15 years one-stop China custom CNC machining parts factory

666 |

Published by VMT at Jan 20 2025 | Reading Time:About 3 minutes

666 |

Published by VMT at Jan 20 2025 | Reading Time:About 3 minutes

Imagine spending countless hours and resources on a custom CNC machining project, only to discover that the chosen material doesn’t meet your needs. Maybe it corroded faster than expected, turned out heavier than you wanted, or didn’t have the desired durability.

It’s frustrating to realize that the metal you picked—whether brass or steel—wasn’t right for your product. You may have to start over, face delays, or even lose customers. You might feel overwhelmed by all the technical details about chemical compositions and mechanical properties, and you’re worried about wasting even more time and money on trial and error.

In this article, we will break down both brass and steel in simple, clear language. We’ll look at their types, properties, common applications, pros and cons, and everything else you need to know. By the end, you’ll be able to pick the perfect metal for your CNC machining parts with total confidence.

When deciding between brass and steel for CNC machining projects, focus on key factors like corrosion resistance, strength, machinability, weight, and cost. Brass is known for its excellent corrosion resistance, lower melting point, and attractive appearance, making it ideal for decorative and low-friction applications. Steel, on the other hand, provides higher tensile strength, increased durability, and strong structural integrity. If you need parts that can withstand heavy loads and harsh conditions, steel might be your best bet. However, if you desire easier machining, better electrical conductivity, or a stylish finish, brass could be the metal for you. Evaluating your project’s specific requirements will help you decide if brass or steel is the right choice.

Now that we’ve highlighted the main differences in a quick snippet, let’s dive deeper. We’ll walk through a comprehensive comparison of brass vs. steel, covering everything from their basic definitions to their respective prices and finishes. This will help you gain a thorough understanding of both metals before you commit to one for your custom CNC machining project.

What Is Brass?

Brass is a metal alloy primarily made of copper and zinc. Depending on the desired properties, certain amounts of other metals might be added too. Brass stands out for its golden color, which is why it’s often used for decorative items like musical instruments, doorknobs, and jewelry. It also offers good corrosion resistance and can conduct electricity relatively well. Thanks to its fairly low melting point and malleability, brass is often considered easy to work with in CNC machining services. This is one reason brass CNC machining parts remain popular in many industries.

What Is Steel?

Steel is an alloy mostly composed of iron and a small percentage of carbon. Additional elements such as chromium, nickel, or manganese may be included to enhance certain properties. Steel is known for its high tensile strength, which makes it suitable for load-bearing structures and mechanical components. It’s also incredibly versatile, with a wide range of types like stainless steel, mild steel, and alloy steel. Given its durability and overall strength, steel CNC machining parts are a go-to solution for countless applications, from automotive components to construction materials.

Both brass and steel come in a variety of types, each tailored to specific purposes. When choosing the right type for a CNC machining project, it’s essential to understand the differences. Factors like strength, corrosion resistance, machinability, and appearance can vary greatly among the different grades of brass and steel. Below, we’ll outline these types so you can make an informed choice for your CNC prototype machining or large-scale production order.

Types of Brass

Types of Steel

To choose between brass and steel, you need to look at their inherent properties. From chemical composition to physical and mechanical attributes, understanding these differences is crucial. In this section, we’ll discuss several key factors such as elemental makeup, conductivity, weight, and corrosion resistance. By comparing these properties, you’ll have a clearer picture of which metal fits your project’s requirements in a CNC machining factory.

Brass vs. Steel: Chemical Composition

Brass is mainly copper and zinc. The ratio of these two metals can change drastically, affecting everything from color to strength. Small additions of elements like lead, tin, or aluminum can tweak its machinability or corrosion resistance. Steel, on the other hand, is primarily iron with carbon. Adding or reducing carbon content influences the steel’s hardness and ductility. Other elements like chromium or nickel further enhance qualities like corrosion resistance or heat tolerance.

Brass vs. Steel: Elemental Composition

Brass vs. Steel: Physical Properties

Brass vs. Steel: Mechanical Properties

Brass vs. Steel: Electrical and Thermal Conductivity

Brass vs. Steel: Weight

While both are considered relatively heavy metals, steel usually has a slightly lower density compared to many brass alloys. However, the difference may not be significant enough to sway a decision unless weight is critical. In that case, carefully checking each alloy’s density is essential.

Brass vs. Steel: Corrosion Resistance

Brass naturally resists corrosion better than most steels, especially if we’re talking about mild or carbon steels. That’s why brass is often used in environments where moisture or chemicals are a concern, like marine settings or plumbing fixtures. Stainless steel is also corrosion-resistant, thanks to its chromium content, making it another good choice for wet or corrosive environments.

Brass vs. Steel: Hardness

Steel can be extremely hard, especially if it’s a specialized alloy or tool steel. Brass is relatively softer, but certain brass alloys can still be quite robust. For parts that demand high surface hardness or wear resistance, steel might be a better choice.

Brass vs. Steel: Durability

Steel is often prized for its ruggedness and durability, particularly in industrial or structural applications. Brass holds up well in less demanding conditions and maintains good durability for decorative pieces, fittings, and certain mechanical parts, but it’s not typically used for heavy construction or major structural components.

Brass vs. Steel: Tensile Yield Strength

Steel outperforms brass in tensile yield strength in most cases. This makes steel a superior option for load-bearing or high-impact tasks. Brass has a lower yield strength, which might be sufficient for moderate-duty parts but won’t match steel’s sheer toughness.

Brass vs. Steel: Price and Cost

Brass often contains a substantial amount of copper, which can be pricey. Steel, depending on the grade, might be less expensive on a per-pound basis. However, factors like machinability can influence the overall production cost. For instance, brass might be quicker to machine, potentially reducing labor time at a CNC machining factory.

Brass vs. Steel: Machinability

Brass, especially leaded brass, is known for being very machinable. This means it can often be cut, drilled, or turned faster and with less tool wear. Steel, while still highly machinable, can vary in difficulty depending on the alloy. Some steels require careful tool selection or specific cutting speeds to avoid damaging the part or equipment. For custom CNC machining projects, the ease of machining brass might result in lower overall costs, whereas certain steels might demand specialized tooling.

Applications of Brass

Applications of Steel

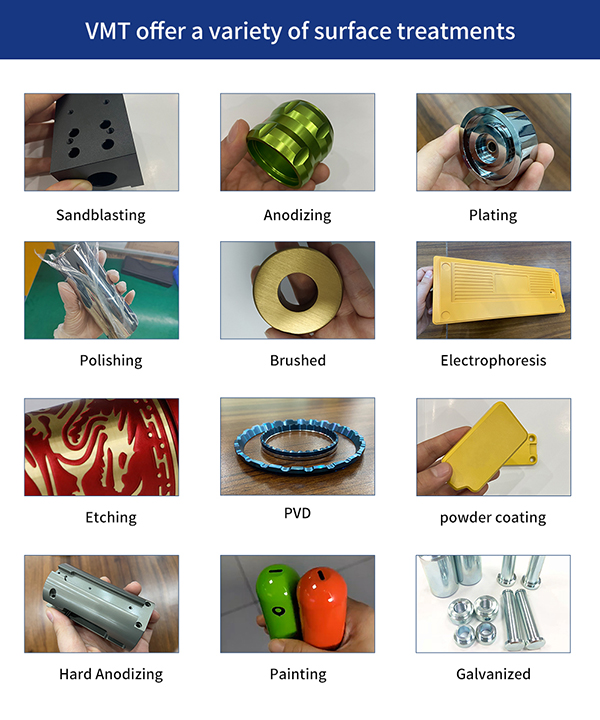

Surface finishes can greatly affect both the look and functionality of machined parts. They can improve corrosion resistance, reduce friction, or simply make a product more visually appealing. Different finishing processes work better on brass than on steel and vice versa. Below, we’ll discuss which finishes are commonly applied to brass CNC machining parts and steel CNC machining parts.

What Surface Finishes Can Be Done on Brass Parts?

What Surface Finishes Can Be Done on Steel Parts?

Pros of Brass

Pros of Steel

Cons of Brass

Cons of Steel

When choosing between brass and steel for CNC machining parts, there isn’t a one-size-fits-all answer. It depends on multiple factors, like cost, intended application, machinability, processing waste, and design preferences.

Cost

If you’re on a tight budget and need high-volume production, steel might be more cost-effective—especially mild steel. But if your part’s performance depends heavily on corrosion resistance and machinability, brass may prove cheaper in the long run due to reduced machining times and less rework.

Application

For decorative, electronic, or low-friction components, brass is often the go-to metal. For robust machinery, structural parts, or automotive applications, steel stands out for its strength and durability.

Machinability

Brass outperforms steel in machinability, meaning you can produce complex shapes quicker and with fewer tool changes. However, if you choose a free-machining steel alloy, the gap might narrow, making steel a viable choice for CNC prototype machining.

Processing Waste

In brass CNC machining, chips produced are often more manageable, and the material is easier to recycle. Steel chips can also be recycled, but steel machining might generate more tool wear and potentially more wasted energy and cutting fluids.

Aesthetic Requirements

If appearance matters—like in high-end fittings, decorative hardware, or musical instruments—brass’s natural shine is hard to beat. Steel, particularly stainless steel, can also look impressive, but it generally offers a modern, industrial vibe rather than the warm look of brass.

At VMT, we specialize in both brass CNC machining parts and steel CNC machining parts, providing customers with top-tier custom CNC machining solutions. Whether you’re prototyping a new design or need high-volume production, our CNC machining factory is equipped to handle a wide range of materials and part complexities. From selecting the right alloy to applying the perfect surface finish, our team ensures each part meets rigorous standards for quality and performance. With years of experience in CNC prototype machining and CNC machining services, we pride ourselves on delivering reliable, precise, and efficient manufacturing capabilities for clients in various industries.

Deciding between brass and steel hinges on your project’s functional demands, desired look, and budget constraints. Brass wins in corrosion resistance, machinability, and visual appeal, making it excellent for decorative and electrical parts. Steel triumphs in strength, durability, and versatility, making it the top choice for structural and high-stress applications. By assessing your needs—like weight requirements, environment, machining efficiency, and final cost—you can make an informed decision. Regardless of whether you opt for brass or steel, partnering with an experienced CNC machining factory like VMT will ensure high-quality custom CNC machining that meets your exact specifications.

1. Does brass corrode faster than steel?

Brass generally resists corrosion better than standard (mild) steel. However, stainless steel can match or surpass brass’s corrosion resistance due to its chromium content.

2. Is brass stronger than mild steel?

Typically, mild steel is stronger in terms of tensile strength. Brass offers good strength for moderate applications but won’t usually outperform steel in load-bearing situations.

3. Does brass rust?

Brass does not rust the way iron-based metals do because it has no iron content. However, it can tarnish or develop a patina over time.

4. Which is heavier, brass or steel?

Brass can be slightly heavier or lighter than steel depending on the specific alloys in question. Generally, steel has a density around 7.8 g/cm³, and brass ranges around 8.4–8.7 g/cm³.

5. Is brass harder to cut than steel?

Brass is usually easier to cut because of its lower hardness and excellent machinability, especially if leaded. Many steels, particularly tool steels, can be tougher on cutting tools.

6. Why is brass so hard to cut?

Some brass grades can still be challenging if they have lower lead content or higher zinc content. But in general, brass is considered easier to cut than most steels.

7. Which is better, brass or stainless steel?

“Better” depends on your application. Stainless steel resists rust very well and is extremely strong, while brass has a softer, more decorative appearance and is easier to machine.

8. Does brass get hotter than steel?

Brass has higher thermal conductivity, so it can both heat up and cool down faster. However, in direct temperature comparisons, each metal’s actual temperature will depend on the environment and heat source.

9. Which is more durable, brass or stainless steel?

Stainless steel is typically considered more durable due to higher tensile strength and superior wear resistance.

10. Which is better, steel or brass?

There’s no universal answer. If you need high strength, steel might be better. If you need easier machining and good corrosion resistance without extreme load requirements, brass may be preferable.

11. Why is brass so cheap?

Brass isn’t always cheaper than steel; it depends on the market price of copper and zinc. Sometimes, mild steel may be cheaper overall. But in some cases, brass could be considered relatively affordable for certain decorative or precision applications.

12. Why not use brass?

You might skip brass if you need extremely high strength or if the patina it forms over time is undesirable. It can also be more expensive than mild steel in some cases.

13. Does brass rust in the rain?

Brass doesn’t rust in the traditional sense, but it can develop a greenish patina (due to copper oxidation) if exposed to moisture and certain environmental conditions over time.

14. Does brass turn green?

Yes, the green layer you might see on brass is called patina, mainly formed by the copper content reacting with oxygen or other substances.

15. Can brass be used with gasoline?

Brass can be used in fuel systems because it generally resists corrosion. However, verify with specific industry standards to ensure safety, as different gasoline blends may react differently.

By understanding the properties, advantages, and drawbacks of both brass and steel, you can make the optimal choice for your next project. Whether you need brass CNC machining parts or steel CNC machining parts, collaborating with a seasoned CNC machining services provider like VMT can ensure that your components meet top-quality standards. Feel free to reach out to discuss your custom CNC machining requirements, and let us help you craft the perfect metal solutions!