15 years one-stop China custom CNC machining parts factory

952 |

Published by VMT at Aug 12 2024

952 |

Published by VMT at Aug 12 2024

The brushed metal surface finishing process involves using mechanical or chemical methods to create fine and uniform textures on the metal surface, imparting a unique tactile and visual effect to the material. This article aims to provide a comprehensive introduction to the brushed surface process, including its definition, operation procedures, influencing factors, applicable materials, common types, comparisons with other surface finishings, areas of application, advantages and disadvantages, and techniques for achieving a uniform brushed finish. Finally, the article discusses VMT CNC machining parts surface finishing services and common FAQs.

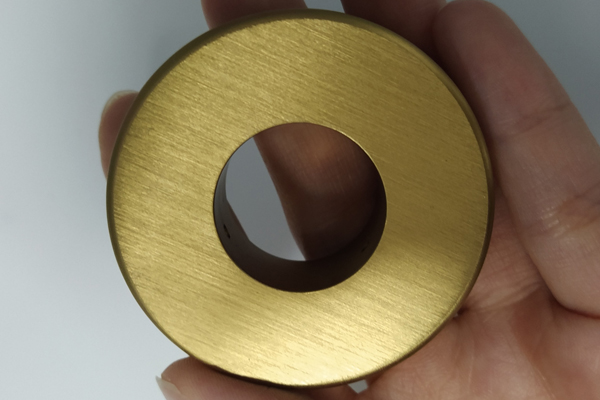

The brushed metal surface finishing process is a technique that uses external force to force metal through molds or brushes, creating fine, uniform linear textures on the metal surface. This process not only enhances the aesthetic appeal of the metal surface but also improves its durability and corrosion resistance. The brushing process is widely used in surface processing for metals such as stainless steel, aluminum, and brass, making it an important technique in modern metalworking.

Pre-Brushing Stage (Removing Contaminants)

Before brushing the metal surface, it is essential to thoroughly remove any dirt, grease, and oxides from the surface. This typically involves using solvents, pickling, or alkaline cleaning methods to ensure that the metal surface is clean and free of impurities, laying a solid foundation for the subsequent brushing process.

Brushing Stage

The brushing stage is the core of the process. Depending on the selected brush and process requirements, fine linear textures are evenly brushed onto the metal surface. This process requires strict control over factors such as the type and quality of the brush, wheel speed, brushing direction, and the skill level of the operator to ensure the desired brushed effect.

Post-Brushing Stage

After brushing, the metal surface needs to be cleaned and dried to remove any remaining brush debris and abrasives. Additionally, the brushed surface should be inspected for quality to ensure there are no scratches, dents, or other defects. If necessary, further polishing or coating may be performed to enhance the surface's appearance and durability.

Brush Type and Quality

The type and quality of the brush directly affect the brushed effect. Different types of brushes (e.g., wire brushes, electric brushes, carbon steel brushes) have different hardness and wear resistance, suitable for different metal processing materials. High-quality brushes can produce finer textures with fewer defects such as scratches or dents.

Wheel Speed

Wheel speed is another crucial factor affecting the brushed effect. The appropriate wheel speed ensures that the metal surface is evenly stressed under the brush, forming uniform linear textures. Excessive speed may increase surface roughness, while insufficient speed may fail to achieve the desired brushed effect.

Brushing Direction

The direction of brushing also plays a significant role in the brushed effect. Proper brushing direction ensures consistent and neatly arranged textures, enhancing the visual effect of the metal surface. In practice, the brushing direction should be selected according to the metal's shape and processing requirements.

Operator Skill

The skill level of the operator is also key to determining the quality of the brushing process. Experienced operators can more accurately control various parameters during the brushing process to ensure the desired brushed effect. Therefore, operator training and skill improvement are crucial in the brushing process.

Stainless Steel

Stainless steel is one of the most commonly used materials for brushed surface finishing. Its excellent corrosion resistance and aesthetic appeal make brushed stainless steel products widely used in architectural decoration, household appliances, and other fields. The brushed surface of stainless steel not only enhances the product's texture but also improves its fingerprint resistance and scratch resistance.

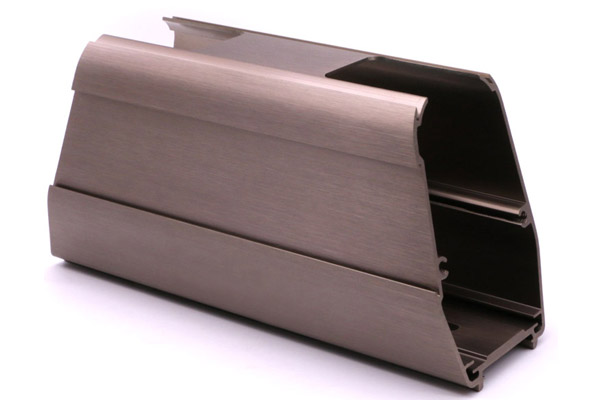

Aluminum

Aluminum is also an ideal choice for brushed surface finishing. Aluminum is lightweight, strong, and easy to process, making it suitable for manufacturing various parts requiring surface decoration. The brushed surface of aluminum has uniform linear textures and a good metallic feel, meeting consumer demands for high quality and fashion.

Brass, Copper, Steel, Titanium

In addition to stainless steel and aluminum, metals such as brass, copper, steel, and titanium are also suitable for brushed surface finishing. These materials can form unique textures and color effects during brushing, adding more design elements and visual impact to products.

Linear Brushing

Linear brushing is one of the most common brushing types. It is achieved by brushing linear textures on the metal surface along a specific direction. The linear brushed surface has a simple and clear appearance, enhancing the product's modern and technological feel.

Circular Brushing

Circular brushing involves creating textures on the metal surface along circular or arc-shaped trajectories. This type of brushing creates unique visual effects and tactile experiences, suitable for situations that emphasize the beauty of curves and gentle touch.

Wire Brushes

Wire brushes are one of the commonly used brush types in the brushing process. Made from high-strength steel wires, they are wear-resistant and durable. Wire brushes are suitable for brushing hard metals like stainless steel and aluminum, creating clear textures and uniform surface roughness.

Electric Brushes

Electric brushes use electric power to rotate the brush head, achieving efficient and uniform brushing results. Electric brushes are suitable for processing large or complex metal surfaces, significantly improving production efficiency and quality.

Carbon Steel Brushes

Carbon steel brushes, known for their hardness and wear resistance, play an important role in the brushing process. They are suitable for applications that require high surface finish and fine textures, such as precision instruments and high-end decorative items. Carbon steel brushes ensure uniform and fine linear textures on the metal surface during brushing, enhancing the overall quality of the product.

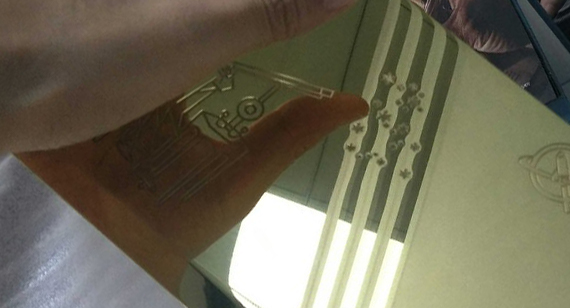

Variable Grit Abrasive Brushing

Variable grit abrasive brushing is an advanced brushing technique that uses a combination of abrasives with different grit sizes to achieve more complex and diverse surface textures. This technique allows adjustments to the grit size and distribution according to customer needs, creating unique visual effects on the metal surface and meeting personalized customization demands.

Wavy Wire Brushes

Wavy wire brushes have a special wavy shape, and their unique structure allows for the creation of distinctive wavy textures during brushing. These textures are not only aesthetically pleasing but can also increase friction and anti-slip properties on the metal surface, making them suitable for applications that require enhanced surface adhesion.

Bristle Brushes

Bristle brushes are favored for their soft bristles and gentle brushing effects. They are suitable for lightly processing metal surfaces or retaining some of the original texture. Bristle brushes can softly brush over the metal surface, forming gentle linear textures while avoiding excessive damage to the metal.

Brushed surfaces and mirror finishes differ significantly in visual effect. Mirror finishing aims for a smooth, reflective surface with high gloss, emphasizing reflectivity and shine; brushed surfaces, on the other hand, enhance the texture and depth of the metal through fine linear textures. Both have their own merits, suitable for different design styles and application scenarios.

Brushing vs. Sandblasting

Sandblasting involves high-pressure sand particles impacting the metal surface to create a rough, uniform matte finish. Compared to brushing, sandblasting focuses more on surface roughness and a matte texture, suitable for applications requiring enhanced anti-slip and fingerprint-resistant properties. Brushing, however, emphasizes the fineness of linear textures and aesthetics.

Brushing vs. Satin Finishing

Satin finishing creates soft, fine textures on the metal surface through mechanical or chemical means. Compared to brushing, satin finishing focuses more on overall surface uniformity and a gentle feel, with less distinct linear textures. Both offer unique visual effects, and the choice depends on specific needs.

Edge Blending

Brushed finishing excels in edge blending of metals. Through the brushing process, sharp edges can be smoothed, allowing them to transition more harmoniously with surrounding surfaces, enhancing the overall aesthetic appeal and safety of the product.

Deburring

Brushed finishing is also effective in removing burrs and small protrusions on the metal surface. Burrs are common issues in metal processing that affect product appearance and may negatively impact subsequent processing and use. Brushing can easily remove these burrs, making the metal surface smoother.

Texturing

In some applications, increasing the surface roughness of the metal is necessary to improve adhesion or anti-slip properties. Brushing can achieve varying degrees of texturing by adjusting factors like brush type, speed, and direction, meeting different usage needs.

Cleaning

Brushed finishing also has a cleaning function. During the brushing process, the friction from the brush can remove dirt, oxides, and other impurities from the metal surface, leaving the metal surface clean and shiny.

Advantages

Visual Effect: Brushed surfaces feature unique linear textures and a metallic feel, significantly enhancing product aesthetics and perceived quality.

Cost-Effective: Compared to other surface finishings, brushing is relatively low-cost and efficient, suitable for large-scale production.

Conceals Surface Defects: Brushed finishing can hide minor surface defects and scratches, improving the overall quality of the product.

Durable: Brushed surfaces have a certain level of wear resistance and corrosion resistance, extending the product's service life.

Easy to Clean: Brushed surfaces are resistant to fingerprints and dirt and are easy to clean and maintain.

Disadvantages:

Susceptibility to Corrosion: In certain environments, brushed surfaces might be more prone to corrosion.

Time-Consuming and Labor-Intensive: Applying brush finishing to complex shapes or large metal surfaces can be time-consuming and require significant labor.

Design Limitations: The texture and effect of brushed surfaces are limited by factors such as brush type, speed, and direction, which may not meet all design requirements.

Selecting the Right Brush: Choosing the appropriate brush based on metal material, surface requirements, and production efficiency is crucial. Different brushes have varying hardness and durability, suitable for different processing scenarios.

Maintaining Consistent Brushing Direction: Keeping a consistent brushing direction ensures the uniformity and consistency of the linear texture. Operators should strictly follow the process requirements and avoid changing the brushing direction arbitrarily.

Adjusting Speed and Pressure: Adjusting the speed and pressure of the brush according to the metal material and surface requirements is key to achieving a uniform brushed effect. Improper speed and pressure can lead to uneven texture and surface roughness.

Maintaining Stainless Steel Brushes for Optimal Performance: Stainless steel brushes are commonly used in brushing processes, and their performance directly affects the outcome. Regular maintenance is essential, including cleaning residue from the bristles, inspecting wear, and replacing brushes with significant wear. Additionally, keeping brushes dry to prevent rust is an important measure to extend their service life.

Surface Cleaning is Crucial: Ensuring thorough cleaning of the metal surface before brushing is indispensable. Any dirt, grease, or oxide can affect the brushing effect, resulting in unclear textures or uneven surface roughness. Appropriate cleaning methods, such as solvent cleaning, pickling, or alkaline cleaning, must be used to remove impurities from the metal surface completely.

Brushed surface processing, as an important metal surface finishing technique, plays a significant role in enhancing product aesthetics, durability, and added value. By selecting the right brush, controlling brushing direction, adjusting speed and pressure, and regularly maintaining brushes, a uniform brushed surface effect on custom-made parts can be achieved. Understanding the similarities and differences between brushing and other surface finishings, as well as its application on different materials, helps in better selection and application of this technique. With the continuous development of CNC machining technology, brushed surface processing will find broader applications in various fields, bringing more innovation and development opportunities to the metalworking industry.

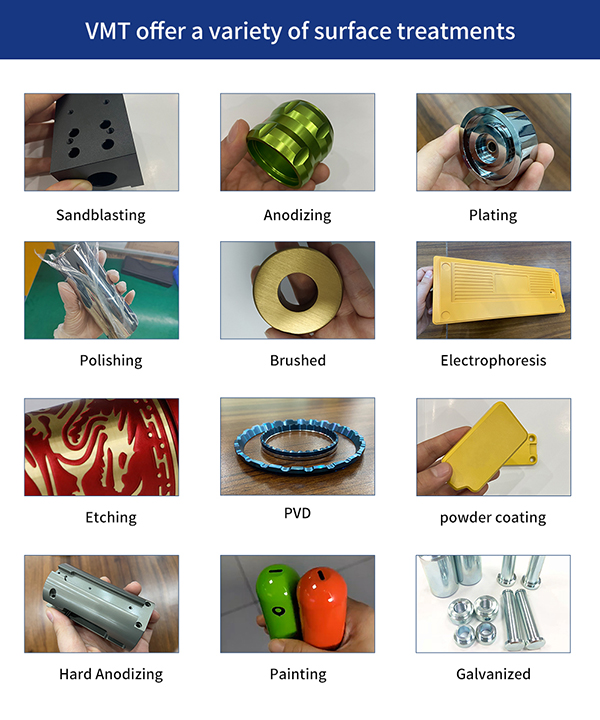

As a professional manufacturer of CNC machined parts, VMT offers a full range of surface finishing services, including brushed surface processing. Equipped with advanced CNC machining equipment and a professional technical team, we can customize various shapes and specifications of metal parts according to customer needs and perform precise brushing finishing. Our services focus not only on product quality and processing efficiency but also on communication and cooperation with customers, ensuring that every processing meets customer expectations and requirements. Choose VMT for high-quality, efficient, and personalized CNC machining part surface finishing services.

What is the brushed surface roughness?

The brushed surface roughness refers to the roughness and evenness of the metal surface after the brushing process. It reflects the delicacy and uniformity of the linear texture, which is one of the important indicators to measure the brushing effect.

Why is brushing technology important?

Brushing technology is important because it can give the metal surface a unique texture and visual effect, enhancing the aesthetics and perceived quality of the product. Additionally, brushing enhances the wear resistance, corrosion resistance, and anti-slip properties of the metal surface, improving the product's service life and safety.

How does brushing compare with other surface finishing methods?

Brushing has its own advantages and disadvantages compared to other surface finishings, depending on the application scenario and requirements. Compared to mirror finishes, brushed surfaces focus more on the delicacy and sense of hierarchy of the linear texture; compared to sandblasting, brushed surfaces are smoother and more delicate; while compared to satin finishes, brushed surfaces have a stronger visual effect and metallic texture.

What materials are suitable for brushed surface finishing?

Metals such as stainless steel, aluminum, brass, red copper, steel, and titanium are suitable for brushed surface finishing. These materials can form uniform linear textures and good metallic textures during the brushing process, meeting the design and manufacturing needs of different products.

Can brushing be applied to mass production?

Yes, the brushing process can be applied to mass production. With the development of CNC machining technology and the popularization of automated equipment, the brushing process has achieved efficient and precise processing and finishing, meeting the needs of large-scale production.

What is the difference between satin and brushed surfaces?

Satin and brushed surfaces have significant differences in their effects. Satin finishes focus on the overall uniformity and softness of the surface, with relatively blurred linear textures; while brushed surfaces emphasize the delicacy and clarity of the linear texture, creating a distinct linear effect and metallic texture.

What is brushed stainless steel?

Brushed stainless steel refers to stainless steel material that has undergone the brushing process. This material has a unique linear texture and metallic texture on the surface, which is not only aesthetically pleasing but also has good wear resistance, corrosion resistance, and anti-slip properties.

What is the best brushing method?

The best brushing method depends on the specific application scenario and requirements. Various factors such as metal material, surface requirements, and production efficiency will affect the choice of brushing methods. Therefore, when selecting a brushing method, it is necessary to consider various factors comprehensively and choose the most suitable process plan.