15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

152 |

Published by VMT at Dec 29 2021

152 |

Published by VMT at Dec 29 2021

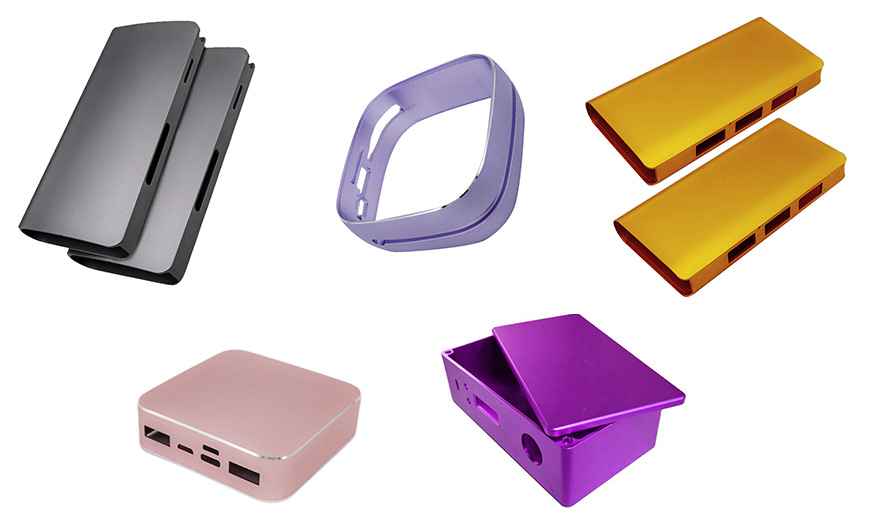

Sandblasting is an important process in the surface treatment of aluminum alloy shells for CNC machining of mobile power supplies. VMT CNC machining service manufacturer has focused on aluminum shell processing for 11 years, and has accumulated rich experience in surface treatment of CNC machining aluminum alloy shells. Here, I will tell you about the issues that need to be paid attention to when sandblasting CNC machining aluminum alloy shells.

What is sandblasting?

Sandblasting, also known as sandblasting or abrasive blasting, is a process that uses high pressure to push solid particles across the surface of an object at a high speed to change the surface roughness. The machine that completes the sandblasting operation is a sandblaster, which sprays a stream of abrasive material through a pressurized fluid such as a centrifugal wheel or compressed air, and pushes it to the area for processing. These materials can be sandblasted and include aluminum, brass, silver, wood, stone, glass and other metals.

How does sandblasting work?

The sandblasting system is mainly composed of air source, sandblasting cabinet, dust collector and blasting medium. The abrasive used for sandblasting is called blasting medium, which usually includes quartz sand, garnet, crushed nut shells or nuts, corn starch, wheat starch, sodium bicarbonate, dry ice, steel shot, steel grit, stainless steel shot, cutting wire, Copper shot, zinc shot, process by-products, etc. The air source is usually bottle gas or air compressor. The sandblasting cabinet is used to store the products to be sandblasted, and the dust collector removes the dust in the cabinet. How is sandblasting performed? The sand blasting process can be simplified as: open the door -> discharge blasting -> close the door -> turn on the power> wear gloves -> grab the explosion-proof gun, step on the pedal -> sandblasting -> nozzle sandblasting -> check whether the product is pressed Request blasting -> Do you need to repeat the blasting process -> Open the door -> Remove from the object

Sandblasting advantage

Sandblasting is an effective method to remove contaminants such as dirt, paint, rust, and oxidation residues on hard surfaces, as well as an effective method to improve the performance of CNC machined parts.

1. Quickly remove deposits and contaminants on different surfaces of CNC machined parts;

2. All kinds of CNC machining parts and materials can be sandblasted;

3. The surface texture of specific CNC machined parts can be obtained;

4. Prepare for bonding, bonding, insert molding, painting, etc.;

5. Eliminate burrs or edge contours on CNC machined parts

Here to tell everyone about the problems that need attention in the sandblasting of the aluminum alloy shell of the CNC machining of the mobile power supply:

1. Before sandblasting, the surface of the aluminum alloy shell of the CNC machined mobile power supply should be cleaned. The cleaning process is to remove the surface oil and dirt with sulfuric acid, and then neutralize it with alkali after pickling;

2. After pickling, dry or dry the aluminum alloy shell of the CNC machined mobile power supply to inspect the surface, mainly to check whether it is cleaned, whether there is a watermark, whether there is yellowing, etc.

3. Start sandblasting. Sandblasting is the process of roughening the surface of the aluminum alloy shell of the mobile power supply through the impact of high-speed sand flow. The type of sand used is generally 80#——320#, the larger the value, the smaller the sand. The roughness of the sand grains on the surface of the aluminum alloy shell of the CNC machined mobile power supply is determined by the sand grain model and the sandblasting pressure. Under the same pressure, the larger the sand grain value, the finer the surface; and the same sand grain model, the greater the pressure , The thicker the surface.

4. Sandblasting is divided into manual sandblasting and automatic sandblasting. Manual sandblasting efficiency is relatively slow, and sometimes the spray is uneven; automatic sandblasting efficiency is high, and the surface thickness of the aluminum alloy shell of the CNC machined mobile power supply is uniform.

5. Drying varnish: The entire baking process is: pretreatment-inspection-shadow-clean dust. Common coating defects of drying varnish are: foaming, pinholes, wrinkles, orange peel, color difference, bleeding, paint Lack, poor concealment, paint peeling, pitting, flow marks, germination, particles, sandpaper printing, scratches, paint spots, line pitting, etc.

6. Pulling: Pulling is a surface treatment method that moves the surface of the aluminum alloy shell of the CNC machined mobile power supply to form a linear surface treatment method, which has a decorative effect. The brushed aluminum alloy shell can better reflect the metal texture of the material.

7. Anodizing: Take the aluminum alloy shell of the CNC machined mobile power supply as the anode, and place it in the electrolyte for current treatment. The process of forming an aluminum oxide film on the surface of the aluminum alloy shell of the CNC machined mobile power supply is called anodization. Aluminum oxide film has good corrosion resistance and wear resistance, which can provide better protection for aluminum alloy casing. The entire working sequence of anodizing is: hanging-chemical degreasing-hot water cleaning-cleaning-sulfuric acid neutralization cleaning-chemical polishing-cleaning-light output-cleaning-anode cleaning-coloring-sealing-cleaning-drying-hanging inspection.

VMT CNC machining service manufacturer is a one-stop factory for drawing design, manufacturing, development, and production of precision CNC machining parts. Mainly develop and manufacture electronic products aluminum alloy shells, aluminum product drawing parts, digital products aluminum profile shells and other CNC machining parts.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!