15 years one-stop China custom CNC machining parts factory

546 |

Published by VMT at Sep 08 2024

546 |

Published by VMT at Sep 08 2024

In the world of CNC machining and manufacturing, choosing the right material is crucial for the success of a project. Delrin and Nylon are two of the most popular engineering plastics used in a wide range of applications, from automotive components to consumer products. Each material offers unique properties, advantages, and limitations that make them suitable for specific applications. This article provides a detailed comparison of Delrin and Nylon, exploring their material properties, processability, and common applications. By understanding the differences between these two polymers, manufacturers can make informed decisions for their precision CNC machining projects.

Delrin (polyoxymethylene or POM) and Nylon (polyamide) are both high-performance thermoplastics known for their strength, durability, and machinability. However, they differ significantly in terms of abrasion resistance, friction, tensile strength, processability, 3D printing capabilities, temperature tolerance, and moisture resistance. Understanding these differences is key to selecting the right material for specific applications.

Abrasion Resistance of Each Process

When it comes to abrasion resistance, Nylon typically outperforms Delrin. Nylon’s inherent toughness and resilience make it more resistant to wear and tear in applications where the material is subjected to constant friction or impact. This makes Nylon ideal for parts like gears, bearings, and other components that are regularly exposed to abrasive environments. Delrin, while still fairly resistant to abrasion, is more susceptible to wear over time in such conditions, making it less suitable for high-abrasion applications.

Friction of Each Technology

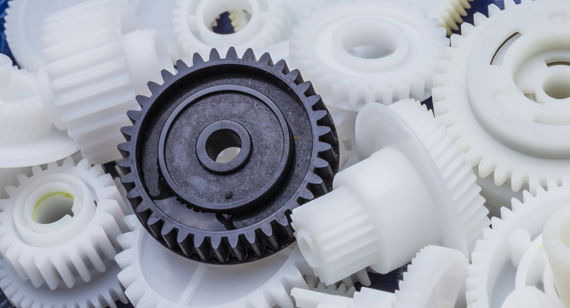

Delrin is known for its low coefficient of friction, which is one of its standout features. This property allows Delrin to operate smoothly in applications where reduced friction is critical, such as in bearings, sliding mechanisms, and gears. Nylon also has a relatively low coefficient of friction, but not as low as Delrin. However, Nylon’s toughness compensates for this, making it a good choice for applications that require both low friction and high wear resistance.

Tensile Strength of Each Technology

Tensile strength is a crucial factor in determining the load-bearing capacity of a material. Nylon generally has a higher tensile strength compared to Delrin, making it more suitable for applications that require the material to withstand high stresses without breaking. This makes Nylon a preferred choice for structural components and heavy-duty industrial applications. Delrin, while strong, has slightly lower tensile strength, making it more suitable for applications where moderate strength and high machinability are prioritized.

Processability of Each Technology

Both Delrin and Nylon are known for their excellent machinability, but they differ slightly in how they respond to various machining processes. Delrin is easier to machine, offering superior surface finish and dimensional stability. It is less prone to warping and does not absorb moisture, which makes it ideal for precision CNC machining parts. Nylon, on the other hand, can be more challenging to machine due to its tendency to absorb moisture, which can lead to dimensional changes during the machining process. However, with the right techniques and considerations, Nylon can still be effectively machined for custom CNC machining projects.

3D Printing Capability of Each Technology

In the realm of 3D printing, Nylon has a clear advantage over Delrin. Nylon’s flexibility, strength, and durability make it a popular choice for 3D printing, especially for parts that require high mechanical performance. Nylon is widely used in the production of functional prototypes, jigs, fixtures, and end-use parts. Delrin, however, is not commonly used in 3D printing due to its higher melting point and the difficulty in achieving consistent results. When precision CNC machining is not feasible or too costly, Nylon’s compatibility with 3D printing offers an excellent alternative for rapid prototyping and low-volume production.

Temperature Tolerance of Each Technology

Temperature tolerance is a critical factor for materials used in high-heat environments. Nylon generally has a higher melting point compared to Delrin, making it more suitable for applications exposed to elevated temperatures. Nylon’s high-temperature stability makes it a preferred choice for under-the-hood automotive parts, cookware, and other applications where the material must withstand consistent exposure to heat. Delrin, while also capable of withstanding moderate temperatures, is better suited for applications where the material will not be exposed to extreme heat.

Moisture Resistance of Each Technology

Moisture resistance is another key differentiator between Delrin and Nylon. Delrin has very low moisture absorption, which makes it ideal for applications where dimensional stability is critical, such as in precision CNC machining parts. Delrin’s resistance to moisture also ensures that it retains its mechanical properties in humid environments. Nylon, in contrast, tends to absorb moisture, which can lead to dimensional changes and a decrease in mechanical strength. This makes Nylon less suitable for applications where the material will be exposed to moisture, unless it is specifically treated to reduce moisture absorption.

| Material Properties |

Delrin |

Nylon |

| Wear Resistance |

Good |

Excellent |

| Friction |

Low friction coefficient |

Low friction coefficient |

| Strength |

10,000 psi tensile strength |

12,000 psi tensile strength |

| Machinability |

Highly machinable |

Machinable |

| 3D Printing Capability |

Easy 3D printable |

Challenging |

| Temperature Tolerance |

Good temperature tolerance |

Better temperature tolerance |

| Moisture Resistance |

Higher moisture resistance |

High moisture resistance |

Delrin, also known as polyoxymethylene (POM), is an engineering thermoplastic used in precision parts requiring high stiffness, low friction, and excellent dimensional stability. Developed by DuPont, Delrin is a popular material in the CNC machining industry due to its machinability and ability to maintain tight tolerances. It is commonly used in applications such as gears, bearings, bushings, and structural components. Delrin’s low moisture absorption and resistance to a wide range of chemicals make it ideal for use in environments where moisture and chemicals are present.

Nylon, or polyamide, is a versatile engineering plastic known for its high strength, toughness, and durability. It is one of the most widely used polymers in the world, finding applications in industries ranging from automotive to consumer goods. Nylon’s ability to withstand high temperatures, its good chemical resistance, and its wear resistance make it suitable for a wide range of applications. In CNC machining, Nylon is often used for producing components that require both strength and flexibility, such as gears, bushings, and fasteners. Despite its tendency to absorb moisture, Nylon’s overall performance makes it a valuable material for various industrial applications.

Delrin is available in various grades, each offering specific properties tailored to different applications. Here are some common Delrin grades used in rapid prototyping and CNC machining:

Acetal 150: This is a general-purpose grade of Delrin, known for its excellent machinability, high strength, and good wear resistance. Acetal 150 is widely used in applications where a combination of low friction and high stiffness is required.

Acetal AF 100: Acetal AF 100 is a self-lubricating grade of Delrin that incorporates PTFE fibers for enhanced wear resistance and reduced friction. This grade is ideal for high-wear applications such as gears, bushings, and sliding components.

30% Glass Filled Delrin: This grade of Delrin is reinforced with 30% glass fibers, providing increased strength, stiffness, and dimensional stability. It is commonly used in structural applications where high mechanical performance is required.

Acetal AF DE588: Acetal AF DE588 is another self-lubricating grade of Delrin, offering excellent wear resistance and low friction. This grade is specifically designed for applications that require long-lasting performance under high-load conditions.

Nylon is also available in several grades, each with unique properties that make them suitable for different applications:

Nylon 6: Nylon 6 is a general-purpose grade known for its toughness, strength, and excellent wear resistance. It is widely used in the production of gears, bearings, and structural components that require high impact resistance.

Nylon 6,6: Nylon 6,6 is a higher-performing grade compared to Nylon 6, offering greater strength, stiffness, and temperature resistance. This makes it suitable for more demanding applications such as automotive components and high-performance industrial parts.

Nylon 12: Nylon 12 is known for its flexibility, low moisture absorption, and chemical resistance. It is often used in applications that require a combination of toughness and resistance to harsh environmental conditions, such as in tubing, fuel lines, and flexible hoses.

Both Delrin and Nylon have distinct properties that make them suitable for specific applications. Understanding these properties helps in selecting the right material for precision CNC machining parts.

Delrin Properties

Delrin offers several key properties that make it a popular choice in CNC machining:

Excellent Dimensional Stability: Delrin maintains its shape and dimensions even in environments with fluctuating temperatures and moisture levels. This makes it ideal for precision applications where tight tolerances are required.

Good Processability: Delrin is easy to machine, allowing for the production of intricate and precise parts with smooth finishes. Its good processability reduces machining time and costs.

High Fatigue Resistance: Delrin’s ability to withstand repeated stress and strain without cracking makes it suitable for applications involving cyclic loading, such as gears and springs.

Excellent Creep and Impact Resistance: Delrin resists deformation under long-term loads and can absorb impacts without breaking, making it ideal for structural components and high-stress applications.

Increased Strength and Stiffness: Delrin’s high mechanical strength and stiffness make it a preferred material for components that must withstand significant loads and forces.

Resistant to Organic Chemicals and Solvents: Delrin’s chemical resistance allows it to be used in environments where exposure to oils, fuels, and solvents is common.

Good Wear Resistance: Delrin’s low coefficient of friction and wear resistance make it suitable for moving parts that require smooth, long-lasting operation.

Low Moisture Absorption: Delrin absorbs very little moisture, ensuring dimensional stability and mechanical performance even in humid conditions.

Low Temperature Stability: Delrin performs well in low-temperature environments, maintaining its mechanical properties and resisting brittleness.

Nylon Properties

Nylon offers a different set of properties that make it ideal for various industrial applications:

High Melting Temperature: Nylon’s high melting point allows it to be used in applications that are exposed to elevated temperatures, such as engine components and industrial machinery.

High Tensile Strength: Nylon’s strength and toughness make it suitable for load-bearing applications where high tensile strength is required.

Low Coefficient of Friction: Like Delrin, Nylon has a low coefficient of friction, making it suitable for applications involving sliding or moving parts.

Wear Resistance: Nylon’s durability and wear resistance make it ideal for applications that involve constant friction or abrasive conditions, such as gears, bearings, and fasteners.

Chemical Resistance: Nylon is resistant to a wide range of chemicals, including oils, greases, and solvents, making it suitable for use in harsh industrial environments.

High Processability: Nylon is highly processable, making it easy to mold, extrude, and machine into complex shapes and parts.

| Material Properties |

Delrin |

Nylon |

| Friction coefficient |

Low friction coefficient |

Low friction coefficient |

| Moisture Resistance |

Higher moisture resistance |

Moderately resistant to moisture |

| Tensile Strength |

10,000 psi tensile strength |

12,000 psi tensile strength |

| Machinability |

Highly machinable |

Good Machinability |

| Wear Resistance |

Good |

Excellent |

| 3D Printing Capability |

Challenging |

Easy 3D printable |

| Temperature Tolerance |

Medium temperature tolerance |

Higher temperature tolerance |

Applications of Delrin Plastics

Delrin is widely used across various industries due to its excellent mechanical properties and machinability:

Automotive Parts: Delrin is used in the automotive industry for components such as windshield wiper and window gears, grille components, and seat belt hardware. Its low friction and wear resistance make it ideal for these applications.

Industrial Equipment: Delrin is used in industrial equipment for fan blades, bearings, gears, and agricultural equipment. Its durability and ability to withstand mechanical stress make it suitable for these demanding applications.

Medical Devices: Delrin’s biocompatibility and ease of sterilization make it a preferred material for medical delivery devices, including insulin pumps and surgical instruments.

Consumer Products: Delrin is used in various consumer products, including door system components, clips, handles, valves, and zippers. Its smooth finish and durability make it ideal for these applications.

Electrical Components: Delrin’s electrical insulation properties make it suitable for electrical components such as switches, appliance housings, cartridge platforms, and coil supports.

Applications of Nylon Plastics

Nylon is also widely used in various industries due to its strength, durability, and versatility:

Plastic Fasteners: Nylon is commonly used to manufacture plastic fasteners such as screws, nuts, and bolts due to its high tensile strength and resistance to wear.

Automotive Parts: Nylon is used in the automotive industry for components such as under-the-hood parts, fan blades, and gears. Its ability to withstand high temperatures and harsh environments makes it suitable for these applications.

Cookware: Nylon’s high temperature resistance and durability make it ideal for non-stick cookware and kitchen utensils.

Food Packaging: Nylon’s barrier properties against moisture and gases make it suitable for food packaging, ensuring the freshness and longevity of food products.

Pump Components: Nylon is used in pump components due to its chemical resistance and ability to withstand abrasive conditions.

Under the Hood: Nylon’s high-temperature stability makes it ideal for automotive applications under the hood, where it is exposed to heat and harsh conditions.

Fan Blades: Nylon is used in the manufacturing of fan blades due to its strength, light weight, and ability to withstand high temperatures.

Gears and Bearings: Nylon’s wear resistance and low friction make it ideal for gears and bearings that operate under continuous friction.

Screws: Nylon is used to manufacture screws for various applications, especially where corrosion resistance and lightweight are required.

Thin Wall Features: Nylon’s strength allows it to be used in applications with thin wall features, providing structural integrity without adding excessive weight.

Both Delrin and Nylon offer distinct advantages and disadvantages that should be considered when selecting the right material for a specific application.

Advantages of Delrin

Lightweight: Delrin is lighter than many other engineering plastics, making it ideal for applications where weight reduction is critical.

High Strength: Delrin offers excellent strength and stiffness, allowing it to be used in structural applications requiring high mechanical performance.

Machinability: Delrin is easy to machine, allowing for the production of precision CNC machining parts with tight tolerances and smooth finishes.

Low Coefficient of Friction: Delrin’s low friction makes it suitable for applications involving sliding or moving parts, reducing wear and improving efficiency.

High Stress and Strain Capability: Delrin can withstand high stress and strain without cracking, making it ideal for components subjected to cyclic loading.

Moisture Resistance: Delrin’s low moisture absorption ensures dimensional stability and maintains its mechanical properties even in humid environments.

Disadvantages of Delrin

Not Abrasion Resistant: Delrin is less resistant to abrasion compared to Nylon, making it less suitable for high-wear applications.

Low Temperature Resistance: Delrin has lower temperature resistance compared to Nylon, limiting its use in high-temperature environments.

Nylon also offers several advantages and disadvantages that should be considered:

Advantages of Nylon

Durability and Strength: Nylon is known for its high strength and durability, making it suitable for heavy-duty applications.

Strong and Durable: Nylon’s toughness allows it to withstand high mechanical loads and impact, making it ideal for structural components.

Nylon is Light: Nylon’s lightweight nature makes it suitable for applications where weight reduction is important, such as in automotive and aerospace industries.

Relatively Waterproof: Nylon has good resistance to water, making it suitable for applications where moisture exposure is a concern.

Easy to Manufacture: Nylon is easy to process and mold into complex shapes, making it a versatile material for various manufacturing processes.

3D Printing Viability: Nylon is highly suitable for 3D printing, offering excellent mechanical properties and surface finish in printed parts.

Disadvantages of Nylon

Poor Machinability: Nylon can be more challenging to machine compared to Delrin due to its tendency to absorb moisture and its high toughness.

Low Moisture Resistance: Nylon’s tendency to absorb moisture can lead to dimensional changes and reduced mechanical strength, making it less suitable for humid environments.

When choosing between Nylon and Delrin, it is important to consider the specific requirements of your project. If the application requires high strength, durability, and resistance to abrasion, Nylon may be the better choice. However, if the project demands excellent machinability, low moisture absorption, and low friction, Delrin may be more suitable. Factors such as operating temperature, environmental conditions, and the intended use of the final product should all be taken into account when selecting the right material.

Delrin and Nylon are both excellent engineering plastics with unique properties that make them suitable for a wide range of applications. By understanding the differences between these materials, manufacturers can make informed decisions that ensure the success of their precision CNC machining projects. Whether you need components with high strength and durability or parts that require low friction and excellent machinability, Delrin and Nylon offer versatile solutions to meet your specific needs.

How to Tell the Difference Between Nylon and Delrin?

Delrin is typically more rigid, has a lower coefficient of friction, and does not absorb moisture like Nylon. Nylon is more flexible, tougher, and can absorb moisture, which may cause dimensional changes.

Which Material is Stronger, Nylon or Delrin?

Nylon generally has higher tensile strength compared to Delrin, making it better suited for load-bearing applications. However, Delrin offers better rigidity and dimensional stability.

Can Nylon and Delrin be 3D Printed?

Nylon is more commonly used in 3D printing due to its flexibility, strength, and durability. Delrin is less suitable for 3D printing due to its high melting point and difficulty in achieving consistent results.

What Material is Stronger Than Nylon?

Materials like polycarbonate and PEEK are stronger than Nylon, offering higher tensile strength and better performance in extreme conditions.

Which is Stronger, Polyoxymethylene or Nylon?

Nylon generally offers higher tensile strength, while polyoxymethylene (Delrin) provides better rigidity and dimensional stability.

Which is More Durable, Nylon or Polypropylene?

Nylon is generally more durable than polypropylene, offering better mechanical properties and resistance to wear and impact.

Which is Stronger, PVC or Nylon?

Nylon is stronger than PVC, with better tensile strength and impact resistance, making it more suitable for load-bearing applications.

Which is Stronger, Polycarbonate or Nylon?

Polycarbonate is stronger than Nylon, offering higher impact resistance and toughness, making it suitable for demanding applications.

Which is Stronger, Acrylic or Nylon?

Nylon is stronger and more durable than acrylic, which is more brittle and prone to cracking under stress.

Which Plastic is More Durable?

The durability of plastic depends on the specific application and environmental conditions. Nylon, polycarbonate, and PEEK are among the most durable plastics available.

This comprehensive comparison of Delrin and Nylon provides valuable insights into their properties, advantages, and applications, helping you choose the right material for your CNC machining projects. Whether you require high strength, low friction, or excellent machinability, understanding the differences between Delrin and Nylon will ensure that you select the best material for your specific needs.