15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

164 |

Published by VMT at May 13 2022

164 |

Published by VMT at May 13 2022

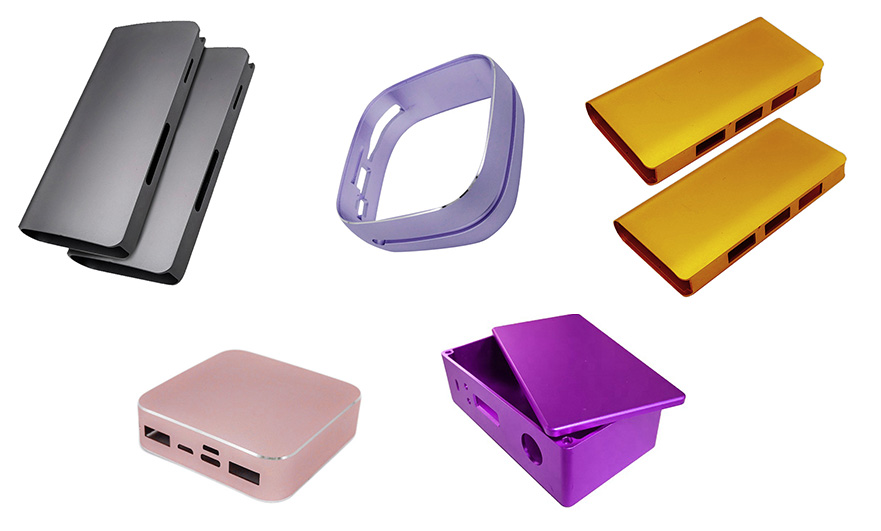

With the increasing application scope of CNC machining parts for aluminum housings, its CNC machining quality and CNC machining efficiency have become increasingly concerned topics for CNC machining manufacturers.

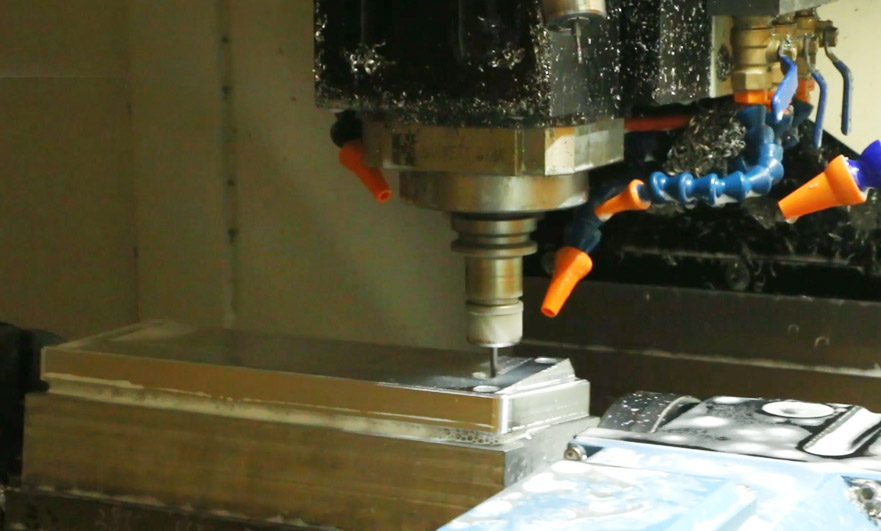

In order to ensure the quality and efficiency of CNC machining, it is necessary to study the process of CNC machining parts of aluminum housing, and put forward the determination principles, selection points and methods of CNC machining process design in the process of CNC machining, so as to ensure the quality of CNC machining and improve productivity.

The aluminum housing parts have an important influence on the performance of the equipment. They all have complex shapes, inner cavities, strict dimensional tolerances and shape and position tolerances, thin walls and uneven wall thicknesses, and are easily deformed. With the development of material science and the advancement of CNC machining technology, the requirements for CNC machining of aluminum housing parts are getting higher and higher. To improve product quality and shorten production cycle, CNC equipment must be used for comprehensive processing, and the optimized CNC machining must be determined. process plan.

The CNC machining process of aluminum housing parts is usually: aluminum housing CNC machining parts drawing → analysis of drawings to determine CNC machining process → writing process specification → determining CNC machining process → numerical calculation → writing program list → mechanical CAD → mechanical CAM → program verification → Prepare control medium → Trial cutting of the first piece → Adjust program and machine tool → Batch processing → Finished product.

In the process of CNC machining of aluminum housing parts, the determination of the division process and the processing route is directly related to the use efficiency of CNC machine tools, CNC machining accuracy, number of tools and economy. pause time and auxiliary time.

During rough machining of aluminum housing parts, the metal layer to be removed is thicker, the cutting force and clamping force are relatively large, and the cutting temperature is relatively high, which will cause large deformation. According to the processing stage, the CNC machining error caused by rough machining can be corrected by semi-finishing and finishing, so as to ensure the quality of CNC machined parts. At the same time, the rational use of equipment can not only improve productivity, but also prolong the service life of precision equipment.

Heat treatment can improve the mechanical properties of materials, improve the performance of metal CNC machining and eliminate internal stress. The heat treatment process of the saddle bracket is arranged to perform high temperature aging and low temperature aging after rough turning and CNC milling to remove the allowance. The main purpose is to eliminate the internal stress generated by the material after CNC machining.

In order to improve the corrosion resistance, wear resistance, high temperature resistance and electrical conductivity of CNC machined parts of aluminum housings, surface treatment methods are generally used. For the surface with high precision requirements, the dimensional accuracy will be affected after surface treatment. Generally, the finishing process is carried out after the surface treatment to ensure the dimensional accuracy and surface roughness of the CNC machined parts of the aluminum housing.

Before and after the CNC machining process are generally interspersed with other ordinary CNC machining processes, if the connection is not good, it is easy to cause conflicts. Therefore, while familiar with the content of the entire CNC machining process, it is necessary to know the respective technical requirements, CNC machining purposes and machining characteristics of the CNC machining process and the ordinary CNC machining process, such as whether to leave the CNC machining allowance and how much; Accuracy requirements and geometric tolerances; technical requirements for the shape calibration process; heat treatment status of the blank, etc., so that each process can meet the needs of CNC machining of aluminum housings, and the quality objectives and technical requirements are clear, and there is a basis for handover and acceptance.

As far as the CNC machining and manufacturing process of the aluminum housing is concerned, the product quality mainly depends on the manufacturing quality and assembly quality of the CNC machining parts of the aluminum housing. The manufacturing quality of CNC machined parts of aluminum housing is generally determined by geometric parameters (such as shape, size, surface roughness), physical parameters (such as electrical conductivity, magnetic permeability, thermal conductivity, etc.), mechanical parameters (such as strength, hardness, etc.) and chemical parameters (such as corrosion resistance, etc.).

The main factors affecting the CNC machining accuracy of the machine tool are the rotation accuracy of the spindle, the linear motion accuracy of the moving parts and the relative relationship of the forming motion. The rotation accuracy of the spindle is usually reflected in the radial runout, axial play and angular swing of the spindle, which largely determines the shape accuracy of the machined surface.

According to the heat treatment state, cutting performance and machining allowance of the workpiece material to be processed, choosing a milling cutter with good rigidity and high durability is the precondition to give full play to the production efficiency of the CNC milling machine and obtain satisfactory CNC machining quality of the aluminum housing. The selection of the CNC machining route should mainly consider: shortening the tool path as much as possible, reducing the idle tool travel, and improving the productivity; ensuring the accuracy and surface roughness of the CNC machining parts of the aluminum housing; it is beneficial to simplify the numerical calculation and reduce the number of program segments. and programming workload; the specific value of the cutting amount should be determined according to the provisions of the CNC machine tool instruction manual, the material of the workpiece to be processed, the processing procedure and other process requirements, and combined with actual experience.

The CNC machining parts of the aluminum housing occupy a very important position in the machining manufacturing industry. In order to improve the CNC machining accuracy and production efficiency of the aluminum housing, advanced processing methods should be adopted. For CNC machining technology, process processing is an important part of its application. It is related to the correctness and rationality of the processed parts. Pay attention to the design of the process rules of CNC machining, and choose reasonable and efficient CNC machining methods and processing routes. It is of great significance to ensure the quality of CNC machined parts of aluminum housing and improve the use efficiency and processing quality of CNC machine tools.

VMT is a factory focusing on CNC machining parts for aluminum housings. It has accumulated rich experience in CNC machining parts for aluminum housings for 12 years. The high-standard and high-quality CNC machining parts service provided by the aluminum housing has been well received by customers.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!