15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

160 |

Published by VMT at Jun 29 2022

160 |

Published by VMT at Jun 29 2022

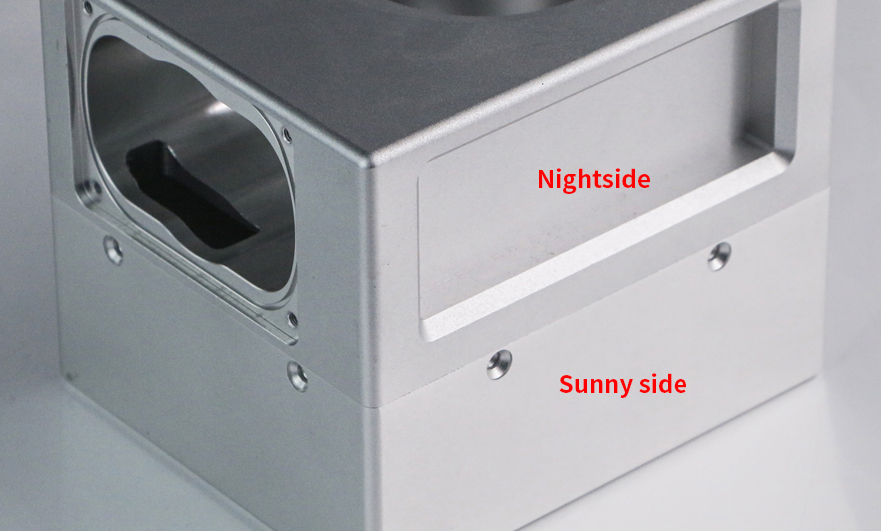

We often find that the appearance defect rate of CNC aluminum parts is very high, and the most direct reasons are:

1. Material line

2. Machining marks

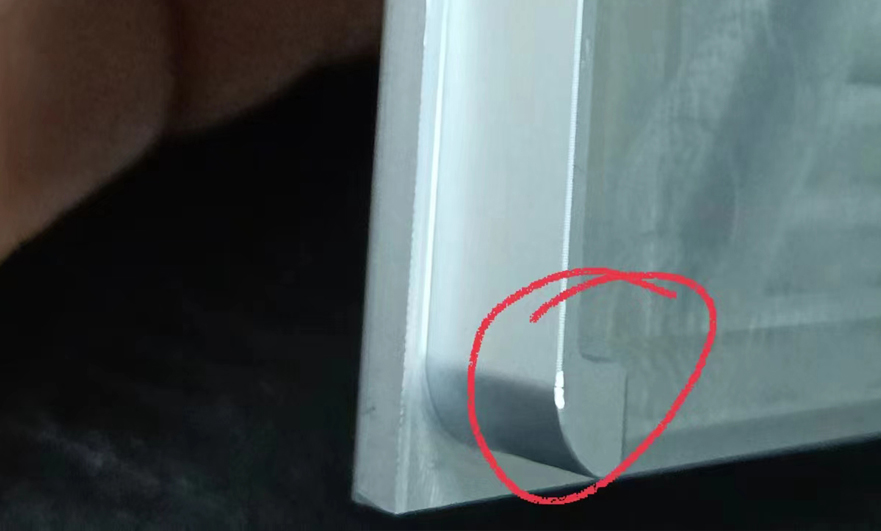

3. Scratches

4. Oxidized sand holes

5. Color difference

6. The size is out of tolerance

This kind of defect will affect the supplier's delivery time and cost seriously, so how do we control the yield in reality?

Here's my approach to these types of bad prevention:

1、Material line: For CNC aluminum parts with high appearance requirements, that is, the customer requires sandblasted to be more than 180 mesh, such parts are most likely to cause the defects due to raw material problems, which is mainly caused by the profile factory. Mainly caused by impure material, secondary material added, wrong extrusion die, extrusion method, and insufficient pressure of the extrusion machine, etc. As a professional CNC aluminum parts machining factory, we will test the material before mass production, and will verify and evaluate the defects in small batches. At the same time, it is also very important to find a professional supplier who has made similar profiles, so as to effectively prevent such defects.

2. Machining Marks: This situation is related to the processing method and the technician’s technology, especially the CNC aluminum parts where the curved surfaces are connected. The place where the knife is connected is a test of the technician’s experience. We directly learn from the knife path and the forming knife. Considering the problem, optimizing the process more reasonably can effectively reduce the occurrence of such defects.

3. Scratches: The clamping method and clamping tool directly affect this. The rationality of the clamping tool when we clamp and the convenience of employees when picking and placing are all factors to be considered, and the packaging method uses blister boxes or the way of pearl cotton is an effective countermeasure for effective prevention.

4. Oxidized Sand Holes: What we mainly found is the cleanliness of the packaging method to ensure that the CNC aluminum machined parts are washed with clean water to remove the oil on the surface. And we must pay attention to the number of times the packaging cotton is recycled. Special attention here is that the storage time in the oxidation factory should not exceed three days. , Because the acid and salt value of the environment is too high, the surface of the parts will be corroded for a long time and cause sanding holes to appear, and the other reasons are caused by the oxidation process.

5. This situation is the most complicated. There are many reasons for it. The pressure,method of sandblasting and the time of acid and alkali are very critical. We usually use Jiugongge to control the color and color system, as well as toner and color. There is a direct relationship between the color cylinder and the time of sealing. To control the parameters of these processes within a standard is the beginning of color management and the beginning of improving the yield rate.

6. The size is out of tolerance: For precision CNC aluminum parts, if you want to control the tolerance within the range of 0.01MM, this is also a very detailed control. The process of cleaning and degrease is very important. If it is not good, the surface will lead to water stains. If it is too acid or alkali, then the size must be out of tolerance, and the sandblasting pressure is also very important. After these two processes are well controlled, the size will not be out of tolerance. The control of professional CNC machined parts manufacturers for appearance parts is above, and make the above prevention will definitely help to improve the yield rate. Thank you!

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!