15 years one-stop China custom CNC machining parts factory

147 |

Published by VMT at Aug 14 2025 | Reading Time:About 6 minutes

147 |

Published by VMT at Aug 14 2025 | Reading Time:About 6 minutes

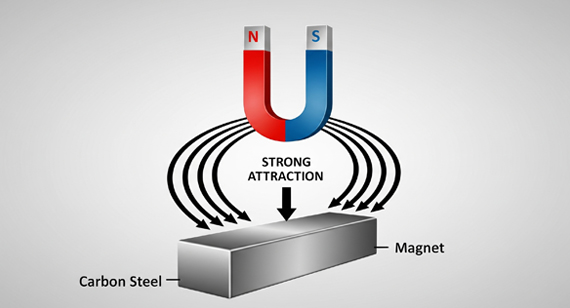

In CNC machining projects, material selection determines the success, cost, and performance of your parts. But for many engineers and buyers, one critical property is often misunderstood—magnetism. When working with carbon steel, the question “Is carbon steel magnetic?” is not just about curiosity; it’s about ensuring functionality in electronic devices, machinery, or tools where magnetic or non-magnetic properties can make or break the design.

Overlooking magnetism in carbon steel can lead to costly mistakes. Imagine investing in CNC machining parts only to find they interfere with sensitive sensors, attract unwanted debris in production, or fail to meet magnetic strength requirements for specialized applications like magnetic locks or industrial separation systems. Without a solid understanding of why and when carbon steel is magnetic, you risk delays, additional machining costs, and compromised product performance.

This guide explains why carbon steel is magnetic, the science behind its properties, how different carbon steel types behave under magnetic fields, and the effect of heat treatment, alloying, and machining processes. By the end, you’ll have the knowledge to confidently select the right carbon steel for your CNC machining parts—avoiding costly surprises and ensuring optimal functionality.

Yes, carbon steel is generally magnetic because it contains iron, a ferromagnetic material. Its magnetism depends on carbon content, crystal structure, and heat treatment. Most carbon steels used in CNC machining parts will strongly attract magnets, making them suitable for applications requiring magnetic properties.

Understanding the magnetism of carbon steel is not just a scientific curiosity—it’s a critical factor in CNC machining services. In the next sections, we’ll explore the exact reasons behind carbon steel’s magnetic properties, its types, and how manufacturing processes like machining and heat treatment influence magnetism. This will help you make the right choice when working with a CNC machining factory.

Yes — carbon steel is magnetic in most cases, and the reason lies in its primary composition. Carbon steel is made predominantly of iron, a well-known ferromagnetic material, combined with varying amounts of carbon (usually up to 2%). The iron atoms in carbon steel have a crystalline arrangement that allows their magnetic moments to align under an external magnetic field, making the steel strongly attracted to magnets.

However, not all carbon steels exhibit the same magnetic strength. The level of magnetism depends on factors such as carbon content, alloying elements, grain structure, and the heat treatment process. For example, low carbon steel (mild steel) typically has higher magnetic permeability than high carbon steel because it retains a more uniform ferrite structure, whereas excessive carbon and certain alloying elements can alter the crystal arrangement and slightly reduce magnetism.

In CNC machining, this property is crucial when designing carbon steel CNC machining parts for applications in electronics, magnetic fixtures, industrial separation systems, and magnetic locks. Understanding whether your specific carbon steel grade is magnetic ensures that the part will function correctly in its intended application—whether that means attracting magnets, resisting magnetic interference, or maintaining magnetic stability after machining.

The magnetism of carbon steel isn’t a coincidence—it’s the direct result of its atomic structure and chemical composition. Since carbon steel is primarily made of iron, a ferromagnetic metal, it naturally exhibits strong magnetic properties. But magnetism isn’t uniform across all grades of carbon steel. It is influenced by carbon content, heat treatment, alloying elements, grain structure, and even the way the material is processed in CNC machining. Understanding these factors allows engineers and buyers to choose the right grade for applications where magnetic performance is either an advantage or a limitation.

Ferromagnetism

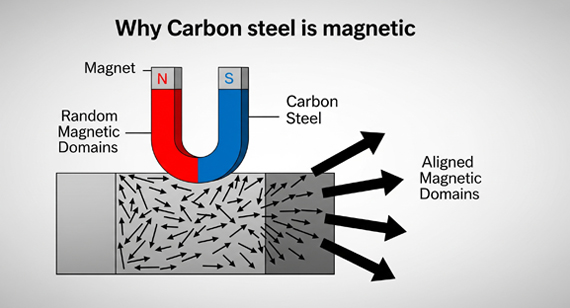

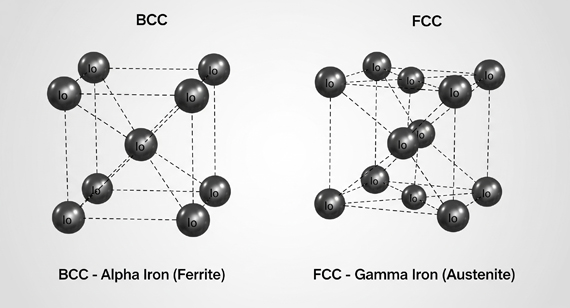

At the core of carbon steel’s magnetism is ferromagnetism—a phenomenon in which certain materials, like iron, have magnetic domains that align in the same direction when exposed to an external magnetic field. In carbon steel, iron atoms are arranged in a body-centered cubic (BCC) crystal structure (ferrite phase) at room temperature. This structure allows the unpaired electrons in iron to align easily, producing strong magnetic attraction.

When carbon steel is heated above its Curie temperature (~770°C for pure iron), it loses this ferromagnetic property because the thermal energy disrupts the alignment of magnetic domains. This is why certain heat treatments temporarily or permanently alter magnetism.

Carbon Content

Carbon content plays a significant role in determining magnetic strength. Low carbon steel (up to 0.25% carbon) retains a mostly ferritic structure, making it highly magnetic. Medium carbon steel (0.25–0.6% carbon) introduces more pearlite (a mix of ferrite and cementite), which slightly reduces magnetic permeability. High carbon steel (>0.6% carbon) has even more cementite, a compound of iron and carbon that is not strongly magnetic, which can lower the overall magnetic response.

In CNC machining, this difference matters. For example, if a component needs to strongly attract magnets for fixtures or sensors, low carbon steel is a better choice. On the other hand, if reduced magnetism is preferred without losing strength, higher carbon grades might be more suitable.

Different Magnetic Field Strengths

Not all carbon steels respond equally to the same magnetic field. Magnetic field strength is influenced by grain size, crystal defects, and processing history. Cold working processes such as forging, rolling, or machining can change grain orientation, sometimes increasing magnetism by aligning more magnetic domains. Conversely, annealing can reduce magnetic hardness by relieving stresses and altering grain boundaries.

In practical terms, two CNC machining parts made from the same carbon steel grade can have different magnetic strengths depending on how they were processed. This is why industries requiring precise magnetic performance often measure magnetic permeability after manufacturing rather than relying solely on raw material specifications.

Magnetic Particle Inspection

Magnetic properties are not only important for performance—they’re also used for quality control. Magnetic Particle Inspection (MPI) is a non-destructive testing method widely used on carbon steel CNC machining parts to detect cracks, seams, or other surface flaws. In MPI, a magnetic field is applied to the steel part, and fine ferromagnetic particles are dusted over the surface. Any discontinuity in the material creates a leakage in the magnetic field, causing the particles to gather and highlight the flaw.

Because carbon steel’s ferromagnetic nature makes it ideal for MPI, it’s the go-to material for industries like aerospace, automotive, and heavy machinery, where detecting structural defects is critical for safety.

Table: Key Factors Behind Carbon Steel’s Magnetism

| Factor |

Description |

Impact on Magnetism |

CNC Machining Tip |

| Ferromagnetism |

Magnetic domains in iron align under an external magnetic field due to its BCC crystal structure. | Produces strong magnetic attraction at room temperature; lost above Curie temperature (~770°C). | Avoid high-heat operations if permanent magnetism is required. |

| Carbon Content |

Varies from low (<0.25%) to high (>0.6%), affecting ferrite and cementite proportions. | Lower carbon = higher magnetism; higher carbon = slightly reduced magnetism. | Choose low-carbon grades for high magnetic strength; high-carbon for reduced magnetic response. |

| Magnetic Field Strengths |

Grain size, defects, and processing history (cold work, annealing) change domain alignment. | Cold work can increase magnetism; annealing can reduce it. | Keep machining and heat treatment processes consistent to maintain predictable magnetism. |

| Heat Treatment |

Alters grain structure and domain alignment; affects phase composition (ferrite/pearlite balance). | Can reduce or enhance magnetism depending on method. | Specify heat treatment requirements clearly in CNC machining orders. |

| Magnetic Particle Inspection (MPI) |

Non-destructive testing method using magnetic fields to detect surface defects. | Relies on strong ferromagnetism for flaw detection. | Use MPI for safety-critical parts to ensure quality control in manufacturing. |

Understanding the basic structure of carbon steel is essential for evaluating its magnetic properties and performance in CNC machining. Carbon steel’s internal arrangement—its atomic structure, composition, and phases—determines not only its mechanical strength and wear resistance but also its magnetic behavior. In most cases, carbon steel is a blend of iron and carbon, with small amounts of other elements. This composition results in a body-centered cubic (BCC) crystal structure at room temperature (ferrite phase), which is responsible for its strong magnetism. Knowing the types and variations in carbon steel helps engineers select the right material for carbon steel CNC machining parts, balancing cost, machinability, and magnetic performance.

Definition of Carbon Steel

Carbon steel is a type of steel where the primary alloying element is carbon. According to the American Iron and Steel Institute (AISI), steel is classified as carbon steel if it contains:

It may also contain trace amounts of other elements, but these are not added for specific alloying purposes. The main characteristic of carbon steel is its direct relationship between carbon content and mechanical properties—higher carbon generally means higher strength but lower ductility.

From a magnetism perspective, the high percentage of iron in carbon steel means it almost always exhibits strong ferromagnetic properties unless heat-treated or alloyed to change its phase structure.

Composition of Carbon Steel

The core composition of carbon steel includes:

This composition determines the balance between mechanical performance and magnetic strength. For example, higher carbon content increases hardness but can slightly disrupt the ferrite structure, reducing magnetic permeability.

Types of Carbon Steel

Carbon steel is typically divided into three categories based on carbon content:

Tip: Match carbon steel type to your part’s intended function—don’t over-specify strength if magnetism is critical to performance.

Table: Basic Structure and Types of Carbon Steel

| Aspect |

Details |

Impact on Magnetism |

CNC Machining Tip |

| Definition |

Steel with carbon as the main alloying element, ≤2% C, limited Mn, Si, Cu content. | High iron content ensures strong ferromagnetic behavior. | Verify grade specifications to match both strength and magnetic requirements. |

| Core Composition |

Iron (>98%), Carbon (0.02–2%), Manganese, Silicon, minimal impurities. | Ferrite-rich structures are more magnetic; excess cementite can reduce magnetism. | Choose grades with minimal non-magnetic alloying elements for stable magnetic output. |

| Low Carbon Steel |

≤0.25% C, soft, ductile, ferrite-rich. | Very high magnetic permeability. | Ideal for magnetic fixtures, electronic components, and easy machining parts. |

| Medium Carbon Steel |

0.25–0.6% C, stronger with less ductility, more pearlite. | Slightly reduced magnetism but still strongly magnetic. | Suitable for automotive and machinery parts needing strength and magnetic response. |

| High Carbon Steel | 0.6–2% C, very strong and wear-resistant, high cementite content. | Lower magnetic permeability than low carbon steel, but still magnetic. | Use for cutting tools or wear-resistant CNC machining parts when some magnetism is acceptable. |

Carbon steel is magnetic primarily because it contains iron, a ferromagnetic metal whose atomic structure allows for strong magnetic alignment. At the atomic level, iron atoms have unpaired electrons in their outer shells. These electrons generate magnetic moments, which, in the solid state, can align in the same direction within microscopic regions known as magnetic domains. When exposed to an external magnetic field, these domains align together, creating a strong overall magnetic effect.

The magnetic properties of carbon steel are also linked to its crystal structure. Most carbon steels at room temperature have a body-centered cubic (BCC) ferrite structure. This arrangement of atoms is highly conducive to ferromagnetism because it allows magnetic moments to align more easily. By contrast, materials with a face-centered cubic (FCC) structure, like austenitic stainless steel, tend to have much lower magnetic permeability.

Carbon content slightly modifies this magnetic behavior. In low carbon steel, the crystal lattice remains mostly ferritic, so magnetism is strong. In higher carbon steels, more cementite (iron carbide) forms, which disrupts domain alignment and slightly reduces overall magnetism—though the steel still remains magnetic.

For CNC machining applications, this means carbon steel CNC machining parts can be engineered with predictable magnetic performance, provided you understand the role of structure, composition, and post-processing. Heat treatment, cold working, and alloying elements can all alter the magnetic response, so design teams should plan for these effects early in production.

The strong magnetism of carbon steel begins with iron’s unique atomic properties. Iron atoms have four unpaired electrons in their 3d orbital, each generating a small magnetic moment. In most materials, these moments point in random directions, canceling each other out. But in ferromagnetic metals like iron, these moments can align parallel to one another within microscopic areas called magnetic domains.

In carbon steel, iron atoms arrange themselves into a body-centered cubic (BCC) crystal structure—also known as the ferrite phase—at room temperature. This structure is especially favorable for ferromagnetism because the BCC arrangement allows magnetic moments to align with less resistance compared to other crystal types. As a result, magnetic domains in carbon steel can easily align when exposed to an external magnetic field, producing strong attraction.

When carbon steel is heated above the Curie temperature (about 770°C for pure iron), the increased atomic vibration disrupts domain alignment, and the material temporarily loses its ferromagnetic properties. If cooled back to room temperature, the BCC structure reforms and magnetism returns—unless alloying elements or heat treatments alter the crystal phase permanently.

From a CNC machining perspective, understanding the role of crystal structure is vital. Machining processes that involve high heat, such as grinding or cutting without proper cooling, can locally alter the steel’s microstructure, sometimes affecting magnetic performance. Similarly, cold working can introduce strain that increases domain alignment, slightly enhancing magnetism.

Carbon itself is not responsible for carbon steel’s magnetism—it is the iron matrix in which the carbon is dissolved that gives the steel its ferromagnetic properties. Carbon atoms occupy small spaces (interstitial sites) within the iron’s crystal lattice. While the carbon content influences mechanical properties like hardness and strength, it does not directly create or remove magnetism. Instead, carbon modifies the microstructure of the steel, affecting how easily the magnetic domains in iron can align.

In most carbon steels, the ferrite phase (BCC structure) remains stable at room temperature, meaning the alignment of magnetic domains persists unless disrupted by heat or mechanical stress. This is why carbon steel parts, once magnetized, tend to retain their magnetic properties over time unless they are heated above their Curie temperature or undergo significant structural changes. Even then, magnetism can often be restored by re-magnetizing the steel.

From a CNC machining perspective, this stability is beneficial for components that rely on consistent magnetic performance—such as magnetic clamps, motor parts, or alignment jigs. Since carbon steel’s magnetism is an inherent property of its iron base rather than the carbon content, the steel will not “lose” its magnetism simply due to age or the presence of carbon.

However, certain manufacturing processes can reduce magnetic performance. For example, prolonged heating during welding or machining can alter grain structure, and alloying elements in specialized steels may reduce magnetic permeability. Therefore, while carbon steel’s magnetism is stable under normal conditions, it is not immune to change if processing alters its crystal structure.

The magnetism of carbon steel is highly dependent on its microstructure, which can be altered significantly through heat treatment and cold working. These manufacturing processes can either enhance or reduce magnetic performance, depending on the intended application.

Heat treatment changes the crystal structure of carbon steel by heating it to specific temperatures and then cooling it at controlled rates. For example, when carbon steel is heated above the austenitizing temperature (generally above 727°C for most grades), the crystal structure transforms from ferrite (BCC) to austenite (FCC). Since FCC structures have much lower magnetic permeability, the steel temporarily loses most of its magnetism at high temperatures. Upon cooling, if the steel reforms into ferrite or martensite, magnetic properties are restored—though the intensity can vary depending on carbon content and cooling rate.

Cold working, on the other hand, involves deforming the steel at room temperature through rolling, bending, drawing, or stamping. This process introduces strain into the crystal lattice, which can influence magnetic domain alignment. In many cases, cold working slightly increases magnetism because it helps domains align more uniformly. However, excessive strain can also cause irregularities that reduce uniform magnetic response.

For CNC machining applications, this knowledge is crucial. Precision parts that require consistent magnetism—such as motor housings, magnetic clamps, or sensor components—must undergo processing steps that preserve their desired microstructure. Inconsistent heat treatment or aggressive cold working without proper control can lead to variable magnetic performance, which might compromise part function.

The magnetic performance of carbon steel is influenced by multiple interconnected factors, from chemical composition to manufacturing processes. While iron’s inherent ferromagnetism forms the foundation, the carbon content, crystal structure, and processing methods all determine the final magnetic strength and stability. For industries using carbon steel CNC machining parts, understanding these factors is essential for designing components that meet both mechanical and magnetic specifications.

Magnetism is not just a fixed property—it can be tailored. By controlling heat treatment, cold working, grain size, and alloying elements, manufacturers can adjust magnetic response to suit applications ranging from motor assemblies to magnetic inspection tools. Below is a detailed breakdown of the most influential factors.

Table: Key Factors Affecting Carbon Steel Magnetism

| Factor |

Description |

Effect on Magnetism |

| Carbon Content |

Percentage of carbon dissolved in iron, influencing phase composition. | Higher carbon increases cementite formation, which slightly reduces magnetism. Low carbon maintains strong magnetism. |

| Crystal Structure |

Arrangement of atoms (BCC ferrite vs. FCC austenite). | BCC is highly magnetic; FCC has low magnetic permeability. |

| Heat Treatment |

Heating and cooling processes that alter phases and grain size. | Can temporarily reduce magnetism (austenite) or restore it (ferrite/martensite). |

| Cold Working |

Mechanical deformation at room temperature. | Often increases magnetism by aligning domains; excessive strain can cause irregularities. |

| Machining |

Cutting, milling, drilling, or grinding that generates localized heat or stress. | Poor cooling can alter microstructure, reducing magnetism; precise machining preserves it. |

| Grain Structure & Uniformity |

Size and consistency of crystal grains within steel. | Fine, uniform grains enhance consistent magnetic response. |

| Alloying Elements |

Added metals like manganese, chromium, or nickel. | Some elements (Ni, Mn) reduce magnetism; others have minimal effect. |

| Impurities |

Unwanted inclusions from raw material or processing. | Can disrupt domain alignment, weakening magnetic performance. |

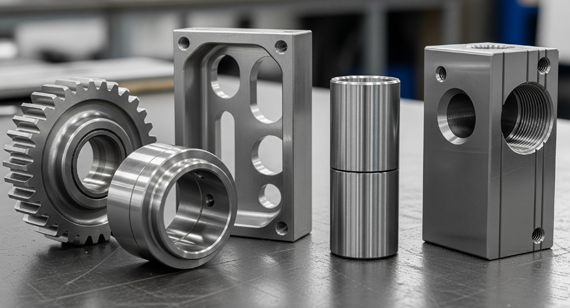

Carbon steel’s magnetism makes it a valuable material for industries where magnetic interaction, detection, or control plays a role in product function. Because it combines ferromagnetism with excellent mechanical strength and machinability, carbon steel is widely used in CNC machining parts that require both durability and magnetic responsiveness. From high-precision motor components to large-scale industrial infrastructure, its applications span electronics, manufacturing, transportation, and more.

In CNC machining services, understanding the magnetic requirements of a part is crucial. Certain components must maintain consistent magnetism for safety, performance, or inspection purposes. By selecting the correct carbon steel grade, controlling machining conditions, and applying proper heat treatment, manufacturers can deliver parts with predictable magnetic performance.

In the electronics industry, carbon steel is used in components like transformer cores, magnetic shielding, and solenoid housings. Its magnetic properties allow for efficient control of electromagnetic fields while providing structural stability. CNC machining ensures precise dimensions, essential for maintaining consistent magnetic flux and avoiding energy loss.

Tip: Always specify magnetic permeability requirements to your CNC machining factory to ensure electronic components perform as intended.

Industrial Manufacturing

In manufacturing plants, carbon steel appears in magnetic separators, lifting devices, and inspection tools. For example, magnetic particle inspection (MPI) uses carbon steel’s ferromagnetism to detect cracks in components. Machined parts such as custom inspection fixtures require high accuracy and surface quality to ensure reliability in testing.

Some medical devices—particularly those outside MRI environments—use carbon steel in surgical clamps, instrument handles, and calibration weights where magnetic behavior is useful for alignment or control. CNC machining services can produce these parts with tight tolerances, ensuring they meet both medical and magnetic specifications.

Automotive and Machinery Parts: Rebar, Magnetic Locks

In the automotive sector, carbon steel’s magnetism is useful for magnetic locking systems, gear housings, and certain drivetrain components. In construction machinery, magnetically detectable rebars help in structural inspection and safety verification. CNC machining allows for custom shapes and features while maintaining required magnetic properties.

Aerospace

Although aerospace often favors non-magnetic alloys for sensitive navigation systems, carbon steel still finds use in magnetic tooling, fasteners, and ground equipment where strong magnetism is an advantage. Machined aerospace fixtures made from carbon steel must maintain dimensional and magnetic stability under high stress.

Railway and Infrastructure: Rails and Fasteners, Elevators and Conveyor Belts

In rail systems, carbon steel’s magnetism aids in position detection and braking systems. Infrastructure components like elevator guide rails and conveyor belt parts often require both strength and magnetic detectability for automated monitoring. CNC machining factories produce these components to exacting safety and operational standards.

Manufacturing and Tooling: Machine Tools and Dies, Magnetic Storage

In tooling, carbon steel’s magnetism helps in magnetic clamping systems for CNC machines, reducing setup time and improving efficiency. In older data storage technologies, magnetism enabled tape and disk drives—many precision components for these systems were carbon steel CNC machining parts.

Table: Magnetic Applications of Carbon Steel

| Industry / Field |

Example Applications |

Magnetic Role |

CNC Machining Relevance |

| Electronics |

Transformer cores, magnetic shielding, solenoid housings | Controls and directs electromagnetic fields | Precision tolerances ensure consistent magnetic flux |

| Industrial Manufacturing |

Magnetic separators, lifting magnets, MPI fixtures | Enables material handling, defect detection | Machined inspection fixtures require high surface quality and accuracy |

| Medical |

Surgical clamps, instrument handles, calibration weights | Alignment, magnetic control | CNC precision ensures compliance with medical standards |

| Automotive & Machinery |

Magnetic locks, gear housings, magnetically detectable rebar | Safety systems, structural inspection | Custom parts maintain strength and magnetism |

| Aerospace |

Magnetic tooling, ground equipment fasteners | Magnetic detection, clamping | High-strength, dimensionally stable fixtures |

| Railway & Infrastructure |

Rails, magnetic brake systems, elevator guide rails, conveyor belt parts | Position detection, automated monitoring | CNC machining ensures durability and precise fit |

| Manufacturing & Tooling |

Magnetic clamps, dies, machine tools, magnetic storage components | Workholding efficiency, data storage | Machined for long service life and consistent magnetic response |

While most carbon steel is magnetic due to its high iron content and ferritic crystal structure, there are certain conditions where it can lose its magnetic properties. This change is typically temporary and depends on environmental factors or deliberate alloying choices. For industries relying on carbon steel CNC machining parts, knowing when magnetism can be reduced—or even eliminated—is critical for applications such as non-magnetic tools, sensitive electronics, or aerospace systems where magnetic interference must be avoided.

Extremely High Temperatures

Carbon steel’s magnetism is strongly influenced by temperature. When heated above its Curie temperature (~770°C / 1420°F), its ferritic structure loses ferromagnetism and becomes paramagnetic, meaning it no longer strongly attracts magnets. However, once cooled below this threshold, the steel regains its magnetic properties.

Tip: If your part operates near or above the Curie temperature, inform your CNC machining factory to select heat-resistant alloys and machining methods.

Alloying Non-Magnetic Elements

Adding specific alloying elements can significantly reduce magnetism. For example:

In CNC machining services, non-magnetic carbon steels or low-magnetism alloys are often chosen for medical devices, electronics, or instruments where stray magnetic fields could disrupt function.

Table: How Carbon Steel Can Become Non-Magnetic

| Condition |

Mechanism |

Magnetism Effect |

Reversibility |

| High Temperature (Above Curie Point) |

Ferritic structure changes to paramagnetic phase | Loses strong magnetic attraction | Reversible upon cooling |

| Alloying with Nickel |

Transforms BCC ferrite to FCC austenite crystal structure | Strongly reduces or eliminates magnetism | Permanent (structural change) |

| Alloying with Manganese/Copper |

Disrupts magnetic domain alignment | Reduces magnetic permeability | Permanent |

| Prolonged Austenitizing |

Heat treatment keeps steel in non-magnetic austenitic phase | Can remove magnetism | Sometimes reversible with heat treatment |

At VMT, we specialize in delivering precision carbon steel CNC machining parts tailored to meet your exact mechanical and magnetic specifications. Whether your project requires components with strong magnetic properties or non-magnetic behavior, our experienced team understands the critical relationship between material selection, processing, and final part performance.

We work closely with clients across industries—including automotive, electronics, aerospace, and manufacturing—to provide custom solutions that balance strength, machinability, and magnetism. Our state-of-the-art CNC machining factory uses advanced equipment and quality control techniques, such as Magnetic Particle Inspection (MPI), to ensure every part meets stringent standards.

With in-depth knowledge of how carbon content, heat treatment, cold working, and alloying elements influence magnetism, VMT is uniquely positioned to advise on material choice and processing methods. This expertise minimizes costly errors and enhances the reliability of your components, especially when magnetic performance is vital.

Furthermore, we offer:

Choosing VMT means partnering with a CNC machining services provider who prioritizes both the mechanical and magnetic integrity of your carbon steel parts, ensuring your project’s success from prototype to production.

Carbon steel is inherently magnetic due to its high iron content and ferritic crystal structure, making it a versatile material for countless applications requiring magnetic responsiveness. Its magnetism varies depending on factors such as carbon content, heat treatment, cold working, and the presence of alloying elements. Understanding these key influences is essential for selecting the right carbon steel grade and processing method, especially when designing carbon steel CNC machining parts that must meet strict mechanical and magnetic specifications.

Whether you need parts that maintain strong magnetic attraction for industrial, automotive, or electronic uses, or you require components with reduced magnetism for sensitive applications, choosing the right material and working with an experienced CNC machining factory like VMT is crucial. Our expertise ensures that your parts not only perform mechanically but also meet your magnetic performance requirements, helping to avoid costly redesigns and project delays.

By considering all aspects of magnetism and carbon steel’s microstructure, manufacturers and designers can confidently deploy carbon steel parts across diverse industries, leveraging their magnetic properties to enhance function and reliability.

Can carbon steel attract magnets?

Yes. Carbon steel is primarily made of iron, which is ferromagnetic, so it strongly attracts magnets. The degree of magnetism depends on the carbon content and heat treatment.

What steels are non-magnetic?

Steels with austenitic crystal structures, such as 304 and 316 stainless steel, are typically non-magnetic. Also, some specially alloyed steels with high nickel content exhibit very low magnetism.

Which steel has the strongest magnetism?

Low carbon steel, with its ferritic (BCC) structure and minimal alloying, usually exhibits the strongest magnetism among steels.

Is carbon magnetic or non-magnetic?

Pure carbon itself is not magnetic. Carbon steel is magnetic because of its iron matrix, which is ferromagnetic.

What is the difference between magnetic and non-magnetic carbon steel?

Magnetic carbon steel contains primarily ferritic or martensitic structures that allow magnetic domains to align. Non-magnetic variants have been heat treated or alloyed to form austenitic phases, which do not support strong magnetism.

Does carbon steel become magnetic after certain treatments?

Yes. Heat treatments such as quenching can form martensite, which is magnetic. Conversely, heating above the Curie temperature temporarily demagnetizes the steel.

How can the magnetism of carbon steel be tested?

Magnetic Particle Inspection (MPI) is a common non-destructive test that uses the steel’s magnetism to detect surface cracks and defects. Simple magnet attraction tests can also indicate magnetism qualitatively.

Is forged carbon steel magnetic?

Yes. Forging typically preserves or enhances the ferritic structure, so forged carbon steel remains magnetic.

What steels are not attracted to magnets?

Austenitic stainless steels (e.g., 304, 316), some aluminum alloys, and non-ferrous metals like copper and brass are not attracted to magnets.

Is carbon steel a permanent magnet?

No. Carbon steel can be magnetized but does not inherently retain magnetism permanently like specialized permanent magnet materials (e.g., neodymium).

What metals are not attracted to magnets?

Non-ferrous metals like aluminum, copper, brass, and some stainless steels are not attracted to magnets.

How can I tell if a metal is carbon steel?

You can test with a magnet—carbon steel will attract it strongly. Additionally, professional methods like spectroscopy or chemical analysis can confirm composition.