15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

120 |

Published by VMT at Jul 12 2022

120 |

Published by VMT at Jul 12 2022

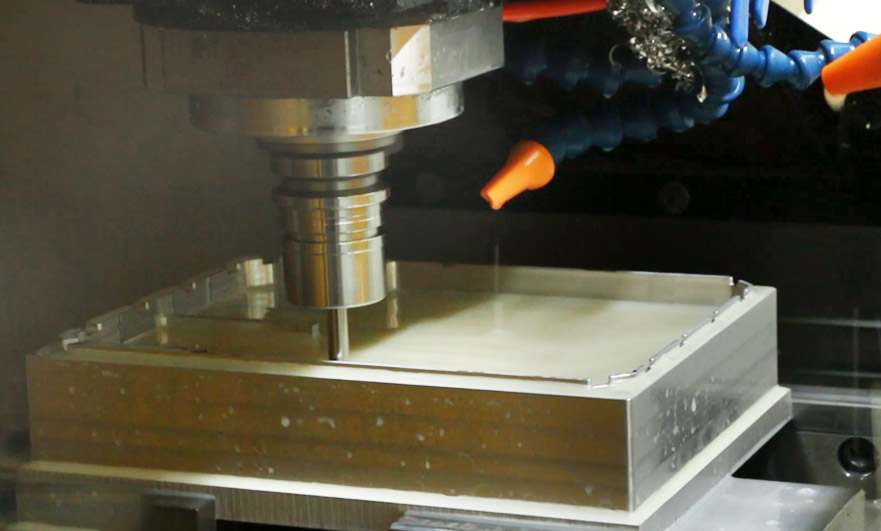

The aluminum part machining process can separate roughing and finishing. After rough machining, the parts are heat treated to fully release the cutting stress and residual heat, and then finish machining, which will greatly improve the machining quality of aluminum parts.

Carrying out roughing and finishing has the following advantages:

(1) It can reduce the influence of residual heat on the processing deformation of aluminum parts. After rough machining, it is recommended to eliminate the stress caused by rough machining by heat treatment to reduce the influence of stress on the quality of finishing.

(2) Improve the CNC machining accuracy and surface quality of aluminum parts. After the roughing and finishing are separated, the finishing allowance is small, and the processing stress and deformation are small, which can greatly improve the machining quality of aluminum parts.

(3) Improve production efficiency because roughing is only to remove excess material and leave enough allowance for finishing, but more consideration should be given to dimensions and tolerances to effectively exert the performance of different types of machine tools and improve cutting efficiency.

After the aluminum parts machined, the metal structure of the machining table changes greatly. In addition, the effect of cutting motion can cause residual heat. In order to reduce the deformation of aluminum parts, the residual stress of the material must be released.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!