15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

177 |

Published by VMT at Jun 07 2024

177 |

Published by VMT at Jun 07 2024

I. Introduction

Steel and stainless steel hold significant importance in CNC machined parts manufacturing. Understanding their differences is crucial for selecting the appropriate material. This article compares them in terms of composition, mechanical properties, corrosion resistance, heat treatment and manufacturing, applications, cost, and environmental considerations.

II. Differences in Composition and Classification between Alloy Steel and Stainless Steel

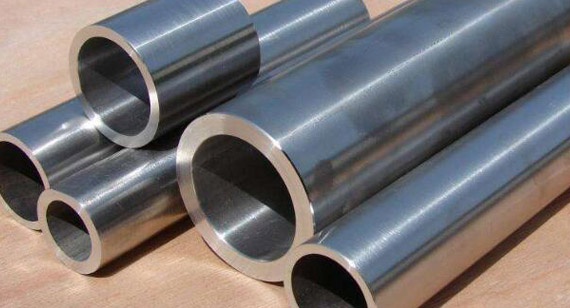

Alloy Steel: Alloy steel is formed by adding one or more alloying elements to plain carbon steel. It is categorized into low alloy steel and high alloy steel based on the content of alloying elements. Elements like chromium and nickel are added to enhance hardness, wear resistance, and other properties.

Stainless Steel: Stainless steel contains a certain percentage of chromium, which allows it to resist chemical corrosion. Chromium is the most crucial alloying element in stainless steel, forming a dense oxide layer that protects the material from corrosion. Stainless steels come in various types, including austenitic and ferritic, such as 304 and 316, where the chromium and nickel ratios determine their corrosion resistance levels.

III. Comparison of Mechanical Properties between Alloy Steel and Stainless Steel

Alloy steel and stainless steel differ in mechanical properties. Alloy steel typically has higher tensile strength and hardness, making it suitable for heavy load and impact applications. Stainless steel, on the other hand, offers excellent ductility and toughness, allowing it to withstand deformation without breaking. In terms of hardness, stainless steel usually ranks lower than alloy steel, although certain types with added nickel can have enhanced hardness.

Mechanical Properties:

Tensile Strength: Alloy steel usually has adjustable tensile strength, depending on the proportion of alloying elements.

Hardness: Both alloy steel and stainless steel hardness can be adjusted through heat treatment, but alloy steel has a broader range.

Ductility: Stainless steel generally has better ductility, making it suitable for deep drawing and forming.

Impact Resistance: Alloy steel can improve impact resistance by adding specific elements like nickel.

Fatigue Strength: Certain alloy steels are designed to withstand repeated loading without cracking.

IV. Differences in Corrosion Resistance between Alloy Steel and Stainless Steel

There are significant differences in corrosion resistance between alloy steel and stainless steel. While alloy steel has some corrosion resistance, it is generally weaker than stainless steel. Due to its high chromium content, stainless steel maintains good stability in various corrosive environments. Stainless steel performs better in resisting pitting, crevice corrosion, galvanic corrosion, and stress corrosion.

Corrosion Resistance:

General Corrosion Resistance: Stainless steel outperforms alloy steel in most environments.

Pitting and Crevice Corrosion: Molybdenum-containing stainless steels (e.g., 316) are more resistant to pitting and crevice corrosion.

Galvanic Corrosion: Stainless steel has a lower risk of galvanic corrosion when in contact with different metals.

Stress Corrosion: Proper selection and treatment of stainless steel can minimize the risk of stress corrosion.

V. Factors Affecting Corrosion Resistance

Factors influencing the corrosion resistance of alloy steel and stainless steel include material composition, microstructure, surface quality, environmental conditions, and the type of medium. Composition and microstructure are crucial determinants of corrosion resistance. Additionally, surface quality impacts the material's corrosion resistance, with poor surface conditions potentially compromising performance in harsh environments like high temperatures, high humidity, and strong acids and alkalis.

VI. Differences in Heat Treatment and Manufacturing

Alloy steel and stainless steel also differ in heat treatment and manufacturing processes. Alloy steel typically undergoes quenching and tempering to enhance hardness and strength. Stainless steel, due to its excellent corrosion resistance, usually doesn't require quenching. In manufacturing, differences in weldability, machinability, and formability are evident. Stainless steel generally offers better weldability and formability, while alloy steel's high hardness and brittleness require careful handling to prevent cracks and fractures during processing.

Heat Treatment and Manufacturing:

Heat Treatment Processes: Alloy steel's properties can be significantly enhanced through heat treatment, while stainless steel's heat treatment effects are limited.

Weldability: Stainless steel is usually easier to weld, but precautions are needed to prevent carbide precipitation.

Machinability: Machining stainless steel is more challenging, especially for high-hardness types.

Formability: Stainless steel is easier to deep draw and bend but may face work hardening issues.

VII. Differences in Applications

Alloy steel and stainless steel have different application areas. Alloy steel, with its high strength and hardness, is often used for parts subjected to heavy loads and impacts, such as bearings and gears. Stainless steel's excellent corrosion resistance and aesthetics make it widely used in food, medical, and chemical industries. When choosing the right steel, it's important to consider functional requirements, budget constraints, aesthetic preferences, and maintenance and lifespan factors.

Applications:

Common Uses of Alloy Steel: High-strength structural components, mechanical parts, and tools.

Common Uses of Stainless Steel: Widely used in chemical processing, food handling, medical devices, and architectural decoration.

Selection Criteria: Based on application needs, considering cost, performance, and machining difficulty.

VIII. Cost and Environmental Considerations

In terms of cost, stainless steel is generally more expensive than alloy steel due to its higher alloy content and production costs. However, considering the lifecycle cost, stainless steel's corrosion resistance can reduce maintenance costs and extend service life, offering better long-term cost efficiency. Environmentally, stainless steel's recyclability supports resource conservation and environmental protection.

Cost and Environment:

Cost Comparison: Stainless steel is typically more expensive, but lower long-term maintenance costs.

Lifecycle Cost: Stainless steel's durability offers lower lifecycle costs.

Environmental Impact and Sustainability: High recyclability of stainless steel minimizes environmental impact.

IX. Advantages of Alloy Steel Compared to Stainless Steel

Alloy steel's advantages over stainless steel mainly lie in its strength and hardness. By adding alloying elements, alloy steel's hardness and wear resistance are enhanced, making it suitable for applications requiring heavy loads and impact resistance.

X. Advantages of Stainless Steel Compared to Alloy Steel

Stainless steel's advantages over alloy steel include superior corrosion resistance and aesthetic appeal, making it ideal for corrosive environments and decorative applications. Its good weldability and formability also facilitate the manufacture of complex parts.

XI. Similarities between Alloy Steel and Stainless Steel

Despite their differences, alloy steel and stainless steel share several similarities. They are both iron-based alloys primarily composed of iron and carbon. Both can be enhanced by adding alloying elements to improve specific properties. They offer versatility and can be widely applied in various fields. In manufacturing and welding, both can utilize similar techniques and processes. Their recyclability also supports resource conservation and environmental protection.

Similarities:

Both are iron-based alloys with recyclability.

Enhanced properties through alloying elements.

Versatile for wide applications.

Involve welding and heat treatment in manufacturing.

Both can undergo cold and hot processing to achieve desired shapes.

XII. Choosing the Right Steel for Your Application

When choosing the right steel, consider several factors. Identify the functional requirements and the necessary mechanical and corrosion resistance properties. Factor in budget constraints to select a cost-effective material. Aesthetic considerations are also important, particularly in decorative applications. Lastly, consider maintenance and lifespan to ensure the material meets long-term usage needs. By evaluating these factors comprehensively, you can select the most suitable steel material for your application.

Selection Standards:

Choose steel with appropriate properties based on functional needs.

Consider budget constraints, balancing initial cost and long-term benefits.

Aesthetic considerations may influence material choice for decorative applications.

Factor in maintenance and lifespan, opting for durable, easy-to-maintain materials.

XIII. Conclusion

In summary, alloy steel and stainless steel exhibit significant differences in composition, properties, and applications. Understanding these differences is crucial for selecting the right material. When choosing, consider functional requirements, budget constraints, aesthetic preferences, and maintenance and lifespan factors. By making informed choices, you can ensure the selected material meets specific application needs, achieving optimal economic and performance results.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!