15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

951 |

Published by VMT at Aug 16 2022

951 |

Published by VMT at Aug 16 2022

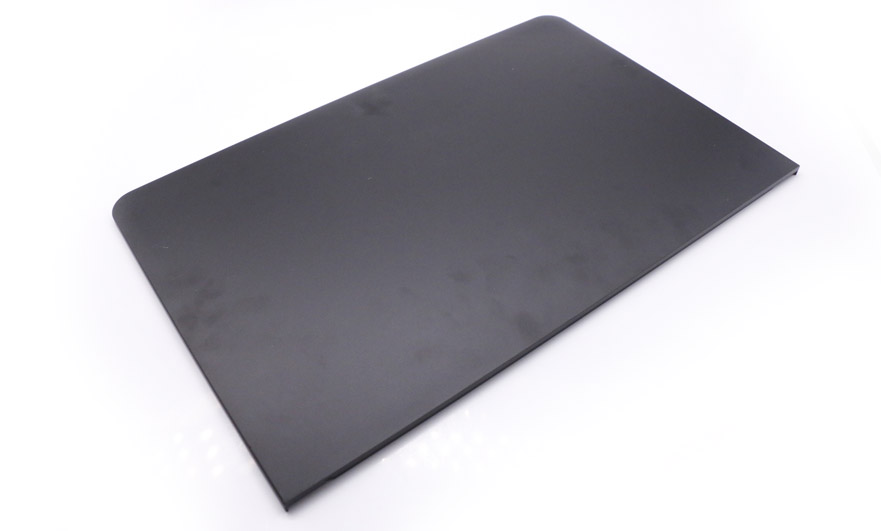

In CNC machining parts, we will encounter some thorny problems such as product deformation or flatness out of tolerance.

The problems affecting the flatness of CNC machined parts are summarized as follows:

1. First of all, we must ensure that the flatness of the incoming material is small and deformed (usually smaller than the customer's drawing requirements)

2. For those with high requirements on flatness, choose a machine tool with good precision during CNC machining. The accuracy of CNC machining equipment is at least 1-2 grades higher than the accuracy of the workpiece to be processed. Otherwise, necessary measures must be taken to make up or repair. It is difficult for low-grade machine tools to process high-precision CNC machining parts.

3. A good CNC machining process is beneficial to reduce the deformation of CNC machined parts, so as to eliminate workpiece deformation due to thermal stress, mechanical stress, and structural changes of aluminum cnc machined parts after machining, which affects the flatness after CNC machining. So as to meet the customer's drawing requirements (such as: clamping method, cutting amount, spindle speed, feed, rough aging, etc.)

4. Then there is the influence of CNC machining parts clamping on CNC machining. No matter how simple the workpiece is, even if it is a flat plate to process a large surface, your unreasonable clamping will result in poor flatness.

5. Finally, the selection of CNC machining form, the selection of tools and the reasonable allocation of cutting amount.

As for which factor is important and which reason has a great influence, it depends on the comprehensive analysis of CNC machining parts material, structure, requirements, CNC machining allowance, machine tool equipment type, precision, tool form, material and many other elements.

6. For material stress release, secondary failure treatment can be used, or T651 failure materials can be purchased.

Points to note to ensure the flatness of CNC machined parts:

When the rough-milled workpiece is placed on the processing platform, first use a 0.02 feeler gauge to check the gap between the bottom plane of the workpiece and the platform. If it is too large, use a feeler gauge to level it, and use a dial indicator to detect when the pressure plate is tightened. , try to control the pointer swing within 0.02.

Milling each plane to leave a margin of about 0.2. The precision milling plane uses the tooling to block at least 6 points on the front, back, left and right of the workpiece to ensure that the workpiece will not move left and right during processing. Do not use the pressure plate to press the plane, and finish milling each plane in a natural state.

Generally, the flatness can be controlled, and the parallelism is about 0.03. (The premise is that the machine tool is accurate, the tool is good enough, and of course it is not suitable for CNC machining of workpieces that are too small or too light).

The above is the summary of VMT on the problems affecting the flatness of CNC machined parts. Everyone's experience is different, and the method is different. If you have a better way, you can contact us to discuss with us.

VMT is mainly engaged in custom precision CNC machining parts, metal and plastic prototype processing. Its business covers 62 countries around the world, covering military, medical, semiconductor, automotive and other fields. 40+ materials and 15+ surface finish options with free service design, project reviews and DFM analysis. To ensure the quality of parts, we passed the ISO9001 quality system and SGS on-site factory audit in 2015. No matter how complex your part structure is, or your product encounters technical problems, we can provide you with professional service! Save 15% of time cost and communication cost for you!

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!