15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

575 |

Published by VMT at Jun 08 2024

575 |

Published by VMT at Jun 08 2024

Plastic CNC prototypes play a crucial role in various stages of product design, development, and production. They are essential tools for designers and engineers to validate design concepts, dimensions, and functionality. Additionally, prototypes serve as critical references for investors and stakeholders to evaluate project feasibility and market potential. By using plastic prototypes, manufacturers can identify and resolve issues before launching the final product, ensuring its success in the market.

Before developing plastic prototypes, it is essential to clarify the product’s design requirements, purpose, expected functions, cost budget, and delivery timeline. Additionally, a thorough understanding of the selected plastic materials is necessary, including their physical properties, chemical stability, and processability. These preliminary preparations will provide clear guidance for subsequent prototyping, ensuring accuracy and practicality.

Vacuum Casting

Vacuum casting is a technique that uses vacuum technology and physical molding to create plastic prototypes. Its advantages include high precision, excellent surface quality, and relatively low cost. However, vacuum casting also has some drawbacks, such as a longer production cycle, high mold material requirements, and unsuitability for large or complex structures.

Advantages: High precision, excellent surface quality, relatively low cost.

Disadvantages: Longer production cycle, high mold material requirements, unsuitable for large or complex structures.

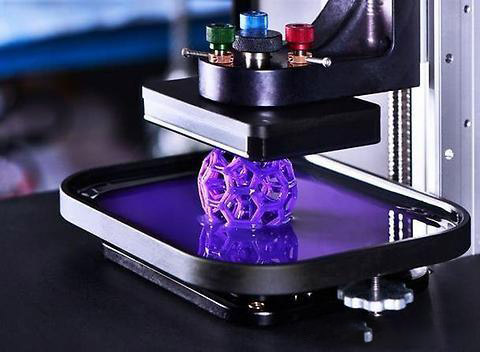

3D Printing

3D printing technology creates plastic prototypes by layering material. It offers high flexibility and customization capabilities, allowing for rapid conversion of design drawings into physical models, significantly shortening the product development cycle. Moreover, 3D printing can produce complex and varied structures, meeting diverse designer needs. However, 3D printing also has limitations, such as limited material choices, higher costs, and slower printing speeds.

Advantages: High flexibility, strong customization capabilities, ability to create complex structures.

Disadvantages: Limited material choices, higher costs, slower printing speeds.

CNC machining uses computer-controlled machinery to precisely cut and shape plastic CNC prototypes. It offers high precision, efficiency, and repeatability, making it suitable for producing prototypes with complex shapes and stringent requirements. CNC machining can also accommodate batch production. However, the investment cost for CNC machining equipment is high, and skilled operators are required.

Advantages: High precision, high efficiency, good repeatability, suitable for batch production.

Disadvantages: High equipment investment cost, requires skilled operators.

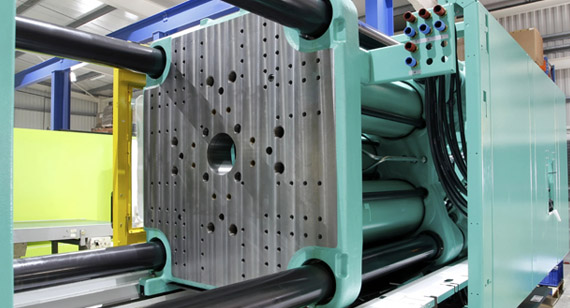

Injection Molding

Injection molding creates plastic prototypes by injecting molten plastic into molds and allowing it to cool and solidify. It is known for high production efficiency, low cost, and suitability for mass production. Injection molding can produce complex and precise prototypes and allows for a wide selection of plastic materials. However, specialized molds and equipment are required, and mold production costs are high.

Advantages: High production efficiency, low cost, suitable for mass production.

Disadvantages: Requires specialized molds and equipment, high mold production costs.

When engaging in rapid plastic prototyping, consider the following key factors:

Prototype Purpose: Choose the appropriate manufacturing method based on the prototype's purpose. For example, use 3D printing or vacuum casting for concept validation, and CNC machining or injection molding for performance testing.

Form: The shape and size of the prototype are important considerations. Complex shapes may be better suited for 3D printing or CNC machining.

Quantity and Cost: The number of prototypes and budget are critical. Injection molding is more economical for large quantities, while 3D printing or vacuum casting may be more suitable for smaller quantities.

Delivery Time: Consider the delivery timeline. Different methods have varying production cycles, so select the method based on project urgency.

Material: Choose suitable plastic materials based on the product's usage environment and requirements. Different plastics have varying physical properties, chemical stability, and processability.

The cost of plastic prototypes varies based on the manufacturing method, material choice, and quantity. Generally, 3D printing and vacuum casting are more cost-effective for small batch and quick production. CNC machining and injection molding have higher costs but offer high precision and large-scale production capabilities. When evaluating prototype costs, also consider mold production costs, equipment depreciation, and labor costs.

VMT Plastic Prototyping Services is a professional prototyping CNC machining factory providing comprehensive services from design to manufacturing. With extensive experience and advanced technology, we offer high-quality, high-precision plastic prototypes for your projects.

At VMT, we understand the unique needs of each project. From prototype design to material selection to production processes, we provide expert advice and solutions. Our team of experienced engineers and technicians possesses deep expertise and practical experience, ensuring your prototypes achieve optimal accuracy, durability, and aesthetics.

We offer various plastic prototyping methods, including 3D printing, CNC machining, vacuum casting, and injection molding. Based on your specific needs, we will recommend the most suitable method and provide detailed quotes and delivery schedules. We are committed to providing efficient, reliable services to ensure your project is completed on time and to high standards.

Q: How do I determine the best plastic prototyping method for my project?

A: Consider the prototype's purpose, form, quantity, and cost. Our team will provide expert advice and solutions to help you make an informed decision.

Q: How is the cost of plastic prototypes calculated?

A: The cost varies based on the manufacturing method, material choice, and quantity. We will provide detailed quotes based on your specific requirements, including material, production, and labor costs.

Q: Can I customize the color and texture of the plastic prototype?

A: Yes, we can customize the color and texture of the plastic prototype based on your requirements. We offer various material and color options to meet your personalized needs.

Q: What is your typical delivery time?

A: Delivery time varies based on project complexity and scale. We will provide detailed delivery schedules based on your specific needs and ensure timely delivery of high-quality prototypes.

Q: Can I test the prototypes at your facility?

A: Yes, we offer prototype testing services. Our advanced testing equipment and professional testing team can conduct comprehensive performance tests and functional verification on your prototypes.

Plastic prototypes play a vital role in product design, development, and production. By selecting the appropriate manufacturing method, materials, and processes, you can create high-quality, high-precision plastic prototypes that ensure successful product launches. At VMT Plastic Prototyping CNC machining Services, we provide professional, efficient, and reliable services to help you turn your ideas into reality. Regardless of your project requirements, we are dedicated to ensuring your project's success.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!