15 years one-stop China custom CNC machining parts factory

332 |

Published by VMT at Aug 18 2025 | Reading Time:About 7 minutes

332 |

Published by VMT at Aug 18 2025 | Reading Time:About 7 minutes

Iron is one of the most widely used metals in history, yet many people underestimate just how many varieties exist and how each type serves a unique purpose. The problem is that not understanding the different types of iron—from pure iron to complex iron alloys—can lead to poor material selection, higher production costs, and even product failure. Engineers, manufacturers, and procurement teams often face the frustration of discovering too late that their chosen iron type does not meet strength, corrosion resistance, or machinability requirements. The good news? With the right knowledge, you can make informed choices that save time, reduce costs, and ensure optimal performance for your applications. This guide will walk you through definitions, properties, classifications, and uses, so you can select the right iron for CNC machined parts, CNC machining services, or any industrial need.

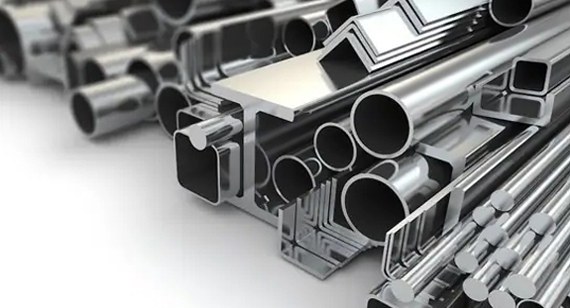

Iron comes in multiple forms—pure iron, pig iron, wrought iron, cast iron, stainless steel, carbon steel, alloy steel, tool steel, ductile iron, and gray cast iron. Each has distinct properties and applications. Understanding their differences ensures optimal material selection for construction, manufacturing, and CNC machined parts production.

Now that you know there’s more than one type of iron, let’s dive deeper. We’ll explore what iron actually is, its properties, the science behind its variations, and how each type serves specific industries. By the end, you’ll have a complete understanding of iron alloys and pure forms, so you can confidently match them to your manufacturing or CNC machining needs.

Iron is a metallic element that serves as one of the most fundamental building blocks of modern industry. Represented by the chemical symbol Fe (from the Latin word ferrum), it is the fourth most abundant element in the Earth’s crust, making up about 5% of its mass. In its pure form, iron has a silvery-gray metallic luster, high density, and is relatively soft compared to many alloys. However, pure iron is rarely used in large-scale applications because it is prone to corrosion and lacks the mechanical strength required for demanding tasks.

Commercially, iron is typically found in combination with other elements—either as ores like hematite and magnetite, or as part of iron alloys such as steel. These alloys are engineered to enhance specific properties like strength, hardness, and corrosion resistance. Iron is also highly magnetic, making it essential in applications like motors, transformers, and various electromagnetic devices.

From a historical perspective, iron has been a cornerstone material since the Iron Age, replacing softer metals like bronze in tools and weapons. Today, it remains indispensable in construction, manufacturing, and precision engineering, especially in the production of CNC machined parts where dimensional stability and machinability are key.

The chemical symbol for iron is Fe, derived from the Latin word ferrum, meaning “iron.” This abbreviation is universally recognized in scientific, engineering, and manufacturing contexts. You’ll see “Fe” on material specifications, engineering blueprints, and datasheets for CNC machined parts when the base metal or alloy contains iron as its primary element. The periodic table assigns iron the atomic number 26, indicating it has 26 protons in its nucleus.

Using chemical symbols like Fe ensures clear, standardized communication across industries and languages. For example, whether you’re sourcing material from a local supplier or an international CNC machining factory, “Fe” will always identify iron without confusion. This consistency is especially critical in industries such as aerospace, automotive, and construction, where precise material identification can mean the difference between a safe, reliable product and a costly, potentially dangerous failure.

It’s worth noting that the symbol “Fe” may appear alongside other elements in alloy designations. For instance, stainless steel might be labeled as Fe-Cr-Ni (iron-chromium-nickel) to indicate its key components. Knowing these abbreviations helps engineers and buyers quickly understand the composition and suitability of a given metal for CNC machining services.

The most common and stable isotope of iron has a mass number of 56, which means the sum of its protons and neutrons equals 56. Since iron’s atomic number is 26 (representing its protons), this isotope contains 30 neutrons. While iron occurs in several isotopes—such as iron-54, iron-57, and iron-58—Fe-56 is by far the most abundant, accounting for over 91% of naturally occurring iron on Earth.

In engineering and CNC machining contexts, the mass number isn’t typically used for ordering materials, but it’s important in fields like metallurgy, materials science, and nuclear engineering. It influences atomic weight, which in turn affects density calculations, especially for precision components. For example, CNC machined parts used in aerospace or defense industries may require exact mass-to-strength ratios, where even small variations can impact performance.

Understanding the mass number also helps when working with high-purity iron or specialty iron alloys. Different isotopic compositions can slightly change thermal or magnetic behavior, which may be critical in applications like electrical transformers, magnetic sensors, or precision instruments.

The weight of iron depends on its volume, but its density provides a consistent way to calculate it. Pure iron has a density of approximately 7.87 grams per cubic centimeter (g/cm³), or 7,870 kilograms per cubic meter (kg/m³). This means that one cubic meter of solid iron weighs nearly 7.87 metric tons. In imperial units, the density is about 491 pounds per cubic foot.

In practical terms, this high density is one of the reasons iron and iron alloys are so valued in construction, machinery, and CNC machined parts—they provide excellent weight-to-strength ratios, especially when structural rigidity is a priority. However, the heaviness of iron can also be a drawback in applications where lightweight materials, such as aluminum or titanium, are preferred for energy efficiency and ease of handling.

For manufacturing, weight calculations are essential. In CNC machining services, knowing the density helps estimate raw material costs, shipping fees, and even machine setup. For example, machining a large iron block requires more power and can increase tool wear compared to lighter metals. Additionally, certain CNC machining factories may have size and weight limitations for their equipment, so confirming the weight early in the planning stage can avoid costly surprises.

Iron originates primarily from iron ore deposits found in the Earth’s crust. The most common ores include hematite (Fe₂O₃), magnetite (Fe₃O₄), goethite (FeO(OH)), and siderite (FeCO₃). These ores are mined from open-pit or underground operations in regions rich in mineral resources. Major producers of iron ore include Australia, Brazil, China, India, and Russia, which supply most of the raw material used in the global steel industry.

Once extracted, iron ore undergoes smelting—a process where the ore is heated in a blast furnace along with coke (a carbon source) and limestone. This removes oxygen from the ore, producing pig iron. From there, the pig iron is refined and alloyed to create different types of iron and iron alloys such as carbon steel, stainless steel, and tool steel, which are then used in countless industries.

Interestingly, iron also exists in meteoritic form. Some of the earliest human tools were crafted from meteorites containing high concentrations of metallic iron and nickel. Today, nearly all industrial iron comes from terrestrial sources, but this historical fact highlights iron’s deep connection to human development.

For CNC machining services, the origin of iron matters because ore quality, refining processes, and alloying methods directly affect machinability, surface finish, and durability of the final CNC machined parts. Sourcing from reliable CNC machining factories that use certified iron alloys ensures consistent quality and performance.

Iron is valued in engineering, construction, and CNC machining services because of its unique balance of physical and chemical properties. These attributes determine its performance in structural applications, manufacturing processes, and as a base metal for iron alloys. Whether you’re designing heavy-duty infrastructure, precision CNC machined parts, or specialized machinery components, understanding iron’s core properties helps you select the right grade and processing method. Below, we explore the most significant characteristics that make iron indispensable.

Strength

Iron offers excellent compressive and tensile strength, particularly when alloyed with carbon and other elements. This makes it capable of withstanding heavy loads, impacts, and mechanical stress. Pure iron is relatively soft, but alloying can produce steels with strengths exceeding 1,000 MPa, ideal for demanding applications.

Versatility

Iron’s ability to form numerous alloys makes it one of the most versatile metals. From corrosion-resistant stainless steel to wear-resistant tool steel, iron can be tailored to meet a wide range of industrial needs. This versatility extends to shaping and joining processes like welding, casting, and forging.

Reactivity

Iron readily reacts with oxygen and moisture, forming rust (iron oxide). While this is a disadvantage in some environments, it can be controlled through protective coatings, galvanizing, or alloying with elements like chromium for corrosion resistance.

High Density

At 7.87 g/cm³, iron is a relatively heavy metal. This density provides stability and vibration resistance in machinery but can be a drawback in applications where weight reduction is critical.

Metallic Luster

Iron exhibits a silvery-gray metallic sheen in its pure form. While this aesthetic can be appealing, most industrial applications require coatings or surface treatments to prevent tarnish or rust.

High Melting Point

With a melting point of about 1,538°C (2,800°F), iron performs well in high-temperature environments. This property is essential for parts exposed to heat in engines, furnaces, and power plants.

Magnetism

Iron is strongly ferromagnetic, making it vital in electrical and magnetic applications such as transformers, motors, and magnetic clamping systems.

Malleability and Ductility

Iron can be shaped, rolled, and drawn into wires without breaking, especially in pure or low-carbon forms. This allows for flexibility in manufacturing processes and design options.

Moderate Electrical Conductor

While not as conductive as copper or aluminum, iron still carries electricity adequately for certain applications. Alloy composition can influence conductivity significantly.

| Property |

Description |

Practical Implication for CNC Machining & Applications |

| Strength |

High tensile and compressive strength, especially when alloyed with carbon. | Suitable for heavy-load CNC machined parts and structural applications. |

| Versatility |

Can form many iron alloys with customized properties. | Enables tailored solutions for corrosion resistance, wear resistance, or strength. |

| Reactivity |

Reacts easily with oxygen and moisture, forming rust. | Requires coatings, galvanizing, or alloying for long-term durability. |

| High Density |

Density ~7.87 g/cm³; provides stability and vibration resistance. | Good for heavy-duty machinery, but may be too heavy for weight-sensitive designs. |

| Metallic Luster |

Silvery-gray shine in pure form. | Can be polished or plated for aesthetic or corrosion protection. |

| High Melting Point |

~1,538°C (2,800°F). | Performs well in high-heat environments like engines or turbines. |

| Magnetism |

Strongly ferromagnetic. | Essential in motors, transformers, and magnetic clamping systems. |

| Malleability & Ductility |

Can be shaped, rolled, or drawn into wires. | Allows for complex part geometries in CNC machining services. |

| Moderate Electrical Conductivity |

Conducts electricity, but less than copper/aluminum. | Suitable for structural parts that also require some electrical conduction. |

Iron can be classified in several ways depending on its composition, processing method, and internal structure. The three most common criteria are carbon content, alloying elements, and microstructure. These classifications are essential for engineers, metallurgists, and CNC machining services providers because they directly affect strength, machinability, corrosion resistance, and cost. By understanding these categories, you can more accurately select the right iron alloys for your project—whether it’s heavy construction, precision CNC machined parts, or high-performance machinery.

Carbon Content

The amount of carbon in iron significantly alters its properties.

Higher carbon generally increases hardness and strength but reduces ductility and machinability.

Alloying Elements

Pure iron is rarely used alone; adding elements like chromium, nickel, molybdenum, vanadium, or manganese creates specialized iron alloys. For example, chromium improves corrosion resistance (stainless steel), while molybdenum increases high-temperature strength. These alloying elements tailor iron to specific industrial applications, from shipbuilding to aerospace.

Microstructure

The internal crystal structure of iron—formed during cooling and heat treatment—affects its properties as much as its composition. Common microstructures include:

Tip: Choosing the right microstructure is critical—especially for CNC machined parts where machining ease and service life must be balanced.

| Classification Criteria |

Type / Category |

Key Characteristics |

Practical Implications for CNC Machining & Applications |

| Carbon Content | Pure Iron (<0.008% C) | Very soft, highly ductile. | Easy to machine but lacks strength; good for decorative parts. |

| Low-Carbon Steel (0.05–0.3% C) | Good ductility, easy to weld. | Common for general CNC machined parts and structural use. | |

| Medium-Carbon Steel (0.3–0.6% C) | Higher strength, lower ductility. | Good for parts needing more wear resistance. | |

| High-Carbon Steel (0.6–1.5% C) | Very hard, less machinable. | Best for cutting tools and wear parts; requires specialized tooling. | |

| Alloying Elements | Chromium | Improves corrosion resistance. | Used in stainless steels for marine or food-grade CNC parts. |

| Nickel | Increases toughness and ductility. | Good for cryogenic applications and impact-resistant parts. | |

| Molybdenum | Enhances high-temp strength. | Used in aerospace and energy components. | |

| Vanadium | Improves hardness and wear resistance. | Common in tool steels for long-lasting cutting tools. | |

| Manganese | Improves strength and hardenability. | Suitable for high-wear machine components. | |

| Microstructure | Ferrite | Soft, ductile, magnetic. | Easy to machine; used in mild steel parts. |

| Austenite | Non-magnetic, corrosion-resistant. | Found in stainless steels; good for food and medical equipment. | |

| Pearlite | Balanced strength and ductility. | Suitable for automotive and mechanical parts. | |

| Martensite | Extremely hard and strong. | Ideal for wear-resistant CNC machined parts; difficult to machine. | |

| Graphite Flakes | Reduce strength; increase damping. | Found in gray cast iron; good for engine blocks. | |

| Graphite Nodules | Improve ductility and toughness. | Found in ductile iron; good for pressure-containing parts. |

Iron exists in many forms, each designed to meet specific mechanical, chemical, and performance needs. These variations are achieved by adjusting carbon content, adding alloying elements, and controlling microstructure. Whether it’s for construction beams, cookware, automotive parts, or precision CNC machined parts, selecting the right type of iron is critical for performance, cost efficiency, and durability. Below are the 10 most common forms of iron and iron alloys, along with their defining properties and key applications.

1. Pure Iron

What is Pure Iron?

Pure iron contains less than 0.008% carbon and is rarely found in a completely pure state in nature. It is primarily produced for scientific, electrical, and specialty industrial purposes.

Properties

Applications

Tip: Pure iron’s softness makes it easy to machine, but it’s rarely suitable for structural applications without alloying.

2. Pig Iron

What is Pig Iron?

Pig iron is the intermediate product from smelting iron ore in a blast furnace. It contains 3.5–4.5% carbon and various impurities like silicon, sulfur, and phosphorus.

Properties

Applications

Tip: Pig iron is not suitable for direct machining—it must be refined into usable alloys first.

3. Wrought Iron

What is Wrought Iron?

Wrought iron contains less than 0.08% carbon and is characterized by its fibrous slag inclusions, which give it a distinctive grain.

Properties

Applications

Tip: Wrought iron machines easily, making it suitable for custom decorative CNC parts.

4. Cast Iron

What is Cast Iron?

Cast iron contains 2–4% carbon along with varying amounts of silicon and other elements. It is produced by remelting pig iron with scrap steel and alloys.

Properties

Applications

Tip: Use cast iron for CNC parts that require vibration damping, but avoid where high tensile stress is expected.

What is Stainless Steel?

An iron alloy containing at least 10.5% chromium, which forms a protective oxide layer for corrosion resistance.

Properties

Applications

Tip: For CNC machining, choose the right stainless grade—some are much easier to cut than others.

6. Carbon Steel

What is Carbon Steel?

An iron-carbon alloy with carbon content up to 2.1%, without significant alloying elements.

Properties

Applications

Tip: Match carbon content to application—higher carbon means harder but more brittle parts.

7. Alloy Steel

What is Alloy Steel?

Steel with added alloying elements (e.g., chromium, nickel, molybdenum) to enhance mechanical and chemical properties.

Characteristics

Applications

Tip: For CNC parts, alloy steels often provide the best performance-to-cost ratio.

8. Tool Steel

What is Tool Steel?

A high-carbon alloy steel designed for cutting, shaping, and forming materials.

Characteristics

Applications

Tip: Tool steels can be challenging to machine—use carbide tooling and appropriate speeds.

9. Ductile Iron

What is Ductile Iron?

Also called nodular or spheroidal graphite iron, ductile iron contains graphite nodules that improve toughness.

Characteristics

Applications

Tip: Ductile iron is an excellent choice for CNC parts requiring both strength and vibration resistance.

10. Gray Cast Iron

What is Gray Cast Iron?

Cast iron containing flake graphite, which gives it a gray fracture surface.

Characteristics

Applications

Tip: Gray cast iron is ideal for large, stable CNC parts where vibration control is key.

10 Common Iron Types Table

| Type of Iron |

Definition |

Key Properties |

Common Applications |

| Pure Iron |

Iron in its most refined form, with very low carbon content (<0.008%). | Soft, ductile, high corrosion tendency, very magnetic. | Electrical applications, laboratory use, electromagnetic cores. |

| Pig Iron |

Crude iron obtained from a blast furnace, high carbon (3.5–4.5%) and impurities. | Brittle, hard, high carbon content, low ductility. | Further processing into steel or cast iron. |

| Wrought Iron |

Iron with very low carbon (<0.08%), high slag content, fibrous texture. | Tough, malleable, corrosion-resistant, low tensile strength. | Gates, fences, railings, decorative items. |

| Cast Iron |

Iron-carbon alloy with 2–4% carbon, produced by remelting pig iron. | Hard, brittle, wear-resistant, excellent casting properties. | Engine blocks, cookware, pipes, machinery bases. |

| Stainless Steel |

Iron alloy with ≥10.5% chromium for corrosion resistance. | Strong, rust-resistant, shiny, durable. | Kitchenware, medical tools, construction, CNC machined parts. |

| Carbon Steel |

Iron-carbon alloy with 0.05–2.0% carbon. | High strength, good hardness, lower corrosion resistance than stainless. | Tools, construction, automotive parts, CNC machining. |

| Alloy Steel |

Iron alloy with other elements (nickel, chromium, vanadium, molybdenum) for enhanced properties. | High strength, toughness, wear and corrosion resistance. | Gears, pipelines, aerospace components, heavy machinery. |

| Tool Steel |

High-carbon steel alloyed with tungsten, molybdenum, vanadium for hardness and wear resistance. | Very hard, heat-resistant, wear-resistant. | Cutting tools, dies, molds, CNC machining tools. |

| Ductile Iron |

Cast iron treated with magnesium to improve ductility. | Strong, shock-resistant, more malleable than gray iron. | Pipes, automotive crankshafts, gearboxes. |

| Gray Cast Iron |

Cast iron with graphite flakes giving a gray fracture. | Excellent machinability, vibration damping, brittle. | Machine bases, engine blocks, brake discs. |

Choosing the right type of iron depends on the specific needs of your project, and several key factors should be considered before making a decision.

First, think about the mechanical strength requirements. For applications that demand high strength and durability, such as construction beams or heavy machinery components, carbon steel or alloy steel might be the best options. If extreme hardness and wear resistance are important—such as for cutting tools or molds—tool steel is an ideal choice.

Second, consider corrosion resistance. If the material will be exposed to moisture, chemicals, or harsh outdoor environments, stainless steel is preferred because of its chromium content, which forms a protective oxide layer. In contrast, pure iron or regular carbon steel will need protective coatings or galvanization to prevent rust.

Next, evaluate ductility and formability. For projects that require intricate shaping, bending, or forging, wrought iron or low-carbon steel is more suitable, as these materials can be worked into complex forms without breaking. Ductile iron is also excellent for applications where shock absorption and impact resistance are important, such as in automotive parts.

Cost is another factor to weigh. Pig iron and gray cast iron tend to be more affordable but may have limitations in strength and corrosion resistance. High-performance alloys, like stainless or tool steels, offer superior properties but come at a higher price.

Finally, think about the specific application requirements. For decorative works like gates and railings, wrought iron is preferred for its aesthetic appeal and ease of fabrication. For engine blocks or machine bases, gray cast iron is chosen for its vibration-damping properties. For precision engineering tools, tool steel’s hardness and wear resistance are invaluable.

By balancing strength, corrosion resistance, ductility, cost, and intended use, you can select the most suitable type of iron to ensure optimal performance and longevity in your project.

Here’s a detailed guide for How to Choose the Right Iron in table form so it’s quick to compare and apply:

| Consideration |

Details |

Example Choices |

| Identify Application |

Determine if the iron will be used for structural, decorative, machining, or special environments. | Construction beams → Carbon steel; Outdoor gates → Wrought iron; Food equipment → Stainless steel |

| Mechanical Strength |

Assess the required tensile strength, yield strength, and hardness for the project. | High strength → Alloy steel; Moderate → Cast iron |

| Corrosion Resistance |

Evaluate exposure to moisture, chemicals, or saltwater. | High resistance → Stainless steel; Low → Carbon steel (needs coating) |

| Wear Resistance |

For parts subject to abrasion, choose iron with high hardness. | Tool steel, white cast iron |

| Machinability |

Consider ease of cutting, drilling, and shaping. | Wrought iron, ductile iron |

| Formability & Ductility |

For bending, rolling, or forging, select more malleable irons. | Pure iron, mild carbon steel |

| Heat Resistance |

For high-temperature environments, use iron with stable microstructure. | Alloy steel, heat-resistant cast iron |

| Cost & Availability |

Match budget and supply. | Pig iron (cheap bulk production), stainless steel (costly but long-lasting) |

| Magnetic Requirements |

If magnetism is desired, choose ferritic/martensitic grades. | Carbon steel, ferritic stainless steel |

| Special Standards or Codes |

Check compliance with industry or regional regulations. | ASTM, ISO grades |

Iron is one of the most widely used metals in the world due to its abundance, versatility, and excellent mechanical properties. From the ancient forging of weapons to modern skyscrapers and advanced engineering projects, iron and its alloys remain essential in countless industries. Its strength, durability, and ability to form alloys make it a cornerstone of modern civilization.

Construction

Iron, especially in the form of steel, is a primary material in the construction industry. It is used to create structural frameworks for buildings, bridges, and towers due to its high tensile strength and load-bearing capacity. Reinforced concrete also relies on steel bars (rebar) for added stability.

Manufacturing

In manufacturing, iron is used to produce machinery, tools, and equipment. Steel alloys are commonly employed in the fabrication of industrial machinery, cutting tools, and heavy-duty manufacturing equipment.

Transportation

Iron and steel are critical in the production of vehicles, railways, and ships. Rail tracks, train carriages, automobile frames, and shipping containers all rely on the strength and durability of iron-based materials.

Infrastructure

Infrastructure projects—such as tunnels, pipelines, and water supply systems—often use iron for its robustness and resistance to wear. Ductile iron pipes, for example, are widely used in water distribution networks.

Energy Generation

In the energy sector, iron is a vital component in wind turbine structures, oil rigs, and power plant frameworks. It is also used in transformers, generators, and various renewable energy systems.

The automotive industry relies heavily on steel for body panels, chassis components, and engine parts. Modern cars use high-strength steel to improve crash resistance while reducing weight.

Aerospace

Though lighter metals like aluminum are common in aerospace, high-strength steel and specialized iron alloys are used in landing gear, engine parts, and structural reinforcements due to their durability and heat resistance.

Shipbuilding

Ships, submarines, and offshore platforms use large quantities of steel for hulls and structural supports. Marine-grade steels are designed to withstand corrosion from saltwater environments.

Machinery and Equipment

Iron and steel are indispensable in the production of agricultural machinery, construction equipment, and industrial tools. Their wear resistance and ability to be cast or forged into complex shapes make them ideal for these applications.

Packaging

In packaging, iron is most notable in the production of tinplate (steel coated with tin), which is used to make food and beverage cans. These containers provide durability and protection against contamination.

Certain stainless steels are used in surgical instruments, implants, and medical equipment because of their corrosion resistance, strength, and biocompatibility.

Agriculture

Iron plays a significant role in agricultural equipment, such as plows, tractors, and harvesters, due to its toughness and long service life.

Mining

Mining machinery, drill bits, and excavation equipment often use hardened steel to endure the extreme wear and stress of extracting minerals.

Iron is also found in electronics, especially in magnetic materials used in transformers, motors, and electrical components. Certain iron-based alloys are key in the manufacturing of hard drives and electrical cores.

Iron: Applications and Uses

| Sector |

Key Applications |

| Construction |

Structural beams, reinforcement bars (rebar), steel frames, roofing sheets, and building facades. |

| Manufacturing |

Machinery frames, industrial tools, molds, fasteners, and heavy equipment parts. |

| Transportation |

Railway tracks, train wheels, bridges, ship hulls, and truck chassis. |

| Infrastructure |

Pipelines, water tanks, power transmission towers, and road/bridge components. |

| Energy Generation |

Wind turbine towers, hydroelectric dams, oil rigs, and power plant frameworks. |

| Automotive |

Car chassis, engine blocks, crankshafts, and brake discs. |

| Aerospace |

Landing gear components, engine casings, and structural supports in aircraft. |

| Shipbuilding |

Hull plating, propeller shafts, and engine room components. |

| Machinery & Equipment |

Press machines, conveyor systems, crushers, and drilling rigs. |

| Packaging |

Tin-plated steel cans for food and beverages. |

| Medical Devices |

Surgical tools, hospital beds, and medical support structures. |

| Agriculture |

Tractor frames, plowshares, irrigation systems, and grain silos. |

| Mining |

Excavator arms, ore crushers, and conveyor belts. |

| Electronics |

Electromagnetic shielding, transformer cores, and electrical cabinets. |

Choosing the right iron supplier is essential for ensuring material quality, cost efficiency, and reliable delivery. Here are the main factors to consider:

Select a supplier who provides iron that meets relevant industry standards such as ASTM, ISO, or EN. High-quality materials ensure durability and consistent performance.

2. Product Range

A good supplier should offer various types of iron—such as pure iron, carbon steel, cast iron, alloy steel, and stainless steel—so you can source all your needs from one place.

3. Certifications and Compliance

Look for suppliers with quality management certifications like ISO 9001, as well as environmental and safety compliance. This shows they follow strict quality control processes.

4. Customization Capabilities

If your projects require special grades, sizes, or machining, choose a supplier who can provide custom processing, cutting, or CNC machining services.

5. Pricing and Cost Transparency

Competitive pricing is important, but avoid choosing solely based on the lowest price. Instead, compare total value—including quality, service, and lead time.

6. Delivery Reliability

Consistent on-time delivery is critical, especially for large projects or tight schedules. Check the supplier’s logistics capabilities and track record.

7. Technical Support

Choose a supplier with knowledgeable staff who can provide material advice, technical data, and assistance in selecting the right type of iron for your application.

8. Reputation and Experience

A supplier with a solid reputation, positive customer reviews, and years of industry experience is more likely to provide reliable products and services.

9. After-Sales Service

Good after-sales support, such as replacement policies, defect handling, and ongoing customer communication, ensures a smooth long-term partnership.

10. Sustainability Practices

If environmental responsibility is important to your business, work with suppliers who follow eco-friendly practices such as recycling scrap and reducing waste.

Here’s a table outlining how to choose the best iron supplier:

| Criteria |

Description |

Why It Matters |

| Product Quality |

Ensure the iron meets industry standards and specifications. | High-quality iron ensures durability, performance, and safety in applications. |

| Material Range |

Check if the supplier offers various iron types (pure iron, cast iron, alloy steel, stainless steel, etc.). | A wide range of materials allows you to select the most suitable option for different projects. |

| Certifications |

Look for ISO, ASTM, or other relevant certifications. | Certifications guarantee compliance with quality and safety standards. |

| Production Capacity |

Assess whether the supplier can meet your required volume. | Ensures steady supply without delays, especially for large-scale projects. |

| Lead Time |

Evaluate the supplier’s delivery speed. | Shorter lead times reduce project delays and downtime. |

| Pricing |

Compare costs while considering quality and value. | Helps in balancing budget constraints with performance requirements. |

| Customization Capability |

Check if they can provide custom sizes, shapes, or processing. | Customized products can improve efficiency and reduce waste. |

| Technical Support |

Availability of engineering and material selection assistance. | Expert advice can help in choosing the right iron for your needs. |

| Reputation |

Research customer reviews, testimonials, and case studies. | A strong track record indicates reliability and trustworthiness. |

| After-Sales Service |

Availability of warranty, returns, and issue resolution. | Good after-sales support ensures long-term partnership success. |

Here’s a clear table comparing pure iron and iron alloys:

| Aspect |

Pure Iron |

Iron Alloys |

| Definition |

Iron in its nearly elemental form, usually 99.9% Fe, with minimal impurities. | Mixtures of iron with other elements (carbon, chromium, nickel, etc.) to improve properties. |

| Composition |

Almost entirely iron, with very low carbon content (≤0.008%). | Contains iron as the base metal plus alloying elements in varying proportions. |

| Strength |

Relatively soft and not as strong as alloys. | Typically stronger and more durable due to alloying. |

| Corrosion Resistance |

Poor—rusts easily when exposed to moisture and oxygen. | Improved corrosion resistance depending on alloying elements (e.g., stainless steel with chromium). |

| Workability |

Very malleable and ductile, easy to shape. | Workability varies—some alloys remain easy to shape, others are harder to process. |

| Magnetic Properties |

Strongly magnetic. | Magnetic properties vary; some alloys remain magnetic, others become non-magnetic. |

| Melting Point |

~1538 °C (2800 °F). | Varies depending on alloy composition—often slightly lower than pure iron. |

| Common Uses |

Laboratory research, electromagnetic applications, decorative purposes. | Construction, automotive, shipbuilding, machinery, tools, and consumer goods. |

Here’s the "Ductile Iron vs. Gray Cast Iron: Key Differences" content in table format:

| Aspect |

Ductile Iron |

Gray Cast Iron |

| Microstructure |

Contains graphite in spherical (nodular) form, which enhances toughness and reduces stress concentration. | Contains graphite in flake form, which increases brittleness and reduces tensile strength. |

| Mechanical Properties |

High tensile strength (400–700 MPa), excellent impact resistance, and good elongation (up to 18%). | Lower tensile strength (150–300 MPa), poor impact resistance, and very low elongation (<1%). |

| Machinability |

Good machinability, though slightly less than gray cast iron due to higher strength. | Excellent machinability because of its softer and more brittle structure. |

| Thermal Conductivity |

Moderate thermal conductivity; better for parts requiring strength over heat dissipation. | High thermal conductivity, making it ideal for heat dissipation applications like engine blocks and brake rotors. |

Ductile iron has spherical graphite particles that give it high tensile strength, excellent impact resistance, and good ductility, making it ideal for high-stress applications. Gray cast iron contains flake graphite, which improves machinability and thermal conductivity but reduces strength and impact resistance. Ductile iron is stronger and tougher, while gray cast iron is easier to machine and better at dissipating heat.

Iron is a widely used metal known for its strength and versatility, but it is prone to corrosion when exposed to moisture and oxygen. Corrosion weakens the metal, shortens its service life, and can lead to costly repairs or replacements. Understanding the causes of iron corrosion and effective protection methods is crucial for ensuring durability and performance.

What Causes Iron Corrosion?

Iron corrosion occurs primarily due to a chemical reaction between iron, oxygen, and water, forming iron oxide (rust). Factors that accelerate corrosion include high humidity, salt exposure (especially in marine environments), industrial pollutants, and acidic conditions. Once rust forms, it can flake off and expose fresh metal underneath, causing the corrosion process to continue.

Key factors that accelerate corrosion include:

How to Protect Iron from Corrosion and Rust?

Several methods can prevent or slow iron corrosion:

By applying these methods, iron can be preserved for decades, even in harsh environments.

VMT provides high-precision CNC machining services for iron components across various industries, ensuring consistent quality, strict tolerances, and reliable performance. Utilizing advanced CNC milling, turning, drilling, and grinding equipment, VMT can machine custom parts from pure iron, ductile iron, gray cast iron, and iron alloys to meet diverse functional requirements—guaranteeing precision, durability, and cost-effectiveness for your projects.

Our Capabilities

Industries Served by Our Iron CNC Machining Services

Why Choose VMT for Iron CNC Machining?

If you’re looking for a trusted CNC machining factory for iron parts,VMT ensures every iron CNC machined part meets the strictest industry requirements, offering long-term durability and cost-effectiveness for your projects.

Iron remains one of the most important and versatile materials in modern industry, with applications spanning construction, manufacturing, transportation, infrastructure, energy generation, and countless other sectors. Whether in its pure form or as part of an alloy, iron offers a unique balance of strength, durability, and cost-effectiveness that makes it indispensable for CNC machining and custom part production.

However, choosing the right type of iron—be it pure iron, ductile iron, or gray cast iron—depends heavily on your project’s specific mechanical, thermal, and corrosion-resistance requirements. Partnering with a reliable CNC machining service provider, like VMT, ensures that your iron components are manufactured to the highest precision, with optimized performance, consistent quality, and tailored surface protection against corrosion.

In a world of evolving manufacturing needs, the right material and machining expertise can mean the difference between average results and exceptional performance. Iron, when processed with precision CNC technology, continues to power industries forward.

Is Iron a Metal?

Yes. Iron is a metallic element (Fe) and one of the most abundant metals on Earth. It is known for its strength, magnetic properties, and ability to form alloys like steel.

Can Iron Be Used in Metal Gaskets?

Yes, but it’s not common for pure iron to be used. Most metal gaskets use stainless steel, copper, or nickel alloys due to their corrosion resistance and sealing performance. Iron may be used in specialized applications where high strength is required and corrosion is not a concern.

What is the Difference Between Iron and Steel?

Iron is a pure chemical element, while steel is an alloy made primarily of iron with carbon and other elements added to improve strength, hardness, and durability.

Which Type of Iron is the Strongest?

Among commonly used types, wrought iron is strong in tension, but ductile iron is generally stronger and tougher for modern engineering applications.

What are the Three Types of Iron?

The main categories are wrought iron, cast iron (including gray and white cast iron), and steel (iron-carbon alloy).

What is the Difference Between a 4-Iron and a 5-Iron?

This refers to golf clubs, not metallurgy. A 4-iron has a longer shaft and lower loft angle, making it hit the ball farther but lower, while a 5-iron has a shorter shaft and higher loft, producing a higher ball flight with slightly less distance.

What is the Rarest Type of Iron?

Meteoric iron—iron that comes from meteorites—is extremely rare and contains high nickel content.

What are the Differences Between Different Types of Iron?

Differences lie in carbon content, microstructure, mechanical properties, corrosion resistance, and workability. For example, wrought iron is malleable, ductile iron is tough, and gray cast iron is brittle but excellent at vibration damping.

Which is Better, Pig Iron or Cast Iron?

Neither is “better” outright; pig iron is an intermediate product high in carbon, used to make steel and cast iron. Cast iron is the finished material, with useful hardness and wear resistance for applications like engine blocks and cookware.

Which Type of Iron Has the Highest Carbon Content?

Pig iron contains the highest carbon content—around 3.5–4.5%—making it very hard but brittle.

How Can You Tell the Difference Between Wrought Iron and Cast Iron?