15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

282 |

Published by VMT at Jun 06 2024

282 |

Published by VMT at Jun 06 2024

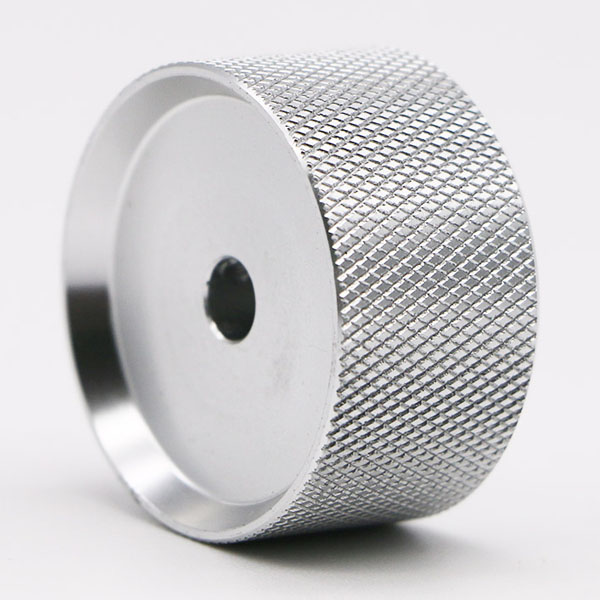

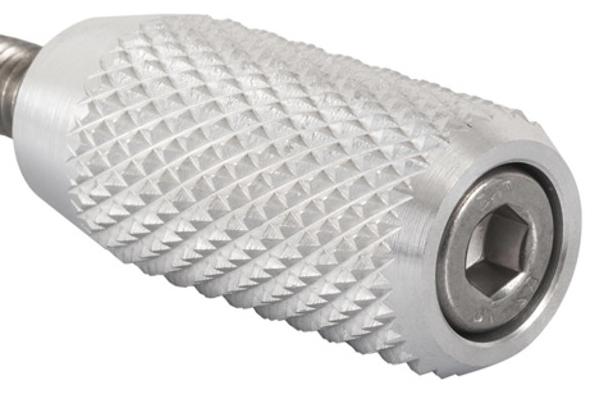

What is Knurling?

Knurling is a machining process that creates specific textures or patterns on the surface of metals, plastics, or other materials. This process involves rolling a knurling tool over the material’s surface, where the tool's texture or pattern imprints onto the material. Widely used across various manufacturing industries, knurling typically produces cross-hatched or diamond-shaped patterns, enhancing the product's aesthetics, improving anti-slip properties, or fulfilling specific functional requirements.

Manual Knurling vs. Machine Knurling

Knurling can be categorized into manual knurling and machine knurling. Manual knurling relies on the skill and experience of the operator, making it suitable for small-batch, customized production. In contrast, machine knurling utilizes CNC equipment or specialized knurling machines for automated processing, ideal for large-scale production, ensuring the consistency and stability of the knurling effect.

Uses of Knurling in Manufacturing

Knurling serves multiple purposes in manufacturing. Firstly, it enhances the aesthetic appeal of products, such as stair railings and balcony handrails in the construction industry. Secondly, it improves the anti-slip properties of products, such as bed frames and chairs in the furniture industry. Additionally, knurling can enhance the physical properties of products, such as increasing wear resistance and reducing noise.

When to Use Knurling?

Consider knurling when you need specific textures or patterns on a product's surface. Knurling is particularly suitable in the following scenarios:

To enhance the anti-slip properties of a product's surface.

To increase the aesthetic appeal of a product.

To improve the physical properties of a product.

Materials Suitable for Knurling

Knurling can be applied to various materials, including metals (e.g., stainless steel, copper, aluminum), plastics, and wood. The methods and tools for knurling different materials may vary, requiring selection based on specific circumstances.

How Does Knurling Work?

Knurling works by rolling a knurling tool over the material's surface. The tool’s texture or pattern imprints onto the material. Typically made of hard materials like steel or carbide, knurling tools ensure clear texture formation during the process. Controlling parameters such as pressure, speed, and angle during knurling is crucial to achieving the desired effect.

Knurling Process: Step-by-Step Guide

Material Preparation: Select appropriate material and ensure its surface is clean and flat.

Tool Selection: Choose the suitable knurling tool based on the knurling requirements and material type.

Equipment Setup: Mount the knurling tool on CNC equipment or a specialized knurling machine, adjusting equipment parameters.

Knurling Operation: Start the equipment, allowing the knurling tool to roll over the material’s surface, creating the desired texture or pattern.

Quality Inspection: Check if the knurling effect meets requirements, making adjustments if necessary.

Post-Processing: Perform any necessary post-processing, such as grinding or polishing.

Types of Knurling Techniques

Knurling techniques can be categorized into several types, including mechanical knurling, manual knurling, and chemical knurling. Mechanical knurling, one of the most common types, uses CNC equipment or specialized machines for automated processing, offering efficiency, stability, and consistency. Manual knurling relies on the operator’s skills and experience, suitable for small-batch, customized production. Chemical knurling creates textures or patterns on the material's surface through chemical reactions, providing unique visual and tactile effects.

Main Knurling Techniques:

Straight Knurling: Used for applications requiring straight line textures.

Diamond Knurling: Provides better grip, commonly used for tool handles.

Various Knurling Tools for Different Effects

Knurling tools are crucial for achieving the desired knurling effects. Different tools produce varying textures or patterns. Common knurling tools include knurling wheels, knurling cutters, and knurling brushes. Knurling wheels, typically used for metal knurling, produce clear texture effects. Knurling cutters are suitable for plastics, wood, and other materials, with adjustable angles and shapes to create different knurling effects. Knurling brushes create rough textures on surfaces, enhancing the anti-slip properties.

Choosing Knurling Tools Based on Texture and Material:

Knurling Cutters: For straight and curved textures.

Knurling Wheels: For continuous knurling operations.

CNC Knurling Attachments: For high precision and complex textures.

Common Defects in Knurling Operations

During knurling operations, common defects may occur, such as unclear textures, misaligned patterns, or uneven surfaces. These defects can affect product quality and aesthetics. To avoid such defects, consider the following:

Select Appropriate Knurling Tools: Choose tools based on material type and knurling requirements.

Control Knurling Parameters: Manage pressure, speed, and angle to achieve the ideal effect.

Maintain Equipment Stability: Ensure CNC equipment or specialized machines are stable to avoid vibrations and shaking.

Inspect Material Quality: Ensure the material surface is clean, flat, and free from oil and impurities.

Uneven Texture: Caused by improper machine settings or worn tools.

Material Damage: Excessive pressure or improper tool use.

Dimensional Deviations: Errors during the processing stage.

Tips for Achieving Optimal Knurling Results

To achieve the best knurling results, consider the following tips:

Select Suitable Materials and Tools: Choose appropriate materials and tools based on product requirements and material properties.

Optimize Knurling Parameters: Find the best parameters through trial and adjustment, such as pressure, speed, and angle.

Maintain Equipment: Regularly check and maintain CNC equipment or specialized knurling machines to ensure proper operation and accuracy.

Design Reasonable Patterns: Design patterns based on product functionality and aesthetics, avoiding overly complex or simple designs.

Use High-Quality Lubricants and Coolants: Reduce friction and heat during knurling to improve effects and tool life.

Conclusion

Knurling is a vital surface treatment technique widely used in manufacturing. By selecting suitable knurling tools, optimizing parameters, maintaining equipment, designing reasonable patterns, and using quality lubricants and coolants, optimal knurling results can be achieved. Knurling not only enhances product aesthetics and anti-slip properties but also meets specific functional requirements. Mastering knurling techniques is essential for improving product quality and competitiveness.

FAQs

Q: What industries use knurling?

A: Knurling is used in various manufacturing industries, including construction, furniture, automotive, and electronics.

Q: What are the costs of knurling?

A: Knurling costs depend on factors such as material type, knurling type, equipment, and production volume. Generally, machine knurling is more economical and efficient for large-scale production than manual knurling.

Q: How is post-processing done after knurling?

A: Post-processing may include grinding, polishing, or coating to enhance product quality and aesthetics.

Q: How to choose the right knurling tool?

A: Choose knurling tools based on factors like material type, knurling type, pattern design, and equipment. Trial and experimentation are recommended.

Q: How to avoid common defects in knurling?

A: Avoid defects by selecting appropriate tools, controlling parameters, ensuring equipment stability, inspecting material quality, and using quality lubricants and coolants. Careful operation and control can minimize defects.

CNC Machining Factory: Your Partner in Knurling

As a professional CNC machining factory, we offer comprehensive knurling services, including CNC prototyping and mass production. Our services cover every step from design to post-processing, ensuring that every knurled CNC part meets the highest standards.

Choosing our CNC machining services offers:

High-Precision Knurling: Advanced CNC machines ensure consistent texture and precision.

Quick Response: Rapid response to customer needs, reducing time from design to final product.

Cost Efficiency: Competitive pricing through optimized production processes.

Quality Assurance: Rigorous quality control ensures every part meets design specifications.

Customized Solutions: Close collaboration with customers to provide tailored services meeting specific needs.

We are dedicated to being your reliable partner in knurling, achieving excellent performance and aesthetic design in your products.

We hope this guide provides comprehensive information on knurling processes. For further details or questions about knurling techniques, feel free to contact us.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!