15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

139 |

Published by VMT at Apr 20 2022

139 |

Published by VMT at Apr 20 2022

CNC machining machines make the machining process very easy and trouble-free. These CNC machining tools enable the machining process to perform a series of cuts and kerfs on the workpiece, transforming it into a custom CNC machined part.

They are many different types of CNC machining tools, from milling to turning and drilling, compatible with their respective CNC machining processes. All of these tools also have their general purpose and limitations. But CNC milling machines are the most used. Because these milling cutters provide a huge convenience to the automated process by allowing the tools on them to be changed automatically.

If you are interested in learning CNC machining, it is very important for you to know these CNC machining tools. It doesn't matter if you are an expert or a novice, you must master the capabilities and limitations of each tool.

In this article, the most widely used types of milling cutters, the materials used in CNC machining, and expert guidance on selecting the right CNC machine will be discussed. Read on if you're interested in learning about milling machines.

The Most Widely Used Type of Milling Cutter

The equipment used to remove workpiece material during CNC machining is called CNC machining machine. Cutting tools are placed on the spindle of a CNC machine and are guided by computer-controlled instructions to perform the intended task.

The shear deformation process is used to remove material from the workpiece. During this process, the high-speed rotating tool interacts with the workpiece, causing many CNC machined parts to be removed.

There are many different types of knives, each with their own unique capabilities, characteristics and limitations. Which tool to use depends on your requirements, and choosing the right tool depends on your expertise. Below we discuss the most widely used types of milling cutters.

1. End Mills

End mills are one of the most widely used CNC machining tools. It also contains sharp teeth and flanks at one end. End mills differ from drills in function, application and shape. Most CNC milling drills are capable of cutting radially, but drills can cut axially.

This milling cutter is available in a variety of shapes. For example some have only one flute, but some can have eight flutes.

Different types of end mills are given below

Flat End Mills

These are general purpose face mills and are well versed in 2D cutting.

Ball Nose End Mill

These are cutting tools with spherical ends, ideal for 3D contours and curves.

Bull Nose End Mill

These tools have flat bottoms and rounded corners for filleting and roughing.

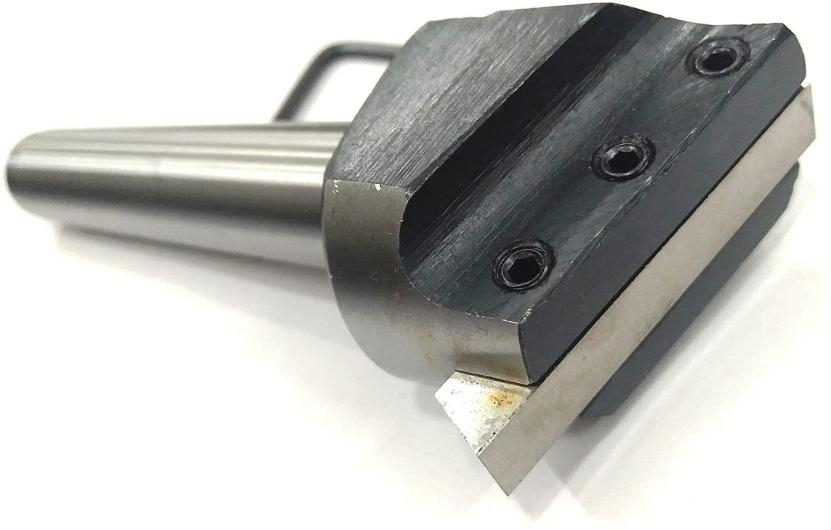

2. Face Mills

Face mills have a very unique body that offers replaceable tool inserts, usually made of carbide. These tools are mainly used for milling a face on the workpiece surface. Since the cutting edge of this type of milling cutter is located on the side of the tool, it can only cut in the horizontal direction.

The cutting insert changing facility makes these tools one of the most widely used CNC machining cutting tools, cost-effective compared to others, increasing their service life and productivity.

3. Roughing End Mills

These end mills are used to remove large quantities of material from workpieces very quickly during heavier operations.

These knives have serrated teeth that help remove huge debris with little vibration but leave a rough finish.

4. Slab Mills

These cutting tools are used for milling planes. Slab mills do not have any side teeth, which are helpful for general or heavy duty operations.

5. Involute Gear Cutter

These CNC machines are used to manufacture metal gears that provide useful functions in manufacturing. These milling cutters are also used to manufacture special milling machines called gear hobbing machines.

6. Fly Cutters

Flying knives have a solid body on which one or two tool bits can be mounted. These tools help create wide, shallow cuts in the workpiece. These cutters are relatively inexpensive compared to other milling cutters. Double-head flying knives are also known as double-ended flying knives or flying rods.

7. Ball Cutters

These milling cutters are used to create fillet radii on the vertical face of the workpiece. These are special CNC machining tools that are easily identifiable due to their hemispherical cutting tips.

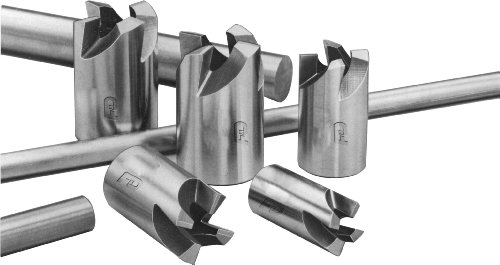

8. Hollow Mill

These tools are tubular and look like inverted end mills. Hollow cutters have cutting edges inside the tube and are used to create shapes such as dots and shape radii.

9. Woodruff Cutters

Half-circle cutters, also known as key seat cutters, are milling cutters used to cut keyways into parts such as shafts. To produce grooves suitable for semi-circular keys, the teeth of these cutting tools are perpendicular to the outside diameter.

10. Side-and-Face Cutters

These knives have teeth on both sides and on the circumference for making grooves and grooves. Due to the development of technology, many tools can be used to produce grooves and grooves of better quality and durability. Therefore, their use has decreased over time.

Materials Used to Manufacture CNC Machine Tools

Different types of materials are used to manufacture CNC machines. The material determines the CNC machining process using the tool and the desired functionality. We discuss the following important types of materials used in CNC machining tool manufacturing.

Carbon Steel

Carbon steel is a special kind of steel. As the name suggests, it contains a higher percentage of carbon than other kinds of steel. 0.05% to 0.3% is the percentage of carbon found in most types of steel, but carbon steels have higher carbon content, up to 2.5%.

This material is cheaper and less durable. Therefore, it is recommended for low-speed operations such as cornering. Because it has a melting point of 200oC, carbon steel tends to degrade faster if used in high-speed operations. Due to its low melting point, it can be used to cut relatively soft materials such as plastics.

High Speed Steel

High Speed Steel (HSS) is a steel alloy that typically contains 18% tungsten, 4% chromium, 1% vanadium and only 0.5-0.8% carbon. It has high hardness, high wear resistance and high heat resistance.

It is recommended for tools that perform higher speed milling operations and can withstand higher operating temperatures. Harder materials like steel or aluminum can also be cut with it.

Cemented Carbides

Carbide is a hard material that is widely used in the manufacture of tools with high quality surface finishes. It consists of fine particles of carbide that are bonded into a composite material by a binder metal. This material is harder than high-speed steel (HSS), but not tougher than HSS. Therefore, these can be used for higher temperature operations and still withstand their hardness.

This material is recommended for tools with a high-quality surface finish due to its higher tendency to crack.

Milling Tool Selection Skills

Here are some tips for milling cutter selection. These tips will help you choose the right CNC machining tool, which is extremely important for a successful machining process.

Tool Material

Above we discussed some of the types of materials used in the manufacture of CNC machining tools. If you want to make the best tool choice then you have to look, what task do you want your CNC machining tool to perform for you? After that, choose the right material for the task, and thus the tool.

For example, if you want a tool for higher speed milling operations, choose a tool made from HSS. But keep in mind that the chosen tool must do what you need.

Tool Coating

In order to perform better machining actions, tool coating is very important. If you want your CNC machining tools to work longer, use a coating such as titanium nitride. Titanium nitride is used to increase the life of CNC machining tools, but the cost also increases. If you want your CNC machining tools to have surface lubricity and hardness, use titanium carbonitride (TiCN).

Number of Slots

The grooves are helical grooves that run down the outside of the tool. The number of pockets is proportional to the feed rate of the milling cutter. As the feed rate increases, the number of grooves will get better and vice versa. But the flutes are carefully selected on request.

VMT is one of the leading CNC machining manufacturers in China. We have advanced CNC machining machines and various tools. We guarantee the accuracy and durability of CNC machined parts. Our team of engineers and technicians have more than 10 years of experience. Just contact us. We can greatly reduce CNC machining costs while ensuring quality. We are an ISO9001 certified, 16949 certified, SGS on-site factory audited CNC workshop.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!