15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

123 |

Published by VMT at Aug 15 2022

123 |

Published by VMT at Aug 15 2022

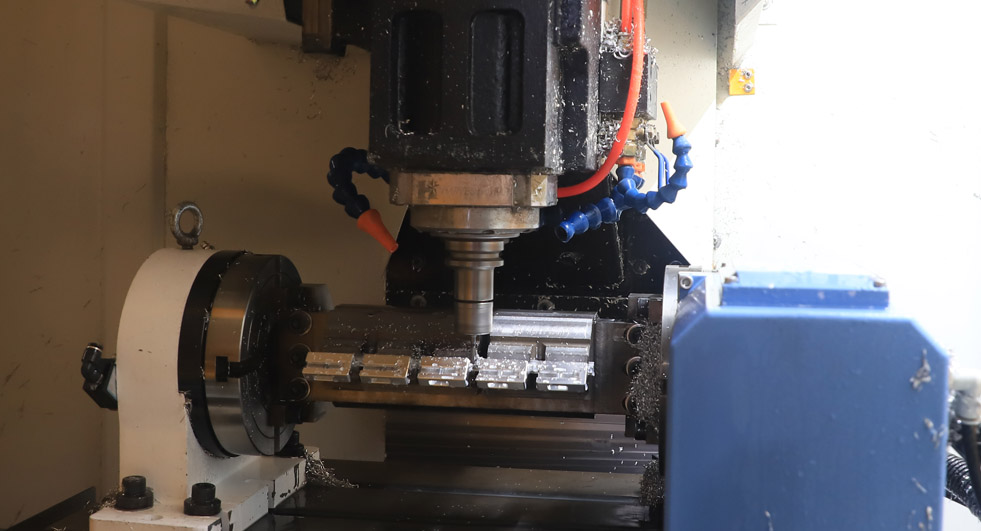

We all know that after the completion of the new product design, enterprises will choose to make a prototype first to see the effect, mainly to test whether the design of the product meets the requirements for use. The main materials for CNC metal prototyping are: aluminum, aluminum alloy, stainless steel, red copper, brass, steel, etc. Among them, aluminum is widely used in prototyping. Then let's talk about the advantages and processes of aluminum CNC prototype machining.

Advantages of aluminum CNC prototype machining

1. aluminum CNC prototype machining parts not only have the characteristics of light weight and good strength, but also have a better appearance after oxidation treatment.

2. Aluminum has low density but high strength. It is close to or exceeds high-quality steel. It has good plasticity and can be processed into various profiles by CNC. It has excellent electrical conductivity, thermal conductivity and corrosion resistance. It is widely used in industry, and its usage is second only to steel.

3. The aluminum CNC prototype machining parts can very accurately reflect the information expressed by the drawings, and the surface quality of the CNC prototype is high, especially after the surface spraying and silk screen printing are completed, even the products produced after opening the mold are even more radiant.

Aluminum CNC prototype machining Process

1. Programming: Write CNC machining programs according to the 3D drawings provided by customers.

2. CNC machining: CNC machining is carried out through CNC machining equipment according to the program written by the programmer, and the material is made into the prototype of the product.

3. Grinding: The hand board that has just been CNC machined on the machine will have many knife marks and skin edges on the surface, which needs to be polished with sandpaper.

4. Sandblasting: The effect of spraying a layer of sand on the surface of the prototype makes the samples of aluminum CNC prototype machining parts look more high-end and perfect.

5. Oxidation: Oxidation occurs on the surface of the parts processed by the aluminum CNC prototype to form a layer of film, so that the product is not easy to scratch.

6. Quality inspection: The aluminum CNC prototype machining parts can be packaged and shipped after being inspected by the QC department without any problems.

Surface treatment process of aluminum CNC prototype machining

1. During the proofing process of aluminum CNC prototype parts, the programmer first needs to write programs according to the drawings, and remove the remaining parts of the data through machine CNC machining to obtain the prototype of the prototype. The processing traces (knife marks and lines) of the aluminum CNC prototype processed by CNC on the machine are polished with sandpaper to make the appearance of the prototype smooth and smooth.

2. When the aluminum CNC prototype parts are sandblasted, the surface of the prototype is sprayed with a layer of sand, which makes the prototype sample look more textured. Then, the oxidation reaction of the aluminum CNC prototype machining parts will form a layer of film to make it not easy to scratch, so that the prototype has high protection and observability.

The above is an introduction to the related matters of aluminum CNC prototype machining, I hope it will be helpful to everyone. Most enterprises will choose CNC prototyping in the selection of prototyping. As a kind of CNC prototyping, aluminum CNC prototyping has many advantages of CNC prototyping, plus the advantages of aluminum itself, it is a very good choice.

VMT is mainly engaged in custom precision aluminum CNC machining parts, metal and plastic prototype machining, and its business covers 62 countries around the world, covering military, medical, semiconductor, automotive and other fields. 40+ materials and 15+ surface finish options with free service design, project reviews and DFM analysis. To ensure the quality of parts, we passed the ISO9001 quality system and SGS on-site factory audit in 2015. No matter how complex your part structure is, or your product encounters technical problems, we can provide you with professional service! Save 15% of time cost and communication cost for you!

If you want to know more about aluminum CNC prototype machining, you can click this link to view: https://www.machining-custom.com/ or contact us: inquiry@vimetal.com.cn.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!