15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

210 |

Published by VMT at Jun 08 2022

210 |

Published by VMT at Jun 08 2022

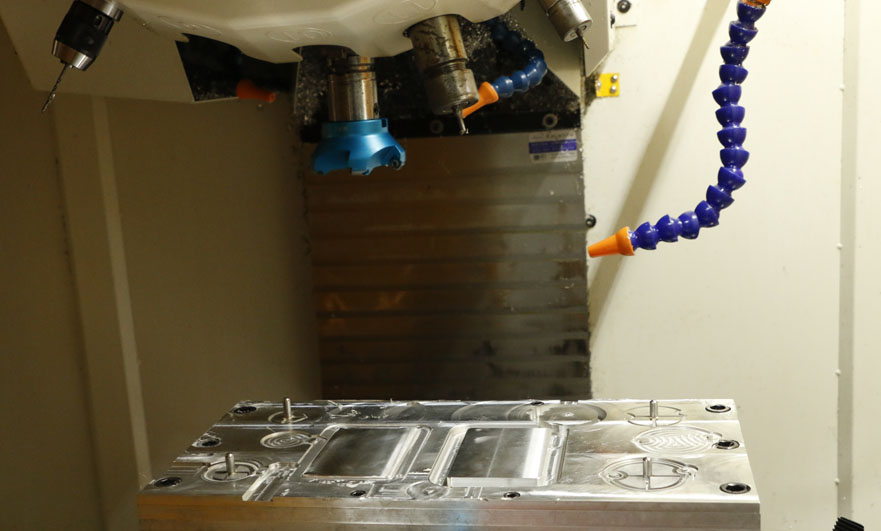

Basic principles of fixture design for CNC machining parts

1. Satisfy the stability and reliability of workpiece positioning during use;

2. There is enough bearing or clamping force to ensure the CNC machining process of the workpiece on the fixture;

3. Satisfy the simple and fast operation in the clamping process;

4. The vulnerable CNC machining parts must be of a structure that can be quickly replaced, and it is best not to use other tools when conditions are sufficient;

5. Satisfy the reliability of repeated positioning of the fixture during adjustment or replacement;

6. Avoid complex structure and high cost as much as possible;

7. Choose standard parts as far as possible as the component CNC machining parts;

8. Form the systematization and standardization of the company's internal products.

Basic knowledge of fixture design

Problems to be considered in the design of fixtures The fixture design generally has a single structure, giving people the impression that the structure is not very complicated. Especially now that the hydraulic fixture is popular, its original mechanical structure is greatly simplified, but if it is not considered in the design process, it will inevitably appear unnecessary trouble:

a) Blank allowance of CNC machined parts

Cause the blank size is too large, resulting in interference. So be sure to prepare the rough drawing before designing. Leave enough space.

b) Chip removal smoothness of the fixture

During the design, due to the limited CNC machining space of the machine tool, the fixture is often designed in a relatively compact space. At this time, it is often ignored that the iron filings generated during the CNC machining process accumulate in the dead corner of the fixture, including the poor flow of the cutting fluid. It will bring a lot of trouble to CNC machining in the future. Therefore, problems in the CNC machining process should be considered at the beginning of practice. After all, the fixture is based on improving efficiency and facilitating operation.

c) The overall openness of the fixture

Ignoring the openness makes it difficult for the operator to install the card, which is time-consuming and labor-intensive, and design taboo.

d) Basic theoretical principles of fixture design for CNC machining parts

Each set of fixtures has to undergo numerous clamping and loosening actions, so it may meet the user's requirements at the beginning, but the fixture should have its precision retention, so don't design something that goes against the principle. Even if you get lucky, it won't last long. A good design should stand the test of time.

e) Replaceability of positioning elements

The positioning elements are seriously worn, so quick and convenient replacement should be considered. It is best not to design into larger CNC machined parts. The accumulation of fixture design experience is very important. Sometimes design is one thing, but it is another thing in practical application, so good design is a process of continuous accumulation and summarization. A good machine tool fixture must meet the following basic requirements:

1. The key to ensuring the machining accuracy (accuracy) of CNC machined parts is to correctly select the positioning datum, positioning method and positioning components. If necessary, it is necessary to analyze the positioning error, and pay attention to other zeroes in the fixture. The influence of the structure of the components on the machining accuracy ensures that the fixture can meet the machining accuracy requirements of the workpiece.

The CNC machining lathe feed processing route refers to the path that the turning tool moves from the tool setting point (or the fixed origin of the machine tool) until it returns to this point and ends the processing program, including the cutting processing path and the cutting-in, cutting-out, etc. Cutting idle travel path. CNC milling machine, which is called "CNC machining center" in the machining industry, is an automatic machine tool equipped with a program control system. , (CNC machine tool) is the abbreviation of Computer numerical control machine tool (Computer numerical control), which is an automatic machine tool controlled by a program. The control system can logically process programs with control codes or other symbolic instructions, and decode them through a computer, so as to make the machine tool move and cnc process parts. Semi-finished products, finished CNC machining parts, etc. are processed from blanks by tool cutting.

2. The complexity of the special fixture for improving production efficiency in CNC machining parts should be adapted to the production capacity. Various fast and efficient clamping mechanisms should be used as much as possible to ensure convenient operation, shorten auxiliary time and improve production efficiency.

3. The structure of the special fixture should be simple and reasonable, and it is convenient for CNC machining, manufacturing, assembly, adjustment, inspection, maintenance and repair.

4. The tooling fixture with good performance should have sufficient strength and rigidity, and the operation should be simple, labor-saving, safe and reliable. CNC computer gong machining is the driving component of the CNC machine tool actuator, including the spindle drive unit, the feed unit, the spindle motor and the feed motor. He realizes the spindle and feed drive through the electric or electro-hydraulic servo system under the control of the numerical control device. When several feeds are linked, the processing of positioning, straight line, plane curve and space curve can be completed. Under the premise of objective conditions and economical application, pneumatic, hydraulic and other mechanized clamping devices should be used as much as possible to reduce the labor intensity of the operator. The tooling fixture should also be convenient for chip evacuation. When necessary, a chip removal structure can be set up to prevent chips from damaging the positioning of CNC machined parts and damage to the tool, and to prevent the accumulation of chips from bringing a lot of heat and causing deformation of the process system.

5. Good economy The special fixture should use standard components and standard structure as much as possible, and strive to be simple in structure and easy to manufacture, so as to reduce the manufacturing cost of the fixture. Therefore, the necessary technical and economic analysis of the fixture scheme should be carried out according to the order and production capacity in the design, so as to improve the economic benefits of the fixture in production.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!