic susceptibility | Aerospace, medical implants |

| Austenitic Stainless Steel |

Generally non-magnetic | FCC crystal structure reduces magnetism | Food processing equipment, medical tools |

At VMT, we specialize in providing high-precision brass CNC machining parts tailored to meet the stringent demands of various industries. Our expertise lies in combining advanced CNC machining services with in-depth material knowledge to deliver brass components that exhibit excellent dimensional accuracy, surface finish, and reliable non-magnetic performance.

Brass is widely appreciated for its machinability, corrosion resistance, and natural non-magnetic properties. These qualities make it an ideal choice for manufacturing CNC machined parts used in electrical connectors, marine hardware, aerospace fittings, medical devices, and musical instruments. At VMT, we ensure that the brass alloys selected for your projects meet the required purity standards, minimizing magnetic impurities that could impact performance.

Our state-of-the-art CNC machining factories employ the latest equipment and quality control systems to produce complex brass components efficiently and consistently. From prototypes to large production runs, we work closely with customers to optimize designs for manufacturability and cost-effectiveness, while maintaining strict tolerances critical for high-performance applications.

Moreover, we offer additional services such as heat treatment, surface finishing, and rigorous magnetic testing to guarantee that your brass parts meet or exceed industry standards. Our commitment to quality and customer satisfaction makes VMT a trusted partner for precision brass CNC machining solutions.

Understanding whether brass is magnetic—and under what conditions it may exhibit magnetic behavior—is crucial for selecting the right material for your projects. Brass, by nature, is a non-magnetic alloy primarily composed of copper and zinc, making it an excellent choice for applications requiring electromagnetic neutrality. However, factors such as trace impurities, mechanical deformation, and plating over ferromagnetic materials can introduce slight magnetic responses.

For industries like aerospace, medical devices, marine, and electronics, where magnetic interference can cause serious issues, choosing high-purity brass and verifying its magnetic properties through appropriate testing is essential. Reliable CNC machining services, like those offered by VMT, ensure precision brass CNC machined parts that meet strict quality and magnetic performance standards.

By understanding brass’s magnetic characteristics and working with experienced CNC machining factories, you can minimize risks, reduce project costs, and achieve superior product performance. When in doubt, always specify your magnetic requirements upfront and request material certifications and testing results to safeguard your investment.

1. Why are door stops and door handles made of brass?

Brass is widely used for door stops and handles because of its excellent corrosion resistance, durability, and attractive appearance. Additionally, its natural non-magnetic property prevents interference with electronic security systems and ensures long-lasting functionality.

2. Why isn’t brass attracted to magnets?

Brass is primarily composed of copper and zinc, both of which are diamagnetic materials. This means they repel magnetic fields slightly and do not have unpaired electrons to generate magnetism, so brass is generally not attracted to magnets.

3. What metals are magnetic?

Common magnetic metals include iron, cobalt, nickel, and their alloys. These are ferromagnetic materials that strongly attract magnets and can be permanently magnetized.

4. What’s the difference between brass and bronze?

Brass is an alloy of copper and zinc, whereas bronze is primarily an alloy of copper and tin. Bronze tends to be harder and more corrosion-resistant than brass but is typically less machinable. Both have different colors and mechanical properties suited for various applications.

5. Is brass or bronze magnetic?

Neither brass nor bronze is inherently magnetic. Both alloys are generally non-magnetic due to their copper base, though trace impurities or plating over magnetic metals can cause slight magnetism.

Brass does not rust because it contains no iron, the metal that oxidizes to form rust. However, brass can tarnish or develop a patina over time when exposed to moisture and air.

7. How do you know if it’s brass?

Brass typically has a distinctive yellowish-gold color and a slightly heavier weight than other common metals. Simple tests include a magnet test (brass is non-magnetic) and chemical tests for copper content. Professional testing can confirm composition accurately.

8. Is brass better than stainless steel?

Brass and stainless steel serve different purposes. Brass offers better machinability and electrical conductivity with natural antimicrobial properties, while stainless steel is stronger, more corrosion-resistant in harsh environments, and magnetic depending on the grade. The choice depends on specific application needs.

Like brass, bronze is generally non-magnetic due to its copper and tin composition. However, bronze alloys containing ferromagnetic metals or plated on magnetic materials may show weak magnetism.

10. How long does brass last?

With proper care, brass components can last for decades. Its excellent corrosion resistance and durability make it suitable for long-term use in many environments, including outdoor and marine applications.

11. Is brass fireproof?

Brass has a high melting point (around 900–940°C) and does not burn, but it can melt or deform under extreme heat. It is not considered fireproof but can withstand moderate fire exposure better than many plastics or composites.

12. What metals never rust?

Metals that do not contain iron, such as aluminum, copper, brass, bronze, and stainless steel (due to chromium content), do not rust. Instead, they may oxidize or tarnish but resist the reddish-brown rust common to iron and steel.

13. Do magnets attract brass?

In general, magnets do not attract pure brass because it is non-magnetic. However, brass alloys with ferromagnetic impurities or brass-plated steel parts may be attracted to magnets.